|

|

|

|

|

Kowloon

Southern Link – KDB300 and

KDB400

Tunnels, Jordan Road to Nam

Cheong

Station Overrun

|

|

Contract Specific

EM&A Manual

|

|

Author:

|

Various

|

|

|

Checker:

|

Sarah James

|

|

|

Approver:

|

Adi Lee

|

|

|

|

|

Report no:

|

01273R0017

|

|

|

Date:

|

July 2007

|

|

This report has been prepared for in accordance with the terms and conditions of China State

Construction Engineering Corporate appointment for Kowloon Southern Link

KDB300 & KDB400 Tunnels, Jordan Road to Nam Cheong Station Overrun -

Environmental Monitoring and Audit in September 2005.

Hyder

Consulting Ltd (Incorporated

in Hong Kong with limited liability—COI Number 126012) cannot accept

any responsibility for any use of or reliance on the contents of this report

by any third party.

|

|

|

|

|

|

|

|

|

|

|

|

Contents

1 Introduction.......................................................................................................................... 1

2 The Purposes

of the Manual........................................................................................... 1

3 Objective of

the EM&A Programme.............................................................................. 2

4 Organisation

for the Environmental Monitoring and Audit Works.................. 3

5 Environmental

Monitoring and Audit Requirements............................................ 6

5.1 General........................................................................................................................... 6

5.2 Air Quality........................................................................................................................ 8

5.3 Airborne Construction Noise.......................................................................................... 17

5.4 Groundwater Quality..................................................................................................... 25

6 ENVIRONMENTAL

SITE AUDIT..................................................................................... 29

6.1 Site Inspection............................................................................................................... 29

6.2 Compliance with Legal and Contractual

Requirement.................................................... 30

6.3 Environmental Complaints............................................................................................. 30

6.4 Environmental Mitigation Measures............................................................................... 31

7 Reporting............................................................................................................................. 49

7.1 General......................................................................................................................... 49

7.2 Electronic Environmental Management System

(EEMS)................................................ 49

7.3 Baseline Monitoring Report........................................................................................... 49

7.4 Monthly EM&A Reports................................................................................................. 50

7.5 Data Keeping................................................................................................................ 54

7.6 Interim Notification of Environmental Quality

Limit Exceedances..................................... 54

A

3.8km new underground railway line (thereafter called “Kowloon Southern Link” or

KSL) would be constructed to connect the

KCRC East Tsim Sha Tsui (TST)

Station to the West Rail (WR) Nam Cheong (NAC) Station, with its alignment

running under Salisbury Road, Canton Road and the West Kowloon Reclamation

area. It is expected that the KSL would improve the accessibility to and

lessen the traffic congestions at TST and West Kowloon districts. The civil

construction works for the KSL are split into three design-and-build contracts namely

KDB200, KDB300 and KDB400.

The

Kowloon Southern Link (KSL) project is a Category ‘A’ Designated Project (DP)

under Schedule 2 and Part 1 of the Environmental Impact Assessment Ordinance

(EIAO). Pursuant to the EIAO, the KCRC

applied for an Environmental Permit (EP) with the submission of the

Environmental Impact Assessment (EIA) report “Kowloon Southern Link, January

2005” (Register No. AEIAR-083/2005). Along

with the EIA report submission, KCRC also prepared the Environmental Monitoring

and Audit Manual (the Project-wide EM&A Manual) which outlines the

recommended EM&A requirements and programme for the entire alignment of

KSL. The Environmental Permit (EP)

(Permit No. EP-215/2005/B) to construct and operate the KSL was issued to KCRC

on 21 March 2006.

KCRC

has awarded the contracts KDB300 and KDB400 (i.e. Jordan Road to Nam Cheong

Station Overrun) to China State Construction Engineering Corporation (CSCE) in

August 2005. CSCE has appointed Hyder

Consulting Limited (HCL) as the Contractor’s Environmental Team (ET)

for these two contracts during the construction period. The Contracts commenced in August 2005 and

the total construction period is approximately 40 months. Pursuant to condition 1.11 of FEP-02.215/2005/A and

FEP-03/215/2005/A, the notified commencement date of construction was on 28

November 2005.

This

Environmental Monitoring and Audit (EM&A) Manual outlines the monitoring

and audit programme to be undertaken during the construction of the KDB300 and

KDB400. It aims to provide systematic

procedures for monitoring, auditing and minimising of the environmental impacts

associated with the construction activities.

The purposes of this Manual are to:

·

guide the establishment of an EM&A programme;

·

ensure the compliance with the recommendations as

stated in EIA; and

·

identify any need for additional mitigation measures or

remedial action.

Hong

Kong environmental regulations and the Hong Kong Planning Standards and

Guidelines have served as environmental standards and guidelines in the

preparation of this Manual. In

addition, the recommendations of the EIA report have been taken into account

while preparing this Manual.

This Manual contains the following information:

·

Responsibilities of the Contractor (i.e. CSCE),

Engineer’s Representative (ER), Independent Environmental Checker (IEC) and

Environmental Team (ET) with respect to the environmental monitoring and audit

requirements during construction;

·

Information on project organization and programming of

construction activities for the project;

·

Requirements with respect to the construction schedule

and the necessary environmental monitoring and audit programme to track the

varying environmental impacts;

·

Details of the monitoring methodologies, including all

field works, laboratory analytical procedures, quality assurance and quality

control;

·

Definition of Action and Limit levels;

·

Establishment of Event and Action plans;

·

Requirements for reviewing pollution sources and

working procedures in the event of non-compliance of the environmental criteria

and complaints;

·

Requirements for reviewing the effectiveness of the

recommended mitigation measures;

·

Requirements of the Environmental Management Plan (EMP)

and other deliverables for the Contractors; and

·

Requirements of presentation of EM&A data and

appropriate reporting procedures.

For

the purpose of this Manual, the ET leader, who shall be responsible for and in

charge of the ET, shall refer to the person delegated the role of executing the

EM&A requirements.

The main objectives of the EM&A programme are:

·

to provide a database against which any short or long

term environmental impacts of the project can be determined;

·

to provide an early indication shall any of the

environmental control measures or practices fail to achieve the acceptable

standards;

·

to monitor the performance of the project and the

effectiveness of mitigation measures;

·

to verify the environmental impacts predicted in the

EIA Study;

·

to determine project compliance with regulatory

requirements, standards and government policies;

·

to take remedial action if unexpected problems or

unacceptable impacts arise; and

·

to provide data against which environmental audits may

be undertaken.

4

Organisation

for the Environmental Monitoring and Audit Works

The

roles and responsibilities of the various parties involved in the construction

phase EM&A process outlined above are further expanded in the following

sections. The organisation chart showing the line of authority and

communication is presented in Appendix B.

The duties and responsibilities of respective parties are as

follows:

KCRC Environmental

Manger (KCRC-EM)

KCRC Environmental Manager shall be responsible for:

·

supervising the EM&A programme, its members and the

timely production and quality of outputs;

·

managing IEC and providing guidance to KCRC personnel

in their dealings with the CSCE’s Environmental Team;

·

ensuring achieving the agreed objectives and deadlines

as set out in this Manual; and

·

ensuring the quality of deliverables.

The Contractor (CSCE):

·

employ an Environmental Team (ET) to undertake

monitoring, laboratory analysis and reporting of environmental monitoring and

audit;

·

provide assistance to ET in carrying out monitoring;

·

submit proposals on mitigation measures in case of

exceedances of Action and Limit levels in accordance with the Event and Action

Plans;

·

implement measures to reduce impact where Action and

Limit levels are exceeded; and

·

adhere to the procedures for carrying out complaint

investigation.

Contractor’s Environmental Manager (EM):

The EM shall be responsible for:

·

Supervise the EM&A Programme, its members and the

timely production and quality of outputs;

·

Provide guidance to CSCE personnel in dealing with the

environmental issues;

·

Ensure achieving the agreed objectives and deadlines as

set out in this Manual; and

·

Ensure the quality of deliverables.

Contractor’s Environmental Team (ET):

The ET shall be headed by an ET

Leader. The ET Leader is a person who has at least 7 years of experience in

environmental monitoring and auditing (EM&A) or environmental management.

The ET Leader shall keep a contemporaneous log-book of each and every instance

or circumstance or change of circumstances, which may affect the compliance with

the recommendations of the EIA Report and the latest EPs for KDB300 and

KDB400. The ET shall carry out the

following duties:

·

monitoring various environmental parameters as required

in the EM&A Manual;

·

analysing the environmental monitoring and audit data

and review the success of EM&A programme to cost-effectively confirm the

adequacy of mitigatory measures implemented and the validity of the EIA

predictions and to identify any adverse environmental impacts arising;

·

carrying out site inspection to investigate and audit

the Contractors' site practice, equipment and work methodologies with respect

to pollution control and environmental mitigation, and effect proactive action

to pre-empt problems;

·

auditing and preparing audit reports on the

environmental monitoring data and site environmental conditions;

·

reporting the environmental monitoring and audit

results to the IEC, Contractor, ER and EPD or its delegated representative;

·

recommending suitable mitigation measures to the

Contractor in the case of exceedance of Action and Limit levels in accordance

with the Event and Action Plans; and

·

adhering to the procedures for carrying out complaint

investigation.

Engineer’s Representative (ER):

·

supervise the Contractor’s activities and ensure that

the requirements in the EM&A Manual are fully complied with;

·

monitor the Contractor’s compliance with Contract

Specifications, including the effective implementation and operation of the

environmental mitigation measures;

·

instruct the Contractor to follow the agreed protocols

or those in the Contract Specifications in the event of exceedances or

complaints;

·

comply with the agreed Event and Action Plans in the

event of any exceedance; and

·

adhere to the procedures for carrying out complaint

investigation.

Independent Environmental Checker (IEC):

The IEC is a

person who has at least 7 years of experience in EM&A or environmental

management. The responsibilities of the

IEC include:

·

verifying the environmental acceptability of permanent

and temporary works, relevant design plans and submissions as per the EPs;

·

notifying EPD

within one working day of receipt of notification from the ET Leader of each

and every occurrence, change of circumstances or non-compliance with the EIA

Report and the EPs, which might affect the monitoring or control of adverse

environmental impacts from the Project;

·

verifying the

ET Leader’s log book;

·

reviewing the EM&A works performed by the ET (at

not less than monthly intervals);

·

auditing the monitoring activities and results (at not

less than monthly intervals);

·

arranging and

conduct monthly site inspections at the different works area along KSL

alignment;

·

reviewing the

programme of work to anticipate any potential environmental impacts that may

arise;

·

ensuring the

impact monitoring is conducted at the correct locations at the correct

frequency as identified in this Manual;

·

checking the

mitigation measures that have been recommended in the EIA and this Manual, and

ensure they are properly implemented in a timely manner, when necessary; and

·

reporting the

findings of site inspections and other environmental performance reviews to EM

and EPD.

·

reviewing the proposal on mitigation measures submitted

by the Contractor in accordance with the Event and Action Plans; and

·

adhering to the procedures for carrying out complaint

investigation.

Sufficient

and suitably qualified professional and technical staff shall be employed by

the respective parties to ensure full compliance with their duties and

responsibilities, as required under the EM&A programme for the duration of

the Contract.

5.1

General

During

the KDB300 and KDB400 works,

air quality, construction noise,

recharge groundwater quality, disposal of marine deposits and landscape & visual impact shall

be subject to EM&A, with environmental monitoring being undertaken for air

quality, construction noise, recharge groundwater

quality as per the EIA.

The

monitoring of the effectiveness of the mitigation measures shall be achieved

through the environmental monitoring programme as well as through site

inspections. The inspections shall include within their scope, mechanisms to

review and assess the Contractor’ environmental performance, ensuring that the

recommended mitigation measures have been properly implemented, and that the

timely resolution of received complaints are managed and controlled in a manner

consistent with the recommendations of the EIA Report.

The

environmental monitoring work throughout the KDB300 and KDB400 contract period shall be carried out by the ET.

Monitoring works shall comprise of quantitative assessment of physical

parameters such as air quality impacts; local

impacts of groundwater system

from the recharge operation and

noise impacts forms an

important part of the whole monitoring programme. Monitoring programme shall be

conducted at chosen representative sensitive receivers and selected monitoring locations in the vicinity of and within the Works site.

Action

and Limit Levels

Action

and Limit (A/L) Levels are defined levels of impact recorded by the

environmental monitoring activities which represent levels at which a

prescribed response is required. These Levels are quantitatively defined later

in the relevant sections of this manual and described in principle below:

·

Action Limits: beyond which there is a clear indication

of a deteriorating ambient environment for which appropriate remedial actions

are likely to be necessary to prevent environmental quality from falling

outside the Limit Levels, which would be unacceptable; and

·

Limit Levels: statutory and/or agreed contract limits

stipulated in the relevant pollution control ordinances, HKPSG or Environmental

Quality Objectives established by the EPD. If these are exceeded, works should

not proceed without appropriate remedial action, including a critical review of

plant and working methods.

Event

and Action Plans

The

purpose of the Event and Action Plans (EAPs) is to provide, in association with

the monitoring and audit activities, procedures for ensuring that if any

significant environmental incident (either accidental or through inadequate

implementation of mitigation measures on the part of the Contractor) does

occur, the cause shall be quickly identified and remedied, and the risk of a similar event recurring is reduced. This

also applies to the exceedances of A/L criteria identified in the EM&A

programme.

Site

Inspections

In

addition, to monitoring noise, air and groundwater

quality as a means of assessing the ongoing performance of the Contractor, the

ET shall undertake regular site inspections and audits of on-site practices and

procedures. The primary objective of the inspection and audit programme shall

be to assess the effectiveness of the environmental controls established by the

Contractor and the implementation of the environmental mitigation measures

recommended in the EIA Report.

Whilst

the audit and inspection programme shall undoubtedly complement the monitoring

activity with regard to the effectiveness of dust suppression, noise

attenuation measures and groundwater

recharging operation, the criteria the audits are made reference shall be derived from the clauses within the

Contract Specifications which

seek to enforce the recommendations of the EIA Report and the established

management systems.

The

findings of site inspections and audits shall be made known to the Contractor

at the time of the inspection to enable the rapid resolution of identified

non-compliances. Non-compliances, and the corrective actions undertaken, shall

also be reported in the monthly EM&A Reports.

Enquiries,

Complaints and Requests for Information

Enquiries,

complaints and requests for information can be expected from a wide range of

individuals and organisations including members of the public, Government

departments, the press and television media and community groups.

All

enquiries concerning the environmental effects of the construction works,

irrespective of how they are received, shall be incepted in the Community Liaison Office established as per the EIA

recommendation. The ET or the

Coordination Manager of CSCE shall set up with agreement with ER and relevant

parties procedures for the handling, investigation and storage of such

information.

In

all cases the complainant shall be notified of the findings, and audit

procedures shall be put in place to minimise the change of reoccurrence of the

problem.

Reporting

Monthly

and final reports shall be prepared and certified by the ET and verified by the IEC. These

reports shall be submitted to ER and EPD. The monthly reports shall be prepared

and submitted to EPD within 10 working days after the end of the reporting month.

Cessation

of EM&A

The ET shall continue to carry out environmental monitoring and site

inspections until the completion of the major construction works. The cessation of EM&A programme shall be

determined based on completion of construction activities, trends analysis of

the EM&A programme, no environmental complaint and prosecution and IEC's

endorsement.

5.2

Air Quality

Monitoring Parameters

Monitoring and audit of the Total Suspended

Particulate (TSP) levels shall be carried out by the ET to ensure that any

deteriorating air quality would be readily detected and timely actions taken to

rectify the situation.

1-hour and 24-hour TSP levels shall be

measured to indicate the impacts of construction dust. The TSP levels shall be measured using the

standard high volume sampling method for Total Suspended Particulates, Part 50

Chapter 1 Appendix B, Title 40 of the Code of Federal Regulations of the USEPA. Upon approval by ER, 1-hour TSP levels would

be measured by a direct reading instrument which is capable of producing

comparable results to that by the high volume sampling method to indicate short

event impacts.

All relevant data including temperature,

pressure, weather conditions, elapsed-time meter reading for the start and stop

of the sampler, identification and weight of the filter paper, and other

special phenomena and work progress of the concerned site etc. shall be

recorded down in details in a designated result table in a Personal Digital Assistant

(PDA). Appendix C shows a sample of the

result table.

Complaints

regarding the noise nuisance to the local residents of Charming Garden (AM5)

were received since March 2007. With

regard to the complaints, a number of measures to minimise the noise nuisance

from the operation of the HVAS to the residents were implemented. Upon further complaint from the residents in

early May 2007, the management office of Charming Garden have requested that

the operation of the air quality monitoring equipment be stopped after 2300

hours or removed from Charming Garden.

Alternative locations for 24-hr TSP monitoring within and outside

Charming Garden were then explored.

However, no suitable alternative location could be identified. With reference to the EIA report for KSL, only

short-term construction dust impact (i.e. exceedance of 1-hr TSP assessment

criterion) would be imposed to Charming Garden if no dust control measures such

as provision of regular watering is implemented. As such, suspension of 24-hr TSP monitoring at Charming Garden

(AM5) was proposed. Documentations

including the details of the measures implemented to minimise the noise

nuisance, considerations of alternatives locations, review of EIA report for

KSL and proposal of the suspension of 24-TSP monitoring at AM5 are given in

Appendix D.

Monitoring Equipment

For measuring TSP, a high volume sampler

(HVS) in compliance with the following specifications shall be used for

carrying out the 1-hr and 24-hr monitoring:

·

0.6 - 1.7 m3/min (20-60 SCFM) adjustable

flow range;

·

equipped with a timing/control device with +/- 5

minutes accuracy for 24 hours operation;

·

installed with elapsed-time meter with +/- 2 minutes

accuracy for 24 hours operation;

·

capable of providing a minimum exposed area of 406 cm2

(63 in2);

·

flow control accuracy: +/- 2.5% deviation over 24-hour

sampling period;

·

incorporated with an electronic mass flow rate

controller or other equivalent devices;

·

equipped with a flow recorder for continuous

monitoring;

·

provided with a peaked roof inlet;

·

incorporated with a manometer;

·

able to hold and seal the filter paper to the sampler

housing at horizontal position;

·

easy to change the filter; and

·

capable of operating continuously for 24-hr period.

The ET shall be responsible for the

provision of the monitoring equipment. He shall ensure that sufficient number

of HVSs with an appropriate calibration kit be available for carrying out the

baseline, regular impacts monitoring and ad-hoc monitoring. The HVSs shall be

equipped with an electronic mass flow controller and be calibrated against a

traceable standard at regular intervals, in accordance with requirements stated

in the manufacturers operating manual and as described below. All the

equipment, calibration kit, filter papers, etc shall be clearly labelled.

The flow rate of each HVS with mass flow

controller shall be calibrated using an orifice calibrator. Initial calibration

of the dust monitoring equipment shall be conducted upon installation and prior

to commissioning. One point flow rate calibration shall be carried out every

two months. Five-point calibration shall be carried out every six months. The

flow-rate of the sampler before and after the sampling exercise with the filter

in position shall be verified to be constant and be recorded down on the data

sheet.

Should a direct reading instrument be

proposed to measure 1-hour TSP levels, the ET leader shall submit sufficient

information to ER to prove that the instrument is capable of achieving a

comparable result as that by the HVS.

The instrument shall also be calibrated regularly, and the 1-hr sampling

shall be determined periodically by HVS to check the validity and accuracy of

the results measured by the direct reading instrument.

The wind data from King’s Park

Meteorological Station of Hong Kong Observatory will be used. Alternatively, wind monitoring equipment shall be provided

and set up at conspicuous locations for logging wind speed and wind direction

near to the dust monitoring locations. For installation and operation of the

wind data monitoring equipment, the following points shall be observed:

·

the wind sensors should be installed on masts at an

elevated level 10 m above the ground, so that they are clear of obstructions or

turbulence caused by building(s);

·

the wind data should be captured by a data logger and

to be downloaded for processing at least once a month;

·

the wind data monitoring equipment should be

re-calibrated at least once every six months; and

·

wind direction should be divided into 16 sectors of

22.5 degrees.

·

In exceptional situations, the ET may propose

alternative methods to obtain representative wind data upon approval from the

IEC and Engineer, and agreed with EPD.

Laboratory Measurement/ Analysis

A clean laboratory with constant temperature

and humidity control, and equipped with the necessary measuring and

conditioning instruments to handle the dust samples, shall be available for

sample analysis and equipment calibration and maintenance. The laboratory shall

be either HOKLAS accredited or another internationally accredited laboratory.

If a site laboratory or a non-HOKLAS

accredited laboratory is used, the laboratory equipment and measurements shall

meet with the satisfaction of ER in consultation with the IEC. The ET shall

conduct regular audits to determine the accuracy of the measurement results.

Filter paper of size 8”x10” shall be

labelled before sampling. It shall be clean without pin holes and shall be

conditioned in a humidity controlled chamber for over 24-hour and be

pre-weighed before use for the sampling.

After sampling, the filter paper loaded with

dust shall be kept in a clean and tightly sealed plastic bag. The filter paper

shall then be returned to the laboratory for reconditioning in the humidity

controlled chamber followed by accurate weighing by an electronic balance with

a read-out down to 0.1mg. The balance

shall be regularly calibrated against a traceable standard.

All the collected samples shall be kept in a

good condition for 6 months before disposal.

Monitoring Locations

Three air monitoring locations near KDB300

and KDB400 were identified in the Project-wide EM&A Manual. They are Man King Building (AM4), Charming

Garden (AM5) and Olympian City Phase III (AM6). As there is no parapet on the roof of AM4, the safety of the

monitoring staff and the anchoring of equipment to avoid wind blown are major

concerns. There is also

constraint to obtain site access for monitoring works.

Alternative monitoring location was selected

according to the following criteria as stipulated in the Project-wide EM&A

Manual:

1)

at the site boundary or such locations close to the major dust

emission source;

2)

close to the sensitive receptors;

3)

proper position/sitting and orientation of the monitoring

equipment; and

4)

take into account the prevailing meteorological conditions.

Therefore it is proposed that the monitoring

location is relocated to the nearby Man Cheong Street Refuse Collection Point

of the Food and Environmental Health Department (FEHD), AM4a, which is, 1)

close to KDB300 work site, 2) the nearest building to the sensitive receivers,

3) available for installation of monitoring equipment without obstructions, and

4) in similar prevailing meteorological conditions as AM4. Table 5-1 gives the

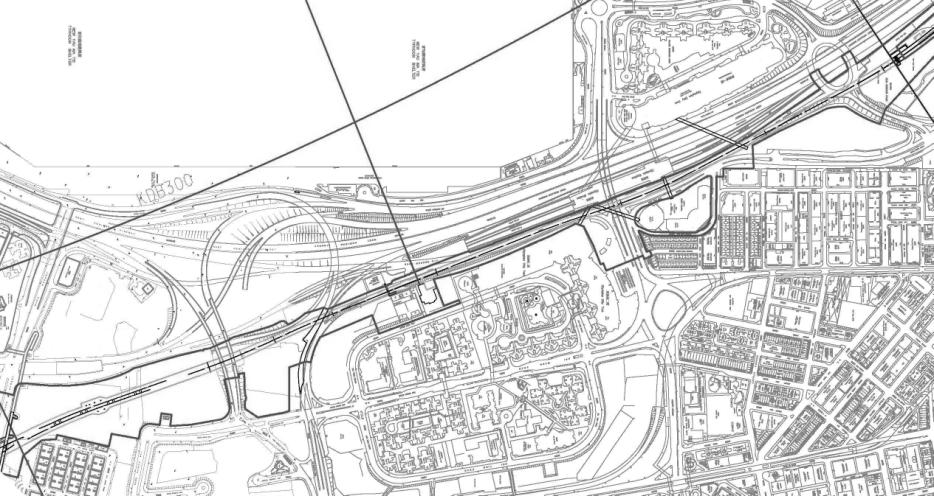

proposed TSP monitoring stations which are illustrated in Figure 5-1.

|

Station ID.

|

Description

|

Monitoring Phase

|

|

AM4a

|

On

the roof of Man Cheong Street Refuse Collection Point

|

Throughout

the Construction

|

|

AM5

|

At podium outside Block 6

of Charming Garden facing Hoi Ting Road

|

Throughout

the Construction{1}

|

|

AM6

|

Rooftop

of Circulation Tower of Olympian City Phase III (Harbour Green)

|

Throughout

the Construction{2}

|

{1} Due to the

complaints regarding the noise nuisance to the local

residents of Charming Garden, suspension of 24-hr TSP monitoring at AM5 was proposed.

{2} Impact monitoring commenced in July 2007.

Table 5-1 Proposed TSP Monitoring Locations

In the case that the status/ and locations

of dust sensitive receivers may change or the proposed monitoring location

becomes unavailable on the commencement of EM&A programme, the ET Leader

shall propose updated / alternative monitoring locations for the agreement with

ER, IEC and EPD. When alternative

monitoring locations are proposed, the following criteria, as far as

practicable shall be followed:

·

At the site boundary or such locations close to the

major dust emission source;

·

Close to the sensitive receptors;

·

Proper position/ sitting and orientation of the monitoring

equipment; and

·

Taking into account the prevailing meteorological

conditions.

When positioning

the samplers, the following points shall be noted:

·

a horizontal platform with appropriate support to

secure the samples against gusty wind shall be provided;

·

no two sampler shall be placed less than 2 m apart;

·

the distance between the sampler and an obstacle, such

as buildings, must be at least twice the height that the obstacle protrudes

above the sampler;

·

a minimum of 2 m separation from walls, parapets and penthouses

is required for rooftops samplers;

·

a minimum of 2 m separation from any supporting

structure, measures horizontally is required;

·

no furnace or incinerator flue is nearby;

·

airflow around the sampler is unrestricted;

·

the sampler is more than 20 m from the dripline;

·

any wire fence and gate to protect the sampler, shall

not cause any obstruction during monitoring;

·

permission must be obtained to set up the samplers and

to obtain access to the monitoring stations; and

·

a secured supply of electricity is needed to operate

the samplers.

5.2.1

Baseline Monitoring

Baseline monitoring shall be carried out to

determine the ambient 24‑hour and 1‑hour TSP levels. Baseline

monitoring shall be carried out at the monitoring locations prior to the

commencement of the construction works for a continuous period of at least 14

consecutive days under typical weather conditions with the 24-hour and three

1-hour ambient measurements taken daily while the highest dust impact is

expected at each monitoring location. During the baseline monitoring, there

shall not be any construction or dust generating activities in the vicinity of

the monitoring stations. A schedule on the baseline monitoring shall be

submitted to ER and IEC for approval before the monitoring commences.

In case the baseline monitoring cannot be carried

out at the designated monitoring locations during the baseline monitoring

period, the ET shall carry out the monitoring at alternative locations which

can effectively represent the baseline conditions at the impact monitoring

locations. The alternative baseline monitoring locations shall be approved by

ER and agreed with the IEC.

Alternatively as KCRC have already carried out their project-wide

baseline monitoring at the dust monitoring stations including AM4a and AM5 in

August 2005, their baseline monitoring results shall be adopted if the contract

specific baseline monitoring cannot be carried out before the commencement of

construction works.

In the exceptional case when insufficient

baseline monitoring data or questionable results are obtained, the ET Leader

shall liaise with the IEC and EPD to agree on an appropriate set of data to be

used as a baseline reference and submit to ER for approval.

Ambient conditions may vary seasonally and

shall be reviewed at every three months. If the ET Leader considers that the

ambient conditions have been changed and a repeat of the baseline monitoring is

required for obtaining the updated baseline levels, the monitoring shall be

conducted at times when the Contractor’s activities are not generating dust, at

least in the proximity of the monitoring stations. Should the change of ambient condition be determined, the

baseline levels and in turn, the air quality criteria should be revised. The

revised baseline levels and air quality criteria should be agreed with EPD and

the IEC.

5.2.2

Impact Monitoring

The monthly schedule of the compliance and

impact monitoring programme shall be drawn up by the ET two weeks prior to the

commencement of the scheduled construction period. For regular impact

monitoring, a sampling frequency of at least once in every six-days shall be

strictly observed at all of the monitoring stations for 24-hour TSP

monitoring. For 1-hour TSP monitoring,

the sampling shall be conducted at least three times in every six-days when the

highest dust impacts are likely to occur.

Before commencing the monitoring, the ET

shall inform the IEC of the impact monitoring programme such that the IEC can

conduct an on-site audit to ensure the accuracy of the impact monitoring

results.

Event and Action Plan

Action and Limit (A/L) levels that provide

an appropriate framework for the interpretation of monitoring results has to be

agreed between ET, IEC, EPD and ER before commencement of the air monitoring.

The air quality monitoring data shall be checked against the agreed A/L

levels. Recommended A/L levels and

action plan are listed in Table 5-2 & 5-3.

|

Parameters

|

Action Level

|

Limit Level

|

|

24-hour TSP level in μg/m3

|

-- For baseline level £ 200 mg/m3,

Action Level = (baseline level * 1.3 + Limit level)/2;

-- For baseline level > 200 mg/m3,

Action level = Limit level

|

HKAQO of

260mg/m3

|

|

1-hour TSP level in μg/m3

|

-- For baseline £ 384 mg m-3,

Action Level = (baseline level * 1.3 + Limit level)/2

-- For baseline > 384 mg

m-3,

Action Level = Limit level

|

EIAO Statutory

Limit of

500mg/m3

|

Table 5-2 Proposed Action and Limit Levels for Air Quality Monitoring

|

EVENT

|

ACTION

|

|

ET

|

IEC

|

ER

|

CONTRACTOR

|

|

ACTION LEVEL

|

|

Exceedance for one sample

|

·

Identify source, investigate the

causes of exceedance and propose remedial measures;

·

Inform IEC and ER;

·

Repeat measurement to confirm

finding;

·

Increase monitoring frequency to

daily.

|

·

Check monitoring data submitted by ET;

·

Check Contractor’s working method.

|

·

Notify Contractor.

|

·

Rectify any unacceptable practice;

·

Amend working methods if

appropriate.

|

|

Exceedance for two or more consecutive samples

|

·

Identify source;

·

Inform IEC and ER;

·

Advise ER on the effectiveness of

the proposed remedial measures;

·

Repeat measurements to confirm

findings;

·

Increase monitoring frequency to

daily;

·

Discuss with IEC and Contractor on

remedial actions required;

·

If exceedance continues, arrange

meeting with IEC and ER;

·

If exceedance stops, cease

additional monitoring.

|

·

Check monitoring data submitted by

ET;

·

Check Contractor’s working method;

·

Discuss with ET and Contractor on

possible remedial measures;

·

Advise the ET on the effectiveness

of the proposed remedial measures;

·

Supervise Implementation of remedial

measures.

|

·

Confirm receipt of notification of

exceedance in writing;

·

Notify Contractor;

·

Ensure remedial measures properly

implemented.

|

·

Submit proposals for remedial to ER

within 3 working days of notification;

·

Implement the agreed proposals;

·

Amend proposal if appropriate.

|

|

LIMIT LEVEL

|

|

Exceedance for one sample

|

·

Identify source, investigate the

causes of exceedance and propose remedial measures;

·

Inform IEC, ER, Contractor and EPD;

·

Repeat measurement to confirm

finding;

·

Increase monitoring frequency to

daily;

·

Assess effectiveness of Contractor’s

remedial actions and keep IEC, EPD and ER informed of the results.

|

·

Check monitoring data submitted by

ET;

·

Check Contractor’s working method;

·

Discuss with ET and Contractor on

possible remedial measures;

·

Advise ER on the effectiveness of

the proposed remedial measures;

·

Supervise implementation of remedial

measures.

|

·

Confirm receipt of notification of

exceedance in writing;

·

Notify Contractor;

·

Ensure remedial measures properly

implemented.

|

·

Take immediate action to avoid

further exceedance;

·

Submit proposals for remedial

actions to IEC within 3 working days of notification;

·

Implement the agreed proposals;

·

Amend proposal if appropriate.

|

|

Exceedance for two or more consecutive samples

|

·

Notify IEC, ER, Contractor and EPD;

·

Identify source;

·

Repeat measurement to confirm

findings;

·

Increase monitoring frequency to

daily;

·

Carry out analysis of Contractor’s

working procedures to determine possible mitigation to be implemented;

·

Arrange meeting with IEC and ER to

discuss the remedial actions to be taken;

·

Assess effectiveness of Contractor’s

remedial actions and keep IEC, EPD and ER informed of the results;

·

If exceedance stops, cease

additional monitoring.

|

·

Discuss amongst ER, ET, and

Contractor on the potential remedial actions;

·

Review Contractor’s remedial actions

whenever necessary to assure their effectiveness and advise ER accordingly;

·

Supervise the implementation of

remedial measures.

|

·

Confirm receipt of notification of

exceedance in writing;

·

Notify Contractor;

·

In consultation with the IEC, agree

with the Contractor on the remedial measures to be implemented;

·

Ensure remedial measures properly

implemented;

·

If exceedance continues, consider

what portion of the work is responsible and instruct the Contractor to stop

that portion of work until the exceedance is abated.

|

·

Take immediate action to avoid

further exceedance;

·

Submit proposals for remedial

actions to IEC within 3 working days of notification;

·

Implement the agreed proposals;

·

Resubmit proposals if problem still

not under control;

·

Stop the relevant portion of works

as determined by ER until the exceedance is abated.

|

Table 5-3 Proposed Event/ Action Plan for Air Quality Monitoring

5.3

Airborne Construction Noise

Monitoring Parameters

The

construction noise level shall be measured in terms of the A-weighted

equivalent continuous sound pressure level (LAeq). LAeq, 30mins shall be used as the monitoring parameter for the

time period between 0700-1900 hours on normal weekdays. For all other time periods (including

restricted hours), LAeq, 5mins shall be employed for comparison with the Noise

Control Ordinance (NCO) criteria.

As supplementary information for data

auditing, statistical results such as L10 and L90 shall also be obtained for

reference.

Monitoring Equipment

In accordance with the Technical Memorandum

(TM) issued under the NCO, sound level meters in compliance with the

International Electrotechnical Commission Publications 651: 1979 (Type 1) and

804: 1985 (Type 1) specifications shall be used for carrying out the noise

monitoring. Immediately prior to and

following each noise measurement, the accuracy of the sound level meter shall

be checked using an acoustic calibrator generating a known sound pressure level

at a known frequency. Measurements may

be accepted as valid only if the calibration level from before and after the

noise measurement agree to within 1.0dB.

The ET Leader shall be responsible for the

provision, installation and maintenance of the monitoring equipment. He shall ensure that sufficient noise

monitoring equipment and associated instrumentation are available for carrying

out the baseline monitoring, regular impact monitoring and ad hoc

monitoring. All the equipment and

associated instrumentation shall be clearly labelled. The location of equipment installation should be proposed by the

ET Leader and agreed with ER and EPD in consultation with the IEC.

Noise measurements should not be made in the

presence of fog, rain, wind with a steady speed exceeding 5m/s or wind with

gusts exceeding 10m/s. The wind speed

shall be checked with a portable wind speed meter capable of measuring the wind

speed in m/s. The measured noise

levels, calibration results and field observations will be recorded down in

detail in a designated result table in the PDA. Appendix C shows a sample of

the result table.

Monitoring Locations

Three noise monitoring locations near KDB300

and KDB400 were identified in the Project-wide EM&A Manual. They are Man King Building (NM4), Charming

Garden (NM5) and Olympian City Phase III (NM6). As there is no parapet on the roof of NM4, the safety of the

monitoring staff and the anchoring of continuous noise equipment to avoid wind

blown are major concerns. There

is also constraint to obtain site access for monitoring works.

Alternative monitoring location was selected

according to the following criteria as stipulated in the Project-wide EM&A

Manual:

1) at

locations close to the major site activities which are likely to have noise

impacts;

2) close

to the noise sensitive receivers; and

3) for

monitoring locations in the vicinity of the sensitive receivers, care should be

taken to avoid disturbance to the occupants during monitoring.

Therefore it is proposed that the continuous

noise monitoring location is relocated to the nearby Man Cheong Street Refuse

Collection Point which is, 1) close to KDB300 works site and, 2) close to the

sensitive receivers. The proposal for relocating the continuous

noise monitoring station has been justified by the ET Leader and verified by

the IEC. Table 5-4 gives the proposed

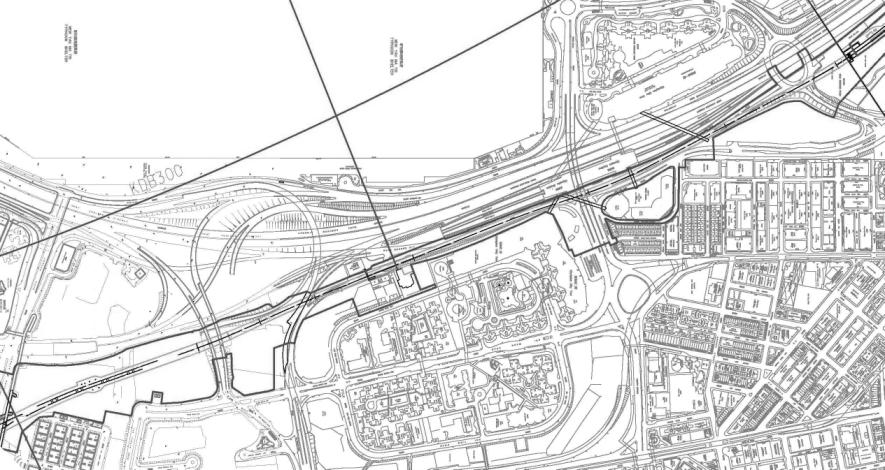

noise monitoring stations which are illustrated in Figure 5-2.

|

Station

ID.

|

Description

|

Monitoring

Phase

|

Monitoring

Mode

|

|

Once

Weekly

|

Continuous

|

|

NM4{1}

|

Man

King Building

|

Throughout the Construction

|

ü

|

û

|

|

NM4a

|

Roof

parapet façade of the Man Cheong Street Refuse Collection Point facing the site

|

Throughout the Construction

|

û

|

ü

|

|

NM5

|

At

the podium façade outside Block 6 of Charming Garden facing Hoi Ting Road

|

Throughout the Construction

|

ü

|

û

|

|

NM6

|

Rooftop of Circulation Tower of Olympian City

Phase III (Harbour Green)

|

Throughout the Construction{2}

|

ü

|

û

|

{1} Weekly noise

monitoring at NM4 since 26 June 2006.

{2} Impact monitoring

commenced in July 2007.

Table 5-4 Proposed Noise Monitoring Locations

5.3.1

Baseline Monitoring

The ET shall carry out baseline noise

monitoring prior to the commencement of the construction works. There shall not be any construction activities

in the vicinity of the stations during the baseline monitoring. Continuous baseline noise monitoring for the

A-weighted levels LAeq, LA10 and LA90 shall be carried out daily for a period

of at least two weeks in a sample period of 5 minutes or 30 minutes between

0700 and 1900, and 5 minutes between 1900 and 0700. A schedule on the baseline monitoring shall be submitted to ER

and IEC for approval before the monitoring starts.

In case the baseline monitoring cannot be carried

out at the designated monitoring locations during the baseline monitoring

period, the ET shall carry out the monitoring at alternative locations which

can effectively represent the baseline conditions at the impact monitoring

locations. The alternative baseline monitoring locations shall be approved by

ER and agreed with the IEC.

Alternatively as KCRC have already carried out their project-wide

baseline monitoring at the noise monitoring stations including NM4a and NM5 in

August 2005, their baseline monitoring results shall be adopted if the contract

specific baseline monitoring cannot be carried out before the commencement of

construction works.

In exceptional case, when insufficient

baseline monitoring data or questionable results are obtained, the ET Leader

shall liaise with IEC and EPD to agree on an appropriate set of data to be used

as a baseline reference and submit to ER for approval.

5.3.2

Impact Monitoring

During normal construction working hour

(0700-1900 Monday to Saturday), monitoring of LAeq, 30min noise levels (as six

consecutive LAeq, 5min readings) shall be carried out at the agreed monitoring

locations once every week.

Other noise sources such as road traffic may

make a significant contribution to the overall noise environment. Therefore, the results of noise monitoring

activities shall take into account such influencing factors, which may not be

presented during the baseline monitoring period.

In case of non-compliance with the

construction noise criteria, more frequent monitoring as specified in the Event

and Action Plan in the preceding section shall be carried out. This additional monitoring shall be

continued until the recorded noise levels are rectified or proved to be

irrelevant to the construction activities.

Continuous Monitoring

CSCE/ the ET shall procure, implement and

maintain a Continuous Noise Monitoring System (CNMS) throughout the

construction period.

The objectives of implementing the CNMS are

summarized below:

·

Measure various noise data (different measurement

parameters) at designated locations continuously during specified period(s);

·

Transmit the measured noise data electronically to a

central computer system within the required time frame;

·

Upload the measurement data to KCRC’s web site in an

agreed format for public inspection;

·

Maintain and keep all the measurement data in an agreed

format during the entire construction period for subsequent analysis, where

necessary.

CSCE

intends to adopt the CNMS configuration as of in Table 5-5. Method Statement with details of the specifications, configuration and

the operation / maintenance of the proposed equipment will be submitted to

KCRC, IEC and EPD for approval before the procurement of the CNMS.

|

Equipment / Components

|

General Requirements

|

|

Sound Level Meter (SLM) with data logger

|

·

Be suitable for outdoor use

·

Comply with IEC 651:1979 (Type 1),

804:1985 (Type 1) and 1672/EN61672 Class 1 requirements

|

|

Data

transmitters and receivers

|

·

Be suitable for outdoor use

·

Transfer noise measurement data from

the SLM to the receiver

·

Transmission power / frequency should

be suitable and adequate for the local conditions

|

|

Modems

|

·

Transfers measurement data to the

computer system

|

|

Computer system

|

·

Complete with the necessary software

(e.g. spreadsheet, word processor and internet access) for data processing

·

Process the measurement data into

the agreed format

·

Upload the processed data (including

tables, charts, trends etc) to KCRC’s website which should allow the user

(including the public) to search previous measurement data

·

Provided with sufficient memory to

keep the measurement data for further use

|

|

Power supply

|

·

Complete with all cabling and

connection to power supply

|

|

Security measures

|

·

Complete with security measures to

prevent unnecessary human interference and damage

|

Table 5-5 Targeted

Configuration of the Continuous Noise Monitoring System

For the

sake of security, CSCE proposes to install the CNMS at the roof floor of LCSD

Refuse Collection Point, NM4a. The major components of the CNMS would be housed

in a purpose built kiosk with locks.

The SLM

shall be calibrated once every 2 weeks against a portable acoustic calibrator

which is traceable to international reference source. Calibration records shall be filed and kept for further

reference. The full set of CNMS including

the acoustic calibrator shall be sent back to the manufacturer (or other

approved agency) for a full calibration every year or as recommended by the

manufacturer. In such an event and when

the prime system is broken down, a standby CNMS would be in place to maintain

uninterrupted noise measurements.

As per

the stipulation in the Project-wide EM&A Manual, the noise parameter as

proposed in the Table 5-6 shall be measured.

|

Period

|

Parameters

|

|

Weekdays

·

0700-1900 hours

|

·

Leq

(30min) in 6 consecutive Leq (5 min)

measurements

· Other parameters in L10,

L90 and Lmax should also be measured

|

|

Restricted hours

·

1900-0700 hours from Monday to

Saturday

·

at any time on Sundays or public

holidays)

|

·

Leq

(15 min) in 3 consecutive Leq(5

min) measurements

· Other parameters in L10,

L90 and Lmax should also be measured

|

Table 5-6 Summary of Noise Parameter

of the Continuous Noise Monitoring

Event and Action Plan

The Action and Limit levels for construction

noise are proposed in Table 5-7. Should

non-compliance of the criteria occur, actions in accordance with the Action

Plan in Table 5-8 shall be taken.

|

Time Period

|

Action

|

Limit

|

|

0700-1900 hrs on

normal weekdays

|

When one documented complaint is received

|

75* / 77#dB(A)

|

|

0700-2300 hrs on

holidays; and 1900-2300 hrs on all other days

|

70 dB(A)

|

|

2300-0700 hrs of

next day

|

55 dB(A)

|

Notes: * For school, 70 dB(A) for schools

and 65 dB(A) during school examination periods.

# For NM4 in

the forth, eleventh, twelfth, nineteenth months of the construction programme

since there will be residual impact of 1 to 2 dB(A) at Man King Building as

predicted in the EIA report.

Table 5-7 Proposed Action and Limit Levels for Noise

Monitoring

|

Event

|

Action

|

|

ET Leader

|

IEC

|

ER

|

Contractor

|

|

Action Level

|

·

Notify IEC and the Contractor.

·

Carry out investigation.

·

Report the results of investigation

to IEC and the Contractor.

·

Discuss with the Contractor and

formulate remedial measures.

·

Increase monitoring frequency to

check mitigation measures.

|

·

Review with analysed results

submitted by ET.

·

Review the proposed remedial

measures by the Contractor and advise ER accordingly.

·

Supervise the implement of remedial

measures.

|

·

Confirm receipt of notification of

exceedance in writing.

·

Notify the Contractor.

·

Require the Contractor to propose

remedial measures for the analysed noise problem.

·

Ensure remedial measures are

properly implemented.

|

·

Submit noise mitigation proposals to

IEC.

·

Implement noise mitigation

proposals.

|

|

Limit Level

|

·

Identify the source.

·

Notify IEC, ER, EPD and the

Contractor.

·

Repeat measurement to confirm

findings.

·

Increase monitoring frequency.

·

Carry out analysis of Contractor’s

working procedures to determine possible mitigation to be implemented.

·

Inform IEC, ER, and EPD the causes

& actions taken for the exceedances.

·

Assess effectiveness of the

Contractor’s remedial actions and keep IEC, EPD and ER, informed of the

results.

·

If exceedance stops, cease

additional monitoring

|

·

Discuss amongst ER, the ET Leader

and the Contractor on the potential remedial actions.

·

Review the Contractor’s remedial

actions whenever necessary to assure their effectiveness and advise ER,

accordingly.

·

Supervise the implementation of

remedial measures.

|

·

Confirm receipt of notification of

exceedance in writing.

·

Notify the Contractor.

·

Require the Contractor to propose

remedial measures for the analysed noise problem.

·

Ensure remedial measures are

properly implemented.

·

If exceedance continues, consider

what activity of the work is responsible and instruct the Contractor to stop

that activity of work until the exceedance is abated.

|

·

Take immediate action to avoid

further exceedance.

·

Submit proposals for remedial

actions to IEC within 3 working days of notification.

·

Implement the agreed proposals.

·

Resubmit proposals if problem still

not under control.

·

Stop the relevant activity of works

as determined by ER, until the exceedance is abated.

|

Table 5-8 Proposed Event and

Action Plan for Noise Monitoring

To

account for cases where ambient noise levels as identified by baseline

monitoring approach or exceed the stipulated Limit Levels prior to commencement

of construction, a Maximum Acceptable Impact Level may be defined and agreed

with EPD, which incorporates the baseline noise levels and the identified

construction noise Limit Level. The

amended level shall therefore be greater than 75dB(A) and shall represent the

maximum acceptable noise level at a specific monitoring station. Correction factors for the effects of

acoustic screening and/or architectural features of NSRs may also be applied

for.

For the

purposes of compliance checking, after taking into account any adjustments

agreed with EPD, comparison with either the Limit or the Maximum Acceptable

Impact Level shall represent the governing criteria for the noise impact.

For

continuous noise monitoring, in cases where the levels exceeds the Action /

Limit Levels set above, the hourly site log shall be examined to check whether

the exceedance is caused by extraneous activities. The ET is required to investigate whether the exceedance is

caused by KDB300 and KDB400 site activities or other extraneous noise

sources. The site log should contain

brief description of prevailing wind speeds and weather, once for a.m. section

and once for p.m. section each day. A

short explanation of the causes of any exceedance of Action / Limit Levels

shall accompany the plots.

5.4

Groundwater Quality

According

to the finding of Contamination Assessment Report (CAR) (Appendix 10.2 of the

EIA Report), groundwater at some spots of the KSL alignment was found

contaminated with primarily heavy metals (i.e. Copper, Lead and Mercury) of

which their levels exceeded the Dutch ‘C’ level for groundwater. The KSL EIA report indicated that the water

sample collected at borehole KSD100/DHEPZ113 exceeded Dutch C level. But the

confirmation of contaminated groundwater shall be subject to

the ambient groundwater measurements to be carried out by the Contractor upon

site handover, as per Appendix AP18.3 “Contract Specific Environmental

Requirements” of Particular Specification.

The

selection and schedule of ambient/ baseline groundwater sampling shall be in

accordance with ProPECC PN3/94 “Contaminated Land Assessment and Remediation”.

Given that the site area of concern exceeds 5,000m2 where the number

of sampling locations shall be agreed with EPD, CSCE shall propose the sampling

schedule in form of a working plan to EPD for agreement.

A working

plan details the monitoring requirements including the number of recharge wells

and their specific locations, the baseline parameters of the recharge and

monitoring locations, and if necessary, the number of treatment facilities and

their treatment capacities shall be prepared and submitted to EPD for approval

before the baseline monitoring. The

location of monitoring and control wells depends on the location of the

recharge wells which are subject to the detailed design of the tunnel.

A separate

Groundwater Monitoring Working Plan was prepared and endorsed by EPD on 31

October 2006. An Updated Groundwater

Monitoring Working Plan was submitted to EPD on 31 January 2007 and approved on

21 February 2007.

5.4.1

Baseline Monitoring

Should

the groundwater contamination be confirmed, the EIA Report recommended to

recharge the contaminated groundwater from the dewatering process into the

ground at places where the existing groundwater quality should not be

affected. The locations of the recharge

wells shall be determined on the basis that the pollutant levels of the

groundwater to be recharged shall not be higher than the baseline at the

recharge well. Monitoring wells would

be selected where practical near to the recharge points and at site boundaries.

A control well shall also be installed.

Baseline Monitoring Parameters

According to the approved Updated Groundwater

Monitoring Working Plan, baseline monitoring parameters are shown in Table 5-9.

The chemical testing of groundwater should be undertaken by a HOKLAS accredited

laboratory and with individual HOKLAS accredited methods.

|

Parameters

|

Monitoring Well

|

Analytical Method

|

Reporting Limit1

(mg/L)

|

TM-Water effluent limit2

for inshore waters of VHWCZ (mg/L)

|

|

Groundwater

Level

|

AGM1

to AGM7, R1 to R2, M1 to M3, C1 and C3 (14 wells)

|

In house

|

0.1m

|

---

|

|

pH

|

In house

|

0.1unit

|

6-9

|

|

Temperature

°C

|

In house

|

0.1°C

|

< 40°C

|

|

TPH

C6 – C9

|

USEPA8015

|

20 mg/L

|

---

|

|

TPH

C10–C14

|

25 mg/L

|

---

|

|

TPH

C15 – C28

|

25 mg/L

|

---

|

|

TPH

C29 – C36

|

25 mg/L

|

---

|

|

Cd

|

USEPA6020

|

0.0002

|

0.001

|

|

Cu

|

AGM1 to AGM6, R1, M1, C1 and C3 (10 wells)

|

0.001

|

0.1 to 0.25

|

|

Pb

|

0.001

|

0.1 to 0.25

|

|

Zn

|

0.01

|

0.1 to 0.25

|

|

Hg

|

APHA3112B

|

0.0005

|

0.001

|

|

Total Toxic Metals

|

N/A

|

N/A

|

N/A

|

0.22 to

1.6

|

Notes:

1.

Lowest detection limits could be achieved by

common commercial laboratories in Hong Kong.

For those substances not detected using these detection limits, it is

assumed that such substances do not exist in the water sample.

2.

As the maximum dewatering rate is 3,200m3/day, Subject to actual flow of

the groundwater to be discharged or the groundwater discharge license obtained

from EPDthe

discharge limits for the flow band of >3,000 and ≤4,000 3,200m3/day are adopted.

Table 5-9 Baseline Groundwater Testing Parameters

Groundwater Collection

Groundwater

samples at each monitoring well should be collected with PVC bailer (or

equivalent). The bailer should be

decontaminated prior to use and in between sampling. The groundwater samples should be transferred to clearly labelled

and pre-cleaned sample containers with necessary preservatives immediately

after collection. Sufficient quantity

of samples should be collected for all laboratory analyses. After collection, the groundwater samples

should be stored at 0-4ºC and delivered to the laboratory within 24 hours under

proper chain-of-custody system. The

sample collection shall be detailed in the working plan.

5.4.2

Impact Monitoring

CSCE

supposes that the impact monitoring of groundwater recharging process is only

required if the ambient/ baseline monitoring reveals contamination of

groundwater within the KDB300 and KDB400 site areas.

During

the re-charging of underground water, the water level at the monitoring wells

should be monitored on a daily basis to ensure that the water levels at the

site boundary shall not increase significantly.

During the

re-charging of underground water, the water quality at the monitoring wells and

control well shall be measured on a weekly basis to ensure that the pollution

levels shall not increase significantly.

According to the approved Updated Groundwater Monitoring Working Plan,

testing parameter includes TPH only.

Should

the pollutants of the recharging groundwater (after petrol interceptor) exceed

the baseline value and there are no justifications from the measurements at the

control well, CSCE shall propose with the consultation of the EPD the treatment

method for the recharging groundwater.

Event and Action Plan

The event

and action plan is summarized in Table 5-10.

|

Event

|

Action

|

|

ET Leader

|

IEC

|

ER

|

Contractor

|

|

Groundwater level exceeds 1m from

baseline Level

|

Notify IEC and the Contractor.

Carry out investigation.

·

Report the results of investigation

to IEC and the Contractor.

·

Discuss with the Contractor and

formulate remedial measures.

·

Increase monitoring frequency to

check mitigation measures.

|

·

Review with analysed results

submitted by ET.

·

Review the proposed remedial

measures by the Contractor and advise ER accordingly.

·

Supervise the implement of remedial

measures.

|

·

Confirm receipt of notification of

exceedance in writing.

·

Notify the Contractor.

·

Require the Contractor to propose

remedial measures for the analysed groundwater problem.

·

Ensure remedial measures are

properly implemented.

·

|

·

Reduce the recharge rate AND / OR

·

Suspend the recharge until the

groundwater level at recharge points falls back to less than 1m difference

with the baseline

|

|

Limit Level Exceedance for TPH

|

·

Notify IEC and the Contractor.

·

Carry out investigation.

·

Report the results of investigation

to IEC and the Contractor.

·

Discuss with the Contractor and

formulate remedial measures.

·

Increase monitoring frequency to

check mitigation measures.

|

·

Review with analysed results

submitted by ET.

·

Review the proposed remedial

measures by the Contractor and advise ER accordingly.

·

Supervise the implement of remedial

measures.

|

·

Confirm receipt of notification of

exceedance in writing.

·

Notify the Contractor.

·

Require the Contractor to propose

remedial measures for the analysed groundwater problem.

·

Ensure remedial measures are

properly implemented.

|

·

Suspended the recharge OR

·

Treatment of the recharging

groundwater

|

Table 5-10 Event and Action

Plan for Groundwater Monitoring

6.1

Site Inspection

Site

inspections provide direct means to trigger and enforce the specified

environmental protection and pollution control measures. They shall be undertaken routinely to

inspect the construction activities to ensure appropriate environmental

protection and pollution control/ mitigation measures are properly

implemented. With well defined

pollution control and mitigation specifications and a well established site

inspection, deficiency and action reporting system, site inspection is one of

the most effective tools to enforce the environmental protection requirements

on the construction site.

The ET

Leader shall be responsible for formulating the environmental site inspection,

deficiency and action reporting system, and carrying out the site inspection

works. He shall submit a proposal on

site inspection, deficiency and action reporting procedures within 21 days

prior to construction commencement to the Contractor for approval from ER and the

IEC.

Regular

site inspections shall be carried out at least once per week. The areas of inspection shall not be limited

to the environmental situation, pollution control and mitigation measures

within the site. It should also review

the environmental situation outside the site area which is likely to be

affected, directly or indirectly, by the site activities. The ET Leader shall make reference to the

following information in conducting the inspection:

·

the EIA recommendations on environmental protection and

pollution control mitigation measures;

·

works progress and programme;

·

individual works methodology (which shall include

proposal on associated pollution control measures);

·

Contract Specifications on environmental protection;

·

relevant environmental protection and pollution control

laws; and

·

previous site inspection results.

CSCE shall

update ET Leader with all relevant information of the construction Contract for

him to carry out the site inspections.

The inspection results and its associated recommendations on

improvements to the environmental protection and pollution control works shall

be submitted to ER, IEC and CSCE within 1 working day for reference and for

taking immediate actions. CSCE shall

follow the procedures and timeframe as stipulated in the environmental site

inspection, deficiency and action reporting system formulated by the ET Leader

to report on any remedial measures subsequent to the site inspections.

After each site inspection, ET will provide

the Contractor the site inspection checklist with the identified deficiencies

on site and the time-frame to rectify the condition. The Contractor after discussion with the ET, will carry out the

rectification action. ET will inspect

the rectified condition in the next weekly inspection or the completion time as

agreed. The result of the rectification

will be reported in the site inspection checklist.

Ad hoc

site inspections shall also be carried out if significant environmental

problems are identified. Inspections

may also be required subsequent to receipt of an environmental complaint, or as

part of the investigation work, as specified in the Event and Action Plans for

environmental monitoring and audit.

6.2

Compliance with Legal and Contractual Requirement

There are

contractual environmental protection and pollution control requirements as well

as environmental protection and pollution control laws in Hong Kong, which the

construction activities shall comply with.

In order to comply with the contractual requirements, all works method

statements submitted by CSCE to ER and IEC for approval shall be sent to the ET

Leader for vetting, to ensure sufficient environmental protection and pollution

control measures have been included.

The ET

Leader shall also review the progress and programme of the works to check that

relevant environmental laws have not been violated, and that any foreseeable

potential for violating the laws can be prevented. CSCE shall regularly copy relevant documents to the ET Leader so

that the checking work can be carried out.

The document shall at least include the updated Work Progress Reports,

the updated Works Programme, the application letters for different license/permits

under the environmental protection laws, and all the valid license/permit. The site diary shall also be available for

the ET Leader's inspection upon his request.

After

reviewing the document, the ET Leader shall advise ER, IEC and CSCE of any

non-compliance with the contractual and legislative requirements on

environmental protection and pollution control for them to take follow-up

actions. If the ET Leader's review

concludes that the current status on license/permit application and any environmental

protection and pollution control preparation works may not cope with the works

programme, or may result in potential violation of environmental protection and

pollution control requirements by the works in due course, he shall also advise

CSCE, ER, and IEC accordingly.

Upon

receipt of the advice, CSCE shall undertake immediate actions to rectify the

situation to the satisfaction of ER

6.3

Environmental Complaints

Complaints

incepted at the Community Liaison Office and other relevant parties shall be

referred to the ET Leader for carrying out complaint investigation. The ET Leader shall undertake the following

procedures upon receipt of the complaints:

·

log complaint and date of receipt onto the complaint

database;

·

investigate the complaint to determine its validity,

and to assess whether the source of the problem is due to works activities;

·

identify mitigation measures if a complaint is valid

and due to works;

·

advise the Contractor accordingly if mitigation

measures are required;

·

review the Contractor's response on the identified

mitigation measures and the updated situation;

·

submit interim report to ER on status of the complaint

investigation and follow-up action within the time frame assigned by ER;

·

undertake additional monitoring and audit to verify the

situation if necessary, and review that any valid reason for complaint does not

recur;

·

report the investigation results and the subsequent

actions to the source of complaint for responding to complainant (If the source

of complaint is EPD, the results should be reported within the time frame

assigned by EPD); and

·

record the complaint, investigation, the subsequent

actions and the results in the monthly EM&A reports.

CSCE and

ER shall also be notified of the nature of complaints. An investigation shall