7.1

Introduction

This section

identifies the potential wastes arising from the construction and operation of

a LNG terminal at Black Point and assesses the environmental impacts associated

with waste handling and disposal.

The main issues are:

·

The management of dredged marine

sediment;

·

Handling and disposal of contaminated

soil/sediments;

·

Handling and disposal of construction

and demolition (C&D) materials ()

arising from the demolition, excavation and construction works; and

·

Chemical wastes, sewage, general refuse

and industrial wastes.

Opportunities

for waste reduction, recycling, storage, collection, transport and disposal

have been examined and appropriate measures for waste reduction and management

are proposed.

7.2

Legislation Requirements and Evaluation Criteria

The following

discussion on legislative requirements and evaluation criteria applies to both

the construction and operational phases of the LNG terminal.

The criteria

and guidelines for evaluating potential waste management implications are laid

out in Annexes 7 and 15 of the EIAO-TM under the EIAO (Cap

499). The following legislation covers,

or has some bearing upon, the handling, treatment and disposal of wastes in

Hong Kong, and will also be considered in this Project.

·

Waste

Disposal Ordinance (Cap 354);

·

Waste

Disposal (Chemical Waste) (General) Regulation (Cap 354C);

·

Land

(Miscellaneous Provisions) Ordinance (Cap 28)

·

Public

Health and Municipal Services Ordinance (Cap 132) - Public Cleansing and

Prevention of Nuisances Regulation; and

·

Dumping

at Sea Ordinance (Cap 466).

7.2.1

Waste

Disposal Ordinance (Cap 354)

The Waste Disposal Ordinance (WDO) prohibits

the unauthorised disposal of wastes, with waste defined as any substance or

article, which is abandoned.

Construction waste is not directly defined in the WDO but is considered to fall within the category of ‘trade

waste’. Trade waste is defined as

waste from any trade, manufacturer or business or any wasted building, or civil

engineering materials, but does not include animal waste.

Under the WDO, wastes can only be disposed of at a

licensed site. The WDO also provides for the issuing of

licences for the collection and transport of wastes. Licences are not, however, currently

issued for the collection and transport of construction waste or trade waste.

The Waste Disposal (Charges for Disposal of

Construction Waste) Regulation defines construction waste as any substance,

matter or thing that is generated from construction work and abandoned, whether

or not it has been processed or stockpiled before being abandoned, but does not

include any sludge, screening or matter removed in or generated from any desludging, desilting or dredging

works.

The

Construction Waste Disposal Charging Scheme entered into operation on 1

December 2005. From that time, any

main contractor who undertakes construction work under a contract with value of

$1 million or above is required to open a billing account solely for the

contract. Application shall be made

within 21 days after the contract is awarded.

For

construction work under a contract with value less than $1 million, such as minor

construction or renovation work, any person such as the owner of the premises

where the construction work takes place or his/her contractor can open a

billing account; the account can also be used for contracts each with value

less than $1 million. The premises

owner concerned may also engage a contractor with a valid billing account to

make arrangement for disposal of construction waste.

Under the new

construction waste charging scheme, charging for disposal of construction waste

started on 20 January 2006 and will also apply to the Project when commenced.

Depending on

the percentage of inert materials in the construction waste, inert construction

waste can be disposed at public fill reception facilities and mixed

construction waste can be disposed of at construction waste sorting facilities,

landfills and outlying islands transfer facilities where different disposal

cost would be applied. The scheme

encourages reducing, reusing and sorting of construction waste such that the

waste producer can minimise their disposal fee. Table

7.1 summarises the government construction waste disposal facilities, types

of waste accepted and disposal cost.

Table 7.1 Government

Facilities for Disposal of C&D Materials

|

Government Waste

Disposal Facilities

|

Type of

Construction Waste Accepted

|

Charge Per Tonne

|

|

Public fill reception facilities

|

Consisting entirely of inert

construction waste

|

$27

|

|

Sorting facilities

|

Containing more than 50% by weight of

inert construction waste

|

$100

|

|

Landfills

|

Containing not more than 50% by

weight of inert construction waste

|

$125

|

|

Outlying Islands Transfer Facilities

|

Containing any percentage of inert

construction waste

|

$125

|

7.2.2

Waste

Disposal (Chemical Waste) (General) Regulation (Cap 354C)

Chemical waste

as defined under the Waste Disposal

(Chemical Waste) (General) Regulation includes any substance being scrap

material, or unwanted substances specified under Schedule 1 of the Regulation,

if such a substance or chemical occurs in such a form, quantity or

concentration so as to cause pollution or constitute a danger to health or risk

of pollution to the environment.

A person

should not produce, or cause to be produced, chemical wastes without

registration with the EPD. Chemical

wastes must either be treated using on-site facility licensed by EPD or be

collected by a licensed collection for off-site treatment at a licensed

facility. Under EPD Regulations,

the waste producer, collector and disposal facility must sign all relevant

parts of a computerised trip ticket for each consignment of waste. The computerized system is designed to

allow the transfer of wastes to be traced from cradle-to-grave.

The EPD Regulation prescribes the storage

facilities to be provided on site which include labelling and warning

signs. To reduce the risks of

pollution and danger to human health or life, the waste producer is required to

prepare and make available written emergency procedures for spillage, leakage

or accidents arising from the storage of chemical wastes. They must also provide their employees

with training on such procedures.

7.2.3

Land

(Miscellaneous Provisions) Ordinance (Cap 28)

The inert

portion of C&D materials (also called public fill) may be taken to public

fill reception facilities. Public

fill reception facilities usually form part of land reclamation schemes and are

operated by the Civil Engineering and Development Department (CEDD) and others.

The Land (Miscellaneous Provisions) Ordinance requires that individuals

or companies who deliver public fill to the public fill reception facilities to

obtain Dumping Licences. The

licences are issued by CEDD under delegated authority from the Director of

Lands.

Individual

licences and windscreen stickers are issued for each vehicle involved. Under the licence conditions, public

fill reception facilities will only accept earth, soil, sand, rubble, brick,

tile, rock, boulder, concrete, asphalt, masonry or used bentonite. In addition, in accordance with

paragraph 11 of the ETWB TC(W) No.31.2004, Public Fill

Committee will advise on the acceptance criteria (e.g. no mixing of

construction waste, nominal size of the materials less than 250mm, etc). The material will, however, be free from

marine mud, household refuse, plastic, metal, industrial and chemical wastes,

animal and vegetable matter and any other materials considered unsuitable by

the public fill reception facility supervisor.

7.2.4

Public

Health and Municipal Services Ordinance (Cap 132) - Public Cleansing and

Prevention of Nuisances Regulation

This

Regulation provides a further control

on the illegal dumping of wastes on unauthorised (unlicensed) sites.

7.2.5

Dumping

at Sea Ordinance (Cap 466)

This Ordinance came into operation in April

1995 and empowers the Director of Environmental Protection (DEP) to control the

disposal and incineration of substances and articles at sea for the protection

of the marine environment. Under

the Ordinance, a permit from the DEP

is required for the disposal of regulated substances within and outside the

waters of the Hong Kong SAR. The

permit contains terms and conditions that includes the following

specifications:

·

Type and quantity of substances

permitted to be dumped;

·

Location of the disposal grounds;

·

Requirement of equipment for monitoring

the disposal operations; and

·

Environmental monitoring requirements.

Management of

Dredged/Excavated Sediments for Marine Disposal

Marine disposal of any

dredged/excavated sediment is subject to control under the Dumping at Sea Ordinance 1995.

Dredged/excavated sediment destined for marine disposal is

classified based on its contaminant levels with reference to the Chemical Exceedance

Levels (CEL), as stipulated in ETWBTC

No. 34/2002: Management of

Dredged/Excavated Sediment.

This Technical Circular includes a set of sediment quality criteria, as

presented in Table 7.2, which

includes heavy metals and metalloids, organic pollutants and a class of

contamination level for highly contaminated sediment not suitable for marine

disposal.

Table 7.2 Dredged/Excavated

Sediment Quality Criteria for the Classification under the ETWBTC No 34/2002

|

Contaminants

|

Lower Chemical Exceedance Level

(LCEL)

|

Upper Chemical Exceedance Level

(UCEL)

|

|

Metals

(mg kg-1 dry weight)

|

|

Cd

|

1.5

|

4

|

|

Cr

|

80

|

160

|

|

Cu

|

65

|

110

|

|

Hg

|

0.5

|

1

|

|

Ni (a)

|

40

|

40

|

|

Pb

|

75

|

110

|

|

Silver (Ag)

|

1

|

2

|

|

Zinc (Zn)

|

200

|

270

|

|

Metalloid

(mg kg-1 dry weight)

|

|

Arsenic (As)

|

12

|

42

|

|

Organic-PAHs (mg

kg-1 dry weight)

|

|

Low Molecular Weight (LMW) PAHs

|

550

|

3,160

|

|

High Molecular Weight (HMW) PAHs

|

1,700

|

9,600

|

|

Organic-non-PAHs (mg

kg-1 dry weight)

|

|

Total PCBs

|

23

|

180

|

|

Organometallics (mgTBT l-1 in interstitial water)

|

|

Tributyl-tin (a)

|

0.15

|

0.15

|

|

Note:

(a)

The contaminant level is considered to

have exceeded the UCEL if it is greater than the value shown.

|

The DEP, as

the Authority under the Dumping at Sea

Ordinance (DASO), will classify sediments based on their contaminant levels

with reference to the CEL laid down in the Table

7.2. In accordance with ETWBTC

34/2002, the sediment is classified into three categories based on its

contamination levels:

Category L : Sediment

with all contaminant levels not exceeding the LCEL. The material must be dredged,

transported and disposed of in a manner which reduces the loss of contaminants

either into solution or by re-suspension.

Category

M : Sediment

with any one or more contaminant levels exceeding the LCEL with none exceeding

the UCEL. The material must be

dredged and transported with care, and must be effectively isolated from the

environment upon final disposal unless appropriate biological tests demonstrate

that the material will not adversely affect the marine environment.

Category

H : Sediment

with any one or more contaminant levels exceeding the UCEL. The material must be dredged and

transported with great care, and must be effectively isolated from the

environment upon final disposal.

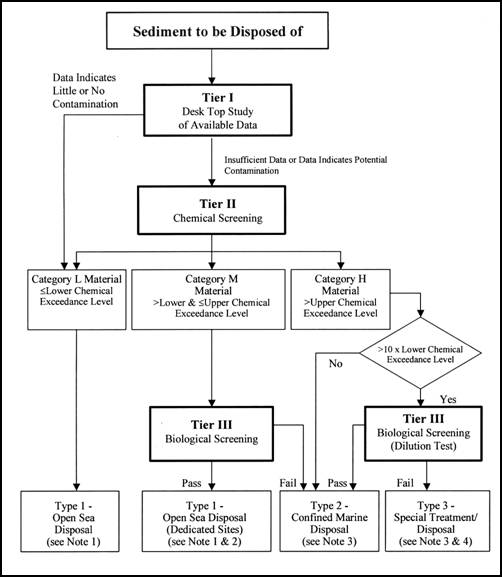

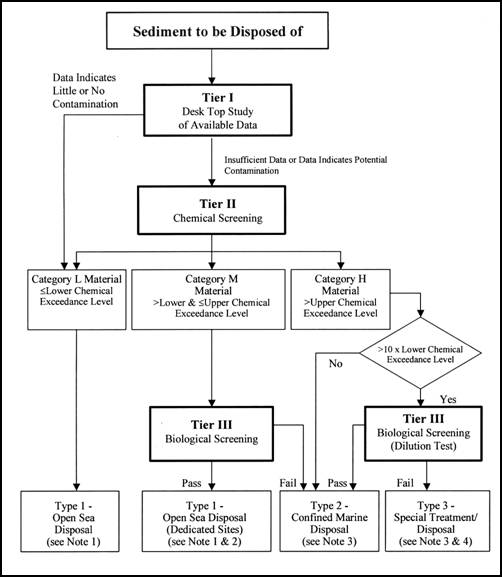

Figure 7.1

summarises the sediment classification and disposal arrangements. The determination of the most

appropriate open sea or confined marine disposal site will be based on the

chemical and biological test results of the sediment.

Figure 7.1 Management Framework for Dredged/Excavated Sediment

Notes:

1.

Most open sea disposal sites are

multi-user facilities and as a consequence their management involves a

flexibility to accommodate varying and unpredictable circumstances. Contract

documents will include provisions to allow the same degree of flexibility to

divert from one disposal site to another during the construction period of a

contract.

2.

Dedicated Sites will be monitored to

confirm that there is no adverse impact.

3.

For sediment requiring Type 2 or Type 3

disposal, contract documents will state the allocation conditions of Marine

Fill Committee (MFC) and DEP. At present, East Sha Chau mud pits are designated for confined marine disposal.

4.

If any sediment suitable for Type 3

disposal (Category H sediment failing the biological dilution test) is identified,

it is the responsibility of the project proponent, in consultation with DEP, to

identify and agree, the most appropriate treatment

and/or disposal arrangement. Such a proposal is likely to be very site and

project specific and therefore cannot be prescribed. This does not preclude

treatment of this sediment to render it suitable for confined marine disposal.

5.

The allocation of disposal space may

carry a requirement for the project proponent to arrange for chemical analysis

of the sediment sampled from 5% of the vessels en-route to the disposal site.

For Category M and certain Category H sediment, the chemical tests will be

augmented by biological tests. Vessel sampling will normally entail mixing five

samples to form a composite sample from the vessel and undertaking laboratory

tests on this composite sample. All marine disposal sites will be monitored

under the general direction of the CEDD. However, exceptionally large

allocations might require some additional disposal site monitoring. These will

be stipulated at the time of allocation.

6.

Trailer suction hopper dredgers

disposing of sediment at East Sha Chau

must use a down-a-pipe disposal method, the design of which must be approved in

advance by Director of the CEDD. The dredging contractor must provide equipment

for such disposal.

Source: Appendix C, ETWBTC 34/2002

In

addition, in accordance with Building

Ordinance Office Practice Note for Authorised Persons and Registered Structural

Engineers No 155, any proposal to remove more than 500,000 m3 of

clean mud or any quantity of contaminated mud must be justified on both cost

and environmental grounds. The

rationale for such removal will also be provided to enable an allocation for

disposal to be considered. It is

desirable, therefore, to demonstrate that any proposed mud dredging has been

reduced as far as reasonably and safely practicable, and to obtain in-principle

agreement from the Secretary of the MFC of the CEDD at an early stage. For projects which involve marine

disposal of dredged/excavated sediments, the Practice Note for Authorised Persons No 252 will be followed.

7.2.6

Other

Relevant Guidelines

Other

guideline documents, which detail how the Contractor will comply with the WDO

and its associated regulations include:

·

Waste

Disposal Plan for Hong Kong (December 1989), Planning, Environment

and Lands Branch Government Secretariat, Hong Kong Government;

·

Chapter 9 Environment (1999),

Hong Kong Planning Standards and Guidelines, Hong Kong Government;

·

New

Disposal Arrangements for Construction Waste (1992), EPD

& CED, Hong Kong Government;

·

Code

of Practice on the Packaging, Labelling and Storage of Chemical Wastes

(1992), EPD, Hong Kong Government;

·

Works

Branch Technical Circular (WBTC) No. 32/92, The Use of Tropical Hard Wood on

Construction Site; Works Branch, Hong Kong Government;

·

WBTC

No. 2/93, Public Dumps. Works Branch, Hong Kong Government;

·

WBTC

No. 2/93B, Public Filling Facilities, Works

Branch, Hong Kong Government;

·

WBTC

No. 16/96, Wet Soil in Public Dumps; Works

Branch, Hong Kong Government;

·

WBTC

Nos. 4/98 and 4/98A, Use of

Public Fill in Reclamation and Earth Filling Projects; Works Bureau, Hong

Kong SAR Government.

·

Waste

Reduction Framework Plan, 1998 to 2007, Planning,

Environment and Lands Bureau, Government Secretariat, 5 November 1998;

·

WBTC

Nos. 25/99, 25/99A and

25/99C, Incorporation of Information on Construction and Demolition Material

Management in Public Works Sub-committee Papers; Works Bureau, Hong Kong

SAR Government;

·

WBTC

No. 12/2000, Fill Management; Works Bureau, Hong Kong SAR

Government;

·

WBTC

No. 19/2001, Metallic Site Hoardings and Signboards; Works

Bureau, Hong Kong SAR Government;

·

WBTC

Nos. 6/2002 and 6/2002A, Enhanced Specification for Site Cleanliness and

Tidiness. Works Bureau, Hong Kong SAR Government;

·

WBTC

No. 11/2002, Control of Site Crusher. Works Bureau,

Hong Kong SAR Government;

·

WBTC

No. 12/2002, Specification Facilitating the Use of Recycled Aggregates. Works

Bureau, Hong Kong SAR Government;

·

ETWBTC

No. 33/2002, Management of Construction and Demolition Material Including Rock; Environment, Transport and Works

Bureau, Hong Kong SAR Government;

·

ETWBTC

No. 34/2002, Management of Dredged/Excavated Sediment; Environment,

Transport and Works Bureau, Hong Kong

SAR Government;

·

ETWBTC

No. 31/2004, Trip Ticket System for Disposal of Construction & Demolition

Materials, Environment, Transport and Works Bureau, Hong Kong SAR

Government; and

·

ETWBTC

No. 19/2005, Environmental Management of Construction Site, Environment,

Transport and Works Bureau, Hong Kong SAR Government.

7.3

Expected Waste sources

7.3.1

Construction

Phase

Optioneering

has been conducted to try to avoid waste generation and reuse and recycling of

waste generated from the construction of the terminal during the planning and

design stages and consideration of options for layout, construction methods and

programme, and the proposed scheme comprises the Applicants’ proposed best

balance. During the construction

phase, the main activities, which will potentially result in the generation of

waste, include site clearance, site formation, blasting, dredging, reclamation, seawall construction, filling and concreting.

The typical

waste types associated with these activities include:

·

Dredged marine sediment;

·

C & D Materials;

·

Chemical waste;

·

Sewage; and

·

General refuse.

Proper waste

management is important to prevent and mitigate potential environmental

impacts.

7.3.2

Operational

Phase

The following

wastes will be generated from the operation of the LNG terminal:

·

Dredged Sediment;

·

Industrial waste;

·

Chemical waste;

·

Sewage; and

·

General refuse.

7.4

Assessment Methodology

The potential

environmental impacts associated with the handling and disposal of waste

arising from the construction and operation of the LNG terminal at Black Point

are assessed in accordance with the criteria presented in Annexes 7 and 15 of the EIAO-TM, which are summarised as

follows:

·

Estimation of the types and quantities

of the wastes to be generated based on information provided by the engineering

design team and the relevant researches and studies on waste arisings;

·

Assessment of the secondary

environmental impacts due to the management of waste with respect to potential

hazards, air and odour emissions, noise, wastewater discharges and traffic; and

·

Assessment of the potential impacts on

the capacity of waste collection, transfer and disposal facilities.

7.5

Waste

Management Assessment

7.5.1

Construction

Phase

Dredged Marine

Sediment

To enable the

safe transit of the LNG carrier, dredging along the approach channel, berthing area,

and turning basin will be necessary.

The quantities of sediment to be dredged are considered as the best

estimate based on the available site investigation data.

In Section 2.2.1, the “partially dredged”

option is selected to be the preferred option for the reclamation in this

Project, therefore, the following assessment is carried out based on the

“partially dredged” approach.

Approximately

16 hectares of land will be reclaimed immediately adjacent to the Black Point

headland. Works will also include

the construction of an approximately 1.1 km long seawall.

Taking

into account the development programme and the long-term stability of the LNG

infrastructure, all marine sediment beneath the seawall will be dredged. The dredging work under the seawalls

will be carried out between the late 2009 and early 2010 and a total of

approximately 0.66 Mm3 of marine sediment is estimated to be dredged

from this area (see Table 7.7).

The dredging

work for the turning basin and approach channel will be carried out for four

months between late 2009 and early 2010.

Approximately 2.49 Mm³ of marine sediments are to be removed along the

proposed approach channel and turning basin (see Table 7.5).

In

summary, a total of about 3.15 Mm3 of marine sediment will be

dredged (which has considered leaving the marine sediment in place as far as

possible) and disposed offsite.

Contaminated

Dredged Marine Sediment

A preliminary marine sediment sampling

programme has been undertaken as part of the EIA Study to provide an indication

of the quality of the sediment and the volumes of different types of sediment

to be dredged. The sediment

sampling programme (including the sampling stations, the chemical analysis

suite and the biological testing programmes) was developed based on the guidelines

described in ETWBTC 34/2002. The sampling and testing programmes are

summarised in Table 7.3 and the sampling locations presented in Figure 7.2.

Table 7.3 Marine

Sediment Sampling and Testing Programme

|

Sampling Location

|

ETWBTC

Grab (a)

|

ETWBTC

Vibrocore (b)

|

|

GV 1

|

ü

|

ü

|

|

GV 2

|

ü

|

ü

|

|

GV 3

|

ü

|

ü

|

|

GV 4

|

ü

|

ü

|

|

GV 5

|

ü

|

ü

|

|

Notes:

(a)

All

sediment grab samples were analysed for sediment quality parameters as listed

in the Appendix A of the ETWBTC 34/2002.

(b)

Vibrocore

samplings were conducted and samples analysed for sediment quality parameters

as listed in the Appendix A of the ETWBTC 34/2002 at these locations.

|

A

combination of grab samples and vibrocore samples

were taken within the proposed Project area. Vibrocore

samples were taken down to the proposed dredging depth (i.e. at seabed, 0.9 m,

1.9 m, 2.9 m below the seabed, every 3 m thereafter and at the end of the vibrocore sampling) or upon refusal, or when encountering

rock head in order to determine the depth of contaminated marine deposit. The contaminants tested include all the

contaminants stated in Table 1 - Analytical Methodology in Appendix B

of ETWBTC No 34/2002 plus PCBs and 12 Chlorinated Pesticides.

Tier III

biological screening was also performed on samples with one or more contaminant

levels exceeding the Lower Chemical Exceedance Level

(LCEL) and exceeded 10 times the Upper Chemical Exceedance

Level (UCEL) (). The ecotoxicological-testing

programme featured a suite of tests that include three phylogenetically

distinct species (amphipod, polychaete and bivalve

larvae) which interact with bedded sediments in different ways. The objective of the bioassays is to

determine if there are any potential risks of toxicological impacts from the

sediment to the marine biota, and whether there is any difference in the

toxicity of the sediments samples taking from the Project site and the

reference station (collected from a clean area in Port Shelter, New

Territories).

The chemical

and biological analysis results of the marine sediment are presented in Table

7.4. All sediment samples

tested have negligible concentration of toxic organics, since they were all

below the detection limits of the chemical analysis. Preliminary estimates of the quantities

of different types of marine sediment to be disposed are presented in Table

7.5.

Based on the

results of the preliminary marine sediment quality testing, heavy metal

contamination exceeding the LCEL (including arsenic and silver) were found in

the surface sediment at four of the five sampling locations (). The sediments were classified as

Category M sediment. Some of the

sediment samples (at locations GV1 and GV2) failed the biological screening.

A

total of 2.49 Mm3 of sediment would be dredged in the turning basin

area. About 2.14 Mm3 of

the sediments within the proposed dredging in the turning basin area were found

to be Category L sediment and could be disposed of at a Type 1 open sea

disposal site. About 0.15 Mm3

of dredged surface sediments (down to approximately 1 m depth) were classified

as Category M (failed the biological screening) and will require to be disposed

of at a confined marine disposal site (i.e. Type 2 disposal) (see Figure 7.2). About 0.20 Mm3 of category M

sediments (GV3 down to 2 m depth) which passed the biological screening could

be disposed at Type 1 dedicated open sea disposal site.

At present the

East of Sha Chau Mud Pits

are designated for confined marine disposal. Due to the size of these pits it is noted

that capacity may not be available at the time of disposal. In view of such a situation an

alternative site for confined marine disposal would be identified in discussion

with the Marine Fill Committee (MFC) and the EPD.

A

total of 0.66 Mm3 of sediments would be dredged along the seawall,

berthing trench and intake/outfall.

Majority of sediments to be dredged (about 0.62 Mm3) was

uncontaminated and hence could be disposed of at a Type 1 open sea disposal

site. A small portion of sediments

to be dredged (about 0.04 Mm3) were found to be category M

contaminated but passed the biological screening and hence could be disposed at

Type 1 dedicated open sea disposal site ()

(see Table 7.5).

Table 7.5 Estimated

Quantities of Different Types of Marine Sediment to be Dredged (Mm3)

|

Sediment Type

|

Turning Basin & Approach

Channel

|

Seawall, Berthing Trench and

Intake/ Outfall

|

Total

|

|

Type 1 Open Sea Disposal Site

|

2.14

(86%)

|

0.62

(94%)

|

2.76

(87%)

|

|

Type 1 Dedicated Open Sea Disposal

Site

|

0.20

(8%)

|

0.04

(6%)

|

0.24

(9%)

|

|

Type 2 Confined Marine Disposal Site

|

0.15

(6%)

|

-

|

0.15

(4%)

|

|

Total

|

2.49

|

0.66

|

3.15

(100%)

|

The dredging works

for the seawall, berthing trenching and intake/outfall construction will take

about 160 days with approximately 6 barge trips per day (). The dredging duration for the turning

basin and approach channel is estimated at around 254 days with approximately

13 barge trips per day.

The dredged

marine sediments will be loaded onto barges using closed grabs and transported

to designated disposal sites depending on their level of contamination. In accordance with the ETWBTC No 34/2002, the Category M sediment

will be dredged and transported with great care in order to avoid leakage of

contaminated sediment into the sea.

With the implementation of the mitigation measures recommended in Section

7.6.2, sediment disposal at

the designated marine disposal sites is not expected to cause adverse

environmental impacts.

The testing

results presented in this report are for EIA purposes only. The procedures detailed below will be

followed prior to obtaining a dumping license. A proposal for sampling and chemical testing

of the sediment will be prepared and submitted to the EPD for approval. The approved detailed sampling and

chemical testing will be carried out prior to the commencement of the dredging

activities to confirm the sediment disposal method. After carrying out the

sampling and testing, a Sediment Quality Report (SQR) will be prepared

for EPD approval as required under the Dumping

at Sea Ordinance. The SQR will

include the sampling details, the chemical testing results, quality control

records, proposed classification and delineation of sediment according to the

requirements of the Appendix A of ETWB TC

34/2002.

The final

disposal site will be determined by the MFC and a dumping licence will be

obtained from the DEP prior to the commencement of the dredging works.

The potential

water quality impacts due to the dredging and disposal of these sediments are

assessed and presented in Section 6,

Water Quality Impact Assessment.

The assessment concluded that the dredging works can meet the relevant

assessment criteria with the implementation of mitigation measures recommended

in Section 6.

C&D

Materials

To accommodate

the necessary infrastructures of the LNG terminal at Black Point, a total of

approximately 32 ha of land will be required. The majority of the land will be formed

through reclamation, however, excavation of the Black Point headland will be

undertaken to provide suitable screening for the LNG tanks.

Approximately

3 hectares of land within the northern face of the existing Black Point

headland will be excavated to approximately +6 mPD

for the two LNG storage tanks. A

third LNG storage tank can be constructed on the reclaimed land. Site clearance and slope cutting of the

Black Point Headland by blasting and excavation will be required. The excavated materials will comprise of

both rock and soft materials and small amount of site clearance wastes.

Excavated

Materials

Rock and soil

will be excavated from site formation works and that will be reused as fill material

for the reclamation within the Project as far as practicable. A rock crushing plant will be provided

to process excavated rock to the required size for reuse. The quantities of excavated/filling

materials are presented in Table 7.6.

Table

7.6 Summary

of Quantity of Excavated/Fill Materials

|

Construction

Works

|

Rock

|

Soil

|

|

In-situ

Volume (m3)

|

Period

|

In-situ

Volume (m3)

|

Period

|

|

Excavation

|

770,000

|

early 2009 – early 2010

|

220,000

|

early 2009 – end 2009

|

|

Filling

|

785,000

|

early 2009 – late 2009

|

2,100,000 (a)

|

mid 2009 – end 2009

|

|

Surplus (+) / Deficit (-)

|

-15,000

|

early 2009 – late 2009

|

-1,880,000

|

early 2009 – early 2010

|

|

Note:

(a) 2,100,000 m3 of fill comprise 1,560,000 m3

of marine fill and 540,000 m3 of public fill.

|

Excavated Soil

Due

to limited space at the Black Point site, all excavated soil (about 0.22 Mm3)

will need to be initially removed from site and stored at a suitable stockpile

site. It is intended that the

material will be returned to the site and reused as fill for the site formation

works or within the reclamation.

Several possible stockpile sites, which can be accessed by barge, have

been identified and the availability of these sites is being investigated with

the District Land Office (DLO).

An alternative

option is to reuse the excavated soil in other concurrent public and private

construction projects either in Hong Kong or China. If all these options are not feasible,

as a last resort, the excavated soil will be delivered to the public fill

reception facilities such as Tuen Mun

Area 38 or other locations as agreed with CEDD.

Excavated Rock

Due

to limited space at the site, all rock material (about 0.77 Mm3)

will need to be initially removed from site. It is intended that the excavated rock

will be taken to a quarry in China for processing. The processed material will be

subsequently reused within the project for the submarine gas pipeline bedding

works or within the reclamation.

However, this option of sending the excavated rock to quarry in China

will be subject to obtaining approval from the PRC government for which further

investigation will be required.

To supplement

the above, some of the excavated rock may be sent to the Lam Tei Quarry. The

amount that may be sent to the quarry will be limited in order to reduce the

impact on existing road traffic.

Construction

Waste

The

non-inert construction waste consisting of timber, paper, plastics and general

refuse (about 0.07 Mm3) ([6]) generated

from site clearance works cannot be reused and need to be disposed of at the

West New Territories (WENT) Landfill.

C&D

Materials Arising from New Building Construction

C&D

materials consisting of waste concrete, packing materials, plastics, metal, concrete, wood, etc will be generated from the new

building construction. The gross

floor areas (GFA) of the main structures to be constructed are summarized in Table 7.7.

Table

7.7 GFA

of Major New Buildings

|

New

Building

|

GFA (m2)

|

|

Administration building

|

1,000

|

|

Control room

|

750

|

|

Maintenance / warehouse building

|

800

|

|

Electrical substation

|

800

|

|

Gate house

|

50

|

|

Total GFA:

|

3,400

|

Based

on a generation rate of 0.1 m3 per m2 of GFA constructed ([7]),

it is estimated that a total of about 340 m3 of C&D materials

will be generated. These materials

will be sorted on-site for public fill (inert portion) (about 272 m3)

and construction waste (68 m3) ([8]) in order to

reduce the amount of construction waste to be disposed of at landfills and the

cost for disposal of the C&D materials arising from the Project.

With proper

implementation of good construction site practice and the mitigation measures

recommended in Sections 4, 5 and 6, the handling and transportation of

C&D materials to the disposal sites will not cause adverse dust, noise or

water quality impacts.

Chemical

Wastes

Chemical

waste, as defined under the Waste

Disposal (Chemical Waste) (General) Regulation, includes any substance

being scrap material, or unwanted substances specified under Schedule 1 of the Regulation. A complete

list of such substances is provided under the Regulation; however, substances likely to be generated from the

construction of the LNG terminal will, for the most part, arise from the

maintenance of construction plant and equipment. These may include, but not limited to

the following:

·

Scrap batteries or spent acid/alkali

from their maintenance;

·

Used paint, engine oils, hydraulic fluids

and waste fuel;

·

Spent mineral oils/cleaning fluids from

mechanical machinery; and

·

Spent solvents/solutions from equipment

cleaning activities.

Chemical

wastes may pose environmental, health and safety hazards if not stored and

disposed of in an appropriate manner as outlined in the Waste Disposal (Chemical Waste) (General) Regulation and the Code of Practice on the Packaging, Labelling

and Storage of Chemical Wastes.

These hazards may include:

·

Toxic effects to workers;

·

Adverse effects on air, water and land

from spills; and

·

Fire hazards.

The amount of

chemical waste that will arise from the construction activities will be highly

dependent on the Contractor’s on-site maintenance activities and the quantity

of plant and equipment utilized.

With respect to the nature of construction works, it is estimated that a

few hundred litres of used lubricant oil will be generated per month during the

construction period. It is

anticipated that the quantities of waste solvent and wasted paint will be

minimal.

With the

incorporation of suitable arrangements for the storage, handling,

transportation and disposal of chemical wastes under the requirements stated in

the Code of Practice on the Packaging,

Labelling and Storage of Chemical Waste, no adverse environmental and

health impacts, and hazards will result from the handling, transportation and

disposal of chemical waste arising from the Project.

Sewage

Sewage will

arise from the construction workforce, site office’s sanitary facilities and

from portable toilets. If not

properly managed, these materials could cause odour and potential health risks

to the workforce by attracting pests and other disease vectors.

It

is conservatively assumed up to 1,600 construction workers will be involved in

the construction of the LNG terminal.

With a sewage generation rate of 0.15 m3/worker/day ([9]), about 240 m3

of sewage will be generated per day.

The sewage generated will either be conveyed to public sewage treatment

works (STW) or treated by on-site STW (see Section

6.6.7). If a small sewage

treatment work (STW) will be used, the sewage will be treated to the required

effluent discharge standards as stipulated in the Technical Memorandum on

Standards for Effluents Discharged into Drainage and Sewerage Systems, Inland

and Coastal Waters before discharging into sea. Therefore, no adverse water quality

impacts are envisaged. The

wastewater discharge impacts have also been discussed in Section 6. Since the

site is remote and the plant will be designed and operated to reduce odour,

adverse odour and noise impacts are not expected.

About

0.26 m3 (at 30% dry solids) of dewatered sewage sludge will be

produced per day from the operation of the sewage treatment plant. It will be disposed of directly to the

WENT Landfill. Due to the small

quantity of sludge to be disposed of at landfill, it will not have adverse

operational to the landfill.

Since the STW

will be enclosed and the nearest ASR is identified at 600 m away, potential

odour impact from the STW will be negligible.

General Refuse

The presence

of a construction site with workers and associated site office will result in

the generation of general refuse (mainly consist of food waste, aluminium cans

and waste paper) which requires off-site disposal. The storage of general refuse has the

potential to give rise to adverse environmental impacts. These include odour if the waste is not

collected frequently, windblown litter, water quality impacts if waste enters

water bodies, and visual impact.

These secondary impacts are discussed in Section 6. The site may also attract pests, vermin,

and other disease vectors if the waste storage areas are not well maintained

and cleaned regularly. Licensed

chemical waste management contractor will be engaged for the collection,

handling, transportation and disposal of the general refuse.

Assuming up to

1,600 construction workers will be working on site at any one time. With a general refuse generation rate of

0.65 kg per worker per day (),

the amount of general refuse to be generated will be about 1,040 kg per day.

Recyclable

materials such as paper and aluminium cans will be separated and delivered to

the recyclers. Adequate number of

waste containers will be provided to avoid over-spillage of waste. The non-recyclable waste will be

collected and disposed of at the North West New Territories refuse transfer

station on daily basis. With

respect to the small quantity of general refuse to be transferred via the North

West New Territories refuse transfer station or directly to the WENT Landfill,

it is not anticipated that it will cause adverse operational impact to these

facilities.

Provided that

the mitigation measures recommended in Section

7.6 are adopted,

no adverse environmental impacts caused by the storage, handling, transport and

disposal of general refuse are expected.

7.5.2

Operational

Phase

Dredged Marine

Sediment

As the

proposed Project area is located within the Pearl River Delta, it is

anticipated that continuous deposition of marine sediment will occur through

out the project period. In order to

enable the safe transit of the LNG carrier, periodic maintenance dredging of

the approach channel and turning basin for the LNG carrier will be required. It is anticipated that approximately 10

to 20 cm of marine sediment deposition per year (please refer to Section 6) will occur in the Project

area. Based on this estimate,

maintenance dredging will be required once every four to five years and will be

restricted to the turning basin and approach channel areas. Bathymetric surveys will be carried out

to ascertain the volume of marine sediment to be removed due to siltation.

Regarding the

sediment quality testing results at the turning basin and surrounding area

(summarized in Table 7.4), the

dredged sediment within the turning basin is anticipated to be contaminated and

would be disposed at respective designated sites according to the level of

contamination. However, a separate

sediment quality testing would be conducted prior to the maintenance dredging

works to confirm the level of contamination and to identify the disposal

method. The sediment quality

testing would follow the requirement set out in the ETWBTC 34/2002. The

final disposal site would be determined by the MFC and a dumping licence will

be obtained from the DEP prior to the commencement of the maintenance dredging

works.

Other

potential impact from the maintenance dredging activities, such as water

quality has been discussed in Section 6. Proposed mitigation measures, monitoring

and audit requirement have also been discussed in Section 6.

Industrial

Waste

Industrial waste will arise from the

maintenance activities at the LNG terminal. The materials may include scrap

materials from maintenance of plant and equipment and cleaning materials. Provided the scrap materials are

collected regularly for recycling, it is not expected that storage, handling,

transport and disposal of industrial waste will cause any adverse environmental

impacts. General industrial waste

such as plastic, metal cans and waste paper, will be

collected together with the general refuse disposed of at the refuse transfer

station at North West

New Territories

or directly to WENT Landfill.

Chemical Waste

With

respect to the operation activities of the terminal, it is anticipated that

chemical waste will be generated from laboratory and also the maintenance

activities at the LNG terminal. The

chemical wastes include various chemical reagents, lubricants from air and BOG

compressors, firewater and potable water pumps, generators, and hydraulic

loading arm package. The quantity

of laboratory waste (including various chemical reagents) and used lubricant

oil to be generated are estimated to be 550 m3 and 1.5 m3

per year, respectively([11]). The quantity of the chemical wastes generated

is small. The chemical waste will

be collected by a licensed chemical waste collector for disposal at the

Chemical Waste Treatment Centre at Tsing Yi. The handling, storage, collection and

transportation of chemical waste will be undertaken in accordance with

requirement stated in the Code of

Practice on the Packaging, Labelling and Storage of Chemical Waste, and no

adverse environmental impacts and hazards are anticipated.

Sewage

Sewage

will arise from the operation staff and canteen facilities. Assuming up to 100 staff will be working

on-site and the sewage generated from the sanitary system (about 6 m3

per day) and

kitchen (about 29 m3 per day) will be approximately 35 m3

per day ([12]). A small sewage treatment system will be

provided on-site to treat the wastewater to the required effluent discharge

standards as stipulated in the Technical Memorandum on Standards for

Effluents Discharged into Drainage and Sewerage Systems, Inland and Coastal

Waters before discharging into sea.

Therefore, no adverse water quality impacts are envisaged. Since the site is remote and the plant

will be designed and operated to reduce odour and noise, therefore adverse

odour and noise impacts from the sewage treatment system are not expected.

About

0.02 m3 (at 30% dry solids) of dewatered sewage sludge per day ([13])will

arise from the operation of the sewage treatment plant. It will be disposed of directly to the

WENT Landfill. Due to the small

quantity of sludge to be disposed of at landfill, it will not have any adverse

operational effect to the landfill.

General Refuse

General

refuse will arise from the operation staff and administrative activities. General refuse may consist of food

waste, plastic, aluminium can and waste paper. With a general refuse generation rate of

0.65 kg per worker per day (),

the amount of general refuse to be generated will be about 65 kg per day.

Recyclable materials (i.e. paper,

plastic bottle and aluminium can) will be separated and delivered to recyclers

in order to reduce the amount of general refuse to be disposed of at

landfill. The non-recyclable

general refuse will be disposed of by barge to the refuse transfer station at

North West New Territories or directly to landfill on a regular basis. With respect to the small quantity of

general refuse to be disposed of, no adverse environmental impact associated

with the handling and disposal of the refuse is anticipated.

7.6

Mitigation of Adverse Impacts

This section

recommends the mitigation measures to avoid or reduce potential adverse

environmental impacts associated with handling, collection and disposal of

waste arising from the construction and operation of the proposed LNG terminal.

The

Contractors will incorporate these recommendations into a Waste Management Plan

for the construction works. The

Contractors will submit the plan to CAPCO’s Engineer

Representative for endorsement prior to the commencement of the construction

works. Such plan will incorporate

site-specific factors, such as the designation of areas for the segregation and

temporary storage of reusable and recyclable materials.

It is the

Contractor’s responsibility to ensure that only reputable licensed waste

collectors are used and that appropriate measures to reduce adverse impacts,

including windblown litter and dust from the transportation of these wastes,

are employed. In addition, the

Contractor must ensure that all the necessary permits or licences required

under the Waste Disposal Ordinance

are obtained for the construction and operational phases.

Waste Management

Hierarchy

The various

waste management options are categorised in terms of preference from an

environmental viewpoint. The

options considered to be most preferable have the least environmental impacts

and are more sustainable in the long term.

The hierarchy is as follows:

·

Avoidance and reduction;

·

Reuse of materials;

·

Recovery and recycling; and,

·

Treatment and disposal.

The above

hierarchy has been used to evaluate and select waste management options. The aim has been to reduce waste

generation and reduce waste handling and disposal costs.

CAPCO will

ensure that their contractors consult the EPD for the final disposal of wastes

and as appropriate implement the good site practices and mitigation measures recommended

in this EIA Study and those given below.

·

Nomination of approved personnel to be

responsible for good site practices, arrangements for collection and effective

disposal to an appropriate facility of all wastes generated at the site;

·

Training of site personnel in proper

waste management and chemical handling procedures;

·

Provision of sufficient waste disposal

points and regular collection for disposal;

·

Appropriate measures to reduce

windblown litter and dust transportation of waste by either covering trucks or

by transporting wastes in enclosed containers;

·

Separation of chemical wastes for

special handling and appropriate treatment at the Chemical Waste Treatment

Centre;

·

Regular cleaning and maintenance

programme for drainage systems, sumps and oil interceptors; and

·

A recording system for the amount of

wastes generated/recycled and disposal sites.

Waste

Reduction Measures

Good

management and control can prevent generation of significant amount of

waste. Waste reduction is best

achieved at the planning and design stage, as well as by ensuring the

implementation of good site practices.

Recommendations to achieve waste reduction include:

·

Segregation and storage of different

types of waste in different containers, skips or stockpiles to enhance reuse or

recycling of material and their proper disposal;

·

Encourage collection of aluminium cans

and waste paper by individual collectors during construction with separate

labelled bins provided to segregate these wastes from other general refuse by

the workforce;

·

Any unused chemicals and those with

remaining functional capacity will be recycled as far as possible;

·

Use of reusable non-timber formwork to

reduce the amount of C&D materials;

·

Prior to disposal of construction

waste, wood, steel and other metals will be separated to the extent practical,

for re-use and/or recycling to reduce the quantity of waste to be disposed of

to landfill;

·

Proper storage and site practices to

reduce the potential for damage or contamination of construction materials; and

·

Plan and stock construction materials

carefully to reduce amount of waste generated and avoid unnecessary generation

of waste.

7.6.1

Dredged

Materials

For sediments

dredged during the construction of the LNG terminal, their disposal will be as

indicated in Section 7.5.1, and in accordance with the requirements

of the ETWBTC No 34/2002.

Detailed

sampling and chemical testing will be carried out prior to the commencement of

the dredging activities to confirm the sediment disposal method. The final disposal site will be determined

by the Marine Fill Committee (MFC) and a dumping licence will be obtained from

EPD prior to the commencement of the dredging works. Uncontaminated sediments

will be disposed of at open sea disposal sites designated by the MFC. For contaminated sediments requiring

Type 2 confined marine disposal, CAPCO will ensure that the relevant contract

documents will specify the allocation conditions of the MFC and EPD.

7.6.2

Excavated

Materials

Management of

Waste Disposal

The contractor will open a billing account

with EPD in accordance with the Waste

Disposal (Charges for Disposal of Construction Waste) Regulation for the

payment of disposal charges. Every

waste load transferred to Government waste disposal facilities such as public

fill, sorting facilities, landfills or transfer station will require a valid

“Chit” which contains the information of the account holder to facilitate waste

transaction recording and billing to the waste producer. A trip-ticket system will be established

in accordance with ETWBTC No. 31/2004

to monitor the reuse of surplus excavated materials offsite and disposal of

C&D waste and general refuse at transfer stations/landfills, and to control

fly-tipping. The billing “chit” and

trip-ticket system will be included as one of the contractual requirements and

implemented by the contractor.

CAPCO will also conduct regular audits of the waste management measures

implemented on site as described in the Waste Management Plan.

A recording system (similar to summary

table as shown in Annex 5 and Annex 6 of Appendix G of ETWBTC No. 19/2005) for the amount of waste generated, recycled and

disposed of (including the disposal sites) will be established during the

construction stage.

Measures for the Reduction of C&D

Materials Generation

Majority of the inert C&D materials

(rock and soil) will be reused within the Project. Public fill and construction waste shall

be segregated and stored in different containers or skips to facilitate reuse

or recycling of materials and their proper disposal. Specific areas of the work site will be

designated for such segregation and storage if immediate use is not

practicable.

7.6.3

Chemical

Waste

Chemical waste producers will be

registered with the EPD.

Chemical

waste, as defined by Schedule 1 of

the Waste Disposal (Chemical Waste)

(General) Regulation, will be handled in accordance with the Code of Practice on the Packaging, Handling

and Storage of Chemical Wastes as follows. Containers used for storage of chemical

wastes will:

·

Be suitable for the substance they are

holding, resistant to corrosion, maintained in a good condition, and securely

closed;

·

Have a capacity of less than 450 L

unless the specifications have been approved by the EPD; and

·

Display a label in English and Chinese

in accordance with instructions prescribed in Schedule 2 of the Regulations.

The storage area for chemical wastes

will:

·

Be clearly labelled and used solely for

the storage of chemical waste;

·

Be enclosed on at least 3 sides;

·

Have an impermeable floor and bunding, of capacity to accommodate 110% of the volume of

the largest container or 20% by volume of the chemical waste stored in that

area, whichever is the greatest;

·

Have adequate ventilation;

·

Be covered to prevent rainfall entering

(water collected within the bund must be tested and disposed of as chemical

waste, if necessary); and

·

Be arranged so that incompatible

materials are appropriately separated.

Chemical waste will be disposed of:

·

Via a licensed waste collector; and

·

To a facility licensed to receive

chemical waste, such as the Chemical Waste Treatment Facility which also offers

a chemical waste collection service and can supply the necessary storage

containers.

7.6.4

Sewage

An adequate number of portable toilets

will be provided for the on-site construction workforce. The sewage generated from the

construction works will be treated by on-site sewage treatment plant. The sludge will be sent to the WENT

Landfill by licensed collector on a regular basis.

7.6.5

General

Refuse

General refuse will be stored in

enclosed bins or compaction units separately from construction and chemical

wastes. A reputable waste collector

will be employed by the Contractor to remove general refuse from the site,

separately from construction and chemical wastes, on a daily basis to minimise

odour, pest and litter impacts. The

burning of refuse on construction sites is prohibited by law.

Recycling bins will be provided at

strategic locations to facilitate recovery of aluminium can and waste paper

from the site. Materials recovered

will be sold for recycling.

7.6.6

Industrial

Wastes

Industrial waste arising from

maintenance activities will be segregated.

It is recommended to send scrap metals for recycling to reduce the

overall quantity of waste disposed from these activities.

7.6.7

Staff

Training

Training will be provided to workers on

the concepts of site cleanliness and appropriate waste management procedures,

including waste reduction, reuse and recycling at the beginning of the

construction works.

7.7

Residual Environmental Impacts

With the implementation of the

recommended mitigation measures no adverse residual impacts are anticipated

from the construction and operation of the LNG terminal.

7.8

Environmental Monitoring and Audit Requirements

7.8.1

Construction

Phase

To facilitate

monitoring and control over the contractors’ performance on waste management, a

waste monitoring and audit programme will be implemented throughout the

construction phase. The aims of the

monitoring and audit programme are:

·

To review the Contractor’s WMP

including the quantities and types of C&D materials generated, reused and

disposed of off-site; the amount of fill materials exported from/imported to

the site and the quantity of timber used in temporary works construction for

each process/activity;

·

To monitor the implementation and

achievement of the WMP on site to assess its effectiveness; and

·

To monitor the follow-up action on

deficiencies identified.

Joint site audits by the CAPCO and the

contractor will be undertaken on a weekly basis. Particular attention will be given to

the contractor’s provision of sufficient spaces, adequacy of resources and

facilities for on-site sorting and temporary storage of C&D materials. The C&D materials to be disposed of

from the site will be visually inspected.

The public fill for delivery to the off-site stockpiling area will

contain no observable non-inert materials (e.g. general refuse, timber,

etc). Furthermore, the waste to be

disposed of at refuse transfer stations or landfills will as practicable contains

no observable inert or reusable/recyclable C&D materials (e.g. soil, broken

rock, metal, and paper/cardboard packaging, etc). Any irregularities observed during the

weekly site audits will be raised promptly to the contractor for rectification.

To facilitate assessment of the

effectiveness of the waste management measures, the WMP will state the

performance targets to be achieved in reducing or minimising generation of

C&D materials taking account the site constraints. The performance targets will cover the

following items and will be agreed with the CAPCO at the beginning of the

contract.

·

The percentage of excavated materials

to be sorted to recover the soil and broken rock for reuse on site or deliver

to the off-site stockpiling area;

·

The percentage of metal to be recovered

for collection by recycling contractors; and

·

The percentage of cardboard and paper

packaging (for plant, equipment and materials) to be recovered. The recovered materials will be properly

stockpiled in dry and covered condition to prevent cross contamination by other

wastes.

The findings of the waste audits will

be reported in the Environmental Monitoring and Audit Reports.

7.8.2

Operational

Phase

As it is not expected that large

quantities of waste will be generated from the operation of the LNG terminal

and no adverse environmental impacts will arise with the implementation of good

waste management practices, waste monitoring and audit programme

for the operational phase of the LNG terminal is not required.

7.9

Conclusions

7.9.1

Construction

Phase

Optioneering

has been conducted to try to avoid waste generation and reuse and recycling of

waste generated from the construction of the terminal during the planning and

design stages and consideration of options for layout, construction methods and

programme, and the proposed scheme comprises the Applicants’ proposed best

balance. The key potential impacts

during the construction phase are related to wastes generated from site

clearance, site formation, blasting, dredging, reclamation,

seawall construction, filling and concreting.

It

is estimated that a total of approximately 3.15 Mm3 of marine

sediment will be dredged between late 2008 and early 2010. It is estimated that about a total of

2.76 Mm3 of the sediments are uncontaminated and could be disposed

of at open sea disposal site. About

0.24 Mm3 of the contaminated sediment will be disposed of dedicated

open sea disposal site. The

remaining portion of contaminated sediment (0.15 Mm3) will have to

be disposed of at the confined marine disposal site. The final disposal site will be subject

to detailed sediment sampling, testing and analysis in accordance with the ETWBTCW

34/2002 and disposal method reviewed prior to the commencement of the

dredging activities. In addition,

CAPCO will liaise with the MFC for the designated disposal site and a dumping

licence will be applied from the DEP prior to the commencement of the dredging

work.

Approximately

0.07 Mm3 construction wastes will be generated from the site

clearance works and will be disposed of at the WENT Landfill.

Approximately

0.22 Mm3 of excavated soil will need to be initially removed from

site. Suitable stockpiling sites

are currently being sought at this stage and if this is not possible, the

excavated soil will be reused in other concurrent construction projects either

in Hong Kong or China. If all these

options are not feasible, as a last resort, the surplus excavated soil may have

to be disposed of at the public fill reception facilities at Tuen Mun Area 38 or other

locations as agreed with CEDD.

Due

to limited space on site, it is intended that all the excavated rock

(approximately 0.77 Mm3) generated from the site formation works

will be taken to a quarry in China for processing and subsequently reused

within the project. Some of the

excavated rock may also be sent to the Lam Tei

Quarry.

The

construction programme is preliminary and subject to reduce, therefore, the

Contractor's programme will be reviewed by CAPCO when the construction

programme is finalized.

About

340 m3 of C&D materials will be generated during the construction

of new buildings. A few hundred

litres of used lubrication oil will be generated per month and a maximum of

about 1,040 kg of general refuse will be generated each day. A small quantity of dewatered sludge

(i.e. approximately 0.26 m3 per day) will be generated from the

on-site sewage treatment works. In

view of the small quantity of waste generated, the handling and disposal of the

waste generated from construction of new buildings, chemical wastes, general

refuse and sludge to licensed facilities will not cause any significant

environmental impacts. With the

implementation of the recommendations in Section

7.6, the potential environmental impacts arising from storage, handling,

collection, transport and disposal of wastes is expected to meet the criteria

specified in the EIAO-TM. No adverse waste management impact is

anticipated based on the information available. No residual and cumulative environmental

impacts and hazards associated with handling and disposal of wastes arising

from the construction of the LNG terminal proposed at Black Point are

anticipated.

A Waste

Management Plan will be prepared by the Contractors and will be audited through

the environmental monitoring and auditing (EM&A) programme recommended in Section 7.8 to reduce the potential

environmental impact arising from waste management.

7.9.2

Operational

Phase

With good site

practice, the potential environmental impacts associated with the storage,

handling, collection, transport and disposal of a small quantity of industrial,

general refuse, sewage and chemical wastes arising from the operation of the

LNG terminal proposed at Black Point will meet the criteria specified in the EIAO-TM and no unacceptable waste

management impact is anticipated.

Handling of

marine sediments resulting from maintenance dredging will be carried out in

accordance with the ETWBTCW 34/2002 and disposal method reviewed prior

to the commencement of the dredging activities.

No residual

and cumulative environmental impacts and hazards associated with handling and

disposal of wastes arising from the operation of the LNG terminal proposed at

Black Point are anticipated.