10 Hazard To Life Assessment

10.1.1.1 This is an update of the hazard to life assessment previously submitted as part of the EIA for the PAFF facility in May 2002 [1]. Following that submission, an Environmental Permit EP-139/2002 was granted on the 28th August 2002. However, the decision to grant the Environmental Permit was subject to a Judicial Review and the Court of Final Appeal quashed the Permit in its judgment of July 2006 [2] (reversing the previous judgements [3], [4]). The project now needs to once again go through the statutory procedures in order to obtain a new environmental permit.

10.1.1.2 The judgement [2] did not envisage going back to square one for the hazard to life assessment, but did require the inclusion of a quantitative assessment of the instantaneous loss of a 100% of the tank’s content (see Paragraph 10.1.3.4).

10.1.1.3 The hazard to life assessment has been updated to address this issue and also to allow for revisions to the design and operation of the PAFF since the original EIA was submitted. At the same time, the opportunity has been taken to reorganise the report to increase clarity and to improve the assessments where appropriate.

10.1.2 Overview of PAFF Hazards

10.1.2.1 The Permanent Aviation Fuel Facility (PAFF) is designed to receive

Jet A1 aviation fuel by ship, store it in tanks and export it to

10.1.2.2 Historically, major accidents in supply depots have been dominated by the presence of gasoline storage, where explosive mixtures can form in a tank, and where flammable clouds can evaporate from spills and catch fire.

10.1.2.3 Fuels like gasoline give off a vapour that you notice as a smell when you fill up a car at a filling station. If the concentration of the vapour in the air is very low, then it can be smelt, but will not ignite. If the concentration is high enough (but not too high), it can be ignited (perhaps by a flame, or the engine of a passing car). If ignited, then the vapour can burn back to its source, and ignite the liquid fuel. This is why filling stations and pumps are carefully designed so that the operation is safe.

10.1.2.4 Under normal conditions, fuels like diesel and Jet A1 might smell a bit, but do not give off flammable vapour. This is because diesel and Jet A1 are less volatile than gasoline and give off less vapours. At ambient temperatures, the vapour above a pool of gasoline will be flammable, whilst the vapour above a pool for Jet A1 will not be flammable.

10.1.2.5 Hydrocarbons (including Jet A1) as a liquid do not self-ignite or burn. In a burning liquid fire, the heat from the fire raises the temperature of the surface of the pool so that vapour boils off, and it is the vapour mixture with air that burns. The same mechanism applies to the burning of liquid droplet sprays in a car engine; the liquid does not burn, only the vapour that has boiled off the droplets.

10.1.2.6 So a spill of Jet A1 is very hard to ignite, whereas a spill of gasoline is relatively easy to ignite, although an ignition source still has to be present. This distinction (based on flash point – see Section 10.2.1) is incorporated into international codes for storing fuel.

10.1.2.7 Jet A1 is essentially the same as kerosene which is widely used all

over the world for domestic heating and cooking because it can be handled safely.

Jet A1 is made to the same specification all over the world, and stored in

tanks of the same design to those proposed for the PAFF, even in places where

the ambient temperature is such that the vapour above the fuel surface may be

flammable (e.g.

10.1.2.8 The PAFF will be built to internationally recognised standards and best practices for fuel storage. Cylindrical steel storage tanks with conical roofs (to API 650) are used throughout the world for storage of liquid hydrocarbon fuels. The same types of tanks are also used to store more volatile fuels such as gasoline, although internal floating roofs are now standard for gasoline to reduce environmental emissions of vapour. Bund walls, will surround the tanks so that, in the case of leaks, any fuel leak is collected and can be cleaned up. The containment capacities of the bunds at the PAFF greatly exceed international standards. The PAFF design also has two additional impervious security walls as well as the more usual single bund wall and fence. This will further reduce the chance of any spill affecting off-site areas.

10.1.2.9 The PAFF design exceeds international standards on the spacing between the storage tanks and the boundary fence, including exceeding the relevant spacing recommendation from the Hong Kong Code of Practice for Oil Installations [5] by a factor of nearly three (see Section 10.2.2). A typical international standard for safety distance of 15 m, is applied in refineries, where hot process equipment and furnaces co-exist with the tank farms, as well as storage terminals where heavy industry and other developments may be immediately outside the fence. This safety distance also applies to storage of more hazardous products such as gasoline, but the distance to the boundary at the PAFF (28.5 m) still exceeds this distance.

10.1.2.10 It is common for fuel terminal facilities to co-exist close to residential areas and other industries, involving large populations and potential ignition sources outside the site, as they are not generally seen as presenting a high risk. A range of examples of this are given in the recent independent risk study for the PAFF conducted for Tuen Mun District Council and the Airport Authority Hong Kong [6]. In contrast, the selected location for the PAFF is in an area zoned as a “Special Industrial Area” and is well away from residential developments.

10.1.2.11 Jet A1 is routinely handled safely in large quantities around airports for refuelling purposes, directly adjacent to potential ignition sources such as aero engines and in the vicinity of large numbers of passengers. For example, a 747 aircraft has 4 large jet engines and may typically carry ~200 m3 of Jet A1 and ~400 passengers.

10.1.2.12 The PAFF involves a simple, single client operation handling only a single fuel. Many other oil terminal facilities have more complex operations including multiple fuels, clients and import and export routes. The simplicity of the PAFF operation reduces the likelihood of operational errors when compared with typical oil storage sites.

10.1.2.13 Based on the operations undertaken, materials handled, facility design and location, the PAFF would be expected to be at the low end of the spectrum of risks presented by hazardous installations world-wide. This is confirmed by the results of this assessment for the PAFF which identifies a risk to individuals on the roads outside the PAFF boundary as significantly less than the risk of them being struck by lightning elsewhere.

10.1.2.14 The operation of the PAFF will reduce the level of marine traffic in the region and the vessels delivering to the PAFF will be of improved design to those currently delivering to the aviation fuel receiving facility (AFRF) at Sha Chau. Currently there are about 1000 barges per annum each delivering 5000 dwt of fuel to the airport via the AFRF. This would increase to ~1100 /yr by the time the PAFF becomes operational in 2009. The vessels delivering to the AFRF are single hulled and the majority transit without pilots or tug boats. With the PAFF in operation, there would be 150‑200 tankers varying from 10,000 to 80,000 dwt delivering fuel to the airport via the jetty at the PAFF instead of the barges delivering to the AFRF. These tankers will be double hulled and use marine pilots and tug boats. Thus with the commencement of the operation of the PAFF and with the reversion of the AFRF at Sha Chau to an emergency back-up facility, the likelihood of an incident in the Ma Wan Channel and in Urmston Channel, and associated collision risk, will be reduced.

10.1.3.1 This section of the Environmental Impact Assessment (EIA) report deals with the hazards to life that may be posed by the Permanent Aviation Fuel Facility (PAFF), as required in the Hazard to Life Assessment Section of the Study Brief [7] which reads:

“3.3.10 Hazard To Life

3.3.10.1 The risk to the life, including the workers of nearby plants, due

to marine transport, jetty transfer, tank farm storage and pipeline transfer of

aviation fuel shall be assessed. The Applicant shall follow the criteria for

evaluating hazard to life as stated in Annexes 4 and 22 of the TM in conducting

hazard assessment and include the following in the assessment:

(i) identification of all hazardous scenarios associated with the

marine transport, jetty transfer, tank farm storage and pipeline transfer of

aviation fuel, which may cause fatalities;

(ii) execution of a Quantitative Risk Assessment expressing population

risks in both individual and societal terms;

(iii) comparison of individual and societal risks with the Criteria for

Evaluating Hazard to Life stipulated in Annex 4 of the TM; and

(iv) identification and assessment of practicable and cost effective

risk mitigation measures as appropriate.”

10.1.3.3 The hazard to life assessment developed by ERM in the previously submitted EIA [1] has now been completely reviewed and updated by ESR Technology (ESR), formerly the Engineering, Safety & Risk Business of AEA Technology, following the recent judgement in the Court of Final Appeal [2] (reversing previous judgements [3], [4]).

10.1.3.4 The judgement [2]

does not envisage ‘going back to square

one’ for the hazard to life assessment, noting that ‘issues other than the QRA for “all hazardous scenarios” have already

been addressed, comments have been obtained and evaluated’ (

10.1.3.5 Much of the information in the original hazard to life assessment [1] therefore remains applicable and has simply been re-ordered, although updates for changes to the design and improved quantification of some scenarios have been included, together with a detailed assessment of the instantaneous release from a tank.

10.1.3.6 As part of the process of updating this assessment the earlier reports by Macinnis [8] and McBride [9] have been reviewed and the issues raised addressed.

10.1.4 PAFF Location and Facilities

10.1.4.1 The PAFF will be located at an undeveloped reclaimed shoreline site at Tuen Mun Area 38. It will consist of the following major elements:

· a jetty with two berths, which together will accommodate a full range of vessels from 10,000 to 80,000 dwt vessels;

· a tank farm with gross aviation fuel capacity of 264,000m3 for the initial development and an ultimate capacity of about 388,000m3 as well as pumps and associated facilities;

· on site operational facilities including offices;

· 500mm diameter twin sub sea pipelines from the tank farm to the existing Aviation Fuel Receiving Facility (AFRF) at Sha Chau for onward transfer of the fuel to the aviation fuel system at the airport.

10.1.4.2 Approximately 6.75 ha of land will be required to locate the

aviation fuel tank farm and associated facilities. The proposed site for the tank farm at Tuen

Mun Area 38 was reclaimed by Government and is zoned as a Special Industrial

Area (SIA). The site is situated at Siu

Lang Shui just southeast of the

10.1.4.3

No residential developments are

present in the area and the closest substantial development,

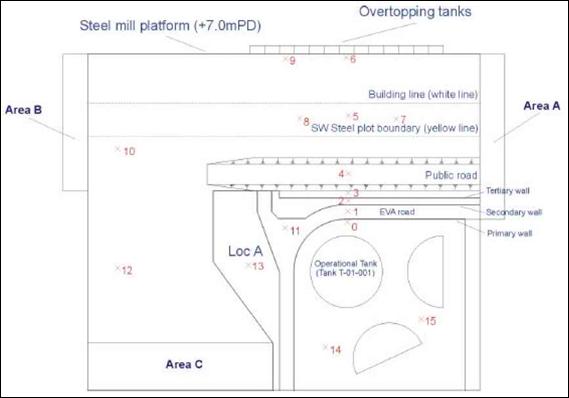

10.1.4.4 The tank farm storage will consist of two bunds each containing six tanks. Initially, only four of the tanks in each bund will be built to be operational in 2009 (tanks 2, 4, 5, 6, 8, 10, 11, 12). The remaining two tanks in each bund (tanks 1, 3, 7 and 9 to the north-west of the site adjacent to SWS - at the top of Figure 10.1) are anticipated to be built in about 20 years to provide the full site storage capacity of 388,000m3. These are referred to as the “initial development” and “final development” cases.

10.1.4.5 Although this hazard to life assessment covers the final development, it is the intention of the Airport Authority to review the EIA if appropriate, prior to the final development, to take account of any changes in standards, technology and statutory requirements at that time.

10.1.4.6 The proposed layout of the tank farm is shown in Figure 10.1 and a cross-section of one tank and the bund wall is shown in Figure 10.2. These are based on the Variation of the Environmental Permit for the PAFF [11].

Figure 10.1: PAFF Tank Farm Layout

10.1.4.7 The tank bund design is such that the total capacity of the bund significantly exceeds the usual 110% of the capacity of the largest tank. The bund containment capacities are 166% and 156% of the capacity of the largest tank for the bunds nearest to the sea and furthest from the sea respectively, with all tanks constructed [12]. Initially, with only four of the tanks in each bund constructed, the bund capacities will be 195% and 188% of the capacity of the largest tank [12].

Figure 10.2: PAFF Tank and Bund

Cross-Sectional Layouts

10.1.5.1 The Emergency Shutdown (ESD) control philosophy at the facility provides for the shutdown of the following:

· receipt of fuel from the jetty;

· tank farm facility; and

· delivery lines.

10.1.5.2 There are two ESD valves on the inlet to the tank farm (from the jetty) and two on the outlet of the tank farm (to the AFRF at Sha Chau). These valves are operated via motorized electric actuators during normal operation and will be closed by pneumatic power during an interruption to the facility’s main power.

10.1.5.3 Each of the above systems has different means of initiating the system. Manual push-buttons provide the primary mode of initiation. However, other initiating devices such as the actuation of the fire alarm system, fuel tank high-high level and a sudden drop in pressure in the delivery pipelines can also activate the ESD system. A leak detection system is provided for the delivery pipeline.

10.1.5.4 The fire fighting facilities at the PAFF include dedicated sea water pumps to provide fire water for tank cooling, foam injection and fire hydrants. Four pumps each of 15,000 litres/min capacity are provided for tank cooling, foam injection and fire hydrants. In addition, one pump with 24,000 litres/min capacity is also provided for the FSD foam canon.

10.1.5.5 The storage tanks are provided with water spray to cool the tank shell. The fire water system is designed to provide for cooling of the tank on fire as well as cooling of adjacent tanks.

10.1.5.6 Foam injection facilities are provided for injecting foam into the base of the tank (in the event of a tank being on fire).

10.1.5.7 Remotely operated foam monitors will be installed, each mounted about 1 m above the top of the external bund, with a minimum discharge rate of 4,200 litres/min.

10.1.5.8 A drencher system and a foam monitor system are provided at the jetty.

10.1.5.9 An automatic fire alarm system is provided for the tank farm as well as the jetty.

10.1.5.10 Emergency access/egress arrangements will be constructed including staircases around the internal bund wall.

10.1.5.11 External fire fighting resources, including fireboats, will be provided by the Fire Services Department. The Pillar Point Fire Station, which has both fire trucks and foam trucks, is the nearest to the PAFF facility and could be reached within the graded response time for the area of 6 minutes under normal traffic conditions. The Fire Services will take immediate measures to extinguish the fire using foam. Foam pourers and foam tanks are also provided on site. Also, in the event of any tank fire or bund fire, the on-site and off-site emergency plan will be activated which will include evacuation of people in the neighbouring sites as well as mobilisation of additional resources including foam stocks within Hong Kong.

10.1.5.12 The storage tanks will be located within a bund, which is designed to contain any spills from the tank or tank piping. The bund is designed to hold much more than the required 110% of the contents of the largest tank in the bund. The bund will be provided with a drain, which will be discharged by a manually operated valve to the sea through an oil interceptor. Drainage from unbunded areas onsite will be discharged through the storm water drain to the sea. The storm water drain will be provided with a remotely operated block valve to contain any oil spill on site.

10.1.5.13 The principal code of practice applicable to the PAFF is the Hong Kong Code of Practice for Oil Installations [5]. This Code makes reference to international codes such as API 650 for the design of tanks and additional standards are specified in the design premise [14].

10.1.5.14 The following fire services installations will be provided to the tank farm and jetty to the satisfaction of the Fire Services Department (FSD) and other relevant standards [15]:

· Fire hydrant / ring main

· Water spray cooling system

· Manual fire alarm system

· Automatic detection and fire alarm systems

· Fixed foam systems

· Emergency lighting

· Fire control centre

· Exit signs and directional signs

· Emergency generators

· Portable hand-operated appliances

· Street fire hydrants

· Drencher system

· Fireboat berthing facilities

· Emergency vehicle access

· Remotely operated foam monitors

· Additional access and egress points around bund

· Ring main for FSD foam cannon

10.1.5.15 The PAFF facility will be provided with a number of security measures including double security fences/walls, with CCTV and microwave intruder detection between them, and security guards on duty 24 hours per day. The PAFF will be considered as a restricted area and a stringent access procedure will be imposed similar to the existing tank farm facility at the airport.

10.1.6 Safety Features of PAFF Tanks

10.1.6.1 The PAFF will adopt the current codes and practices, in its design and construction, as specified in [14] and [16]. Specific features of note include:

· A weak shell to roof connection (specified in API 650) that is designed to fail in the event of an overpressure within the tank. [16].

· Welding procedures, in compliance with API 650. The safeguards are summarised in the Affirmation of The PAFF Contractor [16] as follows, “the welding procedures in API 650 are designed to ensure that there are no out of tolerance defects in the weld, such as voids, inclusions, lack of fusion of the welded metal with the metal being joined or cracks. No weld is to be performed upon the tank unless it is to a specified welding procedure. Welds are radiographed in accordance with API 650 to confirm that the welds produced are sound. The welder qualification tests include testing of welded joints undertaken by the welder to show that the welds meet or exceed the specified requirements, which include any propensity to brittle fracture. All welding personnel are required to be qualified and to demonstrate that they can weld satisfactorily to the relevant welding procedure.”

· Construction materials will be chosen and tested to avoid brittle fracture of the PAFF tanks, as per API 650. The safeguards are summarised in the Affirmation of The PAFF Contractor [16] as follows: “the materials specified in API 650 have been chosen and tested to avoid properties that lead to brittle fracture. The specification for the steel grades ensures that problems experienced historically in the fabrication of tanks are avoided. Plates are tested for chemical composition and mechanical properties to show that they can meet or exceed the specification requirements which include any propensity to brittle fracture;”

· The PAFF tanks will have a full height hydrotest (as required under API 650) and settlement will be monitored for up to 12 weeks [14]. Water is more dense than Jet A1 and places a higher load on the tank structure than the maximum operating load of the tank (about 119% of maximum operating load) [16].

· “Plates of the tanks are staggered so that a single continuous line of welding from top to bottom does not occur” [14].

· The tanks are provided with vents designed to API standard 2000, “Venting Atmospheric and Low Pressure Storage Tanks- Non-refrigerated and Refrigerated”, Fifth Edition 1998.

· The tanks will be protected against static, stray currents and lightning as per API RP 2003 – Protection Against Ignition Arising Out of Static, Lightning, and Stray Current, Fifth Edition, December 1991 [16].

· The PAFF tanks will incorporate fire fighting systems including fixed base foam injection and shell cooling systems on the tanks [16].

· Corrosion and settlement will be monitored [14]. Corrosion allowances are included in the design, the tank base is elevated relative to the bund floor, and the tanks will be inspected as specified in API 653 [16].

· The site will be provided with “security measures such as a double security fencing, CCTV’s within the security fence, and security guards on 24 hours duty” (Affirmation of The PAFF Contractor [16]).

10.1.6.2 In addition, the fuel stored at the PAFF will be Jet A1. Jet A1 will

not produce a flammable vapour at ambient temperatures in

10.1.7 Note on Quantitative Risk Assessment

10.1.7.1 When assessing the level of risk it is normal that there will be uncertainties present. In undertaking these risk calculations, ESR apply a cautious best estimate approach. The cautious best estimate approach ensures that every attempt is made to use realistic best estimate assumptions, but where there is difficulty in justifying an assumption (for example, due to lack of appropriate data) a pessimistic approach is used. A cautious best estimate is cited as the approach used by the UK HSE in the report “Risk criteria for land-use planning in the vicinity of major industrial hazards” (paragraph 26 of [17]). This approach is widely used in QRA and is consistent with Section 4.4.3 of the Technical Memorandum [18] which says:

“When evaluating the residual environmental impacts (the net impacts

with the mitigation measures in place), the following factors shall be

considered: ...

(x) both the likelihood and degree of uncertainty of adverse

environmental impacts: If the adverse environmental impacts are uncertain,

they shall be treated more cautiously than impacts for which the effects are

certain and the precautionary principle shall apply.”

10.1.7.2 The criteria for hazard to human life assessment under the EIAO [19] are provided in the Technical Memorandum [20]. These are reproduced in Appendix H1.

10.1.7.3 The three regions in Figure H1.1 refer to risks which would be considered unacceptable, risks which would be considered acceptable without any further mitigation and risks where there is a requirement to consider mitigation measures to ensure the risks are as low as reasonably practicable (ALARP), under the Technical Memorandum criteria [2].

10.1.8.1 Population data for the areas surrounding the PAFF, that could be impacted by an incident, is provided in Appendix H8. This includes current and future populations at SWS, as identified by Maylor [21] and the expected population in the EcoPark. There is no residential development in the area around the tank farm, with the closest residential properties being about 2km away at Lung Kwu Tan. There is a holiday camp planned on the hillside about 600m from the PAFF. This is elevated relative to the PAFF and will be partially screened by the hill.

10.2 Identification of Hazardous Scenarios

10.2.1 Hazardous Substances and Properties

10.2.1.1 The PAFF is designed to store Jet A1. No other hazardous substances will be stored on site in significant quantities. The principal hazard from Jet A1 is a liquid pool fire.

10.2.1.2 Jet A1 is a Class 2 product according to the Hong Kong Code of Practice for Oil Installations [5]. Class 2 products have a flash point of or exceeding 23oC but not exceeding 66oC [5]. Class 1 and Class 3 products have flash points below and above these limits respectively.

10.2.1.3

Jet A1 is a flammable liquid

with a flash point greater than 38oC (the flash point is

approximately the temperature at which the vapour pressure of the flammable

substance is sufficient to give a concentration of vapour in the air that

corresponds to the lower flammability limit). The minimum flash point is part

of the Jet A1 fuel specification and may be higher in practice. The maximum and

minimum recorded temperatures in

10.2.1.4 Different types of aviation fuel have different characteristics; for example Jet A1 and JP8 are similar and are manufactured from the kerosene cut of crude oil, whilst gasoline based aviation fuels such as Jet B and JP4 have significantly different properties, including significantly lower flash points.

10.2.1.5 This makes Jet A1 much more difficult to ignite than liquids classed as highly flammable (e.g. JP4 and gasoline) or liquefied gases (e.g. butane), which produce flammable vapours that can be directly ignited by a spark and may lead to drifting flammable gas clouds. Jet A1 may be ignited by a strong ignition source such as a fire, but will not be ignited by a simple low energy ignition source such as a spark at the liquid surface, unless heated above 38oC.

10.2.1.6 Jet A1 may be toxic by ingestion, but there is no acute toxic hazard of relevance to major accident scenarios considered here.

10.2.1.7 Physical and chemical properties of Jet A1 are summarised below. Note that the precise composition of Jet A1 can vary, so some variation in the figures is expected.

Table 10.1: Properties of Jet A1

|

Property |

Value |

|

Liquid density |

775-820 kg/m3 @15oC [24] 840 kg/m3 [14] |

|

Boiling Point |

150oC Initial [24] |

|

Minimum Flash Point |

38oC (40oC Test) [24] |

|

Flammable Limits |

1-6% vol [24] |

|

Burning Rate |

0.053 kg/m2/s [1] |

|

Pool rate of flame spread |

<0.5 m/s [24] |

|

Auto-ignition Temperature |

220oC1 [24] |

|

Minimum ignition energy |

0.2mJ [24] |

|

Vapour pressure |

<0.1 kPa @ 20oC kPa [24] |

|

Viscosity |

1.4×10‑3 kgm‑1s‑1

[24] |

|

Latent heat of vaporisation |

291 kJ/kg (based on kerosene Table C.1 of [25]) |

|

Specific heat |

2.19 kJ/kg (based on n-decane Table C.2 of [25]) |

|

1.

Under less ideal circumstances, the auto-ignition temperature may be

substantially higher than 220oC. HSL have measured auto-ignition

temperatures of 690oC and 540oC for tests using sprays

of Jet A1 onto heated surfaces [24],

but Jet A1 has also been ignited when sprayed onto hot engines with probable

maximum temperatures of 420oC [24].

In many circumstances, surface temperatures much higher than 220oC

may therefore be required to ignite Jet A1. |

|

10.2.1.8 In terms of common comparisons, Jet A1 has similar flow properties to water, due to similar viscosity and density (however, Jet A1 is less dense than water), but has a considerably higher boiling point than water. Jet A1 is much more difficult to ignite than gasoline and a flame is predicted to spread less quickly across the surface of a Jet A1 pool if it is ignited.

10.2.2 Safety Distances and Ignition Source Control

10.2.2.1 Jet A1, as stored at the PAFF, is a Class 2 product according to the Hong Kong Code of Practice for Oil Installations [5]. The code states that “it is unnecessary to space tanks for the storage of Class 2 petroleum products at a distance greater than required for constructional and operational convenience.” [5]. It also states that “tanks for the storage of Class 2 petroleum products should be spaced ... at a distance not less than 10 m from the outer boundary of the storage facility.” [5]. For storage of a Class 1 product (e.g. gasoline, but not Jet A1), the recommended distance between a tank and outer boundary of storage facility or any fixed source of ignition is 15 m [5].

10.2.2.2 The distance from the nearest tank wall to the PAFF boundary is 28.5 m (Figure 10.2) which considerably exceeds the recommended distance for both Class 2 and Class 1 products. The distance from the bund wall to the site fence (Figure 10.2) also exceeds these safety distances, so the PAFF design considerably exceeds the recommendations for spacing between the tank walls and the site boundary in the Hong Kong Code of Practice for Oil Installations [5].

10.2.2.3 Other international codes and standards also provide recommended minimum separation distances from a site boundary or other installations: 15m “between a tank outer boundary or installation...” [26]; half the tank diameter (21.75 m) to the “property line that is or can be built upon including the opposite side of a public way” [27]; one sixth of the tank diameter (7.25 m) from the “nearest side of any public way or from the nearest important building on the same property” [27]. Although some of these separation distances also apply to more hazardous Class 1 products, the PAFF exceeds all these recommendations for separation between the tank wall and the site boundary.

10.2.2.4 For practical purposes, ignition sources are normally controlled based on an area classification system; for example, the Institute of Petroleum Model Code of Safe Practice (MCSP [28] Section 1.6.3) defines a hazardous area as “... a three-dimensional space in which a flammable atmosphere may be expected to be present at such frequencies as to require special precautions for the control of potential ignition sources including fixed electrical equipment.” The Jet A1 stored at the PAFF would be classified as a Class II(1) petroleum liquid in the MCSP (Class 2 in the Hong Kong Code of Practice for Oil Installations [5]), for which Section 3.2 of the MCSP [28] states “liquids that are stored under Class II(1) or III(1) conditions will not normally entail a surrounding external hazard zone requirement”. For more volatile liquids (not Jet A1) the hazardous area would usually be considered to extend to the bund wall (e.g. Figure 3.1a [28] or Figure 3‑8.19 of NFPA 497 [29]). Whilst area classification was originally developed for selection and location of fixed electrical equipment, the MCSP Part 15 [28] also provides guidance on its use to aid the location and control of other sources of ignition (e.g. fired heaters, flares, vehicles). The hazardous areas associated with the PAFF, are contained well within the PAFF boundary fence.

10.2.3 Potential Hazardous Scenarios

10.2.3.1 The hazardous scenarios considered in this report are associated with the receiving, storage and export of Jet A1, for the facilities identified within the scope of the project in the Study Brief (Section 3.2 and sections 1.3 to 1.5 of [7]), that is:

· the jetties,

· the fuel tankage,

· pumps and associated facilities and,

· pipelines to transfer the fuel to the airport.

10.2.3.2 The tankers used to transport aviation fuel to the PAFF and the transport route to the PAFF do not fall within the scope of the project identified in the Study Brief [7], for which an EIA is required.

10.2.3.3 However, the risks associated with marine transport of Jet A1 to the PAFF have been assessed elsewhere, to address the administrative constraints imposed on the transport of aviation fuel through the Ma Wan Channel, rather than to meet a statutory requirement [30]. A Marine Traffic Impact Assessment (MTIA) has also been carried out separately to demonstrate that tankers can safely operate at the PAFF jetties, ensure PAFF operations are not impacted by marine traffic within adjacent waterways and identify that the PAFF operations do not unduly impact local marine activity [31].

10.2.3.4 Hazardous scenarios associated with the marine transport of aviation fuel due to manoeuvring of the tankers close to the jetties, and berthing at the jetties, have been identified and are assessed. The identified scenarios due to marine transport are therefore restricted to within ~500m of the PAFF jetty, consistent with the previous EIA (Para 10.4.4.1 of [1])) and also with typical manoeuvring distances out from the jetty identified in the recent MTIA [31]. Beyond this manoeuvring distance, the operation of the PAFF will reduce the risk due to transport of aviation fuel in the region, as noted in Section 10.3.1.

10.2.3.5 A hazardous scenario can have many different causes that all lead to the same basic initial hazardous event (e.g. a bund fire). The initial hazardous scenario may then have a number of different consequences, depending on the specific location of the hazardous scenario, the time it occurs, etc. The facilities have been reviewed to identify the potential hazardous scenarios, based on historical experience (principally the MHIDAS database [32]) and relevant industry guidelines (UK Safety Report Assessment Guidelines (SRAG) for highly flammable liquids [33] and Dutch “Purple Book” [34]).

10.2.3.6 Additional sources of information have been consulted to ensure that all hazardous scenarios in the history of projects of the same genus as the PAFF are covered by the identified scenarios, including: the initial report of the Buncefield investigation [35]; relevant EPA alerts ([51], [61]); marine tanker incident statistics [41]; marine transport risk assessment studies for aviation fuel in Hong Kong waters ([38][30][37]); a study of marine incidents in ports and harbours [60]; a database of offshore pipeline incidents [56]; previous studies undertaken by ESR.

10.2.3.7 The following additional documents have also been specifically reviewed to ensure that a complete set of relevant hazardous scenarios previously identified in relation to the PAFF have been included:

· The previously submitted EIA Hazard to Life Assessment [1].

· The independent review of the above by HSL [9].

· The independent review of the exposure of Shiu Wing Steel Mill from possible fire and explosion incidents at the PAFF by Macinnis Engineering Associates Ltd [8].

10.2.3.8 The following potential hazardous scenarios have been identified:

Table 10.2: Potential Hazardous Scenarios for the PAFF

|

ID |

Scenario |

|

|

|

Marine Transport (Within ~500m of

the Jetty) |

|

|

M1 |

Fire due to rupture/leak of Jet A1 from loaded vessel |

|

|

M2 |

Vessel collision involving tanker with subsequent fire and sinking |

|

|

M3 |

Cargo explosion on tanker |

|

|

|

Jetty Transfer |

|

|

J1 |

Fire due to rupture/leak of Jet A1 from loaded vessel |

|

|

J2 |

Fire due to rupture/leak of loading arm during unloading |

|

|

J3 |

Fire due to rupture/leak of jetty equipment |

|

|

J4 |

Fire due to rupture/leak of jetty riser |

|

|

J5 |

Fire due to rupture/leak of submarine pipeline from jetty to Tank Farm ESDV |

|

|

|

Tank Farm Storage |

|

|

T1 |

Fire due to discharge from tank vent |

|

|

T2 |

Tank head fire / explosion in tank head space |

|

|

T3 |

Multiple tank head fires |

|

|

T4 |

Tank failure due to overpressure |

|

|

T5 |

Explosion in empty tank (under maintenance) |

|

|

T6 |

Bund fire |

|

|

T7 |

Fire outside bund due to rupture/leak of pumps, pipework and fittings |

|

|

T8 |

Fire on sea due to release through drainage |

|

|

T9 |

Fire due to instantaneous tank wall failure, subdivided as follows: |

|

|

|

T9As |

Instantaneous release from bottom seam failure with tank 90-100% full |

|

|

T9Bs |

Instantaneous release from bottom seam failure with tank 60-90% full |

|

|

T9Cs |

Instantaneous release from bottom seam failure with tank 35-60% full |

|

|

T9Ds |

Instantaneous release from bottom seam failure with tank <35% full |

|

|

T9Az |

Instantaneous release from tank unzipping with tank 90-100% full |

|

|

T9Bz |

Instantaneous release from tank unzipping with tank 60-90% full |

|

|

T9Cz |

Instantaneous release from tank unzipping with tank 35-60% full |

|

|

T9Dz |

Instantaneous release from tank unzipping with tank <35% full |

|

|

T9Aa |

Instantaneous release due to aircraft impact with tank 90-100% full |

|

|

T9Ba |

Instantaneous release due to aircraft impact with tank 60-90% full |

|

|

T9Ca |

Instantaneous release due to aircraft impact with tank 35-60% full |

|

|

T9Da |

Instantaneous release due to aircraft impact with tank <35% full |

|

T10 |

Fire due to multiple tank failure |

|

|

T11 |

Boilover |

|

|

T12 |

Fire due to release from top of tank due to overfilling |

|

|

T13 |

Vapour cloud explosion / flash fire |

|

|

T14 |

Fire due to 10% instantaneous release from the top of a tank |

|

|

|

Pipeline Transfer |

|

|

P1 |

Fire on sea due to release/leak from submarine pipeline |

|

10.2.3.9 It should be noted that the SRAG is specifically for highly flammable liquids [33] (no equivalent SRAG exists for flammable liquids such as Jet A1 which are generally less hazardous than highly flammable liquids) and contains some types of event (BLEVEs and Jet fires) which are not applicable to atmospheric pressure storage and are therefore not identified scenarios for the PAFF.

10.2.3.10 A number of the potential hazardous scenarios identified,

particularly boilover, vapour cloud explosions and flash fires and

instantaneous release from a tank, have occurred for storage of oil at

atmospheric pressure and temperature, but may not be applicable to the storage

of Jet A1 at the PAFF due to the properties of Jet A1 and the climate of

10.2.3.11 The scenarios have been selected based on events that have the potential for significantly different consequences. For example, a vapour cloud explosion would produce an overpressure hazard, a bund fire will produce a thermal radiation hazard, a boilover would produce a hazard due to ejection of burning liquid from the top of a tank on fire and an instantaneous release from a tank may produce momentum overtopping of the bund wall resulting in a potentially wider hazard area than a bund fire.

10.2.3.12 Some scenarios have many causes; e.g. a bund fire could result from a large variety of different initial releases, and a fire on the sea due to a release through the drainage may result from initial releases in many different areas of the site. Some scenarios, e.g. boilover, have very specific causes. Each scenario however has a potentially different outcome.

10.2.3.13 Some scenarios have been identified because they have the potential to produce different hazards in general (e.g. fire due to release from the top of a tank due to overfilling) but simply contribute to the other scenarios in the case of the PAFF. It could be argued that these would be best included with the scenarios they contribute to for the PAFF, but they are separated here for clarity.

10.2.3.14 The potential causes, and consequences of each of these potential hazardous scenarios are discussed and the scenario frequency and potential numbers of fatalities are quantified in Sections 10.3 to 10.6.

10.2.3.15 Any workplace may also give rise to occupational hazards such as slips, trips and falls for the workers at the plant. These hazards are not generally quantified in a hazard to life assessment such as this. However, the fatal accident rate per year is typically around 5 per 100,000 workers for the extractive and utility supply industries [36]; i.e. an occupational accident individual risk level of ~5 × 10‑5 /year. This is an on-site individual risk level, not covered by the risk criteria in the Technical Memorandum [20] and is not included further in the assessment.

10.2.4.1 As noted in Section 10.2.1, Jet A1 is stored below its flash point at the PAFF and is more difficult to ignite than lower flash point materials. The distribution of ignition sources surrounding the PAFF and the probability of ignition for Jet A1 in different areas is specifically addressed in Appendix H5. This concentrates on potentially large releases spreading outside the PAFF.

10.2.5.1 The surface emissive power of Jet A1 pool fires is low and the distance to potential lethality is well approximated by the edge of the flame (see Appendix H6).

10.2.5.2 For a pool fire with a fixed pool edge (e.g. a bund fire) the hazard range is taken as the edge of the flame envelope predicted due to flame drag in a range of different wind conditions from 0 m/s to 10 m/s. The drag distance, which varies with pool size and wind speed, is added to the bund edge. This only affects areas downwind of the fire and the hazard radius in upwind and cross-wind directions are taken as equal to the pool radius. The hazard range is taken to correspond to 100% fatality.

10.2.5.3 For an unrestricted pool (e.g. on the sea or having overtopped the bunds), the hazard range is taken as the edge of the predicted pool and is taken to correspond to 100% fatality. This is consistent with previous environmental impact assessments with similar issues for the Hong Kong Administrative region in which “the effect distance was considered to be approximately the same as the pool radius” [37]. The uncertainty in accurately identifying the burning pool edge for these fires means there is no advantage in providing any more complex modelling. There is also a clear opportunity for escape prior to the fire fully developing for an unconfined pool which will be clearly visible to anyone adjacent to it (see Appendix H6).

10.2.5.4 In the previous EIA submission for the PAFF [1] a hazard range of 3m beyond the pool radius was adopted. This analysis has been improved upon for fixed edge pools by allowing for the flame drag effects directly and has been simplified for unconfined pools to reflect the uncertainty in identifying the edge of the burning pool and for consistency with previous assessments ([37], [38]). The simplification for unconfined pools makes no significant change to the results of the assessment, whilst the inclusion of flame drag for confined pools allows more reasonably for potential effects downwind beyond the edge of the pool.

10.2.5.5 Further discussion on the effects of potential Jet A1 pool fires at the PAFF is provided in Appendix H6.

10.2.6.1 The combustion products of aviation fuel include carbon dioxide, nitrogen oxides and sulphur oxides. Incomplete combustion will generate thick black smoke and potentially hazardous gases including carbon monoxide. In the case of fire involving heavier hydrocarbons such as Jet A1 and for large diameter tank/bund fires, smoke production is high. However smoke from such fires is buoyant and does not tend to seriously impact people on the ground in the open air; this was the case in the recent Buncefield tank farm fire for example [35].

10.2.6.2 The occupants of any high-rise buildings in the vicinity of the tank farm could be exposed to potentially toxic smoke effects following a tank or bund fire at the tank farm. The occupants could be incapacitated due to the combined effects of CO2 (causing hyperventilation) and CO (toxic narcosis). The composition of smoke plume of heavy hydrocarbons is estimated as about 11.8% CO2 and 800ppm of CO [1]. At 800 ppm, the time required for incapacitation is about 48 seconds and at 300ppm, the time required is 20 minutes [1]. These times are estimated for persons caught within the smoke plume. For persons away from the fire, the effects will be limited due to the smoke plume rise. However, there are no high rise buildings in the vicinity of the PAFF so the frequency and impact of fatalities from this hazard is assessed as zero.

10.2.6.3 It is assumed that any future buildings immediately opposite the site boundary will not be high rise to avoid the impact of any smoke ingress into buildings. The on-site and off-site evacuation plans should consider the potential for smoke drift from a large fire at the PAFF.

10.2.6.4 The impact of smoke plumes at elevated locations is considered in Section H6.8. Tank head fires only have effects at high elevations because the fire base is well above ground level. Based on the potential frequencies of smoke impact, the smoke plume envelope from a bund fire at the PAFF in a 5 m/s wind is suggested for planning purposes to limit the height of buildings near to the PAFF and maintain risk levels for up to 10 fatalities within the acceptable envelope of the Technical Memorandum criteria [20]. This gives the following building height restrictions:

Table 10.3: Proposed Building Height Restrictions Adjacent to the PAFF

|

Distance

of Building from closest PAFF Boundary (m) |

Proposed

Maximum Height (H) of Building (where

workers may be at elevated levels) (m) |

|

0 |

0 |

|

5 |

6 |

|

10 |

13 |

|

20 |

26 |

|

30 |

39 |

|

40 |

52 |

|

50 |

66 |

10.2.6.5 In each case, the identified heights are greater than those identified in the EcoPark EIA [10] and the prevailing wind direction is not over this area. Should high occupancy buildings, or building heights in excess of these proposed limits be desired then it would be appropriate to consider the risk levels in more detail. For buildings which are specifically designed against smoke ingress (for example by effective sealing and automatically actuated fire dampers in the air intakes) escape at ground level would be expected to be practical, even in the event of such a smoke impact. However, this would need to be assessed on an individual basis for any proposed buildings.

10.2.7.1 Jet A1 at the PAFF will be stored below its flash point and will not give off a flammable vapour unless heated. Ignition of dispersing vapour is therefore not considered as a hazard from the storage of Jet A1 at the PAFF, except in specific circumstances where it may heated above its flash point (see Section H5.3.2).

10.2.7.2 The peak concentration of Jet A1 vapour identified outside the PAFF (in the EcoPark) during normal operations is 0.34 odour units (1 odour unit 5.4 mg/m3) – see Air Quality assessment in this EIA (Section 4.6). This corresponds to a molar vapour concentration of 0.34 × 5.4×10‑6 kg/m3 × 29/156 / 1.2 kg/m3 = 3 × 10‑7 (the last three factors are the molecular weight of air and Jet A1 and the density of air). This is less than 1 ppm, which is a factor of 10,000 below the lower flammability limit.

10.2.7.3 There is therefore no possibility of flammable Jet A1 vapour flowing into neighbouring properties during normal operations at the PAFF.

10.3 Risks due to Marine Transport (Within ~500m of the Jetty)

10.3.1.1 This section presents the quantitative risk assessment carried out

for the identified hazardous scenarios associated with Marine Transport at the

PAFF. As noted in Section 10.2.3,

the tankers used to transport aviation fuel to the PAFF and the transport route

to the PAFF do not fall within the scope of this assessment. The identified

scenarios are therefore restricted to the region related directly to the jetty

operations only (within ~500m of the PAFF jetty, consistent with the previous EIA (

10.3.1.2 Beyond this manoeuvring distance, the operation of the PAFF will reduce the level of marine transport collision risk in the region because ~1100 single hulled barges to Sha Chau per year will be replaced by 150-200 double hulled tankers travelling a shorter route to the PAFF (see 10.1.2.14).

10.3.1.3 The risks associated with marine transport of Jet A1 to the PAFF have also been assessed elsewhere and a range of risk reduction measures already identified [30], including:

·

The operation of the now

established Vessel Traffic System (VTS) by the Vessel Traffic Centre (VTC) of

the Marine Department to control vessel movements within

· Use of double hulled in place of single hulled tankers.

· Stopping double handling of fuel with unloading at Tsing Yi.

10.3.1.4 It was concluded [30] that “Since all practical and cost effective risk mitigation measures have been implemented the level of risk identified is considered ALARP and therefore is acceptable”.

10.3.1.5 A separate Marine Traffic Impact Assessment (MTIA) has been carried

out for the PAFF jetties and tankers [31].

This included a comprehensive ship navigation simulation study for the PAFF

tanker operations and navigation at the adjacent Shiu Wing jetty which showed

that the tankers could safely operate at the PAFF jetty in the prevailing

conditions and that arrivals/departures at Shiu Wing would not be adversely

affected by the PAFF jetty under normal operations. The study concluded that “The PAFF may be constructed, commissioned

and operated with no adverse impact on the marine safety environment within

HKSAR western waters. Indeed, cessation of the operation at Sha Chau will

reduce the frequency of movement of aviation fuel tankers in

10.3.1.6 The relevant hazardous scenarios considered within ~500 m of the jetty are:

· Fire due to rupture/leak of Jet A1 from loaded tanker (M1)

· Vessel collision involving tanker with subsequent fire and sinking (M2)

· Cargo explosion on tanker (M3)

10.3.1.7 The likelihood and consequences of each of these scenarios is assessed below, based on an average population density of 0.15 /ha (Section H8.2) in the Urmston Road Channel post 2011 [38] and excluding the occupants of the tanker itself.

10.3.2 Summary of release size distributions and spill probabilities

10.3.2.1 The table below summarises the release size distributions assumed for releases from sub sea pipelines (see Section 10.7), aviation fuel tankers, and the new jetty (Section 10.4).

Table 10.4: Release Size Distributions From Pipelines, Tankers and Jetty

|

Hazard Source |

Cause |

Size of Leak |

Size Probability |

|

Pipeline Transfer |

All Causes |

Small (20mm) |

0.57 |

|

|

|

Medium (50mm) |

0.15 |

|

|

|

Rupture (500mm) |

0.28 |

|

Marine Transport |

Collisions |

Small (0.3% of dwt) |

0.2 |

|

|

|

Medium (1% of dwt) |

0.2 |

|

|

|

Rupture (7% of dwt) |

0.58 |

|

|

|

Multiple Rupture (100%

dwt) |

0.02 |

|

|

Grounding |

Small (0.3% of dwt) |

0.2 |

|

|

|

Medium (1% of dwt) |

0.2 |

|

|

|

Rupture (7% of dwt) |

0.58 |

|

|

|

Multiple Rupture (100%

dwt) |

0.02 |

|

|

Fire/Explosion |

N/A |

N/A |

|

Jetty Transfer |

Impact |

Small (0.3% of dwt) |

0.2 |

|

|

|

Medium (1% of dwt) |

0.2 |

|

|

|

Rupture (7% of dwt) |

0.58 |

|

|

|

Multiple Rupture (100%

dwt) |

0.02 |

|

|

Strikings |

Small (0.3% of dwt) |

0.2 |

|

|

|

Medium (1% of dwt) |

0.2 |

|

|

|

Rupture (7% of dwt) |

0.58 |

|

|

|

Multiple Rupture (100%

dwt) |

0.02 |

|

|

Loading Arm |

Rupture |

1.0 |

|

Submarine Pipeline |

|

Small (20mm) |

0.57 |

|

|

|

Medium (50mm) |

0.15 |

|

|

|

Rupture (500mm) |

0.28 |

Table 10.5: Release Probabilities for Marine Incidents

|

Cause |

Double

|

|

|

|

<

20,000 dwt |

>

20,000 dwt |

|

Collisions |

0.015 |

0.0075 |

|

Striking |

0.015 |

0.0075 |

|

Grounding |

0.03 |

0.015 |

|

Impact |

0.015 |

0.0075 |

10.3.3 Fire due to rupture/leak of Jet A1 from loaded vessel (M1)

10.3.3.1 Scenario M1 relates to large spills of Jet A1 within ~500m of the new jetty due to ruptures or leaks of loaded tanker, which ignite on the sea surface and spread to boats and other marine traffic in the vicinity. Ruptures/leaks of Jet A1 from loaded tankers whilst underway may be caused by either collisions or groundings.

10.3.3.2 Collision is defined as a contact between the tanker and another vessel underway, drifting, on tow or otherwise untethered. This event is largely related to the level of marine traffic in the channel.

10.3.3.3 Grounding is defined as a tanker coming into unintended contact with a seabed or shore.

10.3.3.4 The frequency of collisions will depend upon the number of ship visits and encounters.

10.3.3.5 The collision frequency is estimated as 3.5 × 10-5 per encounter [38]. The encounter frequency is given as 0.69 per km. This is used for the initial and final development phases of the PAFF. The interaction distance is 0.5 km as only marine transport within 0.5 km of the jetty is considered for this scenario. Therefore the collision frequency is given as 3.5 × 10-5 × 0.69 × 0.5 = 1.2 × 10-5 per visit. The frequencies of collisions have been allocated based on visits of different tanker sizes. These values are presented in the tables for the years 2016 and 2040 respectively.

Table 10.6: Collision Frequency for Initial Development

|

Tanker Size (dwt) |

Base Frequency per visit |

No of visits/year |

Frequency per year |

|

20,000 |

1.2 × 10-5 |

60 |

7.20 × 10-4 |

|

45,000 |

1.2 × 10-5 |

64 |

7.68 × 10-4 |

|

60,000 |

1.2 × 10-5 |

32 |

3.84 × 10-4 |

Table 10.7: Collision Frequency for Final Development

|

Tanker Size (dwt) |

Base Frequency per visit |

No of visits/year |

Frequency per year |

|

30,000 |

1.2 × 10-5 |

70 |

8.40 × 10-4 |

|

45,000 |

1.2 × 10-5 |

80 |

9.60 × 10-4 |

|

80,000 |

1.2 × 10-5 |

38 |

4.56 × 10-4 |

10.3.3.6 The frequency of grounding is influenced by the following factors:

· distance travelled by the tanker in restricted water;

· the draft of the vessel in relation to the available depth of water;

· competency and experience of ships’ masters and human error;

· availability of pilotage service and tug assistance;

· width of navigable water;

· nature of shoreline and seabed (whether smooth or complex);

· weather conditions including sea, tide, wind and likelihood of poor visibility;

· reliability of machinery on the ships;

· density of marine traffic in the area; and

· availability of VTS to provide guidance, etc.

10.3.3.7 The typical draft of the fully laden tankers visiting the PAFF is 11.5 m for the 40,000 dwt tankers and 13.5m for the 80,000 dwt tankers [31]. Soundings in the vicinity of the PAFF jetty are approximately 18.4m below chart datum [31].

10.3.3.8 The frequency of grounding is expressed on a per km basis. The value adopted is 4.3 × 10-6 per km travelled [38].

10.3.3.9 The distance travelled by tankers within the vicinity of the jetty is 0.5km. Therefore the frequency of grounding per year is calculated to be 4.3 × 10-6 × 0.5 × 156 = 3.4 × 10‑4 per year (initial development). For the final development, the frequency of grounding per year is 4.04 × 10‑4 per year.

10.3.3.10 The allocation of the total grounding frequency for different tanker sizes is based on the number of visits. This is presented in the tables below.

Table 10.8: Grounding Frequency for Different Size Tankers (Initial Development)

|

Tanker

Size (dwt) |

Base

Frequency (per km) |

Interaction

Distance (km) |

No

of visits/year |

Frequency

per year |

|

20,000 |

4.3 × 10-6 |

0.5 |

60 |

1.29 × 10-4 |

|

45,000 |

4.3 × 10-6 |

0.5 |

64 |

1.38 × 10-4 |

|

60,000 |

4.3 × 10-6 |

0.5 |

32 |

6.88 × 10-5 |

Table 10.9: Grounding Frequency for Different Size Tankers (Final Development)

|

Tanker

Size (dwt) |

Base

Frequency (per km) |

Interaction

Distance (km) |

No

of visits/year |

Frequency

per year |

|

30,000 |

4.3 × 10-6 |

0.5 |

70 |

1.51 × 10-4 |

|

45,000 |

4.3 × 10-6 |

0.5 |

80 |

1.72 × 10-4 |

|

80,000 |

4.3 × 10-6 |

0.5 |

38 |

8.17 × 10-5 |

10.3.3.11 Not all grounding or collision incidents will result in a pool fire. In order for Scenario M1 to be realised, the incident must be followed by a spill, which may vary in size, and then by ignition. The probabilities assumed for this study are summarised below.

Table 10.10: Frequency of Scenario M1 (Initial Development)

|

Cause |

Vessel Size (dwt) |

Frequency, /yr |

Spill Prob. |

Leak Size |

Size Prob. |

Ignition Prob. |

Outcome Frequency, /yr |

|

Grounding |

20000 |

1.29×10-4 |

0.03 |

Small |

0.2 |

0.001 |

7.74×10-10 |

|

Grounding |

20000 |

1.29×10-4 |

0.03 |

Large |

0.2 |

0.003 |

2.32×10-9 |

|

Grounding |

20000 |

1.29×10-4 |

0.03 |

Rupture |

0.58 |

0.008 |

1.80×10-8 |

|

Grounding |

20000 |

1.29×10-4 |

0.03 |

Multiple

Rupture |

0.02 |

0.008 |

6.19×10-10 |

|

Grounding |

45000 |

1.38×10-4 |

0.015 |

Small |

0.2 |

0.001 |

4.14×10-10 |

|

Grounding |

45000 |

1.38×10-4 |

0.015 |

Large |

0.2 |

0.003 |

1.24×10-9 |

|

Grounding |

45000 |

1.38×10-4 |

0.015 |

Rupture |

0.58 |

0.008 |

9.60×10-9 |

|

Grounding |

45000 |

1.38×10-4 |

0.015 |

Multiple

Rupture |

0.02 |

0.008 |

3.31×10-10 |

|

Grounding |

60000 |

6.88×10-5 |

0.015 |

Small |

0.2 |

0.001 |

2.06×10-10 |

|

Grounding |

60000 |

6.88×10-5 |

0.015 |

Large |

0.2 |

0.003 |

6.19×10-10 |

|

Grounding |

60000 |

6.88×10-5 |

0.015 |

Rupture |

0.58 |

0.008 |

4.79×10-9 |

|

Grounding |

60000 |

6.88×10-5 |

0.015 |

Multiple

Rupture |

0.02 |

0.008 |

1.65×10-10 |

|

Collision |

20000 |

7.20×10-4 |

0.015 |

Small |

0.2 |

0.001 |

2.16×10-9 |

|

Collision |

20000 |

7.20×10-4 |

0.015 |

Large |

0.2 |

0.003 |

6.48×10-9 |

|

Collision |

20000 |

7.20×10-4 |

0.015 |

Rupture |

0.58 |

0.008 |

5.01×10-8 |

|

Collision |

20000 |

7.20×10-4 |

0.015 |

Multiple

Rupture |

0.02 |

0.008 |

1.73×10-9 |

|

Collision |

45000 |

7.68×10-4 |

0.0075 |

Small |

0.2 |

0.001 |

1.15×10-9 |

|

Collision |

45000 |

7.68×10-4 |

0.0075 |

Large |

0.2 |

0.003 |

3.46×10-9 |

|

Collision |

45000 |

7.68×10-4 |

0.0075 |

Rupture |

0.58 |

0.008 |

2.67×10-8 |

|

Collision |

45000 |

7.68×10-4 |

0.0075 |

Multiple

Rupture |

0.02 |

0.008 |

9.22×10-10 |

|

Collision |

60000 |

3.84×10-4 |

0.0075 |

Small |

0.2 |

0.001 |

5.76×10-10 |

|

Collision |

60000 |

3.84×10-4 |

0.0075 |

Large |

0.2 |

0.003 |

1.73×10-9 |

|

Collision |

60000 |

3.84×10-4 |

0.0075 |

Rupture |

0.58 |

0.008 |

1.34×10-8 |

|

Collision |

60000 |

3.84×10-4 |

0.0075 |

Multiple

Rupture |

0.02 |

0.008 |

4.61×10-10 |

Table 10.11: Frequency of Scenario M1 (Final Development)

|

Cause |

Vessel Size

(dwt) |

Frequency, /yr |

Spill Prob. |

Leak Size |

Size Prob. |

Ignition Prob. |

Outcome

Frequency, /yr |

|

Grounding |

30000 |

1.51×10-4 |

0.015 |

Small |

0.2 |

0.001 |

4.53×10-10 |

|

Grounding |

30000 |

1.51×10-4 |

0.015 |

Large |

0.2 |

0.003 |

1.36×10-9 |

|

Grounding |

30000 |

1.51×10-4 |

0.015 |

Rupture |

0.58 |

0.008 |

1.05×10-8 |

|

Grounding |

30000 |

1.51×10-4 |

0.015 |

Multiple

Rupture |

0.02 |

0.008 |

3.62×10-10 |

|

Grounding |

45000 |

1.72×10-4 |

0.015 |

Small |

0.2 |

0.001 |

5.16×10-10 |

|

Grounding |

45000 |

1.72×10-4 |

0.015 |

Large |

0.2 |

0.003 |

1.55×10-9 |

|

Grounding |

45000 |

1.72×10-4 |

0.015 |

Rupture |

0.58 |

0.008 |

1.20×10-8 |

|

Grounding |

45000 |

1.72×10-4 |

0.015 |

Multiple

Rupture |

0.02 |

0.008 |

4.13×10-10 |

|

Grounding |

80000 |

8.17×10-5 |

0.015 |

Small |

0.2 |

0.001 |

2.45×10-10 |

|

Grounding |

80000 |

8.17×10-5 |

0.015 |

Large |

0.2 |

0.003 |

7.35×10-10 |

|

Grounding |

80000 |

8.17×10-5 |

0.015 |

Rupture |

0.58 |

0.008 |

5.69×10-9 |

|

Grounding |

80000 |

8.17×10-5 |

0.015 |

Multiple

Rupture |

0.02 |

0.008 |

1.96×10-10 |

|

Collision |

30000 |

8.40×10-4 |

0.0075 |

Small |

0.2 |

0.001 |

1.26×10-9 |

|

Collision |

30000 |

8.40×10-4 |

0.0075 |

Large |

0.2 |

0.003 |

3.78×10-9 |

|

Collision |

30000 |

8.40×10-4 |

0.0075 |

Rupture |

0.58 |

0.008 |

2.92×10-8 |

|

Collision |

30000 |

8.40×10-4 |

0.0075 |

Multiple

Rupture |

0.02 |

0.008 |

1.01×10-9 |

|

Collision |

45000 |

9.60×10-4 |

0.0075 |

Small |

0.2 |

0.001 |

1.44×10-9 |

|

Collision |

45000 |

9.60×10-4 |

0.0075 |

Large |

0.2 |

0.003 |

4.32×10-9 |

|

Collision |

45000 |

9.60×10-4 |

0.0075 |

Rupture |

0.58 |

0.008 |

3.34×10-8 |

|

Collision |

45000 |

9.60×10-4 |

0.0075 |

Multiple

Rupture |

0.02 |

0.008 |

1.15×10-9 |

|

Collision |

80000 |

4.56×10-4 |

0.0075 |

Small |

0.2 |

0.001 |

6.84×10-10 |

|

Collision |

80000 |

4.56×10-4 |

0.0075 |

Large |

0.2 |

0.003 |

2.05×10-9 |

|

Collision |

80000 |

4.56×10-4 |

0.0075 |

Rupture |

0.58 |

0.008 |

1.59×10-8 |

|

Collision |

80000 |

4.56×10-4 |

0.0075 |

Multiple

Rupture |

0.02 |

0.008 |

5.47×10-10 |

10.3.3.12 The consequence of a fire resulting from a rupture/leak of Jet A1 from a loaded vessel depends on the size of spill.

10.3.3.14 Each tanker has between 12 and 18 cargo tanks, positioned in pairs along the length of the vessel. This longitudinal division of the cargo space is known to almost halve the average amount of oil released in accidents [39], since the damage is almost always restricted to either the port or starboard cargo tanks. Transverse divisions of the cargo space also reduce the chances of the whole cargo being lost. In particular, the proportion of groundings inflicting bottom damage along the full length of the cargo space is of the order of 15%, according to probability density functions taken from IMO Guidelines [39]. Probability distribution functions [40] also indicate the low probability of damage extending the full length of a tanker. Based on collision data for single and double hulled tankers, the mean longitudinal extent of damage is only about 7% of the length between perpendiculars. However, not all of these incidents would be associated with actual spills, since the cargo tanks may not necessarily be penetrated.

10.3.3.15 The International Tanker Owners Pollution Federation Ltd (ITOPF) has published oil tanker spill statistics for the period 1970 to 2005 [41], which indicate a continuing reduction in the number of spills per year. In particular, the number of spills over 700 tonnes has fallen from an average of 17 per year between 1970 and 1989 to only 7 per year between 1990 and 2005.

10.3.3.16 This improvement in safety can be largely attributed to the fact that, in 1992, the MARPOL Convention was amended to make it mandatory for tankers of 5,000 dwt and above ordered after 6 July 1993 to be fitted with double hulls, or an alternative design approved by IMO. The requirement for double hulls that applies to new tankers has also been applied to existing ships under a programme that began in 1995. All tankers have to be converted (or taken out of service) when they reach a certain age (up to 30 years old). Following the Erika incident in 1999, the phasing out of old single hull tankers was accelerated. The final phasing-out date for Category 1 tankers (pre-MARPOL tankers) was 2005, and the final phasing-out date for category 2 and 3 tankers (MARPOL tankers and smaller tankers) has been brought forward to 2010, from 2015. By 2002, 50% of VLCC’s (³200,000 dwt) were already double hulled.

10.3.3.17 In addition, the International Safety Management (ISM) Code was adopted in 1994, and became mandatory for tankers in 1998. The ISM Code imposes strict safety management standards on shipping companies. Other recent regulations, such as the Condition Assessment Scheme (CAS) and mandatory ship reporting, have also contributed to the reduction in spills since the 1990s.

10.3.3.19 Spill size assessment is based mainly on the DNV 2000 Study [38]. The DNV study made the reasonable assumption that only one cargo tank was damaged at any one time, as is generally the case. In order to take into account the remote possibility of all of the tanks within the tanker being ruptured, the DNV study has been extended, using ITOPF data [41]. As a conservative estimate, it is assumed that 2% of spills involve multiple ruptures (100% release). The probability of single tank ruptures (7% release) has been reduced accordingly from 60% to 58%.

10.3.3.20 The resulting spill quantities modelled from the tankers supplying the PAFF are:

· Small Leak - 0.3% of dwt

· Large Leak - 1% of dwt

· Rupture (single tank) - 7% of dwt

· Multiple rupture (all tanks) - 100% of dwt

10.3.3.21 The extent of the fire hazard from a pool of Jet A1 on the sea is assessed based on the predicted area of a spill to a depth where ignition remains possible and stable flame could propagate. The details of the modelling, which varies for different spill sizes, is given in Appendix H2, Section H2.3. The treatment of a release due to multiple tank rupture and evaluation of the hazard area is described in sections H2.4 and H2.5.

10.3.3.22 The effects distances based on an equivalent radius of a circular pool are given below.

Table 10.12: Effect Distances for Sea Surface Pool Fires (M1 and J1)

|

Size

of Release |

Effect

Distance (m) |

Probability |

||||

|

20,000

dwt |

30,000

dwt |

45,000

dwt |

60,000

dwt |

80,000

dwt |

of

Death |

|

|

Small Leak |

17.3 |

21.2 |

26.0 |

30.0 |

34.7 |

1 |

|

Large Leak |

31.7 |

38.7 |

47.5 |

54.8 |

63.3 |

1 |

|

Rupture- 1 tank |

236 |

289 |

354 |

409 |

472 |

1 |

|

Rupture-

all tanks |

236 |

289 |

354 |

409 |

472 |

1 |

10.3.3.23 Fatalities are estimated based on the area of pool fire (pR2) and the averaged population density of 0.15 /ha (Section H8.2). Although the pool may disperse and people may escape before ignition, a fatality probability of one has been used for caution.

Table 10.13: Fatalities for Sea Surface Pool Fires (M1 and J1)

|

Size

of Release |

Estimated

Fatalities |

||||

|

20,000

dwt |

30,000

dwt |

45,000

dwt |

60,000

dwt |

80,000

dwt |

|

|

Small Leak |

0.01 |

0.02 |

0.03 |

0.04 |

0.06 |

|

Large Leak |

0.05 |

0.07 |

0.11 |

0.14 |

0.19 |

|

Rupture- 1 tank |

2.63 |

3.94 |

5.91 |

7.88 |

10.5 |

|

Rupture-

all tanks |

2.63 |

3.94 |

5.91 |

7.88 |

10.5 |

10.3.3.24 The identified risk levels are summarised below:

Table 10.14: Scenario M1 Risk Summary (Initial Development)

|

Cause |

Vessel

Size (dwt) |

Leak

Size |

Outcome

Frequency, /yr |

Fatalities |

|

Grounding |

20,000 |

Small |

7.74×10-10 |

0.01 |

|

Grounding |

20,000 |

Large |

2.32×10-9 |

0.05 |

|

Grounding |

20,000 |

Rupture |

1.80×10-8 |

2.63 |

|

Grounding |

20,000 |

Multiple Rupture |

6.19×10-10 |

2.63 |

|

Grounding |

45,000 |

Small |

4.14×10-10 |

0.03 |

|

Grounding |

45,000 |

Large |

1.24×10-9 |

0.11 |

|

Grounding |

45,000 |

Rupture |

9.60×10-9 |

5.91 |

|

Grounding |

45,000 |

Multiple Rupture |

3.31×10-10 |

5.91 |

|

Grounding |

60,000 |

Small |

2.06×10-10 |

0.04 |

|

Grounding |

60,000 |

Large |

6.19×10-10 |

0.14 |

|

Grounding |

60,000 |

Rupture |

4.79×10-9 |

7.88 |

|

Grounding |

60,000 |

Multiple Rupture |

1.65×10-10 |

7.88 |

|

Collision |

20,000 |

Small |

2.16×10-9 |

0.01 |

|

Collision |

20,000 |

Large |

6.48×10-9 |

0.05 |

|

Collision |

20,000 |

Rupture |

5.01×10-8 |

2.63 |

|

Collision |

20,000 |

Multiple Rupture |

1.73×10-9 |

2.63 |

|

Collision |

45,000 |

Small |

1.15×10-9 |

0.03 |

|

Collision |

45,000 |

Large |

3.46×10-9 |

0.11 |

|

Collision |

45,000 |

Rupture |

2.67×10-8 |

5.91 |

|

Collision |

45,000 |

Multiple Rupture |

9.22×10-10 |

5.91 |

|

Collision |

60,000 |

Small |

5.76×10-10 |

0.04 |

|

Collision |

60,000 |

Large |

1.73×10-9 |

0.14 |

|

Collision |

60,000 |

Rupture |

1.34×10-8 |

7.88 |

|

Collision |

60,000 |

Multiple Rupture |

4.61×10-10 |

7.88 |

Table 10.15: Scenario M1 Risk Summary (Final Development)

|

Cause |

Vessel

Size (dwt) |

Leak

Size |

Outcome

Frequency, /yr |

Fatalities |

|

Grounding |

30,000 |

Small |

4.53×10-10 |

0.02 |

|

Grounding |

30,000 |

Large |

1.36×10-9 |

0.07 |

|

Grounding |

30,000 |

Rupture |

1.05×10-8 |

3.94 |

|

Grounding |

30,000 |

Multiple Rupture |

3.62×10-10 |

3.94 |

|

Grounding |

45,000 |

Small |

5.16×10-10 |

0.03 |

|

Grounding |

45,000 |

Large |

1.55×10-9 |

0.11 |

|

Grounding |

45,000 |

Rupture |

1.20×10-8 |

5.91 |

|

Grounding |

45,000 |

Multiple Rupture |

4.13×10-10 |

5.91 |

|

Grounding |

80,000 |

Small |

2.45×10-10 |

0.06 |

|

Grounding |

80,000 |

Large |

7.35×10-10 |

0.19 |

|

Grounding |

80,000 |

Rupture |

5.69×10-9 |

10.50 |

|

Grounding |

80,000 |

Multiple Rupture |

1.96×10-10 |

10.50 |

|

Collision |

30,000 |

Small |

1.26×10-9 |

0.02 |

|

Collision |

30,000 |

Large |

3.78×10-9 |

0.07 |

|

Collision |

30,000 |

Rupture |

2.92×10-8 |

3.94 |

|

Collision |

30,000 |

Multiple Rupture |

1.01×10-9 |

3.94 |

|

Collision |

45,000 |

Small |

1.44×10-9 |

0.03 |

|

Collision |

45,000 |

Large |

4.32×10-9 |

0.11 |

|

Collision |

45,000 |

Rupture |

3.34×10-8 |

5.91 |

|

Collision |

45,000 |

Multiple Rupture |

1.15×10-9 |

5.91 |

|

Collision |

80,000 |

Small |

6.84×10-10 |

0.06 |

|

Collision |

80,000 |

Large |

2.05×10-9 |

0.19 |

|

Collision |

80,000 |

Rupture |

1.59×10-8 |

10.5 |

|

Collision |

80,000 |

Multiple Rupture |

5.47×10-10 |

10.5 |

10.3.4 Vessel collision involving tanker with subsequent fire and sinking (M2)

10.3.4.1 Scenario M2 is included to take account of collision between a tanker and another vessel involving a release of Jet A1, a fire and subsequent sinking of the vessel. Although collision is considered as part of Scenario M1, the consequences are based on the average population density and do not adequately account for the larger numbers of fatalities that could occur in the case where the other vessel involved in the collision also carries a large crew or passenger load. Although unlikely, it is possible that the fire could completely engulf the vessel, also setting the vessel itself on fire, and lead to the loss of all passengers and crew in the worst case.

10.3.4.2 The impact on a large vessel from a spill at a distance (i.e. one not involved in the collision) would be expected to be much less significant, with the vessel providing protection for the passengers from a transient fire (the identified 10mm thickness of Jet A1 would take only 2.5 minutes to burn off at the nominal burning rate of 4mm/min) and also allow time for escape by the vessel. Only the case where there is a direct collision between a PAFF tanker and a vessel carrying many passengers and crew is therefore relevant to this scenario.

10.3.4.3 The frequency of a collision followed by a large fire is assessed based on the total for all collisions identified in Scenario M1: 1.09 × 10‑7 /yr for the initial development and 0.95 × 10‑7 /yr for the final development. The reduction in frequency, despite the larger numbers of vessels for the final development, is due to the use of larger vessels that are less likely to cause a release following a collision (see 10.3.2.2).

10.3.4.4 The average numbers of fatalities due to these incidents in Scenario M1 is 3.75 for the initial development and 5.24 for the final development, so this scenario is only concerned with cases that could significantly increase these numbers of fatalities.

10.3.4.5 The largest number of passengers on a vessel that the PAFF tankers

would be likely to encounter within ~500 m of the jetty would be on a

fast ferry that operates about 40 times per day in both directions across the

Urmston Channel between Tuen Mun Ferry Pier and Tung Chung on Lantau Island.

This ferry route should pass more than ~500 m from the jetty, but operates

close by, and the passenger numbers are amongst the highest for the ferries in

nearby areas [31].

This ferry carries a maximum load of approximately 235 passengers plus crew.