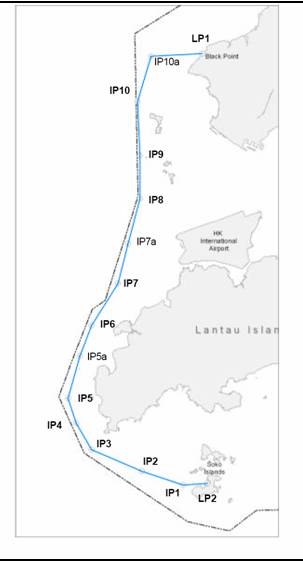

Figure 3.1 Pipeline

Route

This annex covers details of the

Quantitative Risk Assessment (QRA) for the subsea

pipeline from

The following information was reviewed and

formed the basis of the study:

·

Basis

of Design Report, Aker Kvaerner [1];

·

Drawing

8028-PLD-008 detailing the pipeline route, trenching and backfilling details,

Aker Kvaerner [2];

·

Input

to EIA Study Report on pipeline design, Aker Kvaerner [3];

·

Marine

vessel density data, BMT [4];

·

Marine

traffic data in

·

·

Hydrographic & Geophysical Survey of the Seabed,

EGS [8].

This section of the report describes the subsea pipeline, its environment and details of marine

traffic along the proposed route.

The proposed pipeline takes a subsea route from the LNG terminal at South Soko, passing around the western edge of

The proposed pipeline system will consist

of a single 30” OD (762mm outer diameter) API 5L Grade X65 pipeline, with wall

thickness of 1” (25.4mm). It is designed to have a peak flow rate of 1000 MSCFD

(million standard cubic feet per day) with a supply pressure of 101barg. The

pipeline will have an asphalt enamel coat and wrap and sacrificial anodes for

external corrosion protection and an outer layer of reinforced concrete for

buoyancy control and to provide mechanical protection during pipeline

installation and trenching operations. The pipeline is designed in accordance

with the DNV 1981 design code [9]. A summary of the pipeline details is given

in Table 3.1.

Table 3.1 Summary

of Pipeline Details

|

Parameter |

Details |

|

Location Length Outside

diameter Nominal

wall thickness Line pipe

grade External

coating Internal

coating Cathodic

protection Design flowrate Design

pressure LNG

terminal delivery pressure Minimum

terminal delivery pressure Minimum

delivery pressure to BPPS Pressure

assumed for analysis Minimum

operating temperature Maximum

operating temperature Temperature

assumed for this study Water

depth Seabed

soil Pipeline

protection Design

life |

38.3 km 30”

(762mm) 1”

(25.4mm) API 5L

grade X65 Asphalt

enamel coat & wrap and steel reinforced concrete Epoxy Aluminium

based sacrificial anodes 1000

MSCFD 111 barg 101 barg 85 barg 38 barg 101 barg 5 °C 85 °C 20 °C 1.6 – 25

m Very soft

clay becoming firmer with depth 3m cover

with rock armour backfill of varying thickness 30 years |

The composition of the gas is mainly

methane (87.57-96.13 mol%). The composition of the gas is such that no internal

corrosion is expected.

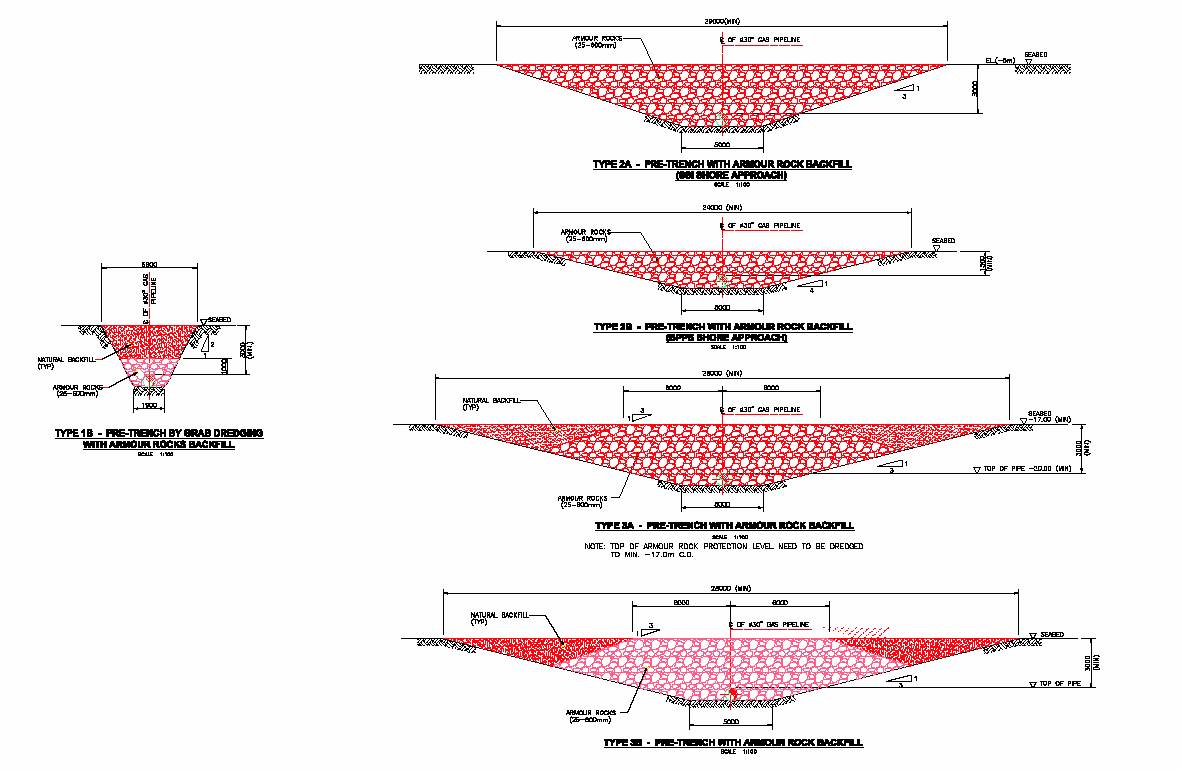

The water depth along the route varies

between 1.6 and 25m, with much of the route characterised by shallow water

below 6m deep. The pipeline will be buried 3m below the seabed with varying

levels of rock armour protection (Figures

3.1 and 3.2). Type 1B trenching

will be used for the shallow water areas away from the busy marine fairways.

The type 1B trench involves jetting with 1m of rock armour backfill and 2m of

natural backfill (to the top of the pipeline). This provides protection for

anchors up to 2 tonnes, essentially protecting against anchors from all ships

below about 10,000 dwt. Trench type 2A is used on the

shore approach to South Soko Island and consists of

pre-trenching with 3m of armour rock backfill. Trench type 2B, used on the BPPS

approach utilizes 1.5m of rock backfill. These are also designed for protection

from 2 tonne anchors and any future dredging work.

The waterways of Urmston Road and the Adamasta Channel will have type 3A or 3B trenches. These

consist of pre-trenching with 3m of rock backfill. The only difference between

3A and 3B is that the seabed will be dredged so that the top of the rock armour

is at least -17m for type 3A. For the purpose of this study, they are

essentially similar and are designed to protect against 20 tonne anchors. This

covers the full range of ships currently operating in Hong Kong and also those

expected in future.

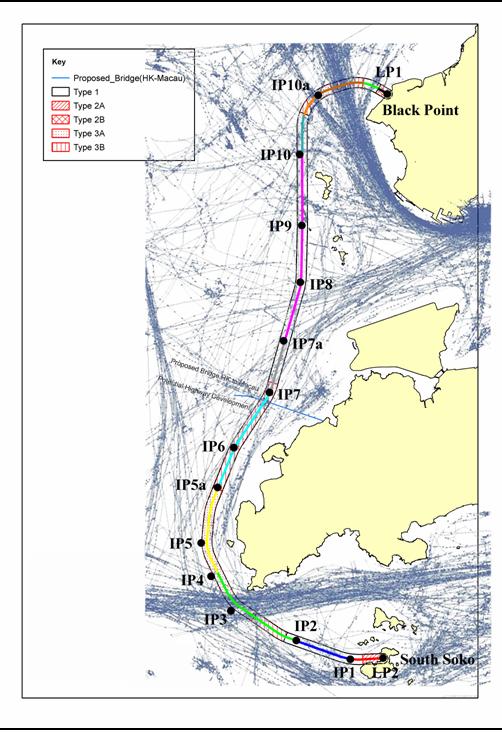

Figure 3.1 Pipeline

Route

Figure 3.2 Pipeline

Trench Types

The marine traffic influences the risks

from the pipeline in two ways:

·

It

increases the potential for damage due to interference such as anchor drop/drag

incidents; and

·

In

the event of a pipeline failure, marine traffic could exacerbate the

consequential effects causing fatalities.

The marine vessel traffic volume was

surveyed by BMT [4] using tracks of vessel movements obtained from radar. The

important details pertinent to the current study are repeated here for

completeness.

3.2.1

Marine Vessel Activity along Pipeline

Route

The marine traffic report [4] divides the

pipeline route into sections using ‘gate posts’ that roughly correspond to key

locations along the pipeline route. These same gate posts are adopted in the

current study (Figure 3.3).

The South Soko approach

(LP2-IP1) is characterised by local fishing activities and the movement of

small craft. The pipeline heads westwards and crosses the Adamasta

Channel between gates IP2-IP4. The marine traffic in this area is dominated by

fast ferries and rivertrade activity. These fast

ferries service Macau and Zhuhai and travel at 40-45

knots. There is also a traffic separation scheme (TSS) and turning buoy in this

area. Section IP4-IP5a around the western edge of Lantau

Island consists mainly of fishing vessels currently. IP5a-IP7 passes by the Y3

Anchorage area. It is understood that this anchorage is used by large oil

tankers transferring their load to smaller vessels that service the Pearl River

[10]. There is very little information available regarding this since the

anchorage is outside Hong Kong waters, but the presence of such activity is

confirmed by the existence of anchor marks on the seabed [8]. There are also

plans to develop a container terminal (CT10) in this area. Although these plans

are very tentative at the moment, a high level of pipeline protection (type 3B)

is maintained through this section.

IP7-IP10 is used by fishing vessels and rivertrade vessels en route between Tuen

Mun and Macau/Zhuhai. The

water is shallow in this region, ranging from 4-8m deep. This precludes its use

by large draft vessels. This section also runs along the edge of the Sha Chau/Lung Kwu

Chau Marine Park.

Gate post IP10a lies near the centre of

Urmston Road. This is the main route for container ships, rivertrade

vessels and fast ferries plying between Hong Kong and the ports of the Eastern

Pearl River Delta.

Figure 3.3 Reference

Points for Proposed Pipeline

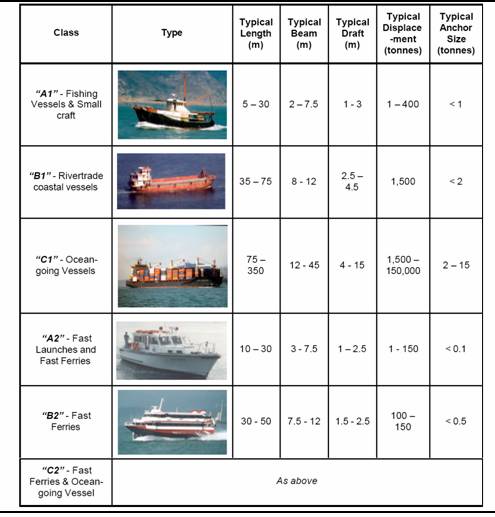

3.2.2

Vessel Types

The marine traffic consultant has calculated

the marine traffic volume between pairs of gate posts based on radar tracks

[4]. The vessel speeds and apparent size from the radar returns are interpreted

into 6 marine vessel categories (Table.

3.2). The same categories are used for the current study.

Table 3.2 Vessel Classes

Adopted for Assessment

Based on this vessel classification, the

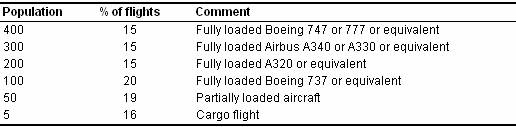

population used in this study are as given in Table 3.3. The maximum population of fast ferries is assumed to be

450, based on the maximum capacity of the largest ferries operating on routes

to Macau and Pearl River ports. However, the average load factor of fast

ferries to Macau is 52% and Pearl River ports is 37% [11] while the overall

average load factor considering all ferries is about 50% [10]. Hence, a

distribution in ferry population was assumed as indicated in Table 3.3. This distribution gives an

overall load factor of about 58% which is conservative and covers any future

increase in vessel population. There is an additional category in the traffic volume

data called ‘Others’ (see Section 3.2.3).

These are assumed to be small vessels with a population of 5.

Table 3.3 Vessel Population

|

Class |

Population |

|

|

|

Fishing

vessel Rivertrade

coastal vessels Ocean-going

vessels Fast

launches Fast

ferries Other |

5 5 21 5 450

(largest ferries in peak hours, 4 hours a day) 350

(average ferry in peak hours, 4 hours a day) 280 (80%

capacity, peak hours, 4 hours a day) 175 (50%

capacity, daytime operation, 9 hours a day) 105 (30%

capacity, late evening, 4 hours a day) 35 (10%

capacity, night time, 7 hours a day) 5 |

3.75% of

trips 3.75% of

trips 22.5% of

trips 52.5% of

trips 12.5% of

trips 5.0% of

trips |

|

3.2.3

Traffic Volume

The traffic volume as provided by BMT [4] is

given in Table 3.4. This is for the

year 2003. BMT also provide predictions for the years 2011 and 2021 (Table 3.5). In this study, 2011 is used

as the base case and 2021 as the future scenario. Two future scenarios are

considered: with and without the development of the Tonggu

Waterway.

The data in Table 3.4 required further interpretation. Vessel class A2 is

described as fast launches and fast ferries. The population of a fast launch is

very different from that of a fast ferry and so a more precise breakdown is

required. Some of these A2 fast ferries clearly belong in class B2 with the

other fast ferries. Taking into consideration the timetable of ferries serving

Macau and the Pearl River ports and information provided by the marine

consultant [10], it was assumed that 55% of fast vessels along Urmston Road and

75% of fast vessels along the Adamasta Channel are

fast ferries. For intermediate sections, such as near Sha

Chau, an intermediate value of 65% was assumed.

Class C2 is described as fast ferries and

ocean-going vessels. Since all fast ferries have now been accounted for, class

C2 are assumed to comprise of cargo ships only. This is consistent with

assumptions made in the marine activity report [4,10].

The data shows a small number of

ocean-going vessels (class C1 and C2) along the route between gates IP6 and

IP10. The shallow water along these sections negates the possibility that these

are large vessels. They must be vessels at the smallest end of the distribution

of ocean-going vessels, no more than 100m long [10]. More likely, they are rivertrade vessels. They were therefore treated as smaller

vessels in the analysis by reclassifying them as either rivertrade

or ‘other’ vessels.

Table 3.4 Traffic Volume

across Gate Sections (Daily Average, 2003)

|

|

Table 3.5 Traffic Growth

Forecast

|

Vessel Type |

2011 compared to 2003 |

2021 compared to 2003 |

|

Ocean-going

Vessel Rivertrade

Coastal Vessel Fast

Ferry Fishing

Vessel/ Small Craft/ Fast launch Others |

-5% +5% +10% +5% +5% |

+10% +15% +30% +15% +15% |

Based on the above discussions, the

pipeline route was divided into 12 sections for analysis (Table 3.6, Figure 3.4). The first section is from LP2 to IP1, named

South Soko Approach. Similarly the second section is chosen

between gates IP1 and IP2, and named West Soko. The Adamasta channel spans IP2 to IP4 and so these are grouped

into one section for analysis. Similar grouping is performed for the remainder

of the pipeline.

Gate IP10a warranted extra interpretation since

it lies in the centre of Urmston Road. The section from IP10 to IP10a spans a

change in rock armour protection from type 1 to type 3A/B. A careful

examination of the radar tracks from marine vessels (overlaid in Figure 3.4) shows a higher density of vessels

along this section pass close to gate IP10a i.e. within Urmston Road where

there is greater rock armour protection on the pipeline. This section was

therefore split into two, denoted North Lung Kwu Chau and Urmston Road West, and some assumptions made

regarding the distribution of vessels between the two parts. It was assumed

that roughly equal numbers of vessels traverse each part, the shorter length of

the Urmston Road West section therefore getting a higher density of ships as

observed in the radar tracks. Large vessels such as ocean-going vessels were

assumed to pass entirely through Urmston Road West since the water would be too

shallow in North Lung Kwu Chau.

Similarly, the final section of pipeline

from IP10a to LP1 was split into 3 sub-sections to reflect changes in rock

armour protection on the pipeline. These were named Urmston Road Central,

Urmston Road East and Black Point Approach. Based on the radar tracks, about

95% of vessels were assumed to pass within Urmston Road Central. Of the remaining

5% of vessels, most were assumed to traverse the Urmston Road East section.

Table 3.6 Pipeline

Segmentation

|

|

Section |

Gate |

Kilometre Post |

Length (km) |

Typ. Water depth (m) |

Trench type |

||

|

From |

To |

From |

To |

|||||

|

1 2 3 4 5 6 7 8 9 10 11 12 |

South Soko Approach West Soko Adamasta

Channel West Lantau Tai O North Lantau Sha

Chau North

Lung Kwu Chau Urmston

Road West Urmston

Road Central Urmston

Road East Black

Point Approach |

LP2 IP1 IP2 IP4 IP5a IP7 IP7a IP10 IP10a |

IP1 IP2 IP4 IP5a IP7 IP7a IP10 IP10a LP1 |

0 1.6 4.5 9.8 14.2 19.5 22.2 31.6 33.5 34.7 37.0 37.8 |

1.6 4.5 9.8 14.2 19.5 22.2 31.6 33.5 34.7 37.0 37.8 38.3 |

1.6 2.9 5.3 4.4 5.3 2.7 9.4 1.9 1.2 2.3 0.8 0.5 |

5 8 25 20 17 7 6 4 20 20 5 4 |

2A 1 3B/3A 3A 3B 1 1 1 3B/3A 3A/3B 1 2B |

Figure 3.4 Segmentation

of the Route

Based on the above discussion, the marine

traffic volume used in the present analysis is summarized in Table 3.7. Additional ocean-going vessels

were injected into Urmston Road as indicated in the marine consultant report

[4].

Table 3.7 Traffic Volume

Assumed for Base Case 2011

|

|

Traffic volume (ships per day) |

|

|||||||

|

Section |

Fishing |

River-trade |

Ocean-going |

Fast Launch |

Fast ferry |

Other |

Total |

||

|

1 2 3 4 5 6 7 8 9 10 11 12 |

South Soko Approach West Soko Adamasta

Channel West Lantau Tai O North Lantau Sha

Chau North

Lung Kwu Chau Urmston

Road West Urmston

Road Central Urmston

Road East Black

Point Approach |

0 21 126 11 42 37 79 21 21 250 11 2 |

0 0 16 2 1 12 22 3 2 265 13 3 |

0 0 7 3 4 0 0 0 6 144 0 0 |

1 2 83 4 7 5 28 24 23 117 5 2 |

0 6 260 9 12 11 44 31 30 150 7 0 |

0 4 4 4 4 6 27 8 2 5 2 0 |

1 33 496 33 70 71 200 87 84 931 38 7 |

|

|

|

Total |

621 |

339 |

164 |

301 |

560 |

66 |

2051 |

|

Tables of traffic

volume for the 2021 future scenarios were created in a similar manner. These

are given in the main text (Section

13.9.3).

3.3.1

Ocean-Going Vessel Distribution

All classes of ship, with the exception of

ocean-going vessels, have anchor sizes below 2 tonnes (Table 3.2), and it is noted that the entire length of the proposed

pipeline will have rock armour protection designed to protect against at least

2 tonne anchors. Ocean-going vessels cover a very wide range of size. A

breakdown of the size distribution for this class of marine vessels is given in

Table 3.8 [4, 10]. These vessels are

predominantly found in Urmston Road which has type 3A/B rock armour protection to

protect against anchors up to 20 tonnes. From the size distribution, it can be

seen that the majority of these ships are below about 100,000 tonnes

displacement and so the majority of anchors are below about 10 to 12 tonnes.

Table 3.8 Size Distribution of

Ocean-Going Vessels

|

Size Range (dwt) † |

Displacement (tonnes)* |

Length |

Anchor Size |

Proportion of Ships (%) |

|

1,500 –

25,000 25,000 –

75,000 75,000 –

100,000 |

1,500

– 35,000 35,000

– 110,000 |

75

– 200 200

– 300 300

– 350 |

2

– 5 5

– 12 12

– 15 |

60 35 5 |

|

† Dead

Weight (dwt) = Cargo + Fuel + Water + others *

Displacement = Total Weight = Hull + Machinery + Outfit + Dead Weight Displacement has been assumed to be ~ 1.4 x dwt |

||||

This section identifies the main hazards

from the subsea gas pipeline during the operational

phase. Hazard identification is based on a literature review as well as HAZID

studies conducted for the proposed pipeline.

4.1.1

Incident Databases and Pipeline Reports

The Consultants (ERM) have examined

incident databases such as the MHIDAS [12] and the IChemE

Accident Database [13]. Only two pipeline incidents in offshore Vietnam have

been reported in the Asia-Pacific region. These occurred at White Tiger and Vung Tau, both in 1994 and both

were caused by anchor damage. No injuries were reported.

Relevant reports on major subsea pipeline failures (that caused fatality) by the

National Transportation Safety Board have also been reviewed [14, 15]. A

summary of a few main incidents from these sources are included in the

following paragraphs.

Tiger

Pass, Louisiana, 1996

On October 23, 1996, in Tiger Pass,

Louisiana, the crew of the dredge Dave

Blackburn dropped a stern spud (a spud is a large steel shaft that is

dropped into the river bottom to serve as an anchor and a pivot during dredging

operations) into the bottom of the channel in preparation for continued

dredging operations. The spud struck and ruptured a 12" diameter submerged

natural gas steel pipeline. The pressurised (about 930 psig) natural gas

released from the pipeline enveloped the stern of the dredge and an

accompanying tug. Within seconds of reaching the surface, the natural gas

ignited and the resulting fire destroyed the dredge and the tug. All 28 crew

members from the dredge and tug escaped into water or onto nearby vessels. No

fatalities resulted.

The incident occurred due to incorrect

information on the location of the gas pipeline that was passed on by the gas

company to the dredging operator. The investigation report on the incident (by

the National Transportation Safety Board) recommended that all pipelines

crossing navigable waterways are accurately located and marked permanently.

Mississippi River Delta, 1979

In an incident in the Mississippi River

Delta in 1979, four workers drowned attempting to escape a fire that resulted

when a crane barge dropped a mooring spud into an unmarked high pressure

natural gas pipeline.

Louisiana, 1987

In July 1987, while working in shallow

waters off Louisiana, a fishing vessel, the menhaden purse seiner

Sea Chief struck and ruptured an 8" natural gas liquids pipeline operating

at 480 psi. The resulting explosion killed two crew

members. Divers investigating found that the pipe, installed in 1968, was

covered with only 6" of soft mud, having lost its original 3-foot cover of

sediments.

Sabine Pass, Texas, 1989

A similar accident occurred in October

1989. The menhaden vessel Northumberland struck a 16" gas pipeline in

shallow water near Sabine Pass, Texas. The vessel was engulfed in flames; 11 of

the 14 crew members died. The pipeline, installed in 1974 with 8 to 10 feet of

cover, was found to be lying on the bottom, with no cover at all.

4.1.2

Pipeline Failure Databases

There are a few international failure

databases for gas and liquid transmission pipelines which are useful in

identifying potential hazards and estimating the frequency of loss of

containment incidents.

The most comprehensive database on

offshore gas pipeline failures is available in a report published by the UK

Health and Safety Executive entitled 'PARLOC 2001' [7]. The most recent version

of this database covers incidents from the 1960s up to 2000. The information in

this database is based on data obtained from regulatory authorities in the UK,

Norway, the Netherlands, Denmark and Germany, Operators in the UK, Dutch and

Danish sectors and published sources. The main causes of pipeline failure, as

identified from a review of the PARLOC 2001 data, are listed in Table 4.1. Based on this, it can be seen

that anchor/impact followed by internal corrosion are the main contributors to subsea pipeline failures.

A similar database on incidents involving

offshore pipelines in the US has also been referred to [16]. This is based on

incidents that are required to be reported to the US Department of

Transportation (DOT) under the Federal Regulations. Out of 109 incidents

reported during the period 1985 to 1994, only one incident involved a fatality,

and only one incident involved leak ignition. The main causes of pipeline

failure, as identified from a review of the US DOT database, are listed in Table

4.2. Based on this, it can be seen that third party damage and internal

corrosion (characteristic of well fluid pipelines) are the main contributors to

subsea pipeline failures.

Table 4.1 Causes

of Subsea Pipeline Incidents from PARLOC 2001 [7]

|

Main cause |

Detail |

No. of Incidents of Loss of Containment |

||

|

|

|

Platform Safety Zone(1) |

Subsea Well Safety Zone(2) |

Mid-line |

|

ANCHOR |

Supply Boat |

6 |

- |

- |

|

|

Rig or Construction |

- |

- |

- |

|

|

Other/ Unknown |

0 |

- |

2 |

|

|

Total |

6 |

- |

2 |

|

IMPACT |

Trawl |

- |

- |

6 |

|

|

Dropped Object |

- |

- |

- |

|

|

Wreck |

- |

- |

1 |

|

|

Construction |

1 |

- |

- |

|

|

Other/ Unknown |

- |

- |

1 |

|

|

Total |

1 |

- |

8 |

|

CORROSION |

Internal |

3 |

4 |

7 |

|

|

External |

1 |

- |

2 |

|

|

Unknown |

1 |

- |

2 |

|

|

Total |

5 |

4 |

11 |

|

STRUCTURAL |

Expansion |

- |

- |

- |

|

|

Buckling |

- |

- |

- |

|

|

Total |

- |

- |

- |

|

MATERIAL |

Weld Defect |

2 |

- |

1 |

|

|

Steel Defect |

2 |

1 |

1 |

|

|

Total |

4 |

1 |

2 |

|

NATURAL HAZARD |

Vibration |

- |

- |

- |

|

|

Storm |

- |

- |

- |

|

|

Scour |

- |

- |

- |

|

|

Subsidence |

- |

- |

- |

|

|

Total |

- |

- |

- |

|

FIRE/ EXPLOSION |

Total |

- |

- |

- |

|

CONSTRUCTION |

Total |

- |

- |

- |

|

MAINTENANCE |

Total |

- |

- |

- |

|

OTHERS |

Total |

2 |

1 |

4 |

|

TOTAL |

|

18 |

6 |

27 |

|

(1) Platform safety zone and subsea

safety zone refer to pipelines located within 500m of an offshore platform

and subsea well respectively (2) Mid-line refers to pipelines located

more than 500m from a platform or subsea well. |

||||

Table 4.2 Causes

of Subsea Pipeline Incidents from US DOT Database [16]

|

Cause of Failure |

Description of Cause |

No. of Incidents |

% of Total Incidents |

Incidents Considered

(1) |

||

|

1. EXTERNAL FORCE |

25 |

29.8% |

24 |

|||

|

Earth Movement |

Subsidence, landslides |

2 |

2.4% |

2 |

||

|

Heavy Rains/Floods |

Washouts, floatation, scouring |

1 |

1.2% |

|

||

|

Third Party |

|

21 |

25.0% |

21 |

||

|

Previously Damaged Pipe |

Where encroachment occurred in the past |

1 |

1.2% |

1 |

||

|

|

|

|

|

|

||

|

2. CORROSION |

45 |

53.6% |

3 |

|||

|

External Corrosion |

Failure of coating/CP |

3 |

3.6% |

3 |

||

|

Internal Corrosion |

|

42 |

50.0% |

|

||

|

|

|

|

|

|

||

|

3. WELDS & MATERIALS |

4 |

4.8% |

4 |

|||

|

Defective Fabrication Weld |

Welds in branch connections, hot taps, weld-o-lets,

sleeve repairs |

2 |

2.4% |

2 |

||

|

Defective Girth Weld |

|

2 |

2.4% |

2 |

||

|

|

|

|

|

|

||

|

4. EQUIPMENT & OPERATIONS |

3 |

3.6% |

|

|||

|

Equipment Failure |

Malfunction of control or relief equipment, failure

of threaded components, gaskets & seals |

3 |

3.6% |

|

||

|

|

|

|

|

|

||

|

5. OTHERS |

7 |

8.3% |

7 |

|||

|

Unknown |

|

7 |

8.3% |

7 |

||

|

|

|

|

|

|

||

|

TOTAL |

84 |

100% |

38 |

|||

|

1.

Only

these incidents are considered relevant to the proposed pipeline. |

||||||

4.1.3

Incident Records and Protection Measures

for Pipelines in Hong Kong Waters

A review of existing and proposed subsea pipelines in

Hong Kong waters including the level of protection provided are reviewed in the

following paragraphs.

Subsea Pipelines

Existing subsea

pipelines in

·

The

28" natural gas pipeline from Yacheng Field, South China Sea (90km south of

·

the

20" dual aviation fuel pipelines

between Sha Chau jetty and

the airport (about 5km length), installed in 1997, are laid in a 2.2m trench and

provided with sand cover plus rock armour protection. The water depth along the

route varies from 4-7m. There has been no incident of damage reported;

·

the

Airport Authority propose to construct another 5km submarine aviation fuel pipeline from Sha Chau jetty to the new tank

farm in Tuen Mun. The

pipeline will be crossing the Urmston Road shipping route and similar

protection as for the existing pipelines (i.e. rock armour protection) is

proposed. It is understood that the rock armour protection will be designed for

22 tonne anchors;

·

the town gas subsea

pipelines are also reported to have no damage record. These pipelines are laid at a depth of 2 to

3m below seabed and protected by engineering backfill materials;

·

the

Hong Kong Electric Company recently laid a pipeline from its Lamma Power Station Extension to Shenzhen LNG Terminal. The

pipeline is jetted to 3m below seabed and protected with rock armour in high

risk areas near the anchorages and shore approaches; and

·

the

recently installed town gas subsea pipeline from Shenzhen to Tai Po is jetted to 3m

below seabed with additional rock armour protection in high risk areas.

By comparison, the proposed CAPCO pipeline

will be laid in waters between 4 and 25m deep. The pipeline will be provided

with 3m of rock cover except in areas of shallow water where it will have 1m of

rock cover. These rock cover requirements are based on water depth (which

determines the size of vessels) and marine traffic volume. The measures

proposed are in line with, or exceed, comparable pipeline installations.

A Hazard Identification (HAZID) workshop

was held on 15th February 2006 as part of this QRA Study for the

pipeline. Representatives from CLP Power, ExxonMobil and BMT participated in the

hazard sessions. Various hazards considered relevant for this pipeline are

discussed in the worksheets presented in Table

4.3.

Table 4.3 HAZID

Worksheet

|

System: 1. Pipeline – General |

|

|||||

|

Subsystem: 1. Third party |

|

|||||

|

Hazards/ Keywords |

Description/ Causes |

Consequences |

Safeguards |

Recommendations |

|

|

|

1.

Anchor Drag |

1.

Emergency anchoring for vessel underway due to loss of steerage, power or control,

either due to mechanical problems or due to collision events. |

1.

Possibility of damage to external coating, damage to pipe requiring remedial

action. |

1.

Engineered rock protection with respect to vessel sizes/types. |

1. Periodic

survey along the route to be carried out to ensure integrity of the

protection. |

|

|

|

2.

Depth of cover. |

|

|||||

|

2.

Potential loss of containment leading to gas release. Impact on passing vessels

and shore population. Vessel involved in the incidents may sink due to loss

of buoyancy caused by the gas bubbling. |

|

|||||

|

3.

Route avoiding anchorage areas. |

|

|||||

|

2.

Drag from anchorage areas under storm condition. |

|

|||||

|

4. Concrete

external coating. |

|

|||||

|

5.

Heavy wall pipe in shore approaches. |

|

|||||

|

3.

Disturbance to the rock cover protection. Possible exposure of the pipe. |

|

|||||

|

6.

Marking marine charts of the pipeline route. |

|

|||||

|

7. Shore

population is at least 3km away along the route except near the shore

approach. |

|

|||||

|

3.

Anchoring by vessels outside anchorages. |

|

|||||

|

||||||

|

||||||

|

||||||

|

||||||

|

2.

Anchor Drop |

1.

Same as cause 1 & 3 of anchor drag hazard |

1.

Same as consequence 1, 2 & 3 of anchor drag hazard but less severe. |

1.

Same as for anchor drag hazard. |

|

|

|

|

3.

Dropped Object |

1.

Loss of cargo |

1.

Same as consequence 1, 2 & 3 of anchor drag hazard but less severe. |

1. Same

as safeguards 1, 2, 4, 5, & 7 of anchor drag hazard. |

|

|

|

|

2.

Construction activities |

|

|

||||

|

4.

Dumping |

1.

Dumping of construction waste and other bulk materials outside of designated

dumping grounds. |

1.

Minor surface damage. |

1. Same

as safeguards 1, 2, 4, 5, & 7 of anchor drag hazard. |

|

|

|

|

5.

Grounding |

1.

Navigation error, loss of control due to mechanical or adverse weather. |

1.

Same as consequence 1,2 & 3 of anchor drag hazard. |

1. Burial

depth appropriate to the type of shipping activities |

|

|

|

|

2.

Displacement of the pipeline leading to exposure |

|

|

||||

|

6.

Vessel Sinking |

1.

Collision, foundering. |

1.

Same as consequence 1, 2 & 3 of anchor drag hazard. |

1. Route

avoids shipping channel where possible. |

|

|

|

|

7.

Fishing & Trawling |

1. Operation of trawl board and other

fishing/trawl gear. |

1.

No damage to the pipeline. |

1.

Pipeline is buried to 3m below the seabed with rock cover flush with seabed. With

respect to shore area at BPPS, it is buried to 1.5m with rock cover flush

with seabed. |

|

|

|

|

8.

Dredging |

1.

Impact from dredge bucket or drag head. Expected location of maintenance

dredging are Adamasta Channel, along the Urmston road,

along the TSS |

1.

Same as consequence 1, 2 & 3 of anchor drag hazard but less severe. |

1.

Burial depth appropriate to the type of shipping activities. |

|

|

|

|

2.

Engineered rock protection with respect to vessel sizes/types. |

|

|

||||

|

3. Depth

of cover. |

|

|

||||

|

4.

Marking marine charts of the pipeline route. |

|

|

||||

|

5.

Concrete external coating. |

|

|

||||

|

9.

Service crossing or other services in the vicinity |

1.

No crossings envisaged |

|

|

|

|

|

|

10.

HZMB Construction |

1. Piling

for bridge structures near the pipeline, dredging, construction vessel

movement, anchoring and dropped object |

1.

Same as consequence 1,2 & 3 of anchor drag hazard |

1.

Interface with HZMB project owner to co-ordinate designs and schedule |

2. Develop

and implement procedures for safeguarding the pipeline during HZMB

construction |

|

|

|

2.

Engineered rock protection with respect to vessel sizes/types. |

|

|

||||

|

3.

Depth of cover. |

|

|

||||

|

4.

Concrete external coating. |

|

|

||||

|

11. HZMB

Operation |

1.

Vehicle fall off the bridge |

1.

Same as consequence 1 & 3 of anchor drag hazard |

1.

Same as safeguards 1, 2 & 4 of anchor drag hazard |

|

|

|

|

System: 1. Pipeline – General |

||||

|

Subsystem: 2. Natural |

||||

|

Hazards/ Keywords |

Description/ Causes |

Consequences |

Safeguards |

Recommendations |

|

1.

Scouring |

1.

Current and wave actions |

1.

Possible reduction of cover |

1.

Alignment is away from areas of high currents |

|

|

2. Engineered

rock cover |

||||

|

3.

Periodic surveys along the route |

||||

|

2.

Seismic event |

1.

Low seismic area |

1.

No damage |

1.

None required |

|

|

3.

Subsidence |

1.

No issue |

|

|

|

|

System: 1. Pipeline – General |

||||

|

Subsystem: 3. Construction |

||||

|

Hazards/ Keywords |

Description/ Causes |

Consequences |

Safeguards |

Recommendations |

|

1.

Damage to pipeline during construction |

1.

Damage after pipelay |

1.

Possible release if gas taken in |

1. Pre-commissioning

procedures to ensure integrity of pipeline before gas-in |

|

|

System: 1. Pipeline – General |

||||

|

Subsystem: 4. Operational |

||||

|

Hazards/ Keywords |

Description/ Causes |

Consequences |

Safeguards |

Recommendations |

|

1. Internal

corrosion |

1.

No issue for regassified LNG since it is clean and

dry gas |

|

|

|

|

2.

External corrosion |

1.

Sea-water; corrosive environment |

1.

Loss of wall thickness leading to potential leak |

1.

Coating system |

|

|

2. Sacrificial

anode system |

||||

|

3.

Designed for intelligent pigging |

||||

|

3.

Pressure cycling |

1.

Pipeline pressure will vary with time of day, loads etc |

1.

Metal fatigue leading to crack |

1.

Design will consider pressure cycles |

|

|

4. Material

defect/ construction defect |

|

1.

Possible leaks |

1.

Quality control during manufacture and construction |

|

|

System: 1. Pipeline – General |

||||

|

Subsystem: 5. Interface at Terminal

End |

||||

|

Hazards/ Keywords |

Description/ Causes |

Consequences |

Safeguards |

Recommendations |

|

1.

South Soko option will include a pig launching

facility. This includes piping and valving which is

covered in the TQRA |

|

|

|

|

|

System: 1. Pipeline – General |

||||

|

Subsystem: 6. Interface at GRS End in

BPPS |

||||

|

Hazards/ Keywords |

Description/ Causes |

Consequences |

Safeguards |

Recommendations |

|

1.

To be covered as part of GRS |

|

|

|

|

|

System: 2. Pipeline - Future

Developments |

||||

|

Subsystem: 1. All |

||||

|

Hazards/ Keywords |

Description/ Causes |

Consequences |

Safeguards |

Recommendations |

|

1.

Potential future CT10 construction |

1.

Dredging to create a new access channel, building of sea wall in proximity to

the pipeline, construction vessel movement, introduction of more shipping

activity, anchoring |

1.

Damage to pipeline |

1.

Current alignment is based on existing seabed profile. Flexibility for

alternative measures to be designed |

|

|

2. Tonggu channel |

1.

As currently shown, this channel is outside HK waters |

1.

No impact along the proposed route |

|

|

|

System: 3. GRS |

||||

|

Subsystem: 1. All |

||||

|

Hazards/ Keywords |

Description/ Causes |

Consequences |

Safeguards |

Recommendations |

|

1.

Leak from tappings, flanges and piping |

1.

Corrosion, mechanical failure, etc |

1.

Potential loss of containment |

1.

Gas and fire detection |

|

|

2. Maloperation during maintenance (including dropped

object), pigging |

2.

Shutdown system |

|||

|

3. Operating

and maintenance procedures |

||||

|

2.

Overpressure downstream of letdown valve |

|

1.

Potential loss of containment |

1.

Active/monitor and slam shut system |

|

4.3

Hazardous

Properties of Natural Gas

The natural gas to be transmitted by the

pipeline predominantly contains methane (87.6 - 96.1 mol%). Other components of

the gas include ethane (3.4 – 7.6 mol%), propane (0.4 - 3.1%) and butane (0.07

– 1.7%). It is a flammable gas that is lighter than air (buoyant). The

properties of natural gas are summarised in Table

4.4.

Table 4.4 Properties of

Natural Gas

|

Property |

Natural Gas |

|

Synonyms State Molecular

Weight Density

(kg/m3) Flammable

Limits (%) Auto-ignition

Temperature (°C) |

Methane Gas 16.7 -

18.7 0.55 (at

atmospheric conditions) 5 - 15 540 |

4.4

Discussion on

Subsea Pipeline Hazards

The incident records highlight the

potential for damage to subsea pipelines from marine

activity such as fishing, dredging and anchoring as well as the potential for

the vessel (that caused damage) to become involved in the fire that follows.

A review of subsea

pipeline incidents in Europe and the US suggests that third party damage

(including anchor and impact incidents) and internal corrosion are the main

contributors to subsea pipeline failures.

It is noted that the above databases

covers a large proportion of well fluid pipelines where internal corrosion is

relevant as compared to clean natural gas transported from an LNG terminal as

considered in this study.

Most existing pipelines in Hong Kong

waters have some rock cover protection in addition to being buries, although it

is noted that these pipelines are either crossing shipping channels or laid in

waters with high levels of marine activity.

A brief description of the main causes of

failure of a subsea pipeline is included in the

following paragraphs.

4.4.1

External Impacts

Anchor drop/drag is the dominant cause of

potential failure or damage to a subsea pipeline.

This occurs when a ship anchor is dropped inadvertently across the pipeline.

The type of damage that could be caused will vary depending on the size of

anchor and other factors such as pipeline protection.

Anchor Drop

The decision for a mariner when to drop an

anchor depends on the particular circumstances and the proximity of the

pipeline route to the flow of marine traffic, port/harbour areas and designated

anchorage locations. In fairways, traffic will normally be underway where the

necessity to drop anchor is expected to be low. Consistent with normal

practice, the pipeline route will be identified on nautical charts. The mariner

is then provided with the necessary information to avoid anchoring where the

pipeline could be damaged.

Emergency situations may arise such as

machinery failure or collision thereby limiting the choice where to drop

anchor. Such a decision will, as part of a mariner’s responsibility, be

influenced by the particular circumstances and the pipeline route delineated on

the navigation chart.

Anchorage area Y3 is believed to be used

by oil tankers transferring their load to smaller vessels. Although it is

expected that vessels should be aware of all subsea

installations (including gas pipelines) since these are marked on the admiralty

nautical charts, erroneous dropping of anchor (i.e. error in position at the

time of deployment) are known to occur. Under adverse weather conditions, it is

also possible for a vessel anchored at the anchorage area to drift with its

anchor dragging along the seabed.

Anchoring activity along the pipeline

route is taken into consideration in the analysis when assigning failure

frequencies for anchor damage (Section

5.3)

Anchor Drag

Anchor drag occurs due to poor holding

ground or adverse environmental conditions affecting the holding power of the

anchor. The drag distance depends on properties of the seabed soil, the mass of

ship and anchor and the speed of the vessel. If there is a subsea

pipeline along the anchor drag path, anchor dragging onto the pipeline may result

in localised buckling or denting of the pipeline, or over-stressing from

bending if the tension on the anchor is sufficient to laterally displace the

pipeline. A dragged anchor may also hook onto a pipeline during retrieval

causing damage as a result of lifting the pipeline.

Anchor dragging is taken into

consideration when assigning anchor damage frequencies in the analysis (Section 5.3).

Vessel Sinking

Vessel sinking in the vicinity of the

pipeline may cause damage to the pipeline resulting in loss of containment.

Vessel sinking will depend on the intensity of marine activity in a given area.

For the years 1990 to 2005, there were 446 incidents of vessel sinking in Hong

Kong waters [17]. This averages 28 cases per year. Most of the recorded incidents

occurred in Victoria Harbour and the Ma Wan Channel and involved mainly smaller

vessels of less than 1,000 dwt, which will have less

impact on a pipeline buried 3m below the seabed. The probability that a vessel

sinking incident will impact the proposed pipeline is therefore considered to

be low, in comparison to anchor impact damage. Additionally, pipeline damage

due to vessel sinking is included in the historical pipeline failure data for

external impact used in this study (see

Table 4.1).

Dropped Objects

Objects other than anchors may be dropped

from vessels passing over the pipeline or vessels operating in the vicinity,

e.g. those carrying out construction of new subsea

installations, new harbour developments, etc. The dropped objects may include

construction tubulars, shipping containers,

construction/maintenance equipment, etc.

The pipeline will be lowered to 3m below

seabed and protected by at least 1m of rock armour. Given the likely sizes of

dropped objects and the level of pipeline protection provided, loss of

containment due to dropped objects is not considered to be a significant

contributor to the risk and is not included in the analysis.

Aircraft Crash

The pipeline route runs within 3.7km of

the threshold of runway 07L at Chep Lap Kok Airport. Although rare, the possibility exists for

aircraft to crash on final approach to landing, or shortly after take-off. Such

a crash may be onto the pipeline, albeit with a small probability.

The water along this section of the

pipeline route is about 7m deep with the pipeline buried 3m below the seabed

and protected by 1m of rock armour and 2m of natural backfill. Aircraft are

constructed from light weight materials such that even a fully loaded Boeing

747 weighs only 400 tonnes. Aircraft also readily breakup

on impact with water, scattering the debris over a larger area. Given that the

pipeline is buried and protected and aircraft have limited weight, it is

considered not possible for an aircraft to damage the pipeline.

Fishing Activity

Based on the BMT report [4], there is

active fishing along much of the proposed pipeline route. Many of the

techniques involve towing of a variety of equipment along the seabed. Pipeline

damage from fishing gear can occur due to impact, snagging of nets or trawl

door on the pipeline or a "pull over" sequence. Impact loads mainly

cause damage to the coating whilst pull over situations can cause much higher

loads, which could lead to damage of the steel pipeline itself.

The vessels of concern are stern trawlers

with lengths up to 30m. Considering the size and weight of trawl gear and since

the pipeline will be lowered to 3m below seabed and protected by rock armour

for the entire route, pipeline damage due to trawling activities are not

possible and are not considered further.

Dredging Activities

Dredging vessels could cause damage due to

dredging operations involving cutting heads. They could also cause damage to

the pipeline by anchoring.

It is assumed that dredging operations

will be closely monitored and controlled and therefore there is no potential

for pipeline damage due to dredging.

4.4.2

Spontaneous Failures

Corrosion

Corrosion is one of the main contributors

to pipeline failures. Corrosion is attributed mainly to the environment in which

they are installed (external) and the substances they carry (internal).

The proposed pipeline will be protected

against external corrosion by sacrificial anodes in addition to an asphalt

coating. However, ineffective corrosion protection due to a failure or

breakdown of the protection system could cause external corrosion resulting in

general or local loss of wall thickness leading to pipeline failure.

Historically, internal corrosion is a

greater cause of pipeline failure compared to external corrosion. However, the

proposed pipeline will transport gas that does not contain components that

induce corrosion such as water/moisture, carbon dioxide, hydrogen sulphide,

etc. This will largely alleviate the effects of internal corrosion.

Despite these considerations, loss of

containment due to corrosion (both internal and external) remains a possibility

and is included in the analysis.

Mechanical Failure

Mechanical failure of the pipeline could

occur for various reasons, including material defect, weld failure, etc.

Stringent procedures for pipeline material procurement, welding and hydrotesting should largely mitigate against these hazards.

In any case, it remains a credible scenario and is included in the frequency

data.

4.4.3

Natural Hazards

Natural hazards such as subsidence,

earthquake and typhoon may cause varying degrees of damage to pipelines.

Soft soil can sometimes suffer from

localised liquefaction which can result in pipelines floating out of their

trenches. The pipeline will be designed to withstand such loads, based on

detailed seabed investigations.

Environmental loads (currents and waves)

on the pipeline during the construction phase can compromise the lateral and

vertical on-bottom stability of the pipeline on the seabed. This problem

becomes more acute in shallower waters (near the shore) where the pipeline

attracts a higher level of environmental loads. The pipeline will be designed

to withstand these environmental loads. Once it is jetted/lowered to 3m below

the seabed, it would not be exposed directly to 100 year return wave loads.

Based on the above considerations,

pipeline damage due to natural hazards is considered negligible and is not

assessed further in this study.

This section presents the base failure

frequency data for the hazards identified as having damage potential in Section 4. The approach to frequency

analysis is based on the application of historical data worldwide for similar

systems, modified suitably to reflect local factors such as proximity of the

pipeline route to busy shipping channels and anchorages.

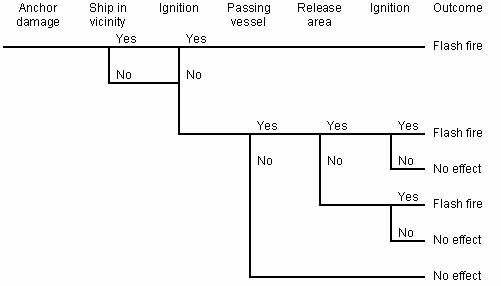

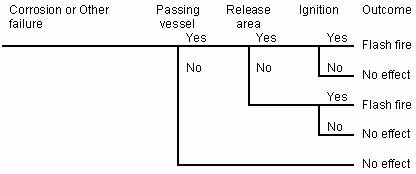

Event tree analysis was used to determine

the probabilities of various hazard outcomes (such as flash fire) occurring,

following a release.

The international database that is most

comprehensive in its coverage of subsea pipelines is

PARLOC 2001 [7]. The most recent version of this database which was used in

this study covers incidents from the 1960s until 2000. Incidents recorded in

the database have been classified according to several categories, including:

·

Failure

location, i.e. risers, pipelines within 500m of an offshore platform, pipelines

within 500m of a subsea well and mid-line (pipelines

located more than 500m from a platform or a subsea

well). Failure data pertaining to risers is not relevant to this study and has

therefore been excluded;

·

Pipeline

contents. The database includes both oil and gas pipelines. Where the contents

in the pipeline have an impact on failure rate, such as corrosion, only

incidents pertaining to gas pipelines are considered; and

·

Pipeline

type, i.e. steel pipelines (both pipe body and fittings) and flexible lines.

Only failures involving the pipe body of steel pipelines are considered here.

A breakdown of the incidents recorded in

PARLOC 2001 by failure location is shown in Table

5.1. The number of incidents of loss of containment that have occurred

within 500m of a platform or a subsea well is almost

equal to the number of incidents that have occurred away from it (i.e.

mid-line). The higher failure rate in the vicinity of an offshore installation

(an order of magnitude higher than mid-line) is due to the effect of increased

ship/barge movements in the vicinity and the potential for anchor damage as a result.

The proximity of some sections of the

proposed pipeline route to high marine traffic environment could be regarded as

similar to the environment in the vicinity of the platform safety zone although

it is not strictly comparable.

Table 5.1 Failure

Rate Based on PARLOC 2001 [7]

|

Region of Pipeline |

Operating Experience |

No. of Incidents |

Failure Rate |

|

Mid-line |

297,565 km-years |

27 |

9.1 x 10-5 /km/year |

|

Platform safety zone |

16,776 years |

18 |

1.1 x 10-3 /year |

|

Subsea well safety zone |

2,586 years |

6 |

2.3 x 10-3 /year |

|

Total |

307,246 km-years* |

51 |

1.66 x 10-4 /km/year |

* The number of years in the case of platform and subsea well safety zone is multiplied by 0.5km of safety

zone to obtain corresponding km-years

The main causes of pipeline failure are

summarised in Table 5.2, based on the causes identified in

PARLOC 2001. As discussed earlier,

anchor/impact followed by internal corrosion are the main contributors to

pipeline failure.

Table 5.2 Main

Contributors to Subsea Pipeline Failure (PARLOC 2001)

|

Cause |

Platform Safety Zone |

Subsea Well Safety Zone |

Mid-line |

Total |

|

Anchor/Impact |

7 (39%) |

- |

10 (37%) |

17 (33%) |

|

Internal corrosion |

3 (17%) |

4 (67%) |

7 (26%) |

14 (27%) |

|

Corrosion -others |

2 (11%) |

- |

4 (15%) |

6 (12%) |

|

Material defect |

4 (22%) |

1 (17%) |

2 (7%) |

7 (14%) |

|

Others |

2 (11%) |

1 (17%) |

4 (15%) |

7 (14%) |

|

Total |

18 |

6 |

27 |

51 |

5.2.1

Analysis of Failure Causes

The failure frequency derived from the

PARLOC 2001 data is further filtered to discount those factors that do not

apply to the proposed pipeline. In the case of factors that could have greater influence

on the failure rate for the proposed pipeline (such as anchor/impact),

appropriate increase factors are adopted.

Corrosion

and Material Defect

Based on experience in Europe (Table 5.2), internal corrosion tends to

be a greater problem than external corrosion. For the proposed pipeline,

failures due to internal corrosion are expected to be less likely as the gas

handled is clean, unlike gas transported from wells/platforms which may contain

moisture and hydrogen sulphide. Also, it is assumed that the condition of the

pipeline will be monitored periodically and maintenance work carried out as

necessary.

Failures due to defects in materials and

welds are also expected to be lower than implied by the historical record due to

technological improvements. The database for PARLOC 2001 dates back to the

1960s; there have been significant improvements in pipe material and welding

over the last 10 to 20 years. An 80% reduction is therefore assumed for all

forms of corrosion and material defects.

Taking the mid-line data as the most

representative for the proposed pipeline, the failure rate is therefore derived

as 13 incidences in 297,565 km-years with 80% reduction, giving 8.7 x 10-6

/km/year.

The PARLOC 96 report [18] provides a

breakdown of loss of containment incidents due to corrosion and material defect

for gas pipelines greater than 5km in length. The failure rate for such

pipelines is lower at 5.9 x 10-6 /km/year (0.7 failures in 119,182 km-years;

the km-years are lower because only gas pipelines are considered). This value

is considered more appropriate for the proposed pipeline. Unfortunately, a more

current value could not be extracted from PARLOC 2001 due to a difference in

presentation format of the data. However, a downward trend in failure

frequencies is to be expected as technology improves and so 5.9 x 10-6

/km/year is considered to be reasonable. Incorporating an 80% reduction again

gives a corrosion/defect frequency of 1.18 x 10-6 /km/year.

Anchoring/Impact Incidents

There is a significant difference in the

failure rate due to anchor/impact incidents for pipelines within 500m of an

offshore platform (8.3 x 10-4/km/year) as compared to mid-line (3.4

x 10-5 /km/year). A further breakdown of incidents based on pipeline

diameter is given in Table 5.3.

Table 5.3 Frequency

of Loss of Containment Incidents due to Anchor/Impact- Breakdown by Pipe

Diameter & Location

|

|

Frequency (per km per

year) |

|||

|

Location |

<10" diameter |

10 to 16" diameter |

18 to 24" diameter |

24 to 40" diameter |

|

Mid-line |

1.53 x 10-4 |

2.26 x 10-5 |

1.76 x 10-5 |

1.37 x 10-5 |

|

Safety zone |

6.68 x 10-4 |

1.94 x 10-3 |

4.24 x 10-4 |

8.6 x 10-4 |

It is seen from the above that the failure

rate (for mid-line) for larger diameter pipelines is lower by an order of

magnitude in comparison to smaller diameter pipelines.

As

discussed previously, it is considered that the likelihood of pipeline damage

due to anchor/impact incidents may be related to the level of marine activity

(this is taken to be a combination of marine traffic and anchoring activity).

The frequency of pipeline failure due to these causes has therefore been

derived as a function of three levels of marine activity: high, medium and low.

Frequency values are based on the large diameters pipes of 24-40” as given in Table 5.3 since these are the most relevant

to the proposed CAPCO pipeline.

For locations with high marine

activity, a frequency of 8.6 x 10-4 /km/year is adopted. For low

marine activity, 1.37 x 10-5 /km/year is used. An intermediate value

of 10-4 /km/year is also applied to locations with medium levels of

marine activity. This is discussed further in Section 5.3 where alternative calculations based on emergency

anchor deployment frequency are also presented for comparison.

These failure frequencies from PARLOC

assume minimal protection for the pipeline. The proposed CAPCO pipeline will be

provided with rock armour protection over its entire length. To allow for this,

the failure frequencies are reduced by appropriate factors as discussed in Section 5.4.

Other Causes

“Other” causes include blockages,

procedural errors, pressure surges etc. As with corrosion, improvements in

technology and operating practices are expected to reduce this significantly

and so a general 90% reduction is assumed for failures due to other causes.

This gives a frequency of

1.34 x 10-6/km/year (4 cases in 297,565 km-years with 90%

reduction).

5.3

Alternate Approach

to Anchor Damage Frequency

While international data is commonly

applied to infer failure rates for Hong Kong subsea

pipelines, in this section an alternative approach is adopted for comparison.

This is based on the marine traffic incident rate, since such incidents are

more likely to result in emergency anchoring. In the first instance, the

effects of rock armour protection are neglected to allow these calculations to

be compared with historical data from PARLOC. The effects of rock armour protection

are then incorporated as described is Section

5.4.

5.3.1

Frequency of Anchor Drop

Emergency Conditions

Vessels may drop anchor due to emergency

conditions such as fog, storm, or due to collisions or machinery failure. The

likelihood of anchoring due to adverse weather conditions is expected to be low

especially for the larger vessels who will determine whether dropping an anchor

is the safest option. Furthermore, knowledge of vessel position from onboard

navigation systems should prevent inadvertent dropping of an anchor onto a

pipeline delineated on the navigation chart.

To

estimate the frequency of emergency anchoring, data from the Marine Department

of Hong Kong [6] is used. The distribution of incidents of all types (Figure 5.1) shows that most incidents are

concentrated in the harbour regions near Yau Ma Tei, Tsing Yi and Tuen Mun. The region near the

proposed pipeline indicates low incident rates for much of the pipeline but

slightly higher values near Urmston Road. This is due to the higher traffic

density in this area. An average value of 0.3 for the period from 2001 to 2003

clearly refers to a single incident that occurred during this 3-year period.

The size of each cell in Figure 5.1

is one arc-minute of latitude and longitude, or approximately 1.86 x 1.73 = 3.2 km2. A

value of 0.3 refers then to an incident frequency rate of 0.09 /km2/year.

For comparison, the total number of incidents from 1990-2004 in the 1830 km2

area of Hong Kong waters was 5161 [17]. This gives an average of 0.19 /km2/year.

So, the incident rate along much of the proposed pipeline route is lower than

average, while the fairway of Urmston Road is a little higher than average.

Based on the above discussion, an incident

rate of 0.1 /km2/year is assumed for most of the pipeline and 0.3

/km2/year is assumed for Urmston Road. Although few incidents are

shown for the Adamasta Channel, the higher traffic

volume here is assumed to give a higher incident rate and so

0.3 /km2/year is assumed for this region also.

Figure 5.1 Average

Annual Incident Distribution (2001-2003)

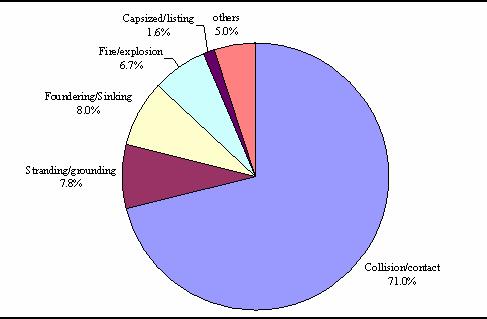

The distribution by types of incidents (Figure 5.2) shows that most incidents

are collisions or contact. Not all incidents will result in an anchor drop. Most

collisions, for example, are not serious. It is assumed therefore that only 10%

of incidents will result in an emergency anchor drop.

Figure 5.2 Distribution

of Incident Types (1990-2004)

Once the anchor is dropped, it may fall

directly on the pipeline causing damage. A greater concern is the possibility

of an anchor being dragged across the seabed and into the pipeline. In an

emergency situation such as mechanical failure, it is possible that the vessel

is still moving when the anchor is deployed. Since anchors can be dragged

significant distances, the resulting pipeline contact frequencies tend to be

higher compared to a simple anchor drop. In most instances, however, the ship

master’s first action will be to reduce speed to near stationary and then drop

anchor if necessary. For the purpose of this analysis, it was assumed that 90%

of ships drop anchor at near rest (1 knot), while the other 10% drop anchor at

4 knots due to mechanical failure and the uncontrolled advance of the vessel.

The efficiency of an anchor is defined

according to its holding capacity:

Holding

capacity = anchor weight ´ efficiency

The efficiencies for different classes of

anchor [20] are given in Table 5.4.

It is believed that types E and F are common on large commercial vessels.

Table 5.4 Anchor Efficiency

|

Class |

Efficiency |

|

A |

33-55 |

|

B C D E F G |

17-25 14-26 8-15 8-11 4-6 <6 |

This definition can be used to calculate the

drag distance. The work done in dragging an anchor through some distance must

be equal to the change in kinetic energy in bringing the ship to rest.

Anchors are designed to penetrate into the

seabed for maximum holding capacity. As an anchor is dragged across the seabed,

it will begin to penetrate into the mud; the softer the soil, the greater the

penetration. Maximum holding capacity is only reached once the maximum

penetration depth has been reached i.e. the efficiency is a function of

penetration depth. As a conservative approach, the lowest efficiency anchor,

type E, is assumed for the calculations. The efficiency is halved again to

allow for the varying restraining force with depth. The efficiency is therefore

assumed to be 2. Table 5.5 gives some

drag distances resulting from these calculations.

It can be seen that most vessels will drag

an anchor for less than about 20m. Ocean-going vessels can drag an anchor over

significantly greater distances due to the larger mass and hence kinetic energy

of the ship. This class of ship is subdivided into different sizes to reflect

the distribution of ships expected along the proposed pipeline route (see Table 3.8). A 150,000 tonne ship is the

largest of ships visiting Hong Kong and this provides the upper limit to the

drag distance of about 170m.

Table 5.5 Drag Distances

|

Class |

Size Range (dwt) |

Displacement (tonnes) |

|

Anchor |

Drag Distance (m) |

|

Fishing

vessel Rivertrade

coastal vessels Ocean-going

vessels Fast

Launches Fast

ferries Other |

1,500

– 25,000 25,000

– 75,000 75,000

– 100,000 |

400 1,500 1,500

– 35,000 35,000

– 110,000 110,000

– 150,000 150 150 200 |

(60%) (35%) (5%) |

1 2 2

– 5 5

- 12 12

- 15 0.1 0.5 0.2 |

7 13 13

– 118 118

– 154 154

– 168 25 5 17 |

The frequency of anchor drag impact can

then be calculated as:

Impact

freq =

incident

freq (/year/km2) ´ probability

of anchor drop ´ drag

distance/1000 (1)

where the drag distance is in meters. This

gives the impact frequency per km of pipeline per year. If an impact occurs,

the damage may not be severe enough to cause containment failure. Based on

PARLOC 2001, approximately 22% of anchor /impact incidents result in

containment failure when considering all pipe diameters. Larger pipes, however,

fail three times less often. This suggests that 7% of incidents would result in

a loss of containment.

This approach was applied to each section

of the pipeline and to each class of vessel. The marine traffic incident rate

was assumed to apply equally to all classes of vessel.

The hydrographic

survey [8] identifies seabed conditions as very soft clay for most of the

route. Under these conditions, significant anchor penetration can occur [20].

For example, a 15 tonne anchor can penetrate to 17m, and a 2 tonne anchor can

penetrate to 9m. These data apply to high efficiency anchors and less

penetration is to be expected for the commonly used types E and F, but

nevertheless, it is likely that a wide range of anchors sizes will be able to

achieve 3m penetration during emergency anchoring scenarios and hence may

interact with the proposed pipeline.

MARAD

Study

An alternative to using the incident

frequency from Figure 5.1 is to use

data from the MARAD study [19] which reported that the frequency of collisions

in Hong Kong waters of ocean-going vessels as 56 per million vessel-km. Since

only 71% of incidents are collisions, this value of 56 per million vessel-km

was scaled upwards to estimate the number of incidents of all types. 90% of

these incidents resulted in only minor damage and so again it is assumed that

only 10% will result in an emergency anchor drop. The approach is then similar

to that described above for anchor dragging.

Routine Anchoring

Estimating anchor drop frequencies from

marine vessel incidents fails to take into account routine anchoring. Routine

anchoring is not expected in the busy fairways but may take place at other

positions along the pipeline route. The EGS seabed survey [8] indicates the presence

of trawling marks from fishing activities and also anchor marks. This data was

used also to estimate anchoring frequencies.

It was assumed that anchor marks persist

for 2 years and so the frequency of anchoring damage for each km of pipeline was

estimated as:

Routine

anchoring damage freq =

number

of anchor marks / 2 x (anchor width

x 0.64 + 0.762)/500m survey width / length of pipeline section. (2)

Anchor dimensions were estimated from the Vyrhof anchor manual [20] for each class of ship. The

factor of 0.64 arises because the anchor may fall at some random angle relative

to the pipeline so the width of the anchor is effectively smaller by a factor

equal to the mean of cosine of the angle = 0.64. It was assumed that the

frequency of anchoring will decrease by 90% once the pipeline is installed and

marked on navigation charts. Also, it was assumed that only 7% of impacts would

result in loss of containment as before.

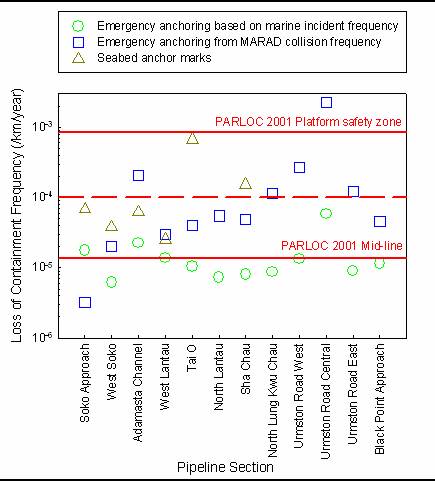

The results from this analysis are

compared in Figure 5.3. Also shown

are the loss of containment frequencies obtained from PARLOC 2001 for the

platform safety zone and mid-line. These are assumed to be representative of

areas of high and low marine activity respectively. It can be seen that there

is some spread in the predictions. The platform safety zone and mid-line

frequencies differ by almost two orders of magnitude but effectively bound most

of the other predictions.

Figure 5.3 Anchor Damage

Frequency Based on Marine Incidents

Predictions based on the MARAD collision

rate are regarded as being a little high because they are simply proportional

to vessel-km (and hence the traffic density) and do not take into account local

conditions along the route. The marine activity in Urmston Road for example is

about 19 times higher than Sha Chau,

but according to Figure 5.1, the

marine vessel incident rate is only about three times higher. On the other

hand, calculations based on emergency incidents are likely low because they

neglect indiscriminate anchoring or anchoring due to mistaken location.

The anchor marks on the seabed are the

least reliable indicator of anchoring activity due to the low number of marks,

the difficulty in distinguishing anchor marks from numerous trawling scars and the

uncertainty over how long the marks will persist in the soft seabed.

Nevertheless, anchor marks on the seabed do show two areas of high activity:

Tai O and Sha Chau. The Y3

anchorage area near Tai O accounts for one of these high activity areas. The second

occurs near Sha Chau. This

is most likely activity from smaller vessels since the water is shallow in this

region.

The calculations are broadly consistent

with failure frequencies from PARLOC 2001. The frequency obtained from PARLOC

2001 for the mid-line is appropriate for regions of low marine vessel volume

and low anchoring activity. The platform safety zone frequency is regarded as a

more appropriate choice for the failure frequency in locations of high marine

traffic or near anchorage areas. Some sections have intermediate levels of

marine activity and so a frequency of 10-4 per km-year is adopted

for these sections.

Based on the above considerations, the

failure frequencies due to anchor impact used in this study are as summarized

in Table 5.6. South Soko Approach and West Soko show

some anchor marks but these are few in number and are from the anchoring of

small vessels in the shallow water. The marine vessel activity is low n the

area so these sections were assigned a low anchor damage frequency. The Adamasta Channel is borderline between a medium and high

failure frequency and Figure 5.1

suggests that the marine incident rate is actually low in this region, perhaps

because of the traffic separation scheme. However, as a conservative measure, a

high frequency is assigned to this section. Tai O has a fairly low volume of

traffic but its position next to the Y3 anchorage and the numerous anchor marks

observed on the seabed warranted a high anchor damage frequency assigned to

this section.

Table 5.6 Anchor Damage

Frequencies used in this Study

|

Pipeline section |

Frequency (/km/year) |

Comment |

|

South Soko Approach West Soko Adamasta

Channel West Lantau Tai O North Lantau Sha

Chau North

Lung Kwu Chau Urmston

Road West Urmston

Road Central Urmston Road

East Black

Point Approach |

1.37 x 10-5 1.37 x 10-5 8.6 x 10-4 1 x 10-4 8.6 x 10-4 1 x 10-4 1 x 10-4 1 x 10-4 8.6 x 10-4 8.6 x 10-4 1 x 10-4 1 x 10-4 |

Low

marine traffic Low

marine traffic High

marine traffic Medium

marine traffic Next to

anchorage Medium

marine traffic Medium

marine traffic + some anchoring Medium

marine traffic High

marine traffic High

marine traffic Medium

marine traffic Medium

marine traffic |

5.4

Pipeline

Protection Factors

Many pipelines are trenched to protect them

from trawling damage. In the pipeline database in PARLOC 2001, 57% by length of

all lines have some degree of protection, either trenching (lowering) or burial

(covering) over part or all of their length. Considering large and small

diameter lines, the proportion of lines with some degree of protection are 59%

by length for lines <16" diameter and 68% for larger diameter lines. It

is, however, concluded in the PARLOC report that there have been insufficient

incidents to determine a clear relationship between failure rate and the degree

of protection.

The loss of containment frequencies given

in Table 5.6 assume minimal

protection since they are based on the PARLOC data. The proposed CAPCO pipeline

has rock armour protection specified for its whole length. To allow for this,

protection factors were applied. Based on the classes of marine vessel found

along the proposed route (Table 3.2),

most classes of ship have anchors below 2 tonnes in weight. Only ocean-going

vessels have anchors up to 15 tonnes. The rock armour protection along the

route is designed to protect against either 2 tonne anchors (trench type 1 and

2A/B) or 20 tonne anchors (trench type 3A/B). Rock armour protection factors

were therefore applied based on whether a ship’s anchor is smaller than or

larger than 2 tonnes.

Trench types 1 and 2A/B (designed to

protect against 2 tonne anchors) were assumed to provide 99%protection for

anchors smaller than 2 tonnes. This trench type should also offer some

protection against larger anchors. For ocean-going vessels, 60% of them have

anchors below about 5 tonnes (Table 3.8)

and so trench type 1 should offer reasonable protection against these vessels.

50% protection was assumed for ocean-going vessels.

Trench type 3A/B (deigned to protect

against 20 tonne anchors) was assumed to provide 99% protection for anchors

greater than 2 tonnes, and 99.9% protection for anchors below 2 tonnes.

5.5

Summary of

Failure Frequencies for CAPCO Pipeline

Based on the above discussions, the

failure frequencies used in this study are as summarized in Table 5.7.

Table 5.7 Summary of Failure

Frequencies used in this Study

|

Pipeline section |

Trench type |

Corrosion /defects (/km/year) |

Anchor/Impact |

Others /km/year |

Total /km/year |

||

|

Frequency (/km/year) |

Protection factor (%) |

||||||

|

anchor<2 |

Anchor>2 |

||||||

|

South Soko Approach West Soko Adamasta

Channel West Lantau Tai O North Lantau Sha

Chau North

Lung Kwu Chau Urmston

Road West Urmston

Road Central Urmston

Road East Black

Point Approach |