13

Quantitative

Risk Assessment

This

section of the EIA presents a summary of the analysis and findings of the Quantitative

Risk Assessment (QRA) study undertaken for the proposed LNG Terminal at Black

Point and associated facilities.

This section is divided into two sub

sections: section 1 relates to the general aspects of the QRA study, and

section 2 relates to the LNG Terminal.

Further details of the analysis

pertaining to the terminal QRA are contained in Annexes 13A1 through 13A7.

Additional

annexes are provided to describe the Safety Management System (Annex 13B) and summarise all the

assumptions adopted in the QRA study (Annex

13C).

13.1

Legislation Requirement and Evaluation Criteria

The

key legislation and guidelines that are considered relevant to the development

of the proposed LNG Terminal and associated facilities are as follows:

·

Gas Safety Ordinance,

Chapter 51

·

·

Dangerous Goods Ordinance,

Chapter 295

·

Environmental Impact Assessment

Ordinance (EIAO), Chapter 499

·

The EIA Study Brief, Section 3.7.9.1

There

is some overlap in the requirements of the various pieces of legislation and

guidelines. The requirement for a Hazard Assessment (HA) study is contained in

the EIAO and HKPSG. Such a study, although not required explicitly in

the Gas Safety Ordinance, is implied in the regulations and has been an

established practice for similar installations in the SAR.

13.1.1

EIAO

Technical Memorandum (EIAO-TM)

The

requirement for hazard assessment of projects involving storage, use and

transport of dangerous goods where risk to life is a key issue with respect to

Hong Kong Government Risk Guidelines (HKRG) is specified in Section 12 of the

EIAO-TM.

The

relevant authority for an QRA study relating to an LNG Terminal and associated

facilities is the Gas Standards Office (GSO) of the Electrical and Mechanical

Services Department (EMSD), as specified in Annex 22 of EIAO-TM.

Annex 4 of EIAO-TM

specifies the Individual Risk and Societal Risk Guidelines.

13.1.2

Risk

Measures and

Individual

risk is the predicted increase in the chance of fatality per year to a hypothetical individual who remains 100% of the time at a given stationary point.

The

individual risk guidelines require that the maximum level of off-site

individual risk associated with a hazardous installation should not exceed 1 in

100,000 per year i.e. 1 x 10-5 per year.

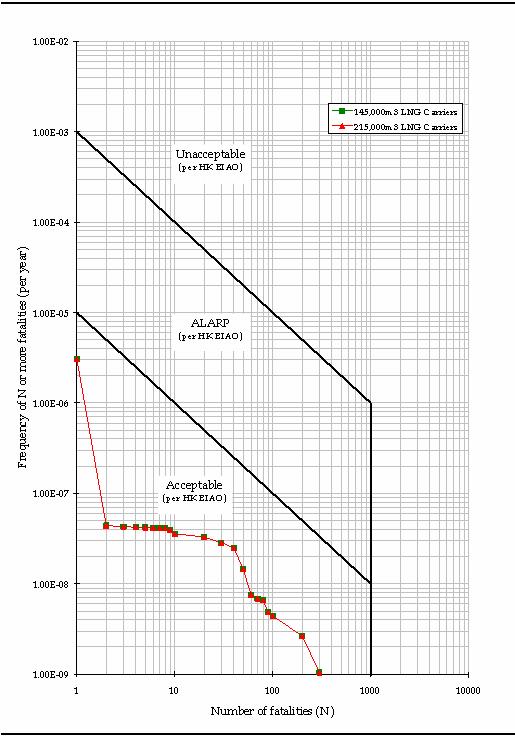

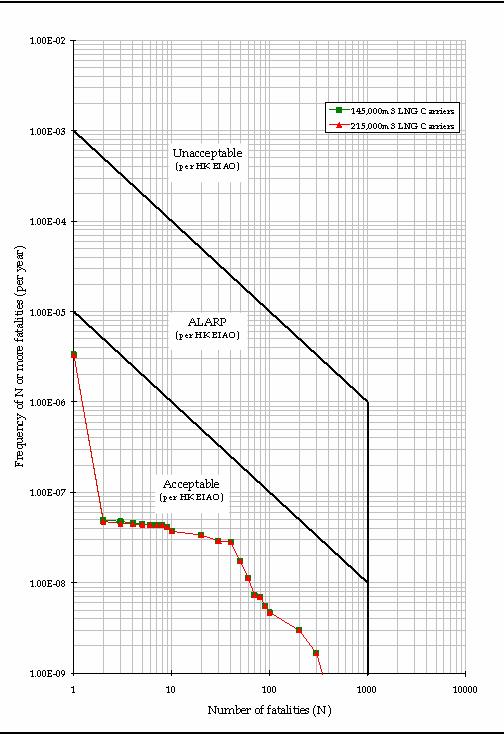

Societal

risk expresses the risks to the whole population. The HKRG is presented

graphically in Figure 13.1.

It is expressed in terms of lines plotting the frequency (F) of N or more deaths

in the population from incidents at the installation. Two FN risk lines are

used in the HKRG to demark “acceptable” or “unacceptable” societal risks. The intermediate region indicates the acceptability of societal

risk is borderline and should be reduced to a level which is “as low as

reasonably practicable” (ALARP). It seeks to ensure that all practicable and

cost-effective measures which can reduce risks will be considered.

Figure

13.1

13.2

Study Objectives and Methodology

The objective of the QRA study is to

assess the risk to life of the general public including the workers of nearby

plants from the proposed facilities during its operational phase. The results

of the QRA are compared with the HKRG.

The detailed requirements of the study

are (see Section 3.7.9.1 of the EIA

Study Brief):

·

To

identify all credible hazardous scenarios associated with storage, handling and

operation of the LNG facility, which has potential to cause fatalities;

·

To

carry out the QRA expressing population risks in both individual and societal

terms;

·

To

compare the individual and societal risks at the proposed development sites

with the HKRG;

·

To

identify and assess practical and cost effective risk mitigation measures as

appropriate;

·

To

identify all LNG leakage scenarios and propose a safety management system for

the operational phase of the project with an aim to contain any accidental

leakage in short notice and to prevent and/or minimise any leakage.

The

elements of the QRA are shown schematically in Figure 13.2.

An

overview of the methodology employed is provided here to briefly introduce the study approach, while the details

are included in the respective sections/ annexes.

Relevant

data on the proposed facilities such as their preliminary layout drawings and

design basis as well as population data in the vicinity were collected and reviewed.

A

Hazard Identification (HAZID) Study was conducted to identify all hazards, both generic and site

specific. A review of literature and accident databases were also undertaken.

These formed the basis for identifying all hazardous scenarios for the QRA

Study.

The

frequencies, or the likelihood, of the various outcomes resulting from an LNG/gas release scenario were derived

from historical databases and, where necessary, these were modified to take

into account local factors.

For

all identified hazards assessed as having a frequency of less than 10-9

per year, their frequency assessment will be documented but no quantification

of consequences will be performed.

For

hazards with frequencies greater than 10-9 per year, the

consequences of each release were modelled.

Hydrocarbon

releases have been modelled using the PHAST

consequence modelling package

developed by Det Norske Veritas,

Inc. (DNV)

The

consequence and frequency data were subsequently combined using ERM’s proprietary software RiskplotTM to

produce the required risk calculations.

Finally,

the results from the risk assessment were compared with the HKRG and found to

be acceptable. No mitigation measures are therefore proposed.

Figure

13.2 Schematic

Diagram of QRA Process

The

QRA study for the terminal includes all planned facilities at the site,

including unloading operations at the jetty, LNG storage tanks, sendout pumps, LNG vaporisers and the boil-off gas system.

This

section presents a summary of the hazard assessment study for the facilities at

the terminal while Annex 13A gives

further details.

As

per the Study Brief, the QRA study for the terminal is also required to include

the marine transit risks for LNG carriers within 500m of the jetty. A separate

Marine Quantitative Risk Assessment (MQRA) study has been conducted by DNV. The

risk results from the MQRA study for the 500m section at the jetty have been

combined with the risk results for the facilities at the terminal to produce an

overall risk result for the terminal, which is presented in this section. For

further details on marine transit risks, DNV’s report

may be referred.

13.3.1

Site

Facilities

The

proposed LNG Terminal and associated facilities will be built to provide a peak

natural gas sendout capacity of 1000 million standard

cubic feet per day (MSCFD).

The

Terminal will comprise the following primary components:

·

one jetty with a berth for LNG

carriers;

·

initially up to two 180,000m3

full containment LNG storage tanks (for Phase I,) followed by one

additional tank (for Phase II);

·

two in-tank LNG single stage

centrifugal pumps for each tank, capable of delivering LNG at about 7 barg;

·

four High Pressure LNG Booster pumps including one spare for Phase I

and three additional pumps for Phase II, to deliver at about 101 barg;

·

four including one spare (plus one

additional for Phase II) open-rack seawater vaporisers.

The

key features of the proposed LNG Terminal are depicted in the preliminary terminal

layout diagram (See Figure 3.1

in Section 3). LNG is transferred by pumps under cryogenic

conditions from the carrier to the tanks, where it is stored at near

atmospheric pressure. LNG from the tanks is pumped to the vaporisers where the

cryogenic LNG is converted into gas phase and the temperature raised to 5 °C

for sendout to the adjoining power station.

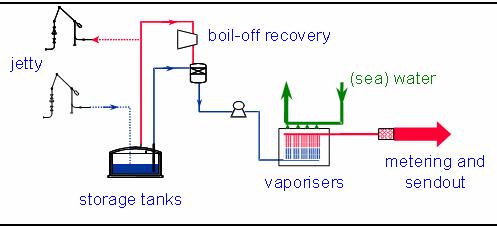

Figure

13.3 shows a schematic of the overall process in an LNG

terminal. A more detailed Process Flow Diagram for the Terminal, including

details on the design features and the operating philosophy are included in Annex 13A1. Further details of safety features and the Safety Management System

are provided in Annex 13B.

Figure 13.3 Process

Overview

13.3.2

Land Use

in the Vicinity

The current land use within a 2km

radius of the proposed site at Black Point includes

According

to data provided by Planning Department, Lung Kwu Sheung

Tan and the government land allocated for temporary use are the only areas

assumed to hold population within 2km radius of the Black Point site [1]. The

population in these areas was taken to be 100 persons for both years 2011 and

2021.

Lung Kwu Tan

village is situation 3km form the site and has a population of 753, predicted

to rise to 1,297 by the year 2021. To the north lies Ha Pak Nai

village with a population of 216.

Marine

population in the vicinity has been considered based on the marine traffic data

provided by BMT [2]; approximately 3-5 person/km2 is estimated in

the vicinity of Black Point.

Further details on land use adjoining

the proposed site, as well as the land and marine population surrounding Black

Point, are presented in Annex 13A2.

13.3.4

Weather Data

Weather data for the Black Point site

is based on data from Sha Chau

weather station which is the closest and most relevant. Details are presented

in Annex 13A3.

Hazards associated with the LNG

terminal have been identified based on a detailed review of known incident

records worldwide and experience gained from operations at similar facilities.

In addition, a systematic Hazard Identification (HAZID) process was undertaken to

identify any local or site specific factors.

13.4.1

Hazards

from LNG

LNG

is an extremely cold, non-toxic, non-corrosive and flammable substance. As LNG

is released from a temperature-controlled container, it will likely contact warm surfaces and air that transfer heat into

the liquid. The heat input begins to vaporise some of the liquid, returning

the liquid to the

gaseous phase.

The relative proportions of liquid and gaseous phases immediately following a

release depend on the release conditions. The liquid phase will form an LNG pool on the ground which will begin to “boil”,

due to heat input from the surrounding environment.

Immediately

following vaporisation, the gas is colder and heavier than the surrounding air

and forms a vapour cloud. As

the gas disperses, it mixes with the surrounding air and warms up. The vapour

cloud will only ignite if it encounters an ignition source while concentrated

within its flammability range.

Downstream

of the vaporisers the natural gas will be in the gas phase. A release from this

piping and equipment will result in a gaseous phase release directly.

13.4.2

Hazard

Effects

In the

event of an accidental release of LNG from piping or equipment, the

characteristics of the possible hazardous effects are described below.

Pool Fire

A

pool fire occurs when a flammable liquid is spilt onto the ground and ignited.

A pool formed from the release of liquid LNG will initially spread due to the

gravitational and surface tension forces acting on it. As the pool spreads, it

will absorb heat from its surroundings causing evaporation from the pool

surface. Ignition of this vapour leads to a pool fire.

Jet Fire

Jet

fires result from ignited releases of pressurised flammable gas or

superheated/pressurised liquid. The momentum of the release carries the

materials forwards in a long plume entraining air to give a flammable mixture.

Jet fires only occur where the LNG is being handled under pressure or when

handled in gas phase and the release is unobstructed.

Flash Fire

Following

an LNG release, a large proportion of the liquid will evaporate immediately to

form a cloud of methane, initially located around the release point. If this

cloud is not ignited immediately, it will move with the wind and be diluted as

a result of air entrainment. Similarly, a gas release may not be ignited

immediately and will disperse in the air.

The

dispersing vapour cloud may subsequently come in contact with an ignition

source and burn rapidly with a sudden flash. If the source of material which

created the cloud is still present, then the fire will flash back to the source

giving a pool fire, or if under pressure, a jet fire. Direct contact with the

burning vapours may cause fatalities but the short duration of the flash fire

means that thermal radiation effects are not significant outside the cloud and

thus no fatalities are expected outside of the flash fire envelope.

Vapour

Cloud Explosion

A

flash fire is the most likely outcome upon ignition of a dispersing vapour

cloud from an LNG release. If ignited in open (unconfined) areas, pure methane

is not known to generate damaging overpressures (explode). However, if the gas

is ignited in areas where there is significant degree of confinement and

congestion, such as the process areas, an explosion may result.

Fireball

Immediate

ignition of releases caused by a rupture in a gas piping may give rise to a

fireball upon ignition. Fireballs have very high thermal radiation, similar to

jet fires although the duration of the event is short.

To

summarise, a liquid phase release may result in a flash fire, vapour cloud

explosion, pool fire or jet fire. A gas phase release can result in a flash

fire, fireball or jet fire.

13.4.3

Review

of Industry Incidents

A

review of industry incidents at LNG terminal facilities was carried out.

Incident records over the last few decades show small LNG vapour releases and

minor fires with impact limited to within the plant boundary. These were

associated with leaks from valves and process equipment. There have been no

instances of leaks to the environment from full containment tanks. There have

been no injuries or fatalities recorded outside the plant boundary since 1944.

Other incidents have occurred during the construction and repair of LNG

facilities but no LNG was directly involved.

In

general LNG facilities have shown an exceptionally high safety record due to

the high level of safety features incorporated in an LNG terminal design

including the use of full containment tanks and emergency shutdown systems.

13.4.4

HAZID

Study

A

Hazard Identification (HAZID) Study was conducted in October 2005 involving

representatives from the Project Proponent: CLP and ExxonMobil and their expert

consultants: ARUP, Foster Wheeler and ERM. The

potential hazards posed by the facility were identified based on the HAZID

team’s expert opinion, past accidents, lessons learnt and checklists. The

details of the HAZID study can be found in Annex

13A4.

A

systematic approach was

adopted, whereby the facility was divided into a number of “subsystems” based

on the layout and the process; guidewords from the checklist (see Annex 13A4) were then applied to each subsystem as

relevant.

The Study

considered each area of the LNG Terminal and identified any potential hazards that apply to it. The study output served as a basis for identification of

scenarios for the QRA study.

13.4.5

Scenarios

for QRA Study

Scenarios

for the QRA study were identified based on the HAZID Study as well as a review

of incident records. Loss of containment events have been identified for each

section of the terminal, corresponding to the relevant process conditions, as

listed in Table 13.1.

A

detailed discussion on the hazards, particularly in relation to the LNG storage

tanks, is given in Annex 13A5.

Table

13.1 Scenarios

for QRA Study

|

Plant Section |

Initiating

Event |

Potential

Outcome Scenario |

|

Jetty Area Unloading arm Piping & equipment

at the jetty |

Leak, rupture |

Pool fire/Jet fire, Vapour

dispersion/ Flash fire |

|

Transfer Piping on Trestle Piping |

Leak, rupture |

Pool fire/Jet fire, Vapour

dispersion/ Flash fire |

|

Tank Area Piping on tank

roof Storage Tank |

Leak, rupture Rupture |

Pool fire/Jet fire, Vapour

dispersion/ Flash fire Pool fire, Vapour dispersion/

Flash fire |

|

Process Area (HP Pumps, Recondenser, Vaporisers)

Piping/equipment |

Leak, rupture |

Pool fire/Jet fire, Vapour

dispersion/ Flash fire/Vapour cloud explosion |

|

Process Area (Compressors)

Piping/equipment |

Leak, rupture |

Jet fire, Gas dispersion/Flash

fire, Fireball |

|

Sendout Piping |

Leak, rupture |

Jet fire, Gas dispersion/ Flash

fire, Fireball |

This

includes an assessment of the likelihood or the frequency of events resulting

in a hydrocarbon release from piping and equipment and the subsequent potential

outcomes such as fires. Details of the frequency analysis are provided in Annex 13A6.

Release

frequencies have been derived from generic data on loss of containment events.

Reference has been made to a number of sources. A summary is presented in Table 13.2. Release scenarios include a

range of hole sizes from small leaks to catastrophic rupture.

The

frequency of various outcomes following a loss of containment event is

estimated using an event tree model. The various outcomes considered include pool

fire, jet fire, flash fire and vapour cloud explosions for liquid releases, jet

fire and flash fire for continuous gas releases and fireball and flash fire for

instantaneous gas releases.

Table

13.2 LNG

Release Event Frequencies

|

Equipment |

Release

Scenario |

Release

Phase |

Release

Frequency |

Unit |

Reference |

|

Process

Vessels |

i)

10

& 25mm hole |

Liquid |

1.00E-05 |

per year |

Crossthwaite

et al [3] |

|

|

ii) 50 & 100mm

hole |

Liquid |

5.00E-06 |

per year |

Crossthwaite

et al |

|

|

iii) Full

bore rupture |

Liquid |

1.00E-06 |

per year |

Crossthwaite

et al |

|

Pumps |

i)

Leak |

Liquid |

1.00E-04 |

per year |

COVO Study

[4] |

|

|

ii) Full

bore rupture |

Liquid |

1.00E-05 |

per year |

COVO Study |

|

Unloading

Arm |

i)

Leak |

Liquid/ Gas |

4.05E-03 |

per year |

COVO Study |

|

|

ii) Full

bore rupture |

Liquid/ Gas |

4.05E-05 |

per year |

COVO Study |

|

Pipe size

600mm to 750mm |

i)

10 & 25mm hole |

Liquid/ Gas |

1.00E-07 |

per meter

per year |

Hawksley

[5] |

|

|

ii) 50 &

100mm hole |

Liquid/ Gas |

7.00E-08 |

per meter

per year |

Hawksley |

|

|

iii) Full

bore rupture |

Liquid/ Gas |

3.00E-08 |

per meter

per year |

Hawksley |

|

Pipe size

150mm to 500mm |

i)

10 & 25mm hole |

Liquid/ Gas |

3.00E-07 |

per meter

per year |

Hawksley |

|

|

ii) 50 &

100mm hole |

Liquid/ Gas |

1.00E-07 |

per meter

per year |

Hawksley |

|

|

iii) Full

bore rupture |

Liquid/ Gas |

5.00E-08 |

per meter

per year |

Hawksley |

|

LNG

Storage Tank |

i)

Rupture |

Liquid |

1.00E-08 |

per

tank-year |

“Purple

Book” [6] |

This

section gives a brief summary of the approach adopted to model the consequences

of an LNG/natural gas release. Details are given in Annex 13A7.

A range

of hole sizes from small leaks to full bore ruptures is considered in the

analysis. Discharge rates, dispersion modelling, pool fire modelling, jet fire

modelling, fire ball modelling and vapour cloud explosion modelling are

considered and are all performed using the PHAST

suite of models.

The

plant was divided into twenty three isolatable process sections based on the

provision of emergency shutdown valves. Physical properties of the fluid

(pressure, temperature, density, phase) and equipment dimensions (pipe diameter

and length) for each section were applied from the heat and mass balances to

estimate the maximum release rate and the inventory in each section.

Fire

radiation contours are calculated to 7.3, 14.4, 20.9 and 35.5 kW/m2,

and the fatality to people within each contour calculated. Overpressure effects

from vapour cloud explosions are calculated to 5psi and 2psi contours.

Dispersion of vapour clouds is determined to 0.85 of the lower flammability

limit. A range of weather conditions is also considered, to represent a full

year of conditions that occur within

13.7.1

Individual

Risk Results

The

individual risk (IR) contours associated with the LNG terminal are shown in Figure 13.4. The maximum off-site risk is less than 1 x 10-5

per year at the site boundary, hence meets the HKRG requirements.

Figure 13.4 Individual Risk

Contours

The societal risk for the Black Point site has been

estimated based on the land and marine population in the area. Three cases are

considered: year 2011, year 2021 “no Tonggu” and year

2021 “with Tonggu”. The potential development of the Tonggu Waterway will reduce the marine traffic along

The

societal risk results for the onshore terminal facilities have been combined

with the risk results for the LNG carrier during berthing manoeuvres within

500m of the jetty to produce the

overall societal risk results (Figures 13.5-13.7). The results for

the berthing manoeuvres are taken from the Marine Quantitative Risk Assessment

(MQRA).

The FN Curve for the 2011 case is shown in Figure 13.5.

Most of the points on the curve arise from scenarios involving the catastrophic

failure of the LNG storage tanks, which is a very low frequency event. Because of

limitations in the modelling, these results are likely conservative. For

example, the model is unable to allow for the restrictions in the pool

spreading from the coastline and other obstructions. The models simple assume

an unconfined isotropic spreading on water. Hence, the model predicts a

spreading of the LNG pool towards land populations which is not possible in

reality. In any case, Figure 13.5 demonstrates that the risks

are well within the acceptable region as per HK EIA Ordinance.

The risks from the carrier berthing manoeuvres within

500m of the jetty are small compared to the risks from the terminal and make

negligible contribution to the combined risk.

Compared

to 2011, the risks in 2021 (Figures 13.6 and 13.7) are marginally higher, in line with

the increase in marine traffic.

The

FN curves for 2021 “No Tonggu” (Figure 13.6) and 2021 “With Tonggu” (Figure 13.7) are essentially very similar.

The development of the Tonggu Waterway is not

predicted to have any effect on the marine population but does affect the

collision frequency with the LNG carrier. There are small changes in the

carrier manoeuvring risks as a result of this but since this 500m marine risk

is small compared to risks from the terminal, there is no discernable

difference in the overall risks.

Also

shown in the figures are results for large (215,000m3) and small

(145,000m3) carriers. If LNG is delivered from smaller carriers, the

number of transfers required per year will be higher. The frequency of possible

releases therefore increases, but the consequences would be less severe. Again,

this only affects the berthing risks and there is negligible difference in the

overall risks for large and small carriers.

The

risks for all cases are well within the Acceptable

Region as per HK EIAO.

The Potential Loss of Life (PLL), or equivalent

fatalities per year, are given in Table

13.3. The total PLL for the whole terminal is very low at 6.1 x 10-6

per year, or equivalently, one fatality every 163,000 years.

Table 13.3 Main

Contributors to Potential Loss of Life

|

Section |

2011 |

2021 |

|||

|

|

|

PLL |

% |

PLL |

% |

|

L02 T2 T1 T3 L05 L01 G07 L03 L06 P20 |

Liquid

unloading arm LNG tank 2 LNG tank 1 LNG tank 3 Liquid

unloading line from shore to tank Liquid piping

from tank to HP pump Sendout piping from

metering station to battery limit Liquid

unloading line from jetty to shore Recondenser In-tank pump

discharge piping |

1.21 x 10-6 9.53 x 10-7 9.43 x 10-7 9.18 x 10-7 7.47 x 10-7 6.53 x 10-7 2.94 x 10-7 1.30 x 10-7 7.21 x 10-8 4.5 x 10-8 |

19.8 15.6 15.4 15.0 12.2 10.7 4.8 2.1 1.2 0.7 |

1.33 x 10-6 1.04 x 10-6 1.02 x 10-6 9.93 x 10-7 8.26 x 10-7 7.20 x 10-7 3.25 x 10-7 1.43 x 10-7 7.91 x 10-8 5.05 x 10-8 |

19.9 15.5 15.3 14.9 12.4 10.8 4.9 2.1 1.2 0.8 |

|

|

Total |

6.11 x 10-6 |

|

6.68 x 10-6 |

|

Figure 13.5 FN Curve for 2011

Figure 13.6 FN Curve for 2021

"No Tonggu"

Figure 13.7 FN Curve for 2021

"With Tonggu"

13.8

Risk from Existing Power Plant

As described in Section

13.3, the proposed LNG Terminal at Black Point will be located adjacent to the

existing Black Point Power Station (BPPS). The BPPS is itself classified a Notifiable Gas Installation (NGI) and hence was the subject

of a Quantitative Risk Assessment (QRA) prior to commencing operation. This

section discusses BPPS and the risks from the site.

13.8.1

BPPS Description

The BPPS is a gas-fired power plant. The plant

receives gas via a subsea pipeline from an offshore

platform to a gas receiving station within the premises. The gas receiving

station includes:

· Emergency shutdown valves

· Pig receiver

· Slug catcher

· Heaters

· Filters

· Pressure reducing assembly

· Metering facilities

Gas from the receiving station is fed directly to the

power station. The power station includes the following gas holding equipment:

· Filter separators

· Fuel gas modules

· Turbines

13.8.2

BPPS QRA Study

The BPPS QRA study was conducted by DNV in 1994. The

study considered the gas receiving station and power station separately.

The hazards identified in the QRA study at both the

receiving station and power station were fire hazards due to a loss of

containment of hydrocarbon gas. The study evaluated the scenarios including jet

fires, flash fires and vapour cloud explosions following a gas release.

The gas receiving station QRA performed a quantitative

analysis considering gas leaks. The analysis considered small, medium, large

and full bore ruptures of the major equipment items.

The power station QRA considered small, medium, large

and full bore ruptures of the major equipment items. Risks to the offsite

populations were evaluated.

13.8.3

Risk Levels due to

BPPS

The BPPS QRA reports show no offsite risk posed by the

BPPS.

13.8.4

Offsite Risk Levels Including BPPS

As the BPPS QRA reports there are no offsite risk

posed by the BPPS, the total offsite risk in the vicinity of the LNG Terminal

is not affected by BPPS. The results of this study therefore present the total

offsite risk posed by the power station/LNG Terminal complex.

Based on the above discussion, the combined risk for

the existing Black Point Power Station and the proposed LNG terminal is within

the Acceptable Region as per HK EIAO.

13.9

Conclusions of QRA Study for

Terminal

The results indicate that the societal risks from the

proposed facility are within the Acceptable

Region of the HK EIAO.

The individual risks also meet the requirements of the HKRG.

References

[1] Projected

Hong Kong Resident Population by TPU, Planning Department, Hong Kong SAR, 2004.

[2] Marine Impact

Assessment for Black Point & Sokos islands LNG

Receiving Terminal & Associated Facilities, Pipeline Issues, Working Paper

#3, Issue 6, BMT Asia Pacific Ltd, May 2006.

[3] Crossthwaite,

P.J., Fitzpatrick, R.D. & Hurst, N.W., Risk Assessment for the Siting of Developments Near Liquefied Petroleum Gas

Installations, IChemE Symposium Series No 110, 1988.

[4] Rijnmond

Public Authority, A Risk Analysis of Six Potentially Hazardous Industrial

Objects in the Rijnmond Area – A Pilot Study, COVO,

D. Reidel Publishing Co., Dordrecht,1982.

[5] Hawksley,

J.L., Some Social, Technical and Economic Aspects of the Risks of Large Plants,

CHEMRAWN III, 1984

[6] Committee for the

Prevention of Disasters, Guidelines for Quantitative Risk Assessment – Purple

Book, 1st Edition, 1999.

Sub-Section

3: Black Point and