Introduction

Background

13.1

This section of the EIA presents a summary

of the analysis and findings of the Hazard to Life Assessment (also referred as

Quantitative Risk Assessment (QRA)) undertaken for the proposed Hong Kong (HK) Section of the Guangzhou-Shenzhen-Hong

Kong Express Rail Link (XRL) project. This is a

cross-boundary transport infrastructure project providing high speed rail

services between HK and Guangzhou and a

connection to the national high-speed passenger rail network serving major

mainland cities outside the Guangdong

province (The Project).

13.2

The Project consists of an

underground terminus in West Kowloon and

approximately 26 km of tunnels from the terminus to the mainland boundary near

Huanggang. After crossing the boundary, the Mainland section of the high-speed

railway runs north for a further 116 km to Guangzhou. Trains on the Hong Kong section are intended to operate at speeds up to

200 kph. Construction is scheduled to commence in late 2009

for completion in 2015.

13.3

Referring to Chapter 2 of the

EIA, the selection of construction methods has been optimised to minimise, as

far as possible, the use of explosives depending on the type of material to be

excavated. The breakdown per excavation method is approximately:

·

Tunnel

Boring Machine (TBM) (specially designed for soft soil excavation): approx. 8.5

km;

·

Cut

and Cover: approx. 2.0 km; and

·

Drill

and Blast: approx. 15 km.

13.4

As shown above, a substantial

length of the tunnels and adits (approximately 15 km) will be excavated in

rock. A significant amount of explosives will be required for the construction

of rock caverns, tunnels and adits.

13.5

To enable a timely delivery of

explosives to site and in order to meet the proposed construction work

programme, two Explosives Storage Magazines (Magazines) are required. These

will be located at Tai Lam and So Kwun Wat. The sites were selected considering

the distance to the work areas as well as other constraints such as land

availability, minimum separation distances from magazine to populated area, etc

(ref.1).

13.6

With reference to the EIA Study

Brief (ESB-197/2008), there is no work area within the consultation zone of the

PHIs under which the alignment is passing through. Based on this, the PHI assessment is not considered

applicable for this hazard to life assessment.

13.7

The QRA for the storage and transport of explosives relates to the construction

phase of the project, in which blasting activities are expected. There will be

no explosives handled during the operational phase.

13.8

The Hazard to Life assessment

under this section of the EIA, addresses, in particular, the following:

·

Storage

of explosives at the proposed magazines (cartridged emulsion, detonating cord

and detonators) including handling of explosives within the magazine sites; and

·

Transport

of Explosives to the delivery points.

13.9

Further details of the QRA for

the Project are presented in the Appendix 13.

Legislation requirement and evaluation criteria

13.10

The

key legislation and guidelines that are

considered relevant to the development of the proposed Express Rail Link

project are as follows:

·

Dangerous

Goods Ordinance, Chapter 295;

·

Environmental

Impact Assessment Ordinance (EIAO), Chapter 499; and

·

The

EIA Study Brief (ESB-197/2008), Section 3.4.2.

EIAO Technical Memorandum (EIAO-TM)

13.11

The

requirement for a QRA of projects that involve the storage and transport of

dangerous goods where a risk to life is a key issue with respect to the Hong Kong Government

Risk Guidelines (HKRG) is specified in Section 12 of the Environmental Impact

Assessment Ordinance Technical Memorandum (EIAO-TM).

13.12

The relevant authority for a QRA study relating to an explosives

magazine storage facility and the transport of the explosives

is the Environmental Protection Department (EPD), as specified in Annex 22 of

the EIAO-TM.

13.13

Annex 4 of the EIAO-TM specifies the Individual and Societal Risk

Guidelines.

Hong Kong Government Risk Guidelines (HKRG), EIAO TM Annex 4

13.14

Individual risk is the predicted increase in the chance of fatality per

year to an individual due to a potential hazard. The individual risk guidelines

require that the maximum level of individual risk should not exceed 1 in

100,000 per year i.e. 1 x10-5 per year.

13.15

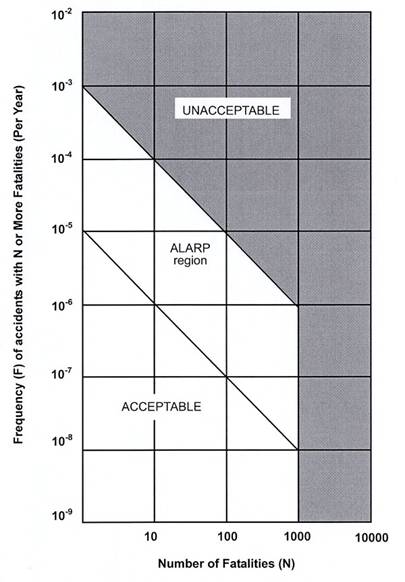

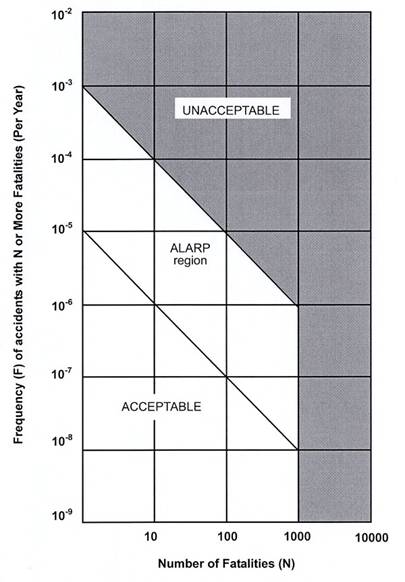

Societal risk expresses the risks to the whole population. The HKRG is

presented graphically in Figure 1. It is expressed in terms of lines plotting the

frequency (F) of N or more deaths in the population from incidents at the

installation. Two F-N risk lines are used in the HKRG that demark “acceptable”

or “unacceptable” societal risks. The intermediate region indicates the

acceptability of societal risk is borderline and should be reduced to a level which is “as low

as is reasonably practicable” (ALARP). It seeks to ensure that all practicable

and cost effective measures that can reduce risk will be considered.

Figure

1 Hong Kong Government Risk Guidelines

Study Objectives and Methodology

13.16

The

objective of the QRA study is to assess the risk to life of the general public

from the hazards that arise

from the storage and transport of the explosives that are required to

facilitate the construction of the Project. The results of the QRA should then be compared with the HKRG.

13.17

The detailed

requirements of the study are given in Section 3.4.2 of the EIA study brief.

The main requirements are:

·

To

identify hazardous scenarios associated with the storage and transport of

explosives and then determine a set of relevant scenarios to be included in the

QRA;

·

To

carry out a QRA to determine risks to the surrounding population in both

individual and societal terms;

·

To

compare the individual and societal risks with the Criteria for Evaluating

Hazard to Life stipulated in Annex 4 of the EIAO-TM; and

·

To

identify and assess practicable and cost effective risk mitigation measures.

13.18

The methodology

of the hazard assessment should be consistent with previous studies having

similar issues.

13.19

The elements of the QRA are shown schematically in Figure 2. It includes the following:

·

Collection and review of

relevant data for the proposed Magazines, the transport from the magazines, as

well as population and vulnerable receptors, such as slopes, retaining walls

etc., in the vicinity of storage, the tunnel

construction and proposed transport routes;

·

Hazard identification. A review

of literature and accident databases was undertaken and updated. These formed

the basis for identifying all the hazardous scenarios for the QRA study;

·

Frequency estimation. The

frequencies, or the likelihood, of the various outcomes that result from the

hazards associated with the storage and transport of explosives was taken primarily from the ERM 2008 study (ref.2), which has been accepted by the relevant

authorities. Where necessary, to consider specific factors applicable for the

Project, recent accident statistics, and to reflect the current knowledge on the explosives’ properties,

these frequencies were modified or updated making reference, as far as possible

to published references; such as the previous Hong Kong studies , UK HSE, US

DoD, Dutch TNO, latest accident statistics from the Transport Department and

Fire Service Department, etc.;

·

For all identified hazards, the

frequency assessment has been documented and the consequences were modelled;

·

The consequence model employed

in this study is the ESTC model (ref.3), developed by the

UK Health and Safety Commission (HSC). Although,

there have been a number of recent studies suggesting that the ESTC (2000)

models should be reviewed for applicability to explosive stores and transport, these

models are still the recommended models in the UK and adopted in the ERM 2008

study (ref.2).

·

The frequency model was

updated, in accordance with the methodology adopted in the ERM 2008 study and

the DNV 1997 study (ref.4) which was based on the ACDS (ref.5) and Moreton 1993 studies (ref.6), to reflect the current Transport Department

statistics, Fire Services Department

statistics, specific design features applicable for the Project and current

knowledge of explosives.

·

The consequence and frequency

data were subsequently combined using ERM’s in-house proprietary software

Riskplot TM to produce the required risk estimates. The transport

part of the risk assessment has been updated compared to the ERM 2008 study

(ref.2). An in-house Explosive Transport GIS Risk Assessment

tool (E-TRA) has been developed to account for three-dimensional blast effects

on buildings and the effect of accidental explosions on elevated roads. It also

accounts for traffic jam scenarios which could occur in some accidental

scenarios as reported in ref.4. The model is summarised in Section 3.2 of Appendix

13 and has been validated against Riskplot TM.

·

Finally, the results from the

risk assessment were compared to the EIAO-TM Criteria. Recommendations have

been made where required to ensure compliance with EIAO-TM Criteria, relevant

best practice, and to reduce the overall risk levels.

Figure 2 Schematic Diagram of QRA Process

13.20

The methodology

used in this hazard assessment is consistent with previous studies. However,

the methodology has been updated and refined, particularly the frequency of

explosives truck accident, following the comments from Mines Division to review

and update the accident data based on recent history. Details of the analysis

can be found in Appendix 13.

Facility

Details

Project Overview

13.21

The Project

comprises the following key elements:

·

Approximately

26km of underground railway running from the terminus in West

Kowloon to the boundary at Huanggang;

·

A

terminus in West Kowloon, and its associated building

elements such as ventilation buildings, ventilation

shafts, traction sub-station, and seawater cooling system;

·

Seven

tunnel ventilation buildings at Mai Po,

Ngau Tam Mei, Pat Heung, Shing Mun, Kwai

Chung, Nam

Cheong and Mong Kok West, and an Emergency Access Point (EAP) at Tai Kong Po;

·

Stabling

sidings and maintenance facilities located at Shek Kong (Shek Kong Stabling

Sidings (SSS)) to provide for stabling, maintenance and cleaning; and

·

An

emergency rescue station (ERS) located next to the SSS.

13.22

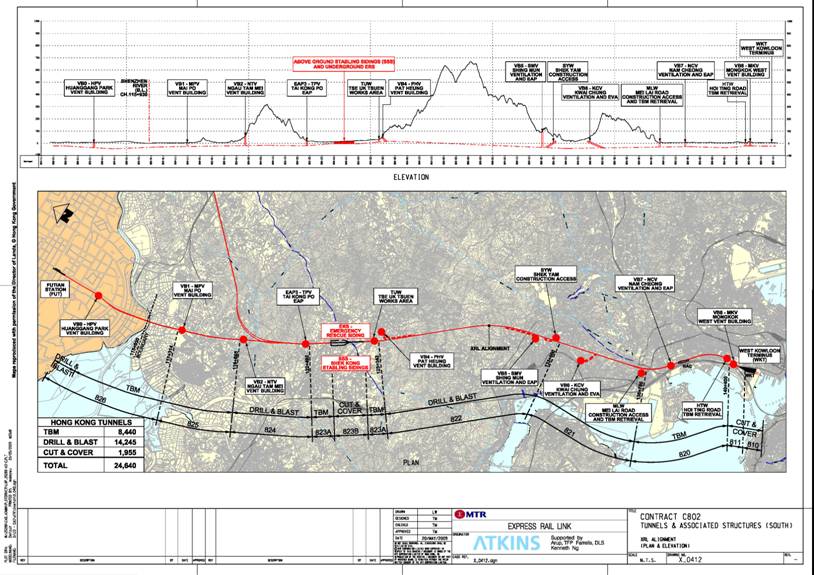

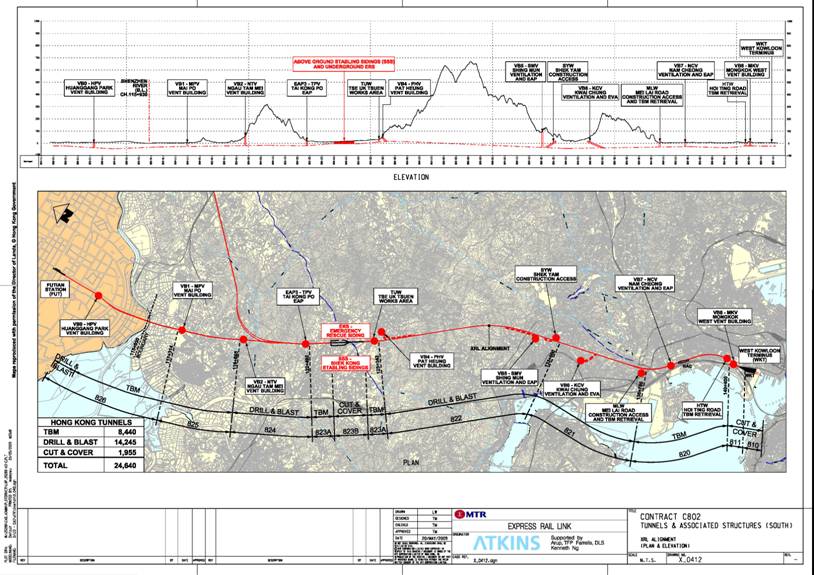

The proposed Project alignment

and work areas are shown in Figure 3.

13.23

The Project is scheduled to commence in

late 2009 for

completion in 2015. Excavation in rock by blasting will be ongoing generally from 2011 to mid 2013 for a significant length of the tunnels

and adits (approximately 15 km).

13.24

For the purpose of this study,

the alignment is divided into two areas. The northern area contains those

tunnels and associated structures for which excavation will be carried out from

worksites within the northern New

Territories. The southern

area contains those tunnels and associated structures for which excavation will

be carried out from worksites within the urban Kowloon areas. Each of the northern and southern areas has its own explosives

magazine site to limit the

travelling distances of explosive trucks from the magazine to the worksites.

13.25

Two categories of explosives will be used for

the construction of tunnel by Drill and Blast methods.

These are:

·

Initiating explosives:

cartridged emulsion explosives, detonating cord and detonators; and

·

Blasting

explosives: site-sensitized bulk emulsion explosives or site-mixed ammonium

nitrate – fuel oil (ANFO).

13.26

Cartridged emulsion

and detonating cord will be delivered from the explosives magazines to the various

construction sites by the appointed contractors using Mines Division licensed

trucks. These explosives are classified as an explosive Class 1.1D under United

Nation (UN) Classification (ref.7) and as a Category 1 (Explosive and blasting agents)

Dangerous Goods under the Hong Kong Dangerous Goods Ordinance.

13.27

Detonators

will also be used to

initiate the blast at the working face. As used in this

project, they are classified as Class 1.4B or 1.4S explosives under the UN

classification system and Category 1 (Explosives and Blasting Agents) under the

Hong Kong Dangerous Goods Ordinance, and will be transported from magazines to

work areas by a dedicated truck, which is identical to, but independent of the

truck carrying the emulsion explosives and detonating cord. Detonators approved for use in Hong Kong

are of the Non-Electric Type, ie. initiated by shock tube.

13.28

Explosives classified as Class 1.1 is

defined as substances and articles which have a mass explosion hazard while

Class 1.4 explosives present no significant hazard outside the packaging. To

comply with the classification, it is required to ensure that the explosive is

safe to transport, to pass a series of classification tests in accordance with

the UN test manual, 2003 (ref.8). Due to different properties of explosives, a

compatibility class is also assigned, as applicable to this Project. Type “B”

is defined as “An article containing a primary explosive substance and not

containing two or more protective features” and type “S” is defined as “The

substance or article so packed or designed that any hazardous effects arising

from accidental functioning are limited to the extent that they do not

significantly hinder or prohibit fire fighting or other emergency response

efforts in the immediate vicinity of the package”.

13.29

Bulk emulsion precursor will be transported to the blast sites by the appointed third party

supplier. It is classified

as an oxidising agent Class 5.1 under the UN Classification system and as Category 7, ie. strong supporter

of combustion under the Hong Kong Dangerous Goods Ordinance. Prior

to sensitizing, it is not considered as

an explosive, and hence outside the scope of this QRA. Bulk

emulsion will not be stored within the magazine.

13.30

Depending on blasting

requirements, ANFO may be used in this project. ANFO is classified as UN HD

1.1D under UN Classification. It consists of an

oxidizing substance mixed with 6% by weight of diesel fuel oil. ANFO will be

produced at the construction work area by using a mixing truck and hence

outside the scope of this QRA.

Statutory/ Licensing

Requirements

13.31

The statutory / licensing requirements

with respect to the explosives (Cat. 1 Dangerous Goods) or the oxidizing

substances (Cat. 7 Dangerous Goods) used to prepare explosives at the

construction work area as well as relevant government departments/ authorities’

advice and practice on the proposed transport and storage of explosives for the

blasting activities are summarized below.

Category

1 Explosives and Blasting Agents

·

Responsible authority: The Commissioner of Mines Division

·

Applicable

regulations/ guidance notes:

-

Supply

of detonators and cartridged emulsion explosives (under the Dangerous Goods

(General) Regulations Cap. 295B);

-

Approved

explosives for blasting in Hong Kong (under

the Dangerous Goods (General) Regulations Cap. 295B);

-

Blast

design (under the Dangerous Goods (General) Regulations Cap. 295B);

-

Blast

loading and execution (under the Dangerous Goods (General) Regulations Cap.

295B);

-

Removal

of explosives (under Regulation 4 of the Dangerous Goods (General) regulations

Cap. 295B);

-

Approval

of an explosives delivery vehicle (under CEDD’s “Guidance Note on Requirements

for Approval of an Explosive Delivery Vehicle” (ref.9));

-

Explosive

delivery vehicle design features and safety requirements (under CEDD’s

“Guidance Note on Requirements for Approval of an Explosive Delivery Vehicle”

(ref.9);

-

Explosive

magazine (under CEDD’s document “How to Apply for a Mode A Explosives Store

Licence” (ref.10));

-

Explosives

produced at site (under Regulation 31A of the Dangerous Goods (General)

Regulations Cap. 295B); and

-

Explosives

load per truck (in accordance with the Removal Permit

under the

Dangerous Goods (General) Regulations Cap. 295B).

Category

7 Strong Supporters of Combustion

·

Responsible authority: Fire Services Department

·

Applicable

regulations:

-

Storage

of oxidizing agents (under Dangerous Goods (General) Regulations Cap. 295B)

13.32

This Project will use

cartridged emulsion explosives as initiating explosives. For blasting

explosives, bulk emulsion or ANFO will be used. Therefore, the storage and

transport requirements for explosives are the minimum required quantities for

the Project.

Storage Magazine

Details

13.33

A magazine site

is proposed to be built at Tai Lam (for northern area) and another one at So

Kwun Wat (for the southern area). The design, construction and operation of the

magazines will comply with the general requirements from the Commissioner of

Mines (ref.10).

13.34

Each magazine is designed to

store sufficient quantities of explosives for two days so as to allow blasting

to be carried out 24 hours per day and provide a buffer in the event of

delivery interruption to the magazines by Mines Division.

13.35

The northern

magazine at Tai Lam (Tai Lam Magazine) serves three worksites (Contract 824 and

Contract 822) in the Northern

New Territories.

The site comprises two individual magazine stores, each with a single structure

storing 400 kg of explosives such as cartridged emulsion, detonating cord and

boosters. A storage chamber for detonators holding 1900 detonators, equivalent

to two days supply, is provided next to each explosives chamber. The detonators

have a very low explosive mass and contain less than 1 gram of high explosives

per detonator. Therefore, the net explosive quantity within the detonator

chamber is less than 2 kg.

13.36

The southern

magazine at So Kwun Wat (So Kwun Wat Magazine) serves four worksites within the

urban Kowloon areas

(Contract 822 and Contract 821). The site comprises two magazine compounds,

with two magazine structures storing 300 kg of explosives each. Similarly,

detonator storage chambers holding a total of 2800 detonators, equivalent to

two days supply, are provided next to the explosives chamber for each contract.

13.37

The work areas

and the associated explosives using contract packaging for the two magazines

are shown in Table

13.1.

13.38

Each of the

magazine buildings is a single-storey, detached and bunded structure, which is

fenced and secured in accordance with the Commissioner of Mines’ requirements.

Details of the requirements are defined in the CEDD document “How to Apply for

a Mode A Explosives Store Licence” (ref.10). Surface road

access suitable for 11-tonne trucks is also provided for delivery of

explosives.

Table 13.1 Project Contracts and Work Areas (Blasting only)

|

Contract No.

|

Storage Magazine

|

2 Day Explosive Storage

Requirement per contract

|

Delivery Point (Work

Area)

|

|

Southern Area

|

|

821

|

So Kwun Wat

|

600 kg (300 kg each x 2)

|

2d - Kwai Chung

|

|

2e - Mei

Lai Road

|

|

822

|

So Kwun Wat

|

600 kg (300 kg each x 2)

|

2b - Shek Yam

|

|

2c - Shing Mun

|

|

Northern Area

|

|

822

|

Tai Lam

|

400 kg

|

1b - Pat Heung

|

|

824

|

Tai Lam

|

400 kg

|

1c - Tai Kong Po

|

|

1d - Ngau Tam Mei

|

Transport Route Details

13.39

Mines Division will deliver

explosives to the Magazines on a daily basis,

from where explosives will be transferred to the work areas by the contractors

for the daily or twice-daily blasts depending on requirements for construction.

Loads will be limited to a maximum of 200 kg per

truck or less in accordance with the Removal Permit issued by Mines Division.

13.40

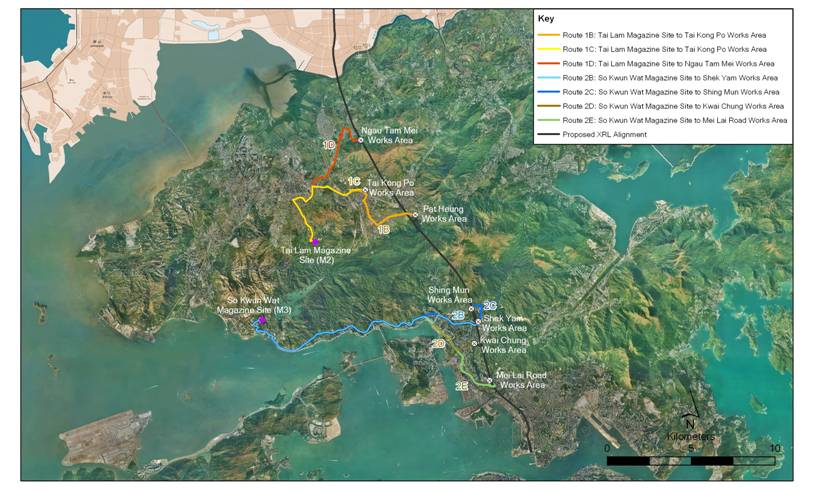

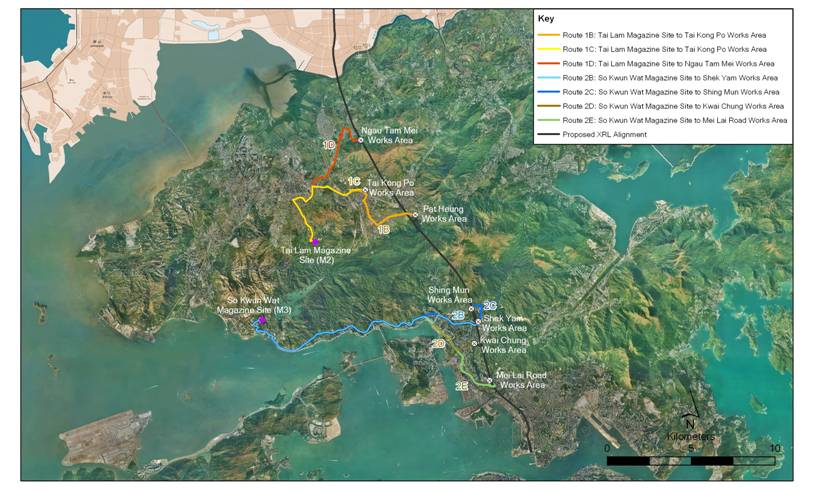

The explosives will be delivered to the

various construction work areas using the public roads as shown in Figure 4. The proposed delivery points from the two magazines

are shown in Table 13.1.

13.41

According to

the current construction programme, delivery of explosives to the seven

delivery points will be required from 2011 to 2013. A maximum of 6 will be in operation simultaneously during the 8-month period from March to October 2012 while on average, deliveries to 4 or 5 works sites are expected at any one

time during the 3-year construction phase.

13.42

In addition to

cartridged emulsion and detonating cord, detonators will also be transported.

Detonators will be transported in a separate and dedicated licensed vehicle.

13.43

The licensed explosives delivery vehicles (LGV pick-up trucks) for delivery of explosives from the site magazines

to the worksites, used as the basis for this QRA, will have the following safety features:

·

Diesel powered;

·

Manual fuel isolation

switch;

·

Forward mounted exhaust with spark arrestor;

·

All electrical

wiring or electrical devices will be shrouded in fire resisting conduits;

·

Fuel tank will

be protected from accidental damage, and designed to prevent accumulation of

spilt fuel on any part of the vehicle;

·

Two fire extinguishers will be

mounted on an easily accessible position on the vehicle;

·

Fire resistant

material will be fitted between the wheel arches and the goods compartment;

·

Lockable wood lined steel or aluminium

receptacles mounted

on the vehicle tray; and

·

Fold down / up explosives warning signs and rotating flashing light.

13.44

In addition, a fire screen will be fitted between the cab and the load

compartment and between the load compartment and the chassis.

Base Case and Worst

Case for Quantitative Risk Assessment

13.45

The actual construction programme will depend on the detailed design and

appointed contractors. It may also depend on the actual achievable progress

rates which may vary due to specific site conditions (e.g. geology). To

consider the uncertainty in the envisaged construction programme, a Base Case,

which accounts for expected programme variations, and a Worst Case, which

presents the worst programme scenario, have been considered for the assessment.

Base

Case Programme for Hazard to Life Assessment

13.46

Based on the envisaged

construction programme and sequence of works, the annual travel distance by

explosive vehicles, carrying cartridged emulsion and detonating cord, will

reach a peak in the period between September 2011 and August 2012, with an

annual number of deliveries of 2671 and a travel distance is around 42,000 km.

This period is referred as the peak explosive delivery period which is taken to

represent the Base Case scenario for the Hazard to Life Assessment. The delivery frequency

has been estimated on the basis that, for a given delivery point, each delivery

will be made to each blast face independently of the other blast faces even if

the load could be transported on the same truck. This approach, although slightly

conservative, accounts for expected delivery variations during the peak

delivery period, within which, separate deliveries will be generally

undertaken.

13.47

The explosive load has been estimated on the

basis that, for a particular delivery point, when the blast time for various

faces coincides in the construction programme within the peak delivery period,

explosives will be transported on the same truck. This applies, for instance,

when the blast programme of the northern drives and

southern drives for a particular delivery point overlaps.

13.48

In the Base

Case, it was considered that blasting

could be carried

out at predetermined time during the day following the envisaged construction

programme. A distribution of delivery time has thus been considered based on

the construction programme.

13.49

The Base Case programme is summarized in Table 13.2.

Table 13.2 Summary of Explosives

Deliveries and Transport Quantities (for Base Case)

|

Delivery Point

|

Explosive Deliveries in

Peak Delivery Period (trips/y)

|

Peak Transport Quantity

(kg/trip)

|

|

|

|

1b - Pat Heung

|

531

|

61

|

|

|

1c - Tai Kong Po

|

341

|

42

|

|

|

1d - Ngau Tam Mei

|

157

|

42

|

|

|

2b - Shek Yam

|

392

|

51

|

|

|

2c - Shing Mun

|

27

|

27

|

|

|

2d - Kwai Chung

|

606

|

78

|

|

|

2e - Mei

Lai Road

|

617

|

31

|

|

|

Total

|

2671

|

|

|

Worst Case Programme for Hazard

to Life Assessment:

13.50

The Hazard to Life

Assessment also covers the Worst Case scenario. It addresses the possibility

that, due to construction uncertainties or contractors’ methods of working, the

contractors propose an actual construction programme which differs from the

envisaged construction programme. Such a case may result in a higher number of

delivery trips. Return trips loaded with explosives will generally be avoided,

however, due to some construction uncertainties, a number of return trips could

be made. Overall, in the worst case, a 20% increase in the number of deliveries

compared to the base case scenario may result based on previous project

experience.

13.51

In this project, for a particular delivery

point, it is possible that the explosive load required for each delivery will

be higher than that indicated in the envisaged programme due to particular site

conditions and blasting requirements; however, the explosive load to be

transported will be, as a worst case, the maximum explosive load for the site (sum of the loads for each blast face within the same work site).

The delivery load, in the Worst Case Scenario, has been selected as the sum of

the loads for each blast face within the same work site.

13.52

In this Worst

Case Scenario, explosives could be delivered at peak day times.

13.53

The Worst Case programme is summarized in

Table 13.3.

Table 13.3 Summary of Explosives Deliveries and Transport Quantities (Worst Case)

|

Delivery Point

|

Explosive Deliveries in Worst

Case (trips/y)

|

Transport Quantity

(kg/trip)

|

|

|

|

1b - Pat Heung

|

637

|

125

|

|

|

1c - Tai Kong Po

|

409

|

42

|

|

|

1d - Ngau Tam Mei

|

188

|

42

|

|

|

2b - Shek Yam

|

470

|

112

|

|

|

2c - Shing Mun

|

32

|

27

|

|

|

2d - Kwai Chung

|

727

|

129

|

|

|

2e - Mei

Lai Road

|

740

|

76

|

|

|

Total

|

3205

|

|

|

Figure 3 Proposed Alignment and Work Areas

Figure 4 Project Alignment, Proposed Magazine Locations and

Explosives Transport Routes

Population Data

13.54

Population

within the vicinity of the explosives

magazines is estimated based on site surveys and information

gathered from Geographic

Information System (GIS) database 2007/2008 data (ref.11) and aerial maps. There are no

known (current or future) buildings or any other structures in the hazard zone

of the proposed Magazines.

13.55

Population data

used for the transport risk assessment have been collected by a combination of

site survey, Base District Traffic Model (BDTM) 2011, Annual Traffic Census

2007 (ref.12), Road Traffic Accident Statistics 2007 (ref.13&14), Centamap (2008) and GIS tools. For areas where

information is not available, assumptions have been used consistently with the

previously approved studies. Three types of population have been considered.

·

Pedestrian population on footpaths and pavements next to delivery

routes;

·

Road population; and

·

Building population.

13.56

The

approach to modelling the risks during transport of explosives is fully

3-dimensional and GIS based. It also accounts for the potential increased risk

when explosives truck travel on elevated roads.

13.57

The population

data adopted in the QRA is detailed in Appendix 13.

Hazard

Identification

13.58

Hazard identification consisted of a review

of the following:

·

Explosives properties;

·

Scenarios presented in previous relevant studies;

·

Historical accidents; and

·

Discussions with explosives and blasting specialists.

Hazards of Explosives

13.59

Explosives present a hazard to both property

and people. This hazard manifests itself in the following ways:

·

Blast and pressure wave;

·

Flying fragments or missiles;

·

Thermal radiation; and

·

Ground shock.

13.60

In the case of explosions, the biggest damage is usually caused by the

blast effects. The blast and pressure waves can cause injury

to sensitive human organs such as the ears and lungs. However, considerable

overpressures are required for fatalities to occur, and consequently people

need to be fairly close to the scene of the direct explosion effects to be

significant.

13.61

Other effects due to the blast or overpressure are associated with damage to

buildings and other structures/ objects or the impact of debris and fragments

from damaged building structure, and the vehicle or container in which the

explosives are held. Moreover, injury may occur when people are displaced or swept away, or

due to the violent movement of internal organs within the body.

13.62

An explosion may result in the formation of a

short duration fireball since the fuel content of the emulsion is oxidised. However,

although it is generally the case that the thermal hazards from an explosives

detonation event is of less concern than the blast and fragment hazards.

Review of Incidents

13.63

A review of reported safety incidents involving storage, transport and

disposal of explosives (in industrial applications) was carried out.

Records were

retrieved mainly from the UK Health and Safety Executive (UK HSE)’s Explosives

Incidents Database Advisory Service (EIDAS) (ref.15), US Mine Safety and Health Administration (MHSA)

(ref.16) and Western

Australia’s Department of Consumer and Employment

Protection (DOCEP) (ref.17). The records provided are also supplemented with information obtained from various

sources. An analysis of accident data is provided in Section 5 and Section 6 of Appendix 13.

Scenarios for Hazard

Assessment

13.64

The following table (Table 13.4) provides a summary of the scenarios considered in

this QRA.

Table 13.4 Scenarios Considered in the QRA study

|

Tag

|

Scenario

|

|

Storage of Explosives

|

|

01

|

Detonation of full load of explosives in one store

in So Kwun Wat site

|

|

02

|

Detonation of full load of explosives in one store

in Tai Lam site

|

|

03

|

Detonation of full load of explosives in one contractor

truck on the access road within the So Kwun Wat magazine site boundary

|

|

04

|

Detonation of full load of explosives in one

contractor truck on the access road within the Tai Lam magazine site boundary

|

|

Transport of Explosives

|

|

05

|

Detonation of full load of explosives in one

contractor truck on public roads – from So Kwun Wat site to delivery point 2b

Shek Yam

|

|

06

|

Detonation of full load of explosives in one

contractor truck on public roads – from So Kwun Wat site to delivery point 2c

Shing Mun

|

|

07

|

Detonation of full load of explosives in one

contractor truck on public roads – from So Kwun Wat site to delivery point 2d

Kwai Chung

|

|

08

|

Detonation of full load of explosives in one

contractor truck on public roads – from So Kwun Wat site to delivery point 2e Mei Lai Road

|

|

09

|

Detonation of full load of explosives in one

contractor truck on public roads – from Tai Lam site to delivery point 1b Pat

Heung

|

|

10

|

Detonation of full load of explosives in one

contractor truck on public roads – from Tai Lam site to delivery point 1c Tai

Kong Po

|

|

11

|

Detonation of full load of explosives in one

contractor truck on public roads – from Tam Lam site to delivery point 1d

Ngau Tam Mei

|

Frequency

analysis

13.65

Deflagration or detonation explosion

may occur during the transportation of explosives from the magazines to the

construction sites. This accidental explosion can be caused by

spontaneous fire (non-crash fire), fire after a vehicle crash (crash fire),

impact initiation in crash (crash impact) or spontaneous explosion during the

normal condition of transport which may occur if the cargo load contains

‘unsafe explosives’.

13.66

In this study, a fault tree has been developed to assess the overall explosion

frequency as applicable to the Project contractors’ trucks based on the latest

information available on the explosives properties, vehicle incident

frequencies provided by the Transport Department and Fire Services Department,

and the specific explosive transport vehicle design and operation to be used as

part of the Project. The details of the frequency assessment are provided in

Section 6 of Appendix 13.

Frequency analysis for

Transport of Explosives

13.67

Based on Hong Kong vehicle accident data, the frequencies of

explosives initiation during road transport are estimated as 7.69 x 10-10/km

for the truck on non-expressway and 6.87 x 10-10/km on expressway,

using a fault tree approach. The fault tree model has considered the

frequencies of non-crash fire, crash fire, crash impact and unsafe explosive.

Adjustment factors were applied to the model to account for the probabilities

of explosive initiation due to thermal stimulus or crash impact.

Frequency analysis for

Storage of Explosives

13.68

The overall initiating event frequency within the

storage magazine is based upon the UK HSE recommended value of 1 x 10-4

per storehouse year. Additional risk due to manual transfer of explosives, lightning strike, aircraft

crash, hill/ vegetation fire, earthquake and other site specific considerations

to XRL project were

also considered but their contribution was negligible. (see Section 6 of Appendix

13).

Consequence analysis

13.69

The probability of fatality due to blast

over-pressure, have been estimated using the method detailed by the UK HSE

Explosives Storage and Transport Committee (ref.3) The fatality contours are calculated at 90%, 50%, 10%, 3% and

1% fatality. Details of the model and

the results are given in Section 7 of Appendix 13.

13.70

Special features such as slopes and service

reservoirs along the transport routes or near the magazine sites were

identified with respect to the potential secondary hazards. These aspects of

risk were evaluated separately, and were found either insignificant or already

covered by applying the blast overpressure-fatality model (ie. ESTC model (ref.3)).

Risk

Summation

Individual Risk Results

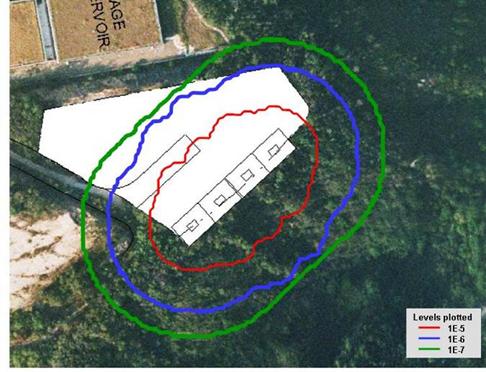

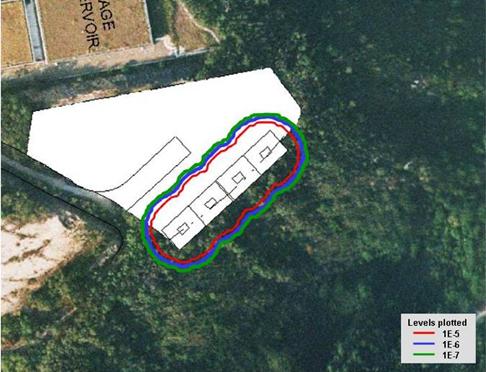

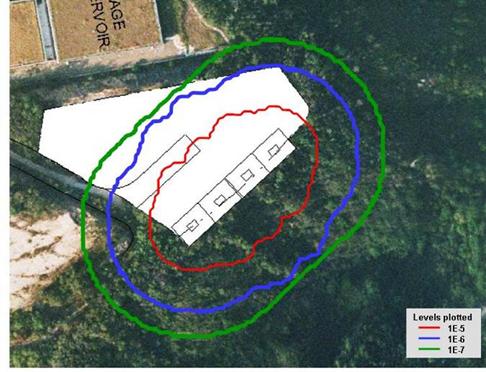

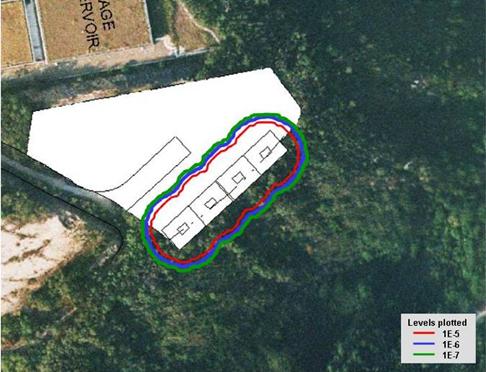

13.71

The individual risk (IR)

contours associated with the Project are shown in Figure 5, Figure 6, Figure 7 and Figure 8. In Figure 7 and Figure 8, the ‘indoor’ refers to the population located inside

buildings, and the ‘outdoor’ refers to the population located outside buildings

ie in open area. At the same distance from a potential explosion, persons

located inside buildings are more vulnerable to explosion than persons located

outside buildings as they are exposed to more hazards such as debris from

broken windows, etc. This explains a higher individual risk for indoor

population.

13.72

For the delivery routes, the IR

data represent the highest individual risk, occurring on the road in the same

lane as the explosives delivery truck. It is observed that the maximum IR is

about 4.6´10-8 per year. This is a low risk when compared to Hong

Kong Risk Guidelines which require the offsite IR from a fixed installation to

be below 10-5 per year.

13.73

Both storage magazines are in

remote areas. The individual risk contours of 1 x 10-5 per year

extend outside the site boundary. However this impacts only on woodland areas

where there is no continuous presence of people. Assuming occupancy factor by

members of the public for about 2 hours per week (during the weekend or

weekdays people may be in the vicinity hiking) this would translate to a

presence factor of 0.01. The IR for specific individuals offsite would

therefore be about two orders of magnitude less than that indicated by the IR

contours, and clearly less than 10-5 per year for all the off-site

areas. Hence it can be concluded that individual risk is acceptable.

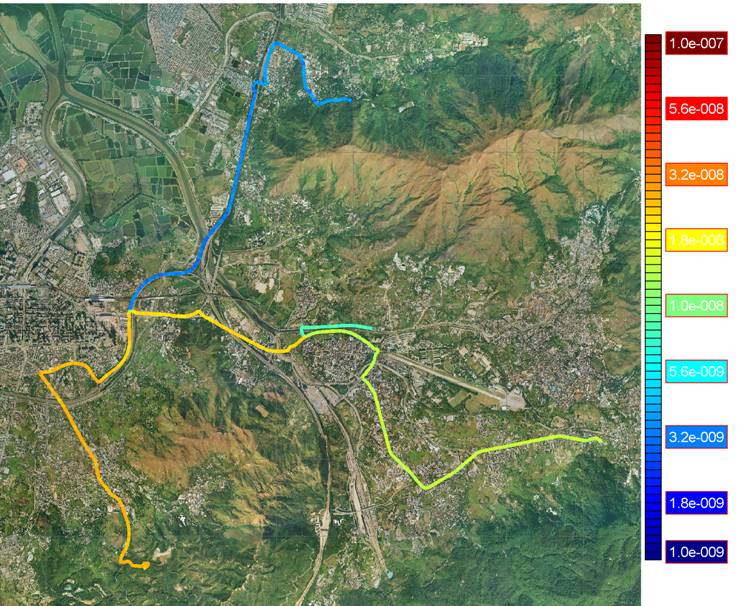

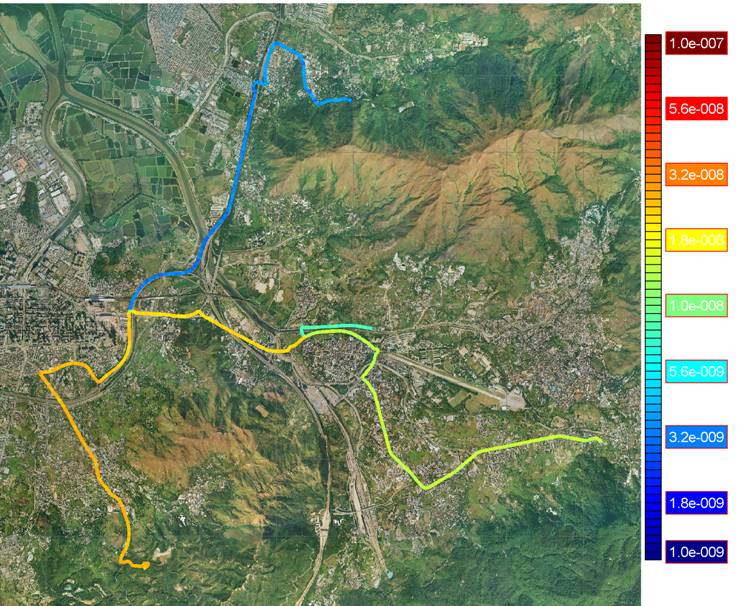

Figure 5 Maximum IR for Northern Delivery

Routes (from Tai Lam Magazine)

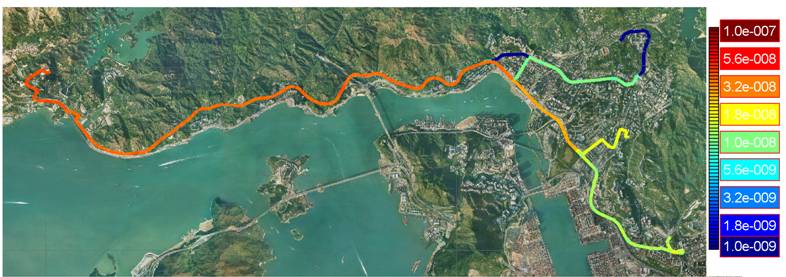

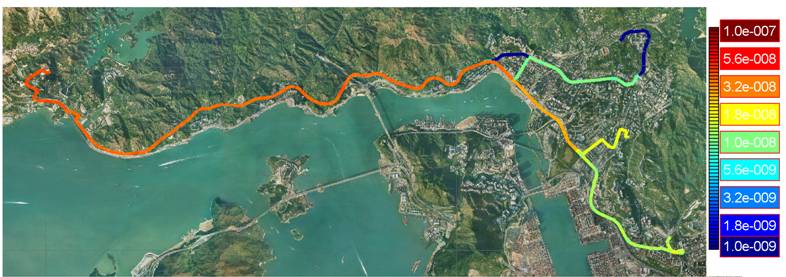

Figure 6 Maximum IR for Southern Delivery

Routes (from So Kwun Wat Magazine)

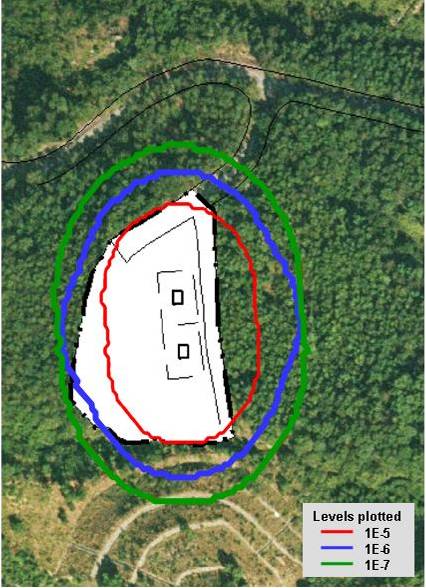

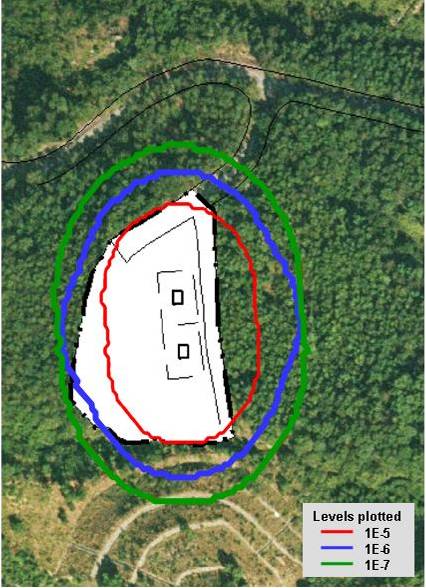

Figure 7 IR of Proposed Tai Lam Magazine

Indoor Outdoor

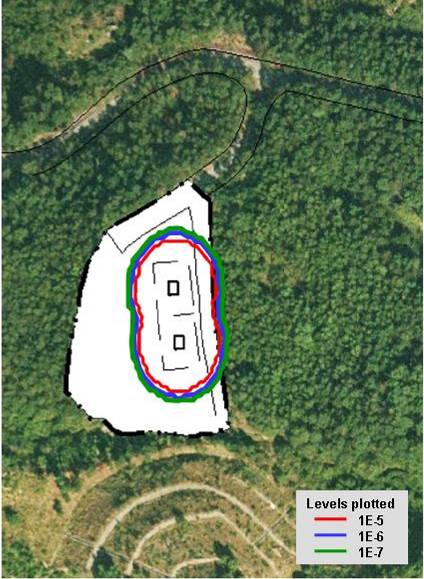

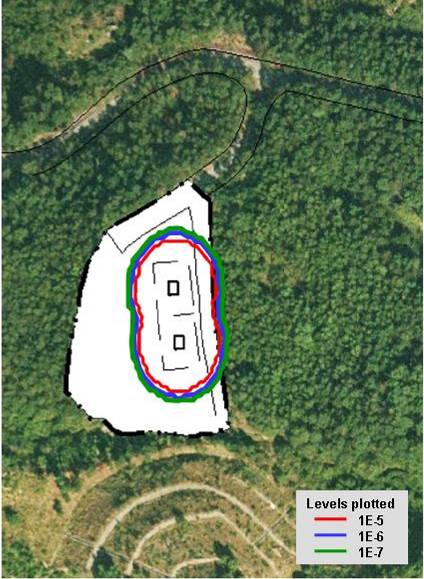

Figure 8 IR of Proposed So Kwun Wat Magazine

Indoor Outdoor

Societal Risk Results

13.74

The societal risk results for explosives storage and transport have been

combined to produce the overall societal risk results for the base case and the

worst case (Figure 9). These include the two magazine sites at Tai Lam and

So Kwun Wat and the associated transport routes to the 7 work sites.

13.75

The Base Case represents the risks associated with the envisaged

blasting programme. It can be seen that the risks lie in the upper ALARP

region.

13.76

The Worst Case represents the maximum risks associated with the worst

blasting scenario. The risks, as expected, are higher than the base case but

still within the ALARP region.

13.77

Figure 10 shows the F-N curve for the Base Case with a

breakdown by storage and transport. It is observed that risks from the

magazines are negligible compared to the transport risks since the two

magazines are located in remote areas with very low population density nearby.

13.78

The F-N curves for both base case and

worst case are within the As Low as Reasonably Practicable (ALARP) Region as

per HK EIAO-TM. Therefore, mitigation measures need to be considered to reduce

the risk. The ALARP assessment is provided in Section 9 of Appendix 13.

13.79

The potential Loss of Life (PLL) for the base case and the worst case

are given in Table 13.5 and Table 13.6 respectively. The PLL for this project has been

evaluated at 3.45 x 10-4 per year. The maximum PLL value for the

Project is estimated at 1.27 x 10-3 per year, which is obtained from

the worst case.

Figure 9 F-N Curves for Storage

and Transport of Explosives

Figure 10 F-N Curve for Base Case

with Breakdown by Transport and Storage

Table 13.5 Potential Loss of Life for Base Case

|

Base Case

|

PLL (per year)

|

Percentage Contribution (%)

|

|

Storage of Explosives

|

|

|

Tai Lam Magazine

|

7.99E-09

|

0.002%

|

|

So Kwun Wat magazine

|

7.99E-09

|

0.002%

|

|

Transport of Explosives

|

|

Tai Lam Magazine to Pat Heung

|

5.24E-05

|

15.21%

|

|

Tai Lam Magazine to Tai Kong Po

|

1.81E-05

|

5.26%

|

|

Tai Lam Magazine to Ngau Tam Mei

|

9.49E-06

|

2.75%

|

|

So Kwun Wat Magazine to Shek Yam

|

6.45E-05

|

18.72%

|

|

So Kwun Wat Magazine to Shing Mun

|

2.94E-06

|

0.85%

|

|

So Kwun Wat Magazine to Kwai Chung

|

1.14E-04

|

32.98%

|

|

So Kwun Wat Magazine to Mei

Lai Road

|

8.35E-05

|

24.23%

|

|

Total

|

3.45E-04

|

100.00%

|

Table 13.6 Potential Loss of Life for Worst Case

|

Worst Case

|

PLL (per year)

|

Percentage Contribution (%)

|

|

Storage of Explosives

|

|

|

Tai Lam Magazine

|

7.99E-09

|

0.001%

|

|

So Kwun Wat magazine

|

7.99E-09

|

0.001%

|

|

Transport of Explosives

|

|

Tai Lam Magazine to Pat Heung

|

1.88E-04

|

14.87%

|

|

Tai Lam Magazine to Tai Kong Po

|

4.81E-05

|

3.80%

|

|

Tai Lam Magazine to Ngau Tam Mei

|

2.48E-05

|

1.96%

|

|

So Kwun Wat Magazine to Shek Yam

|

2.57E-04

|

20.26%

|

|

So Kwun Wat Magazine to Shing Mun

|

7.33E-06

|

0.58%

|

|

So Kwun Wat Magazine to Kwai Chung

|

4.08E-04

|

32.24%

|

|

So Kwun Wat Magazine to Mei

Lai Road

|

3.33E-04

|

26.29%

|

|

Total

|

1.27E-03

|

100.00%

|

ALARP Assessment

13.80

Since the risks posed by the project, for both cases considered, are

within the ALARP region specified in EIAO-TM Annex 4, this implies that risk

reduction measures and / or alternate options should be explored for the

Project.

13.81

It was found that the risks arising from explosives transport are much

more significant than that of explosives storage; hence the ALARP assessment

focuses on the transportation aspects of explosives.

13.82

Where the risk falls into the

ALARP region, the risks associated with each probable hazardous event should be

reduced to a level ‘as low as reasonably practicable’. This firstly requires

the identification of any ‘practicable’ options regardless of their cost. A

mitigation option is considered ‘practicable’ if an engineering solution exists

and can be implemented on the XRL project regardless of the cost without

affecting the project construction programme. Secondly, the extent to which the

risk should be reduced is usually measured as a trade off between the risk

reduction, ie the safety benefits and the cost of the risk reduction measure. A

mitigation option is considered ‘reasonable’ if the cost of implementing the

option is not grossly disproportionate to the achieved safety benefits.

13.83

Risk mitigation measures may

take the form of engineered measures, controls in the zones most impacted by

the hazardous scenarios presented by this project, or operation and procedural

controls.

Approach

to ALARP Assessment

13.84

The approach consists of

identifying potential justifiable mitigation measures, assessing their practicability for this project and evaluating their cost and

comparing with the safety benefits of implementing the measures. Combinations

of mitigation measures are also considered.

13.85

The

safety benefits are evaluated as follows:

Safety Benefits = Value of Preventing a Fatality x Aversion Factor x Reduction in PLL

value

x Design life of mitigation measure

13.86

The Value of Preventing a Fatality

(VPF) reflects the tolerability of risk by the society and therefore the

monetary value that the society is ready to invest to prevent a fatality. For

the purpose of this assessment and for consistency with previous studies, the

Value of Preventing a Fatality is taken as HK$33M per person, which is the same

figure as used in previous Hazard Assessment studies (derived from ref.5 but updated to current prices.

13.87

Depending on the level of risk,

the value of preventing a fatality may be adjusted to reflect people’s aversion

to high risks or scenarios with potential for multiple fatalities. The

methodology for application of the ‘aversion factor’ follows that developed by

EPD (ref.18), in which the aversion factor is calculated on a

sliding scale from 1 (risks at the lower boundary of the ALARP region of the

Risk Guidelines) up to a maximum of 20 (risks at the upper boundary of the

ALARP region). The adjusted VPF using the aversion factor of 20 is HK$660M.

This value is a measure of how much the society is willing to invest to prevent

a fatality, where there is potential for an event to cause multiple fatalities.

13.88

The maximum justifiable expenditure for

this Project is calculated as HK$ 2.51M assuming the design life of mitigation

measure is 3 years based on the construction phase of the XRL project during

which storage and transport of explosives will be involved, with the PLL of

1.27 x 10-3 per year, which is obtained from the Worst Case.

13.89

For an ‘achievable’ mitigation

measure to be potentially justifiable, its cost should be less than the Maximum

Justifiable Expenditure.

Potential

Justifiable Mitigation Measures

13.90

The potential options that have been examined

in the ALARP assessment include the following categories.

·

Options eliminating the need for a Magazine or eliminating the risk (eg. Use of alternative methods of construction

(‘hard rock’ TBMs));

·

Options reducing significantly the quantities of explosives to be used

such as use of ‘hard rock’ TBM or alternatives to cartridged emulsion;

·

Options reducing significantly the distance run by contractors’

explosive trucks such as closer magazine sites and alternative routes. The

magazine and route options considered are summarised below:

-

The

alternative magazine sites to So Kwun Wat for the southern area and Tai Lam for

the northern area considered are: Helicopter site at Lam Kam Road, Pat Heung, Firing Range

at Golden Hill, Ying Wa Street,

CLP OHL Training School,

Kau Wa Keng, Gin Drinkers’ Bay, Kowloon Reservoir, Route Twisk, CAS Yuen Tun

Camp and Lo Wai.

With the exception of the Lam Kam Road site, all the alternative candidate

sites meeting the Commissioner of Mines’ external separation requirements require

an additional cost, due to site constraints, significantly greater than the

maximum justifiable expenditure for risk mitigation of HK$ 2.51M (refer to

the detailed ALARP assessment in Appendix 13 Table 9.2). Therefore, the alternative

magazine site at Lam Kam Road

has been selected for further cost-benefit evaluation;

-

Based

on the review of the possible transport routes for this project, Castle Peak Road

has been presented as an alternative route for explosive deliveries from the So

Kwun Wat magazine site to the southern work areas. This route option has been

selected for further cost-benefit evaluation;

·

Options reducing significantly the number of trips to be carried out by

contractors’ explosive trucks;

·

Options considering improved explosive truck design; and

·

Options considering better risk management systems and procedures.

13.91

In summary, the following options have been considered for cost-benefit

analysis.

·

Option 1: Alternative Magazine Site in Lam Kam, closer to the tunnel alignment

·

Option 2: Alternative Route

– Castle Peak Road

13.92

The PLL for Option 1 and Option 2 is compared to the PLL for the Worst

Case in Table 13.7. This was used as the basis for the cost-benefit

analysis/ ALARP assessment presented in Table 13.8

13.93

Other options considered practicable have been either recommended for

implementation or assessed comparing the implementation cost with the maximum

justifiable expenditure. The evaluation for each option is shown in Table 13.8. More details are available in Section 9 of Appendix

13.

|

Case

|

PLL (per year)

|

|

|

|

Worst Case

|

1.27 x 10-3

|

|

Option 1: Alternative Magazine Site in Lam Kam

|

1.08 x 10-3

|

|

Option 2: Alternative

Route – Castle Peak Road

|

1.27 x 10-3

|

Table 13.7 Potential Loss of Life for

Worst Case, Option 1 and Option 2

Table 13.8 ALARP Assessment Results

|

Option Description

|

Practicability

|

Implementation Cost

|

Safety Benefits or Justifiable Expenditure

|

ALARP Assessment

Result

|

|

Use of alternative methods of

construction (TBMs)

|

Not Practicable

|

> HK$ 100M

|

HK$ 2.51M

|

Not Justified

|

|

Use of Magazines Closer to the

Construction Sites (Lam Kam Road)

(Option Case 1)

|

Practicable

|

> HK$ 1M

|

HK$ 380k

|

Not Justified

|

|

Use of Alternative Route (Castle Peak Road)

(Option Case 2)

|

Practicable

|

< HK$ 10k

|

Negative

|

Tuen Mun Highway is the

preferred option

|

|

Use of different explosive types

(different types of detonating cord)

|

Pose some limitations

|

HK$ 1M

|

No safety benefit

|

Not Justified

|

|

Use of smaller quantities of explosives

|

Not Practicable

|

HK$ 6M

|

HK$ 2. 51M

|

Not Justified

|

|

Safer explosive truck (reduced fire load)

|

Practicable

|

-

|

-

|

Based on low implementation costs, this

option has been directly incorporated in recommendations

|

|

Lower Frequency of Explosive Transport

|

Not Practicable

|

|

|

Option considered but ruled out as not

practicable. Not Justified

|

|

Reduction of Accident Involvement

Frequency (training programme etc.)

|

Practicable

|

-

|

-

|

Based on low implementation costs, this option

has been directly incorporated in recommendations

|

|

Reduction of Fire Involvement Frequency

(better emergency response, extinguisher types etc.)

|

Practicable

|

-

|

-

|

Based on low implementation costs, this

option has been directly incorporated in recommendations

|

Conclusions

13.94

A QRA has been carried out to assess the

hazard to life issues arising from the storage and transport of explosives

during construction of the XRL Project.

13.95

The criterion of Annex 4 of the EIAO-TM for Individual Risk

is met. The assessment results show that the societal risk lies within the

ALARP region when compared to the criteria stipulated in the EIAO-TM. A

detailed ALARP assessment has been undertaken considering a wide range of

mitigation measures and the results show compliance with the ALARP principles

provided that the following recommendations are followed.

Recommendations

13.96

Following the

ALARP principles, the following recommendations are justified and should be implemented

to meet the EIAO-TM requirements:

·

The truck design should be improved to reduce the amount of combustibles

in the cabin. The fuel carried in the fuel tank should also be minimised to

reduce the duration of any fire;

·

The explosive truck accident frequency should be minimized by

implementing a dedicated training programme for both the driver and his

attendants, including regular briefing sessions, implementation of a defensive

driving attitude. In addition, drivers should be selected based on good safety

record, and medical checks;

·

The contractor should as far as practicable combine the explosive

deliveries for a given work area;

·

Only the required quantity of explosives for a particular blast should

be transported to avoid the return of unused explosives to the magazines.

·

Whenever practicable, a minimum headway between two consecutive truck

convoys of 10 min is recommended; and

·

The explosive truck fire involvement frequency should be minimized by

implementing a better emergency response and training to make sure the adequate

fire extinguishers are used and attempt is made to evacuate the area of the

incident or securing the explosive load if possible. All explosive vehicles

should also be equipped with bigger capacity AFFF-type extinguishers.

General Recommendations

13.97

Blasting

activities including storage and transport of explosives should be supervised

and audited by competent site staff to ensure strict compliance with the

blasting permit conditions. The following general recommendation should also be

considered for the storage and transport of explosives:

·

The security plan should address different alert security level to

reduce opportunity for arson / deliberate initiation of explosives. The

corresponding security procedure should be implemented with respect to

prevailing security alert status announced by the Government.

·

Emergency plan (ie magazine operational manual) shall be developed to

address uncontrolled fire in magazine area and transport. The case of fire near

an explosive carrying truck in jammed traffic should also be covered. Drill of

the emergency plan should be carried out at regular intervals.

·

Adverse weather working guideline should be developed to clearly define

procedure for transport explosives during thunderstorm.

Storage of Explosives in Magazine

Store

13.98

The magazine should be

designed, operated and maintained in accordance with Mines Division guidelines

and appropriate industry best practice. In addition, the following

recommendations should be implemented:

·

A suitable work control system should be introduced, such as an

operational manual including Permit-to-Work system, to ensure that work

activities undertaken during the operation of the magazine are properly

controlled.

·

There should be good house-keeping within the magazine to ensure that

combustible materials are not allowed to accumulate.

·

The magazine shall be without open drains, traps, pits or pockets into

which any molten ammonium nitrate could flow and be confined in the event of a

fire.

·

The magazine building shall be regularly checked for water seepage

through the roof, walls or floor.

·

Caked explosives shall be disposed of in an appropriate manner.

·

Delivery vehicles shall not be permitted to remain within the secured

fenced off magazine store area.

·

Good housekeeping outside the magazine stores to be followed to ensure

combustibles (including vegetation) are removed.

·

A speed limit within the magazine area should be enforced to reduce the

risk of a vehicle impact or incident within the magazine area.

Transport of Explosives

General

Recommendations:

13.99

The following measures should be

considered for safe transport of explosives:

·

Detonators shall not be transported in the same vehicle with other Class

1 explosives. Separation of vehicles should be maintained during the whole

trip.

·

Location for stopping and unloading from truck to be provided as close

as possible to shaft, free from dropped loads, hot work, etc. during time of

unloading.

·

Develop procedure to ensure that parking space on the site is available

for the explosive truck. Confirmation of parking space should be communicated

to truck drivers before delivery. If parking space on site cannot be secure,

delivery should not commence.

·

During transport of the explosives within the tunnel, hot work or other

activities should not be permitted in the vicinity of the explosives offloading

or charging activities.

·

Ensure lining is provided within the transportation box on the vehicle

and in good condition before transportation.

·

Ensure that packaging of detonators remains intact until handed over at

blasting site.

·

Emergency plan to include activation of fuel and battery isolation

switches on vehicle when fire breaks out to prevent fire spreading and reducing

likelihood of prolonged fire leading to explosion.

·

Use only experienced driver(s) with good safety record.

·

Ensure that cartridged emulsion packages are damage free before every

trip.

·

Contractors Licensed Vehicle Recommended Safety Requirements:

·

Battery isolation switch;

·

Front mounted exhaust with spark arrestor;

·

Fuel level should be kept as far as possible to the minimum level

required for the transport of explosives;

·

Minimum 1 x 9 kg water based AFFF fire extinguisher to be provided;

·

Minimum 1 x 9 kg dry chemical powder fire extinguisher to be provided;

·

Horizontal fire screen on cargo deck and vertical fire screen mounted at

least 150mm behind the drivers cab and 100mm from the steel cargo compartment,

the vertical screen shall protrude 150mm in excess of all three ( 3 ) sides of

the steel cargo compartment;

·

Cigarette lighter removed;

·

Two ( 2 ) battery powered torches for night deliveries;

·

Vehicles shall be brand new, dedicated explosive transport vehicles and should

be maintained in good operating condition;

·

Daily checks on tyres and vehicle integrity;

·

Regular monthly vehicle inspections;

-

Fuel

system

-

Exhaust

system

-

Brakes

-

Electrics

-

Battery

-

Cooling

system

-

Engine

oil leaks

·

Vehicle log book in which monthly inspections and maintenance

requirements are recorded; and

·

Mobile telephone equipped.

Recommended

Requirements for the Driver of the Explosive Vehicles:

13.100

The driver shall:

·

be registered by the Commissioner of Mines and must be over the age of

25 years with proven accident free records and more than 7 year driving

experience without suspension.

·

hold a Driving License for the class of vehicle for at least one ( 1 )

year;

·

adopt a safe driving practice including having attended a defensive

driving course;

·

pass a medical check and is assessed as fit to drive explosives

vehicles;

·

not be dependent on banned substances;

13.101

Some of the following requirements may also apply to

the vehicle attendant(s).

·

The driver is required to attend relevant training courses recognized by

the Commissioner of Mines. The training courses should include the following

major subjects, but not limited to:

-

the

laws and Regulations relating to the transport of explosives;

-

security

and safe handling during the transport of explosives;

·

Attend training courses provided by the explosives manufacturer or

distributor, covering the following:

-

explosives

identification;

-

explosion

hazards; and

-

explosives

sensitivity;

-

the

dangers which could be caused by the types of explosives;

-

the

packaging, labelling and characteristics of the types of explosives;

-

the

use of fire extinguishers and fire fighting procedures; and

-

emergency

response procedures in case of accidents.

13.102

The driver should additionally be responsible for the

following:

·

The driver shall have a full set of Material Safety Data Sheets ( MSDS )

for each individual explosive aboard the vehicle for the particular journey;

·

The MSDS and Removal Permit ( where applicable ) shall be produced to

any officer of the Mines Division of CEDD upon request;

·

A card detailing emergency procedures shall be kept on board and

displayed in a prominent place on the drivers door;

·

Before leaving the magazine the driver together with and/or assisted by

the shotfirer shall check the following:

·

Packaging integrity and labelling;

·

Check that the types and quantities of explosives loaded onto the

vehicle are as stipulated in the Removal Permit(s);

·

Check that the explosive load does not exceed the quantities stated in

the removal permit;

·

Check the condition and integrity of the cargo compartment or box;

·

Check that detonators are not loaded in the explosives cargo compartment

and vice versa;

·

Check that the cargo is secured and cannot be damaged during the

delivery;

·

Ensure that the appropriate placards and a red flag are displayed before

leaving the magazine;

·

Be competent to operate all equipment onboard the vehicle including fire

extinguishers and the vehicle emergency cut-off switches;

·

Prohibit smoking when the vehicle is loaded with explosives;

·

When explosives are loaded, ensure the vehicle is not left unattended;

·

Be conversant with emergency response procedures.

Specific

Recommended Requirements for the Explosive Vehicle Attendants:

13.103

When the vehicle is loaded with explosives, it shall be

attended by the driver and at least one (1) other person authorized by the

Commissioner of Mines. The vehicle attendant shall:

·

Be the assistant to the driver in normal working conditions and in case

of any emergency

·

Be conversant with the emergency response procedures

·

Be competent to use the fire extinguishers and the vehicle emergency

cut-off switches

·

One of the vehicle attendant(s) should be equipped with mobile phones

and the relevant MSDS and emergency response plan.

Type of Explosives & their

Disposal

13.104 For explosive selection, the following should be

considered

·

Cartridged Emulsions with perchlorate formulation should be avoided;

·

Cartridged Emulsions with high water content should be preferred.

13.105 If disposal is required for small quantities,

disposal should be made in a controlled and safe manner by a Registered

Shotfirer.

References

1.

MTRC, Consultancy Agreement No. NEX-2102, Express Rail

Link – Preliminary Design for XRL Tunnels & Associated Structures, “Working

Paper No. 13A – Explosives Magazine Site Selection“, 2008. (MTRC 5)

2.

ERM, West Island Line: Hazard to Life

Assessment for the Transport Storage and Use of Explosives, 2008 (EIA153/2008)

(ERM, 2008)

3.

HSC, Selection and Use of

Explosion Effects and Consequence Models for Explosives, Advisory Committee on

Dangerous Substances, 2000 (ESTC, 2000)

4. DNV, The Risk Assessment of the Transport of Explosives in Hong Kong

QRA Report, Environmental Protection Department Hong Kong Government, 1997, EPD

CE63/94 (DNV, 1997)

5.

ACDS, Risk from Handling

Explosives in Ports, HSC Advisory Committee on Dangerous Substances, HMSO, UK, 1995 (ACDS, 1995)

6.

P A Moreton, An Investigation

of the Relative Risks from the Road Transport of Blasting Explosives in Maximum

Size Loads of 5te and 16te, February 1993, SRD/HSE R596 (Moreton, 1993)

7.

United Nations, Recommendations

on the Transport of Dangerous Goods – Manual of Tests and Criteria, 4th Revised

Edition, 2003 (TDG-Test Manual, 2003)

8.

United Nations, Recommendations

on the Transport of Dangerous Goods – Model Regulations, 15th Revised Edition,

2007 (TDG-Model Regulation, 2007)

9. CEDD, Guidance Note on Requirements for

Approval of an Explosives Delivery Vehicle, http://www.cedd.gov.hk/eng/services/mines_quarries/doc/gn_03_edv.pdf (CEDD 2)

10. CEDD, How to apply for a Mode A Explosives

Store Licence, http://www.cedd.gov.hk/eng/services/mines_quarries/doc/mode_a_store.pdf (CEDD 3)

11.

Lands Department,

Geographic Information System (GIS) database, http://www.landsd.gov.hk/mapping/en/digital_map/mapprod.htm The latest information on

the GIS map of buildings from the Lands Department used in this study comes

from 2007/2008 (LD, 2008)

12.

Transport Department, Annual

Traffic Census 2007 (ATC, 2007)

13.

Transport Department,

"Road Traffic Accident Statistics”, Government of Hong Kong S.A.R, 2007

(and previous years) (TD, 2007a)

14.

Transport

Department, Road Traffic Accidents at Junction by Junction Type, Junction

Control and Severity 2007, http://www.td.gov.hk/FileManager/EN/Content_1943/07fig2.12e.pdf (TD, 2007b)

15.

UK Health and Safety Executive (UK HSE)’s

Explosives Incidents Database Advisory Service (EIDAS)

16.

Incident database retrieved from US Mine Safety and

Health Administration (MHSA)

17.

DOCEP, Incident Log Reports

retrieved from http://www.docep.wa.gov.au/resourcesSafety/Content/Dangerous_Goods/Incident_log_reports/index.htm (DOCEP)

18.

EPD, Technical Note: Cost

Benefit Analysis in Hazard Assessment, Environmental Protection Department,

Rev. January 1996. (EPD, 1996)