11. Water Quality Impact

11.1 This section presents an assessment of the potential water quality impacts associated with the construction and operation phases of the Project. Recommendations for mitigation measures have been provided, where necessary, to minimize the identified water quality impacts to an acceptable level.

11.2

In order to evaluate the potential water quality

impacts from the Project, water sensitive receivers (WSR) in

Ÿ Seawater intakes; and

Ÿ Important coral communities

Seawater Intakes

11.3

Seawater intakes identified in

11.4 It should be noted that a number of cooling water pumping stations and intakes are located within the proposed permanent reclamation limit of Wan Chai Development Phase II (WDII) along the existing waterfront of Wan Chai. These intakes supply cooling water to the air conditioning systems of various commercial buildings in the Wan Chai area including:

Ÿ

Ÿ Shui On Centre

Ÿ Telecom House

Ÿ The

Ÿ Government Buildings (Wan Chai Tower/Revenue Tower/Immigration Tower)

Ÿ

Ÿ

Ÿ Great Eagle Centre

Ÿ Sun Hung Kai Centre

11.5 Cooling water intake for Sun Hung Kai Centre will be reprovisioned to the new waterfront of Wan Chai during operational phase of the proposed WDII. The rest of the above listed cooling water intakes (except for the intake of HKCEC Extension) will be reprovisioned to the intake chambers to the north of HKCEC Extension. No relocation of the existing intake of HKCEC Extension is required under the WDII project.

11.6 An existing WSD flushing water intake is also located within the proposed WDII reclamation limit at Wan Chai which will be reprovisioned to the new waterfront of Wan Chai under the WDII project.

11.7

Figure

No. NEX2213/C/331/ENS/M59/002

shows the locations of the existing and reprovisioned seawater intakes along

the waterfront of Wan Chai,

11.8 Two seawater intakes are located within the Causeway Bay Typhoon Shelter (CBTS), which supply cooling water to the air conditioning systems of Excelsior Hotel, World Trade Centre, no. 27- 63 Paterson Street as well as Windsor House as shown in Figure No. NEX2213/C/331/ENS/M59/002. No permanent reclamation is required in CBTS under either the WDII project or this Project, and thus no permanent intake relocation would be required at CBTS. However, the cooling water intake for Windsor House would be located within the temporary reclamation works area in CBTS and therefore would need to be temporarily relocated to the adjacent area to allow continuous operation of the intake during the construction phase. Further discussion on the temporary intake relocation within CBTS is provided in Section 11.76. Location of the existing and temporarily diverted intake within the CBTS is indicatively shown in Plate 1 under Section 11.69.

11.9 There are several cooling water intakes operated in close proximity to the Project alignment at the Hung Hom landfall. Locations of these cooling water intakes are shown in Figure No. NEX2213/C/331/ENS/M59/003.

Important Coral Communities

11.10

Water quality impacts

on important coral communities with conservation interest are addressed in this

water quality impact assessment. Recognized

important coral sites that are within the Study Area (Western Buffer,

Shek O

11.11 WSRs

most likely to be affected by the proposed Shek O casting basin would be the

marine water and beneficial uses in Tai Tam Bay including three gazetted

beaches at Turtle Cover, Hairpin, Stanley Main respectively. The whole

11.12 There

are no fish culture zones within

Environmental Legislation, Policies, Plans, Standards and Criteria

11.13 The criteria for evaluating water quality impacts in this EIA Study include:

Environmental Impact Assessment Ordinance (EIAO)

11.14 The Technical Memorandum on Environmental Impact Assessment Process (EIAO-TM) was issued by EPD under Section 16 of the EIAO. It specifies the assessment method and criteria that were followed in this Study. Reference sections in the EIAO-TM provide the details of assessment criteria and guidelines that are relevant to the water quality assessment, including:

Ÿ Annex 6 – Criteria for Evaluating Water Pollution

Ÿ Annex 14 – Guidelines for Assessment of Water Pollution

Water Quality Objectives

11.15 The

Water Pollution Control Ordinance (WPCO) provides the major statutory framework

for the protection and control of water quality in

Table 11.1

Summary

of Water Quality Objectives for

|

Parameters |

Objectives |

Sub-Zone |

|

Offensive odour, tints |

Not to be present |

Whole zone |

|

Visible foam, oil scum, litter |

Not to be present |

Whole zone |

|

Dissolved oxygen (DO) within 2 m of the seabed |

Not less than 2.0 mg/l for 90% of samples |

Marine waters |

|

Depth-averaged DO |

Not less than 4.0 mg/l for 90% of samples |

Marine waters |

|

pH |

To be in the range of 6.5 - 8.5, change due to human activity not to exceed 0.2 |

Marine waters |

|

Salinity |

Change due to human activity not to exceed 10% of ambient |

Whole zone |

|

Temperature |

Change due to human activity not to exceed 2℃ |

Whole zone |

|

Suspended solids (SS) |

Not to raise the ambient level by 30% caused by human activity |

Marine waters |

|

Unionised ammonia (UIA) |

Annual mean not to exceed 0.021 mg/l as unionised form |

Whole zone |

|

Nutrients |

Shall not cause excessive algal growth |

Marine waters |

|

Total inorganic nitrogen (TIN) |

Annual mean depth-averaged inorganic nitrogen not to exceed 0.4 mg/l |

Marine waters |

|

Toxic substances |

Should not attain such levels as to produce significant toxic, carcinogenic, mutagenic or teratogenic effects in humans, fish or any other aquatic organisms. |

Whole zone |

|

Human activity should not cause a risk to any beneficial use of the aquatic environment. |

Whole zone |

Source: Statement

of Water Quality Objectives (

Table 11.2

Summary of Water Quality Objectives for

|

Parameters |

Objectives |

Sub-Zone |

|

Offensive odour, tints |

Not to be present |

Whole zone |

|

Visible foam, oil scum, litter |

Not to be present |

Whole zone |

|

Dissolved Oxygen (DO) within 2 m of the seabed |

Not less than 2.0 mg/l for 90% of samples |

Marine waters |

|

Depth-averaged DO |

Not less than 4.0 mg/l for 90 % of samples |

Marine waters excepting fish culture subzones |

|

Not less than 5.0 mg/l for 90% of samples |

Fish culture subzones |

|

|

Not less than 4.0 mg/l |

Inland waters |

|

|

pH |

To be in the range of 6.5 - 8.5, change due to human

activity not to exceed 0.2 |

Marine waters excepting bathing beach subzones; Mui

Wo (A), Mui Wo (B), Mui Wo (C), Mui Wo (E) and Mui Wo (F) subzones |

|

To be in the range of 6.0 – 9.0 |

Mui Wo (D) sub-zone and other inland waters. |

|

|

To be in the range of 6.0 –9.0 for 95% of samples,

change due to human activity not to exceed 0.5 |

Bathing beach subzones |

|

|

Salinity |

Change due to human activity not to exceed 10% of

ambient |

Whole zone |

|

Temperature |

Change due to human activity not to exceed 2 ℃ |

Whole zone |

|

Suspended Solids (SS) |

Not to raise the ambient level by 30% caused by human

activity |

Marine waters |

|

Change due to waste discharges not to exceed 20 mg/l

of annual median |

Mui Wo (A), Mui Wo (B),

Mui Wo (C), Mui Wo (E) and Mui Wo (F) subzones |

|

|

Change due to waste discharges not to exceed 25 mg/l

of annual median |

Mui Wo (D) subzone and other inland waters |

|

|

Unionized Ammonia (UIA) |

Annual mean not to exceed 0.021 mg(N)/l as unionized

form |

Whole zone |

|

Nutrients |

Shall not cause excessive algal growth |

Marine waters |

|

Total inorganic nitrogen (TIN) |

Annual mean depth-averaged inorganic nitrogen not to

exceed 0.1 mg(N)/l |

Marine waters |

|

E. coli |

Not exceed 610 per 100 ml, calculated as the

geometric mean of all samples collected in one calendar year |

Secondary contact recreation subzones and fish

culture subzones |

|

Not exceed 180 per 100 ml, calculated as the

geometric mean of all samples collected from March to October inclusive in 1

calendar year. Samples should be taken at least 3 times in 1 calendar month

at intervals of between 3 and 14 days. |

Bathing beach subzones |

|

|

5-Day Biochemical Oxygen Demand (BOD5) |

Change due to waste discharges not to exceed 5 mg/l |

Inland waters |

|

Chemical Oxygen Demand (COD) |

Change due to waste discharges not to exceed 30 mg/l |

Inland waters |

|

Dangerous Substances |

Should not attain such levels as to produce

significant toxic effects in humans, fish or any other aquatic organisms |

Whole zone |

|

Waste discharges should not cause a risk to any

beneficial use of the aquatic environment |

Whole zone |

Source: Statement of Water Quality Objectives (Southern Water Control Zone)

Water Supplies Department (WSD) Water Quality Criteria

11.16 Besides the WQO set under the WPCO, the WSD has specified a set of objectives for water quality at flushing water intakes as listed in Table 11.3 which shall not be exceeded at all stages of the Project. The target limit for suspended solids (SS) at these intakes is 10 mg/l or less.

Table 11.3 WSD’s Water Quality Criteria for Flushing Water at Sea Water Intakes

|

Parameter (in mg/l unless otherwise stated) |

Target Limit |

|

Colour (HU) |

< 20 |

|

Turbidity (NTU) |

< 10 |

|

Threshold Odour Number (odour unit) |

< 100 |

|

Ammoniacal Nitrogen |

< 1 |

|

Suspended Solids |

< 10 |

|

Dissolved Oxygen |

> 2 |

|

Biochemical Oxygen Demand |

< 10 |

|

Synthetic Detergents |

< 5 |

|

E. coli (no. per 100 mL) |

< 20,000 |

Cooling Water Intake Standards

11.17 Based on a questionnaire survey conducted under the approved Comprehensive Feasibility Study for Wan Chai Development Phase II (WDIICFS) EIA ([1]), a SS limit of 40 mg/L was adopted as the assessment criterion for MTR cooling water intakes. No information on the SS limit is available for other cooling water intakes. These findings have been confirmed by a telephone survey conducted under the recent approved EIA for the Hong Kong Convention and Exhibition Centre (HKCEC) Atrium Link Extension (ALE). The SS criterion for cooling water intakes is different from that for the WSD’s intakes as their beneficial uses are different (the former is used for cooling water system and the latter for flushing purpose).

Technical Memorandum

11.18

Discharges of effluents are subject to control

under the WPCO. The Technical

Memorandum on Standards for Effluents Discharged into Drainage and Sewerage

Systems, Inland and Coastal Waters (TM-DSS) gives guidance on the permissible

effluent discharges based on the type of receiving waters (foul sewers, storm

water drains, inland and coastal waters).

The limits control the physical, chemical and microbial quality of

effluents. Any sewage from the

proposed construction and operation activities must comply with the standards

for effluents discharged into the foul sewers, inshore waters or marine waters

of Victoria Harbour WCZ and

Practice Note

11.19 A Practice Note for Professional Persons (ProPECC) was issued by the EPD to provide guidelines for handling and disposal of construction site discharges. The ProPECC PN 1/94 “Construction Site Drainage” provides good practice guidelines for dealing with ten types of discharge from a construction site. These include surface runoff, groundwater, boring and drilling water, bentonite slurry, water for testing and sterilisation of water retaining structures and water pipes, wastewater from building constructions, acid cleaning, etching and pickling wastewater, and wastewater from site facilities. Practices given in the ProPECC PN 1/94 should be followed as far as possible during construction to minimise the water quality impact due to construction site drainage.

Assessment Criteria for Corals

11.20 This water quality impact assessment

has covered the impacts upon the sensitive coral communities with conservation

interest identified in the far field at

11.21 Potential impacts on corals may arise through excessive sediment deposition. The magnitude of impacts on corals is assessed based on the predicted sedimentation rate and SS elevation.

11.22

According

to Pastorok and Bilyard

([2]) and Hawker and

Connell ([3]),

a sedimentation rate higher than

11.23

Besides

the sedimentation rate criterion, the WQO for SS established under the WPCO

(i.e. the SS elevations should be less than 30% of ambient baseline conditions)

is also used to evaluate the water quality impact on corals. The WQO for SS has also been adopted under the approved Tai Po Sewage

Treatment Works Stage 5 EIA as one of the assessment criteria for evaluating

the water quality impact from the sewage effluent on corals identified at

Metals and Micro-pollutants

11.24

Elutriate

tests were conducted to estimate the amount of pollutants that would be released into the water

during dredging. However, there are no relevant standards in

Table 11.4

Proposed Assessment Criteria for Dissolved Metals and Micro-Pollutants

with Reference to Standards Adopted by Other Countries

|

Parameters |

Assessment Criteria (µg/L) |

|

Arsenic |

25 1 |

|

Cadmium |

2.5 1 |

|

Chromium |

15 1 |

|

Copper |

5 1 |

|

Lead |

25 1 |

|

Mercury |

0.3 1 |

|

Nickel |

30 1 |

|

Silver |

2.3 1 |

|

Zinc |

40 1 |

|

PCBs |

0.03 2 |

|

PAHs |

3 3 |

|

TBT |

0.1 4 |

Notes:

1. European Union Environmental Quality Standard (EQS) Values to Protect Marine Life.

2. The Criterion Continuous Concentration (CCC) of National Recommended Water Quality Criteria for Saltwater of the USEPA (2006).

3. Australian water quality guidelines for fresh and marine waters.

4.

Michael H. Salazar and Sandra M. Salazar (1996).

“Mussels as Bioindicators: Effects of TBT

on Survival, Bioaccumulation, and Growth under Natural Conditions” in

Organotin, edited by M. A. Champ and P. F. Seligman. Chapman & Hall,

Description of the Environment and Baseline Conditions

Marine Water Quality in

11.25 Marine

water quality monitoring data routinely collected by EPD were used to establish

the baseline condition. The EPD

monitoring data collected in 2008 were summarized in Table 11.5 for Central Victoria Harbour WCZ (Stations VM4

and VM5). Locations of Stations VM4

and VM5 are shown in Figure No. NEX2213/C/331/ENS/M59/001. Descriptions of the baseline water

quality conditions provided in the subsequent sections are extracted from the

EPD’s report “2008 Marine Water Quality

in

11.26 In

the past, wastewater from both sides of the

Table 11.5

Baseline Marine Water Quality Condition for

|

Parameters |

|

WPCO WQO (in marine waters) |

||

|

VM4 |

VM5 |

|||

|

Temperature (℃) |

23.4 (16.2 – 27.1) |

23.5 (16.3 – 27.2) |

Not more than 2℃ in daily temperature range |

|

|

Salinity |

31.3 (26.2 – 33.2) |

30.9 (25.7 – 32.7) |

Not to cause more than 10% change |

|

|

Dissolved Oxygen (DO) (mg/L) |

Depth Average |

5.3 |

5.0 (3.0 – 6.2) |

Not less than 4 mg/L for 90% of the samples |

|

Bottom |

4.9 |

5.0 (3.0 – 6.8) |

Not less than 2 mg/L for 90% of the samples |

|

|

Dissolved Oxygen (DO) (% Saturation) |

Depth Average |

73 |

70 (45 – 89) |

Not Available |

|

Bottom |

69 |

69 (45 – 85) |

Not Available |

|

|

pH |

8.0 |

8.0 (7.9 – 8.3) |

6.5 - 8.5 (± 0.2 from natural range) |

|

|

Secchi disc Depth (m) |

2.5 |

2.3 (1.8 – 3.3) |

Not Available |

|

|

Turbidity (NTU) |

7.9 |

7.9 (3.1 – 12.0) |

Not Available |

|

|

Suspended Solids (SS) (mg/L) |

5.1 |

5.0 (2.8 – 8.7) |

Not more than 30% increase |

|

|

5-day Biochemical Oxygen Demand (BOD5) (mg/L) |

0.8 |

1.2 (0.3 – 3.5) |

Not Available |

|

|

Ammonia Nitrogen (NH3-N) (mg/L) |

0.13 |

0.17 (0.05 – 0.27) |

Not Available |

|

|

Unionised Ammonia (UIA) (mg/L) |

0.006 |

0.007 (0.001 – 0.010) |

Not more than 0.021 mg/L for annual mean |

|

|

Nitrite

Nitrogen (NO2-N)

(mg/L) |

0.035 |

0.039 (0.020 – 0.146) |

Not Available |

|

|

Nitrate Nitrogen (NO3-N) (mg/L) |

0.156 |

0.176 (0.098 – 0.447) |

Not Available |

|

|

Total Inorganic Nitrogen (TIN) (mg/L) |

0.32 |

0.39 (0.22 – 0.71) |

Not more than 0.4 mg/L for annual mean |

|

|

Total

Kjeldahl Nitrogen (mg/L) |

0.33 |

0.40 (0.23 – 0.59) |

Not Available |

|

|

Total Nitrogen (TN) (mg/L) |

0.52 |

0.62 (0.40 – 0.93) |

Not Available |

|

|

Orthophosphate Phosphorus (OrthoP) (mg/L) |

0.028 |

0.032 (0.009 – 0.057) |

Not Available |

|

|

Total Phosphorus (TP) (mg/L) |

0.04 |

0.05 (0.04 – 0.09) |

Not Available |

|

|

Silica (as SiO2) (mg/L) |

1.0 |

1.1 (0.1 – 2.7) |

Not Available |

|

|

Chlorophyll-a (µg/L) |

3.5 |

3.9 (0.3 – 19.3) |

Not Available |

|

|

E.coli (cfu/100mL) |

2,900 |

4,200 (840 – 23,000) |

Not Available |

|

|

Faecal Coliforms (cfu/100mL) |

6,300 |

10,000 (1,400 – 81,000) |

Not Available |

|

Notes:

1.

Data source: Marine Water Quality in

2. Except as specified, data presented are depth-averaged values calculated by taking the means of three depths: Surface, mid-depth and bottom.

3. Data presented are annual arithmetic means of depth-averaged results except for E.coli and faecal coliforms that are annual geometric means.

4. Data in brackets indicate the ranges.

Marine Water Quality in

11.27 The

EPD monitoring data collected at

Table 11.6

Baseline Marine Water Quality Condition for

|

Parameters |

|

WPCO WQO (in marine waters) |

|

|

SM1 |

|||

|

Temperature (℃) |

22.7 (13.9 – 26.8) |

Not more than 2℃ in daily temperature range |

|

|

Salinity |

31.7 (26.3 – 33.8) |

Not to cause more than 10% change |

|

|

Dissolved Oxygen (DO) (mg/L) |

Depth Average |

6.6 (4.6 – 9.1) |

Not less than 4 mg/L for 90% of the samples |

|

Bottom |

5.9 (2.8 – 9.2) |

Not less than 2 mg/L for 90% of the samples |

|

|

Dissolved Oxygen (DO) (% Saturation) |

Depth Average |

91 (66 – 115) |

Not Available |

|

Bottom |

81 (40 – 117) |

Not Available |

|

|

pH |

8.2 (7.8 – 8.5) |

6.5 - 8.5 (± 0.2 from natural range) |

|

|

Secchi disc Depth (m) |

2.6 (1.2 – 4.5) |

Not Available |

|

|

Turbidity (NTU) |

8.1 (4.2 – 11.1) |

Not Available |

|

|

Suspended Solids (SS) (mg/L) |

4.2 (1.3 – 10.0) |

Not more than 30% increase |

|

|

5-day Biochemical Oxygen Demand (BOD5) (mg/L) |

0.6 (0.3 – 1.2) |

Not Available |

|

|

Ammonia Nitrogen (NH3-N) (mg/L) |

0.03 (0.01 – 0.06) |

Not Available |

|

|

Unionised Ammonia (UIA) (mg/L) |

0.002 (<0.001 – 0.005) |

Not more than 0.021 mg/L for annual mean |

|

|

Nitrite

Nitrogen (NO2-N)

(mg/L) |

0.023 (0.002 – 0.110) |

Not Available |

|

|

Nitrate Nitrogen (NO3-N) (mg/L) |

0.133 (0.002 – 0.670) |

Not Available |

|

|

Total Inorganic Nitrogen (TIN) (mg/L) |

0.18 (0.01 – 0.84) |

Not more than 0.1 mg/L for annual mean |

|

|

Total

Kjeldahl Nitrogen (mg/L) |

0.17 (0.12 – 0.23) |

Not Available |

|

|

Total Nitrogen (TN) (mg/L) |

0.33 (0.12 – 0.95) |

Not Available |

|

|

Orthophosphate Phosphorus (OrthoP) (mg/L) |

0.010 (0.006 – 0.017) |

Not Available |

|

|

Total Phosphorus (TP) (mg/L) |

0.03 (0.02 – 0.03) |

Not Available |

|

|

Silica (as SiO2) (mg/L) |

0.9 (0.3 – 2.8) |

Not Available |

|

|

Chlorophyll-a (µg/L) |

3.0 (0.8 – 7.9) |

Not Available |

|

|

E.coli (cfu/100mL) |

2 (1 – 20) |

Not Available |

|

|

Faecal Coliforms (cfu/100mL) |

4 (1 – 38) |

Not Available |

|

Notes:

1.

Data source: Marine Water Quality in

2. Except as specified, data presented are depth-averaged values calculated by taking the means of three depths: Surface, mid-depth and bottom.

3. Data presented are annual arithmetic means of depth-averaged results except for E.coli and faecal coliforms that are annual geometric means.

4. Data in brackets indicate the ranges.

5. Bold number indicates exceedance of WQO.

Marine Water Quality within

11.28 A

summary of published EPD monitoring data (in 2008) collected from the

monitoring station at the Causeway Bay Typhoon Shelter (VT2) is presented in Table 11.7.

Location of Station VT2 is shown in Figure

No. NEX2213/C/331/ENS/M59/001. The data are extracted from the EPD’s

publication “2008 Marine Water Quality in

Table 11.7

Baseline Marine Water Quality Condition for

|

Parameters |

EPD Monitoring Station (Bi-Monthly) |

WPCO WQO (in marine waters) |

|

|

VT2 |

|||

|

Temperature (℃) |

23.2 (15.6 – 26.8) |

Not more than 2℃ in daily temperature range |

|

|

Salinity (ppt) |

30.0 (28.3 – 31.8) |

Not to cause more than 10% change |

|

|

Dissolved Oxygen (DO) (% Saturation) |

Depth Average |

60 |

Not Available |

|

Bottom |

60 |

Not Available |

|

|

Dissolved Oxygen (DO) (mg/L) |

Depth Average |

4.3 |

Not less than 4 mg/L for 90% of the samples |

|

Bottom |

4.4 |

Not less than 2 mg/L for 90% of the samples |

|

|

pH |

7.9 |

6.5 - 8.5 (± 0.2 from natural range) |

|

|

Secchi disc Depth (m) |

2.1 |

Not Available |

|

|

Turbidity (NTU) |

8.5 |

Not Available |

|

|

Suspended Solids (SS) (mg/L) |

5.6 |

Not more than 30% increase |

|

|

Silica (as SiO2) (mg/L) |

1.4 |

Not Available |

|

|

5-day Biochemical Oxygen Demand (BOD5) (mg/L) |

1.4 |

Not Available |

|

|

Nitrite

Nitrogen (NO2-N)

(mg/L) |

0.033 |

Not Available |

|

|

Nitrate Nitrogen (NO3-N) (mg/L) |

0.199 |

Not Available |

|

|

Ammonia Nitrogen (NH3-N) (mg/L) |

0.24 |

Not Available |

|

|

Unionised Ammonia (UIA) (mg/L) |

0.009 |

Not more than 0.021 mg/L for annual mean |

|

|

Total Inorganic Nitrogen (TIN) (mg/L) |

0.47 |

Not more than 0.4 mg/L for annual mean |

|

|

Total Nitrogen (TN) (mg/L) |

0.74 |

Not Available |

|

|

Orthophosphate Phosphorus (OrthoP) (mg/L) |

0.042 |

Not Available |

|

|

Total Phosphorus (TP) (mg/L) |

0.07 |

Not Available |

|

|

Chlorophyll-a (µg/L) |

2.0 |

Not Available |

|

|

E.coli (cfu/100mL) |

3,500 |

Not Available |

|

|

Faecal Coliforms (cfu/100mL) |

8,800 |

Not Available |

|

Notes:

1. Except as specified, data presented are depth-averaged data.

2. Data presented are annual arithmetic means except for E.coli and faecal coliforms that are geometric means.

3. Data enclosed in brackets indicate ranges.

4. Bold number indicates exceedance of WQO.

11.29 Due to the embayment form and reduced flushing capacity of the typhoon shelter, marine water within the typhoon shelter is vulnerable to pollution. In 2008, high levels of E.coli were recorded at the Causeway Bay Typhoon Shelter (CBTS) indicating faecal contamination. The water quality level marginally exceeded the WQO for TIN but fully complied with the WQO for DO and UIA. Significant long-term improvements in terms of decreasing trends in TIN, TN, OrthoP and TP were observed in CBTS.

Sediment Quality

11.30 The results of marine sediment quality analysis from the marine ground investigation works at the Project site are presented in Section 12 (under the Waste Management Section). A review of the sediment quality data from the marine ground investigation indicated that most of the marine sediments to be dredged under the Project were classified as contaminated (Category M or H). Details of the sediment quality criteria and guidelines as well as a comprehensive review of the sediment quality data collected at the proposed marine works areas are given in Section 12.

Identification of Potential Impacts

General Description of

Onsite Construction Works in

11.31 SCL (HUH-ADM) is a 6-km extension of East Rail Line from a new Hung Hom (HUH) Station across the harbour to new stations at Exhibition (EXH) and Admiralty (ADM). The cross-harbour tunnels of the SCL (HUH-ADM) would be constructed using immersed tube (IMT). The sections of tunnels at Hung Hom landfall as well as within the CBTS would be constructed by cut and cover method involving temporary reclamation. Tunnels from the CBTS to ADM would be constructed using tunnel boring machine (TBM) with a section of cut and cover method at the sea channel between Hong Kong Convention and Exhibition Centre, which would be reclaimed under the WDII Project. Hard rock sections of the alignment south of ADM would be constructed using drill-and-blast method.

11.32 Dredging of marine mud would be required at the southeast corner of the CBTS to provide additional space for temporary relocation of anchorage area due to the proposed temporary reclamation within the CBTS.

11.33 The temporary reclamation within the CBTS would also require relocation of the temporary RHKYC jetty to a new location within the CBTS, which would involve minor piling works. No dredging is required for construction of the temporary jetty.

11.34 Engineering assessments have been undertaken by reviewing the latest geological profile within the Study Area to determine the optimal IMT alignment for SCL (HUH-ADM) to minimize the risk of encountering rock head and thus minimizing the need of underwater blasting during the IMT construction whilst meeting all other Project or engineering requirements. Hence, underwater blasting would unlikely be needed for the IMT construction but would still be potentially required in areas where the rock head level is relatively high.

11.35 Two barging point locations are proposed for transportation of spoil generated under this Project for reuse/disposing of. These barging points are located at ex-Wan Chai Public Cargo Working Area and Hung Hom Freight Pier respectively. No dredging is required for construction of these barging points.

11.36 Consideration of alternative construction options and development of the preferred option are discussed in detail under Section 2.

General Description of Offsite Construction Works in Shek O

11.37

Offsite works areas required for construction

of the Project include the site for casting of IMT segments (at

11.38 The

construction works required at Shek O would basically involve installation of gates at the gate frames of the

existing quarry. No marine works / dredging would be required

for construction of the proposed casting basin at Shek O.

Identification of Potential Construction Phase Impacts

Marine Construction Works

Temporary Reclamation

at Hung Hom Landfall and Associated Works

11.39 Temporary reclamation would be required at Hung Hom landfall where a temporary cofferdam will be constructed adjacent to temporary piled platform for works access. Removal of fender piles of Hung Hom Bypass and minor piling works would be undertaken prior to the construction of the platform and cofferdam. Release of sediment and wastewater generated from the demolition and pilling works would potentially elevate the SS concentrations in the water column, if not well controlled. Nonetheless, excavation and tunnel construction works will be undertaken within the cofferdam. Upon completion of tunnel construction works, reinstatement of fender piles will be carried out. If it is not properly implemented, the potential impact will be similar to that arising from marine piling works as described above. Since no open dredging would be required for abovementioned works, no significant water quality impact would be expected. Layout of works area at Hung Hom landfall is shown in Figure No. NEX2213/C/331/ENS/M50/021 in Section 3.

Removal and

Reinstatement of the Tip of Freight Pier at Hung Hom for IMT Construction

11.40 The

tip of Hung Hom Freight Pier would need to be removed for construction of the

IMT. The freight pier

is a masonry gravity structure. The grain size of materials to be involved in

the pier removal works would hence be large and no dredging work would be

required. Therefore no off-site migration of fines would be expected.

11.41 After

the completion of the IMT construction of the SCL tunnel, the tip of Hung Hom

Freight Pier would be reinstated back at its original position. The

reinstatement works would involve marine piling, which would potentially increase the SS

concentrations in the water column, if not well controlled. No dredging would

be required for the reinstatement of the tip of Hung Hom Freight Pier. With the

application of the appropriate mitigation measures as shown in Section 11.217, no significant water quality impact is expected.

IMT Across the

11.42 The key potential water quality impacts would be associated with the proposed dredging and filling works required for the IMT construction (across the Victoria Habour) as well as the temporary reclamation within the CBTS as identified below.

Ÿ Dredging works will disturb the marine bottom sediment, causing an increase in SS concentrations in the water column and forming sediment plume along the tidal flows.

Ÿ Loss of fill materials into the water column during filling activities causing an increased SS level.

Ÿ Release of sediment-bound contaminants such as heavy metals into the water column, either via suspension or by disturbance as a result of dredging.

Ÿ Release of the same contaminants due to leakage and spillage as a result of poor handling and overflow from barges during dredging and transport.

Ÿ Temporary embayments will be formed between the partially reclaimed land as the temporary reclamation within the CBTS proceeds in stages. Potential accumulation of pollutants from contaminated stormwater runoff (due to debris and oil / grease left on the ground, and organic matter from expedient connections) into the temporary embayments may increase the dissolved oxygen demand in the slack water, causing dissolved oxygen depletion and, in turn, potential odour impacts on the neighbouring sensitive receivers.

Construction of Temporary RHKYC Jetty within the CBTS

11.43

Minor

piling works would be required for construction of the temporary jetty within

the CBTS. Release of sediment and wastewater generated from the pilling works

would potentially increase the SS concentrations in the water column, if not

well controlled. The associated

water quality impact and mitigation measures in relation to the construction of

the temporary jetty are separately addressed in the EIA for SCL Protection

Works at CBTS.

Underwater

Blasting along the IMT Across the

11.44 The provisional underwater blasting works will have mitigation measures to avoid loss of fines and release of contaminants into the marine waters from the bottom sediments around the blasting areas.

11.45 Construction

of the

11.46 Activities

relating to the flooding and emptying of the casting basin for the removal of

the formed tunnel units would have the potential to impact on water

quality. Water in the basin may be

contaminated with particulates from cement and concrete which could affect pH. Suspended solids in the flooded basin may

be expected to be elevated above the background.

11.47 After

completion of all the IMT fabrication and construction works, the Shek O site

will be reinstated to the layout originally planned under the Rehabilitation of Shek O Quarry project. No marine

works would be involved in the proposed reinstatement work and hence no adverse

water quality impact would be expected.

General Construction Activities

11.48 The land-based construction works could have the potential to cause water pollution. Various types of construction activities may generate wastewater. These include general cleaning and polishing, wheel washing and dust suppression. These types of wastewater would contain high concentrations of SS. Impacts could also result from the sewage effluent from the construction work force involved with the construction. If uncontrolled, these effluents could lead to deterioration in water quality.

Construction Site Run-off

11.49 Construction site run-off would cause potential water quality impacts. Potential pollution sources of site run-off may include:

Ÿ Run-off and erosion of exposed bare soil and earth, drainage channel, earth working area and stockpiles.

Ÿ Release of any bentonite slurries, concrete washings and other grouting materials with construction run-off, storm water or wastewater from dewatering process.

Ÿ Wash water from dust suppression sprays and wheel washing facilities.

Ÿ Fuel, oil and lubricants from maintenance of construction vehicles and equipment.

11.50 During rainstorms, site run-off would wash away the soil particles on unpaved lands and areas with the topsoil exposed. The run-off is generally characterized by high concentrations of SS. Release of uncontrolled site run-off would increase the SS levels and turbidity in the nearby water environment. Site run-off may also wash away contaminated soil particles and therefore cause water pollution.

11.51 Wind blown dust would be generated from exposed soil surfaces in the works areas. It is possible that wind blown dust would fall directly onto the nearby water bodies when a strong wind occurs. Dispersion of dust within the works areas may increase the SS levels in surface run-off causing a potential impact to the nearby sensitive receivers.

Accidental Spillage

11.52 A large variety of chemicals may be used during construction activities. These chemicals may include petroleum products, surplus adhesives, spent lubrication oil, grease and mineral oil, spent acid and alkaline solutions/solvent and other chemicals. Accidental spillage of chemicals in the works areas may contaminate the surface soils. The contaminated soil particles may be washed away by construction site run-off or stormwater drainage which in turn causes water pollution.

Excavation Activities

11.53 The construction of the Project involves excavation of soil materials for the cut and cover railway alignment, and ventilation building / ventilation shafts. Excavated materials may have to be stored on-site before being sorted, reused or transported to disposal sites. If stored as open air stockpiles with no cover during rainfall, excavated materials would have a potential risk to be washed away and thereby causing sudden increase of SS and oxygen demand in the receiving water.

Disposal of Waste

11.54 Construction and demolition (C&D) material as well as excavated material from the construction works would be required to send offsite for recycling or disposal. In case if these materials are dumped at inappropriate location or without proper precautionary measures, water quality impact may arise. Measures for proper disposal of C&D material as well as excavated material generated from the Project have been discussed in detail in Section 12. The destinations of the different kinds of waste generated in the Project construction have been listed in Table 12.8.

11.55 Surplus inert C&D materials generated from the Project may be delivered to two Public Fill Reception Facilities operated by CEDD which are Tuen Mun Area 38 Fill Bank and Tseung Kwan O Area 137 Fill Bank. The Project Proponent should be responsible for obtaining confirmation and approval from Public Fill Committee (PFC) on the allocation of the disposal site before commencement of the Project works. Construction work should not proceed until all issues on management of C&D materials have been resolved and all relevant arrangements have been endorsed by relevant authorities including PFC and EPD.

11.56 The contractor for the excavation / dredging works shall apply for the site allocations of marine sediment disposal based on the prior agreement with MFC/CEDD. The Project proponent should also be responsible for the application of all necessary permits from relevant authorities, including the dumping permit as required under DASO from EPD, for the disposal of dredged and excavated sediment prior to the commencement of the excavation works.

11.57 No water quality concern would be expected from the disposal of waste provided that the mitigation measures as recommended in Section 12 are properly implemented.

Groundwater Seepage from Uncontaminated Area

11.58 During excavation works, groundwater would be required to be pumped out from works areas in case seepage of groundwater occurs. Groundwater pumped out or from dewatering activities as a potential source of site run-off may wash away construction site and therefore would cause potential water quality impacts by increasing the SS levels and turbidity in the nearby water environment.

Groundwater from Contaminated Area

11.59 Groundwater pumped out or from dewatering process during excavation works in any contaminated sites could be potentially contaminated. Discharge / recharge of potentially contaminated groundwater generated from these areas may affect the surface / ground water quality, if uncontrolled.

Identification of Potential Operational Phase Impact

Potential Impact on Water Quality

11.60 Major water quality impacts from the Project operation include:

Ÿ Run-off and foul water discharges from railway tunnels;

Ÿ Sewage and wastewater effluents from stations and ventilation building; and

Ÿ Station / building run-off.

11.61 No seawater cooling system is proposed under the Project.

Run-off and Foul Water Discharges from Railway Tunnels

11.62 The proposed railway alignment would be placed in underground tunnel. During rainstorm, water falls from the train when it enters to the tunnel may generate tunnel run-off. The amount of groundwater seepage into the tunnel may also generate tunnel run-off. Such run-off may contain limited amount of lubricants, SS, iron, oil and grease. Sources of foul water discharges from the railway tunnel would include the tunnel track wash and fire protection water discharges. Direct discharge of tunnel run-off and railway foul water discharges may cause adverse water quality impact on nearby water environment.

Sewage and Wastewater Effluents from Stations and

11.63 Sources of sewage and wastewater that will be generated from the stations and ventilation building would include the toilet sanitary wastewater, fire protection water discharges, floor cleaning / washed water and floor drainage and mechanical equipment wastewater. Direct discharge of these sewage and wastewater discharges may cause adverse water quality impact on nearby water environment.

Station and

11.64 The stations and ventilation building would be enclosed and therefore run-off will be limited to wash-off from the outside of the stations and ventilation building. Sources of potential polluted stormwater that may arise from the station and ventilation building run-off include dust from the roof of the buildings and cleaning agents used for washing building facade.

Potential Impact on Flow Regime or Hydrology

11.65 There

would be some changes in the seabed levels along the tunnel section within

Marine Construction

11.66

Construction of the tunnel section of the SCL

(HUH-ADM) across the

Temporary Reclamation within CBTS

Construction Method

11.68 It should be noted that temporary mooring areas would be proposed inside the existing CBTS and Pubic Cargo Working Area (PCWA) under the current construction scheme. Therefore, the temporary breakwater originally proposed under the approved EIA for WDII and CWB for temporary moorings outside the CBTS breakwater will not be implemented under the currently adopted scheme. Dredging of marine mud would be required at the southeast corner of the CBTS to provide additional space for temporary relocation of anchorage area due to the Protection Works (which is addressed to be environmentally acceptable in the separate EIA for SCL Protection Works at CBTS).

Phasing and Sequence

11.69 The

construction for SCL and CWB within the CBTS would be undertaken in 13 phases,

namely TS1, TS4, TS4 Ext., PW1.1, PW1.2, PW1.3, PW1.4, TS2, TS3(W), TS3(E),

SCL2, SCL3.1 and SCL3.2 respectively, as shown in Plate 1 below. Staging

of the temporary reclamation works is shown indicatively in Appendix 11.2, which aims only to illustrate the general

reclamation sequence within the CBTS. It should be noted that PW1.1,

PW1.2, PW1.3 and PW1.4 would be constructed under the SCL Protection works and

their associated environmental impact has been fully assessed in the separate

EIA for SCL Protection Works at CBTS.

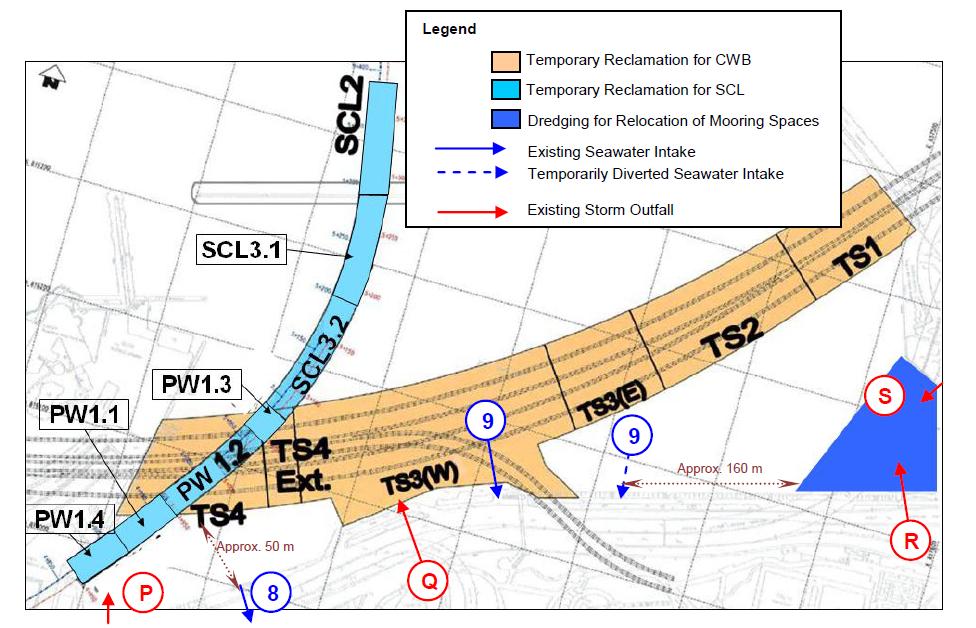

Plate 1. Temporary Reclamation Scheme

11.70 Dredging for TS1 and TS4 will be undertaken tentatively in 2010. Dredging for TS4 Ext., PW1.1, PW1.3 and PW1.4 as well as dredging for relocation of mooring space will commence tentatively in 2012 and will be undertaken after the dredging works for TS1 and TS4 are completed. Construction of PW1.2 will be undertaken within the seawall of TS4 and hence no seawall construction would be required under PW1.2.

11.71 Dredging and construction of temporary seawall for TS2 will also commence tentatively in 2012, potentially concurrent with the construction works for TS4 Ext., PW1.1, PW1.3 and PW1.4. Demolition of TS1 will proceed before commencement of TS2, TS4 Ext., PW1.1, PW1.3 and PW1.4. The whole TS1 will be removed before commencement of TS2, TS4 Ext., PW1.1 to 1.4. Hence, dredging at TS2, TS4 Ext., PW1.1, PW1.3 and PW1.4 would potentially take place when the seawall of TS4 is in place. On the other hand, dredging at southeast corner for relocation of mooring space is tentatively scheduled for carrying out in early 2012 before commencement of TS2, TS4 Ext., PW1.1, PW1.3 and PW1.4 and would be potentially undertaken when the seawalls of both TS1 and TS4 are in place (with no other concurrent dredging work inside the CBTS). In case dredging at the southeast corner of CBTS for relocation of mooring space and dredging for TS2, TS4 Ext., PW1.1, PW1.3 and PW1.4 are required to work concurrently within the CBTS during the actual implementation of the Project, the potential cumulative water quality impact would be controlled by limiting the total combined dredging rate within the CBTS as discussed in detail under Sections 11.80, 11.83 and 11.91.

11.72 Dredging for TS3(E) is tentatively scheduled for commencement in the first quarter of 2014 when only PW1.4 is in place. TS4, TS2, TS4 Ext. and PW1.1 to 1.3 will be completely removed before commencement of TS3(E). Therefore, water body behind temporary reclamation area will not be fully enclosed, which minimize water quality impacts.

11.73 Dredging and seawall construction for TS3(W) would commence tentatively in the second quarter of 2014. Dredging for TS3(W) would be carried out when TS3(E) and PW1.4 are in place. Dredging and seawall construction for SCL2 would tentatively take place in 2015 when PW1.4 and TS3(W) are in place. TS3(E) would be completely removed before commencement of SCL2. Dredging for SCL2 would be undertaken immediately outside the existing breakwater of CBTS. Dredging for SCL3.1 would tentatively commence in the first quarter of 2016 when PW1.4, SCL2 and TS3(W) are in place.

11.74 Dredging and seawall construction for SCL3.2 would tentatively commence in the first quarter of 2017 after the temporary reclamations for PW1.4, SCL2 and TS3(W) are completely removed.

11.75 Dredging within the CBTS will be carried out at a maximum rate of 6,000 m3 per day and no more than two closed grab dredgers would be operated for the dredging works at any one time within the CBTS. Dredging for SCL2 will be undertaken outside the CBTS and are separately addressed in Section 11.92.

11.76 There are two existing cooling water intakes (namely Intakes 8 and 9 respectively as shown in Figure No. NEX2213/C/331/ENS/M59/002) and four existing storm outfalls (namely Culverts P, Q, R and S respectively as shown in Figure No. NEX2213/C/331/ENS/M59/004) located in the CBTS. As shown in Plate 1 above, the storm outfall (Culvert Q) and the cooling water intake for Windsor House (Intake 9) are located in the area of TS3(W). Before the seawall construction at TS3(W) is completed, the cooling water intake will be diverted to the adjacent area and the intake point would be slightly shifted to the east along the existing seawall outside the TS3(W) site to ensure continuous operation of the intake during the construction period (similar to the arrangement adopted under the approved WDII & CWB EIA). Furthermore, the storm outfall (Culvert Q) will be temporarily diverted to the north of TS3(W) before the seawall of TS3(W) is completely constructed. No temporary diversion will be implemented for Intake 8 as well as Culverts P, R and S.

Impacts from Sediment Plume upon the Water Quality inside the CBTS

11.77 There is no biological sensitive receiver within the CBTS and there are no areas of conservation value, ecological importance or mariculture activities in the vicinity. The closest water sensitive receivers to the temporary reclamation works would be the cooling water intakes for Excelsior Hotel and World Trade Centre (namely Intake 8) and Windsor House (namely Intake 9) as shown in Plate 1 and Figure No. NEX2213/C/331/ENS/M59/002. No SS criterion was available for these cooling water intakes (refer Section 11.17).

11.78 The dredging work along the southern seawall of TS4, PW1.1 and PW1.4 would be closest to Intake 8. The dredging work along the seawall of TS3(W) and TS3(E) (which are non-SCL activities) as well as the dredging for relocation of mooring space would be closest to Intake 9. Hence, these dredging activities would be most critical in terms of the water quality impact upon the cooling water intakes. The remaining dredging works would be further away from the cooling water intakes and the associated water quality impacts are considered less significant. Following the recommendations provided in the approved EIA for WDII and CWB, the following water quality mitigation measures are recommended for seawall constructions inside the CBTS due to their close proximity to the cooling water intakes:

Ÿ Temporary seawall should be partially constructed to protect the nearby seawater intakes from further dredging activities. For example, the seawalls along the southeast and southwestern boundaries of PW1.1 and PW1.4 should be constructed first (above high water mark) so that the seawater intake at the inner water would be protected from the impacts from the remaining dredging activities along the northwest boundary;

Ÿ Dredging should be carried out by closed grab dredger to minimize release of sediment and other contaminants during dredging;

Ÿ Silt curtains should be deployed to fully enclose the closed grab dredger during any dredging operation, i.e. all dredging works proposed inside the CBTS (including those within the boundary of PW1.1 to PW1.4, SCL2, SCL 3.1, SCL 3.2, TS1, TS4, TS4 Ext., TS2, TS3(W) and TS3(E) for temporary reclamation and at southeast corner of the CBTS for relocation of mooring space) as indicated in Plate 1 would be carried out with the deployment of silt curtain;

Ÿ Silt screens will be installed at the cooling water intakes within the CBTS during the temporary reclamation period;

Ÿ Site audit and water quality monitoring should be carried out at the seawater intakes during the marine works.

11.79 In addition, no more than two dredgers (of about 8 m3 capacity each) would be operated for dredging within the typhoon shelter at any time. The total dredging rate of no more than 6,000 m3 per day will be maintained within the CBTS throughout the construction period. Works for the SCL that will likely have interfacing issues with the CWB construction within the CBTS (including PW1.1 to PW1.4 as well as dredging at the southeast corner of the CBTS for relocation of mooring space) will be carried out by the same contractor of the CWB project. Hence, TS1, TS2, TS4, TS4 Ext, PW1.1 to 1.4 and dredging for relocation of mooring space will be carried out under the same contract to ensure that the maximum dredging rate within the CBTS would not exceed the required limit of 6,000 m3 per day. SCL2, SCL 3.1 and SCL3.2 are scheduled to be carried out after all the proposed dredging works for CWB within the CBTS are fully completed.

11.80 One modelling scenario was proposed under the separate EIA Study for SCL Protection Works at CBTS to assess the water quality impact during the seawall dredging along PW1.1 within the CBTS. This scenario assumed that dredging along the southern seawall of PW1.1 would take place after the formation of TS4 and TS1, and hence, a temporary embayment would be formed at the southwest corner of the CBTS where Intake 8 is located. Based on the tentative programme, TS1 would already be removed when dredging at PW1.1 is carrying out. TS1 was however assumed to be in place under the modelling exercise, which would be a conservative assumption in terms of the flushing impact at CBTS. Under this scenario, dredging will be carried out within this temporary embayment at the maximum dredging rate of 6,000m3 per day, which would be the worst case in terms of the tidal circulation at the southwest corner of the CBTS and potential impact upon Intake 8. Impact from dredging along the seawall of TS4 would be less critical as the dredging work would be conducted before formation of any temporary seawall within the CBTS which would result in a better tidal flushing. Water quality impact from seawall dredging at TS4 (before formation of any temporary reclamation within the CBTS) had been fully assessed under the approved EIA for WDII and CWB to be acceptable. Impact from dredging at TS4 Ext. would also be less critical and the dredging work would be undertaken in a more open area with better flushing and dispersion capacity. Details of this assessment scenario and model result are presented in the separate EIA Report for SCL Protection Works at CBTS which showed that the marine construction works would not result in adverse water quality impact in the CBTS as well as the open harbour.

11.81 Impact during the seawall dredging work for the remaining dredging phases (i.e. PW1.3, SCL2, SCL3.1 and SCL3.2) would be less critical as the dredging locations would be further away from the cooling water intakes than PW1.1. In particular, impact upon cooling water intakes during the dredging for SCL2 would be shielded by the breakwater of CBTS. In addition, the pollution loading from Culvert Q was significantly larger than that from the other storm outfalls within the CBTS (based on the field survey results available from the approved WDII & CWB EIA) and this culvert would be diverted to the north of TS3(W) during the dredging work at SCL2. Thus, less pollutant will be discharged into the temporary embayments where the seawater intakes are located, which would reduce the background SS level at the intake points. Therefore, no significant adverse impact would be expected from the seawall dredging at SCL2, SCL 3.1 and SCL3.2.

11.83

Dredging of marine mud at the southeast corner

of CBTS for relocation of mooring space is tentatively scheduled to be

undertaken in 2012. The total dredging rate within the CBTS shall not exceed

6,000m3 per day at any time as recommended in Table

11.24. As

discussed under the separate EIA for SCL Protection Works at CBTS, dredging is

assumed to be undertaken at PW1.1 at the maximum dredging rate of 6,000m3

per day inside the temporary

embayment close to Intake 8, which would represent a worst case in terms of the

potential impact upon the seawater intakes due to the dredging activities for

SCL within the CBTS. As the distance between the dredging area for relocation

of mooring space and the nearest seawater intake point would be greater than

the distance between PW1.1 and the nearest intake point assumed under the EIA

for SCL Protection Works at CBTS (see Plate

1 under Section 11.69), dredging for relocation of mooring space would

not be worse than dredging at PW1.1 assumed under the EIA for SCL Protection Works

at CBTS in terms of the potential impact upon the intake points. In case

dredging at the southeast corner of CBTS for relocation of mooring space and

dredging at PW1.1 to PW1.4 are required to work concurrently within the CBTS,

the total maximum dredging rate of 6,000m3 per day as

stipulated in Table

11.24 would still be maintained within the CBTS, i.e. the combined production

rate for the dredging work at TS1, TS4, TS4 Ext., PW1.1 to PW1.4, TS2,

TS3(W), TS3(E), SCL2, SCL3.1 and SCL3.2 (for tunnel construction) and the

dredging work at the southeast corner of CBTS (for relocation of mooring space)

would not exceed 6,000m3 per day.

Water Quality in Temporary Embayments within the CBTS

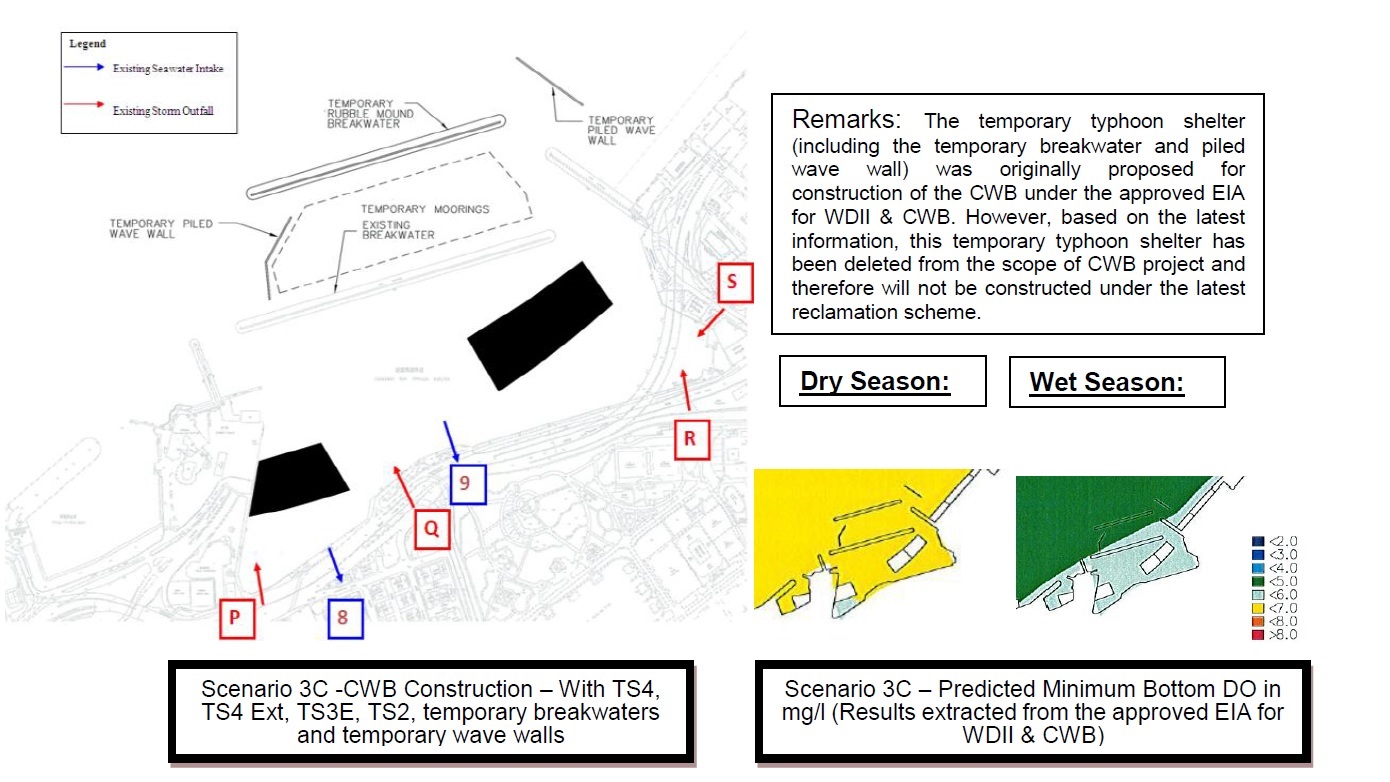

11.85 Because of the relatively low flushing capacity, the interim construction phase water quality of the temporary embayments at the existing CBTS is of particular concern. However, there is no biological sensitive receiver within the CBTS and there are no areas of conservation value, ecological importance or mariculture activities in the vicinity. The only water sensitive receivers inside the CBTS would be the cooling water intakes (namely Intakes 8 and 9) with no water quality (e.g. suspended solids) requirements. Therefore, the key concern would be the accumulation of pollutants discharged from the polluted storm culverts within any temporary embayment formed from the temporary reclamations, potentially causing an increase in the dissolved oxygen (DO) demand and, in turn, potential DO depletion and odour impacts.

11.86 In

2013 (i.e. when TS2, TS4, TS4 Ext. and PW1.1 to 1.4 will be in place

simultaneously) would be the worst-case scenario in terms of the water quality

impact, considering that these land formations would create a temporary

embayment at the southwest corner of the CBTS inside which a storm outfall,

namely Culvert P, and a cooling water intake, namely Intake 8, are located

close to each other. Potential

water quality impact associated with the accumulation of pollutants discharged

from the storm culverts into the temporary embayment was modelled under the

approved WDII & CWB EIA for one interim construction scenario (namely

Scenario 3C). This scenario assumed

that TS4, TS4 Ext, TS2 and TS3(E) as well as a temporary typhoon shelter

(including a temporary breakwater and piled wave wall) outside the existing

CBTS (the temporary typhoon shelter has been deleted from the scope of CWB

project, see remarks in the figure below) would be in place at the same time,

which represented a very worse case in terms of the water circulation in CBTS as

shown in the figure below.

11.87 As shown by EPD’s routine marine water quality monitoring data, the existing DO levels measured in the CBTS fully comply with the WQO and potential DO depletion inside the CBTS is not a concern. The model results available from the approved EIA for WDII and CWB also indicated that the DO levels would not be significantly depleted inside the embayments formed by the temporary reclamations. The predicted minimum DO levels were all > 5 mg/L (see figure above) which means full compliance with the WQOs.

11.88 As compared to Scenario 3C simulated under the approved WDII & CWB EIA, changes in the land configuration in 2012 proposed under the latest reclamation scheme would involve a relatively small amount of additional temporary land for PW1.1, PW1.3 and PW1.4, which could slightly reduce the flushing capacity in the CBTS, but on the other hand, the temporary breakwaters and wave walls assumed under the approved EIA will not be implemented under the current scheme (better flushing effect would be achieved in the CBTS with no temporary breakwaters and wave walls). Also, TS3(E) assumed under Scenario 3C of the approved EIA would not be in place during 2013 under the current reclamation sequence. The proposed changes in land configurations under the current reclamation scheme are considered minor in terms on their overall impact on the flushing capacity in the CBTS and would unlikely affect the conclusion of the model results available from the approved WDII & CWB EIA for the interim construction scenario. A water quality monitoring and audit programme will be implemented during the construction phase to avoid aggravation of odour nuisance from seawater arising from temporary reclamation in the CBTS. In case the temporary reclamation work for the Project is found during the water quality monitoring and audit programme to cause unacceptable oxygen depletion (e.g. DO level <2 mg/L) in the CBTS, additional water quality improvement measures (e.g. use of aeration method to improve the DO levels in the marine embayment) will be considered and implemented in the CBTS as necessary to rectify the problems. Details of the water quality monitoring and audit programme including the Event and Action Plan are provided in the standalone EM&A Manual for this Project.

11.89 Another worst case scenario would occur in 2016 when PW1.4, SCL2, SCL3.1 and TS3(W) will be in place at the same time. This scenario is however considered less critical as Culvert Q (with the largest pollution loading amongst the other outfalls) will be temporarily diverted to the north of TS3(W) before the seawall of TS3(W) is completely constructed. Thus, less pollutant will be discharged into the temporary embayments where the cooling intakes are located. In addition, this temporary land configuration would create two openings close to the storm outfalls (Culverts P, R and S). Thus, more water circulation at the storm outfalls would be expected under this scenario when compared to the early reclamation stage.

11.90 SCL3.1 and SCL3.2 (which would be potentially in place in 2017) will be less critical as their configurations will allow more open waters flushing near the storm culverts and they will be carried out in phase to minimize the pollution loads to the nearby waters. Also, TS3(W) and TS3(E) will be completely removed before commencement of SCL3.2 and the associated pollutant dispersion effects would not be worse than that under Scenario 3C (see figure above). Hence the potential concern on DO depletion is not expected. Therefore, no significant water quality impact will be created from the SCL works.

Dredging for Relocation of Mooring Space within CBTS

11.91

Dredging would be undertaken at the eastern

part of the CBTS tentatively in 2012 for relocation of mooring space. The

proposed dredging extent is shown in Plate

1 under Section 11.69. The total dredging rate within the CBTS

shall not exceed 6,000m3 per day at any time. In case dredging at the southeast

corner of CBTS for relocation of mooring space and dredging for SCL and CWB

tunnel construction are required to work concurrently within the CBTS, the

total maximum dredging rate of 6,000m3 per day would still be maintained within the

CBTS (refer to Section

11.82).

Silt curtain would be installed around the dredging operation to

minimize the release of sediments. As previously mentioned, the closest water

sensitive receivers to the proposed works would be the cooling water intakes

for Excelsior Hotel and World Trade Centre (namely Intake 8) and Windsor House

(namely Intake 9) as shown in Plate 1

above. The sediment plume modelling scenario assessed under the separate EIA

Study for SCL Protection Works at CBTS already represented the worst case in

terms of the potential water quality impact within the CBTS assuming a maximum

dredging rate of 6000m3 per day. The sediment source assumed under

that EIA was located near PW1.1, which is approximately 50m away from Intake 8

(see Plate 1 above) and both the

source point and the intake point would be located in a temporary embayment

with low flushing capacity. This considered being a highly conservative

assumption since the dredger would not ever be stationary at the same location

close to the intake point. It

should be noted that the nearest distance of Intake 8 from PW1.1 (i.e. 50m) as

shown in Plate 1 above has already

taken account of the maximum temporary reclamation extent proposed for the

tunnel construction at CBTS. On the other hand, dredging for relocation of

mooring space at the eastern part of CBTS would result in the same total

effective sediment loss rate but the sediment source would be further away from

the nearest cooling water intake (i.e. Intake 9), see Plate 1 above. Therefore, the water quality impacts upon Intake 9

due to the dredging work for relocation of mooring space would not be worse than

that upon Intake 8 due to the dredging works for PW1.1. Hence, no additional modelling scenario

is necessary for dredging at the southeast corner of the CBTS for relocation of

mooring space. Similarly, the concurrent dredging for TS2 (which is not

SCL activity) would be carried out at a more open marine environment while the

minimum distance from the closest WSR (Intake 9) is about 65m. Given that the

maximum dredging rate within the CBTS will be maintained at 6,000 m3

per day, the assumed modelling scenario in the EIA for SCL Protection Works at

CBTS would already represent the worst case water quality impact and therefore

no additional modelling scenario will be required for assessing the dredging

for relocation of mooring space in CBTS. No unacceptable water quality impact was predicted due to the

dredging for mooring space in CBTS in the EIA for SCL Protection Works at CBTS.

Dredging for SCL2 and IMT Construction in

11.92 The key water quality impact from the IMT construction would be associated with the bulk dredging and bulk filling activities in the open harbour, which would be conducted in the period from 2016 to 2017. The proposed IMT alignment would run across the open harbour from the HUH side to an area just outside the existing CBTS breakwater. Dredging for SCL2 (refer to Plate 1 under Section 11.69) will also be undertaken outside the CBTS in the open harbour and would potentially take place in 2015. The key water quality impact for the Project would be the proposed dredging and filling activities in the open harbour area with cumulative impacts from other possible concurrent marine works.

11.93 Bulk dredging along the IMT alignment would be undertaken as the first stage. Laying of the tunnel segment would be carried out in the subsequent stage. Bulk filling along the IMT alignment would be conducted after laying of the tunnel segment is completed. As the proposed IMT tunnel construction would be relatively large in scale, it was assumed that laying of the tunnel segment could be conducted together with the bulk filling operation. Based on the tentative construction programme, bulk filling along the IMT tunnel alignment would be carried out after all the bulk dredging works are completed. Hence, bulk dredging and bulk filling along the IMT alignment would not occur at the same time. Bulk dredging is considered more critical activity as it would potentially release sediment-bound contaminants and is therefore assumed for water quality modelling purpose.

11.95 Any

potential blasting work, if required, would be undertaken after completion of

the dredging works required for the IMT construction. The marine sediments at or near the

blasting area would be removed prior to the blasting work. Activities associated with the

underwater blasting works include the preparation of drilling holes within

which the charges are placed and firing the charges. Fragment rock will then be removed by

grab dredger. The diameter of the resulting materials will be large and as such

no off-site migration of fines is expected.

Consideration of Possible Water Quality Mitigation Measures

11.96 Silt

curtains should not be used in areas where current speeds are high, as the

effectiveness of the silt curtains will be reduced in areas of high current

speeds. Thus, silt curtains are

considered less effective to mitigate the SS impacts in the middle of the

11.97 Deployment of floating type silt curtain would be practical for dredging and sand filling operations within the embayed area or in near shore region near the coastline where the water currents would be relatively small. The northern section of the IMT tunnel would be constructed in close proximity to the cooling water intakes along the Hung Hom landfall (refer to Figure No. NEX2213/C/331/ENS/M59/003) but these cooling water intakes are considered to have high SS tolerance. Nevertheless, the bulk dredging and sand filling work at the northern tunnel segment (close to the Hung Hom landfall) would be undertaken in sequence rather than operated concurrently to minimize the dredging impact. Following the approach of temporary reclamation inside the CBTS which would also be conducted close to the cooling water intakes, it is recommended that installation of floating type or frame type silt curtain around the closed grab dredger and deployment of silt screen at the nearby cooling water intakes should be implemented for construction of the IMT segment in the near shore region (e.g. within 200m from the Hung Hom landfall) to minimize the potential water quality impacts. Deployment of floating type silt curtain in the offshore waters near the fairway would be less effective and therefore only the frame type silt curtain would be recommended for the dredging works in the offshore waters near the fairway. In view that the implementation of silt curtain around the closed grab dredgers would reduce the dispersion of SS and implementation of silt screen at the intake could further reduce the SS level at the intake, no significant overall water quality impacts would be expected from the IMT construction in the near shore region or close to the Hung Hom landfall.

11.98

The following precautionary / mitigation measures will be adopted to

minimize the potential water quality impacts from the underwater blasting work,

if required:

Ÿ Charge will be placed in cores within the rock in order that there will be no blast directly into the water. The shock wave pressures will be reduced as much as possible;

Ÿ In terms of the construction sequence, sediment dredging (within the planned IMT works area) will be conducted prior to underwater blasting. Entrainment of suspended solids can then be minimized during the underwater blasting.

Other Possible Concurrent Projects

11.99 With reference to the EIA Study Brief, the assessment area shall include the Victoria Harbour Water Control Zone (WCZ), the Eastern Buffer WCZ and the Western Buffer WCZ as declared under the Water Pollution Control Ordinance (WPCO), and any areas within a distance of 300m from the Project boundary and from any works sites. Other possible concurrent dredging and filling activities within the assessment area such as those for the construction of the proposed WDII & CWB and the Kai Tak Development (KTD) as well as the Installation of Submarine Gas Pipelines from Ma Tau Kok to North Point for Former Kai Tak Airport Development (New Submarine Gas Main) have been considered in the water quality assessment.

Wan Chai Development Phase II (WDII) and Central-Wan Chai Bypass (CWB)

11.100 Based on the latest design information available from the project “WDII – Design and Construction for Trunk Road Tunnel Option under SA2 to Agreement No. CE 54/2001” and the project “Design & Construction of CWB / IEC Link under SA3 to Agreement No. CE8/95”, the proposed marine construction works for WDII and CWB will involve:

Ÿ Permanent reclamation at Hong Kong Convention and Exhibition Centre (HKCEC)

Ÿ Permanent reclamation at Wan Chai (WCR)

Ÿ Permanent reclamation at North Point (NPR)

Ÿ Temporary reclamation at Public Cargo Working Area (TPCWA) and Causeway Bay (TCBR) for construction of the CWB tunnel

Ÿ Construction of new cross-harbour water mains from Wan Chai to Tsim Sha Tsui

Ÿ Construction of Wan Chai East submarine sewage outfall

Ÿ The odour mitigation works at the south-western corner of CBTS

11.101 The following measures have been implemented in the design of reclamation phasing to ensure the continuous operation of the existing waterfront facilities and, simultaneously, to minimize the impacts on water quality:

Ÿ a number of small and confined areas of land formation are planned;

Ÿ containment of fill within each of these confined areas by seawalls is proposed, with the seawall constructed first (above high water mark) with filling carried out behind the completed seawalls. Any gaps that may need to be provided for marine access will be shielded by silt curtains to control sediment plume dispersion away from the site. Filling should be carried out behind the silt curtain.

11.102 Therefore, potential water quality impact of SS would only arise during the dredging for seawall foundation. There will be a total of five main reclamation shoreline zones, namely HKCEC, WCR, NPR, TPCWA and TCBR respectively. Each of these reclamation shoreline zones, except for the TCBR, is subdivided into different stages as indicated in Table 11.8 below. The TCBR for construction of the CWB tunnel inside the CBTS would be combined with the SCL tunnel construction as detailed in Sections 11.67 to 11.98 and Table 11.24 above and is therefore not further described in this section. Within the same reclamation zone, seawall dredging will be performed in sequence instead of operating concurrently. Thus, dredging along the seawall will be undertaken for only one stage at a time to minimize the potential water quality impacts within each reclamation zone. The indicative programme for seawall dredging works at different stages of the WDII and CWB construction are also provided in Table 11.8 below. The layout of different reclamation stages for HKCEC, WCR and NPR as well as the locations of the proposed water mains and sewage outfall would follow those presented in Figure 2.7 of the approved WDII & CWB EIA[4]. Layout of the revised temporary reclamation scheme inside CBTS is indicatively presented in Plate 1 above.

11.103 Dredging will be carried out by closed grab dredger for the following works:

Ÿ Seawall construction in all the reclamation shoreline zones (HKCEC, WCR, NPR, TPCWA)

Ÿ Construction of the proposed water mains

Ÿ Construction of the proposed sewage outfall

11.104 Deployment of silt curtains around the closed grab dredgers to contain SS within the construction site during seawall dredging and seawall trench filling is recommended for the areas of HKCEC, WCR and NPR. Based on the water quality modelling and assessment result, deployment of silt curtains is considered not necessary for the dredging works at TPCWA.

11.105 The maximum dredging rates recommended for different marine works zones are given in Table 11.8. The dredging rate and mitigation measures recommended for the TCBR are detailed in Sections 11.67 to 11.98 and are therefore not repeated in this section. It should be noted that the dredging rates listed in Table 11.8 have not considered the effect of silt curtains as recommended for HKCEC, WCR and NPR. The dredging work for Wan Chai Reclamation and HKCEC reclamation under the WDII Project would be potentially concurrent with the dredging work proposed for the SCL Protection works and the associated cumulative water quality impact has been fully assessed under the separate EIA for SCL Protection Works at CBTS. The temporary reclamation works in CBTS for construction of the CWB and SCL, as discussed in Sections 11.67 to 11.98, would potentially be concurrent with the IMT construction proposed under this Project and hence would be included in Scenario 1 of this water quality modeling to assess their cumulative water quality impact.

Table 11.8 Tentative Programme and Recommended Maximum Dredging Rates for WDII and CWB

|

Reclamation Zone |

Tentative Programme |

Maximum Dredging Rate |

||

|

m3 per day |

m3 per hour |

m3 per week |

||

|

Dredging along seawall or breakwater |

||||

|

North Point Reclamation (NPR) Shoreline

Zone |

||||

|

NPR Stage 1 |

2010 |

6,000 |

375 |

42,000 |

|

NPR Stage 2 West |

2010 |

6,000 |

375 |

42,000 |

|

NPR Stage 2 East |

2011 |

6,000 |

375 |

42,000 |

|

Temporary Public Cargo Working Area (TPCWA) Reclamation

Shoreline Zone |

||||

|

TPWCA East |

2010 |

5,000 |

313 |

35,000 |

|

TPWCA West |

2013 |

5,000 |

313 |

35,000 |

|

Wan Chai Reclamation (WCR) Shoreline Zone |

||||

|

WCR Stage 1 See Note (3) |

2010 |

1,500 |

94 |

10,500 |

|

WCR Stage 2 |

2012 |

6,000 |

375 |

42,000 |

|

WCR Stage 3 |

2013 |

1,500 |

94 |

10,500 |

|

WCR Stage 4 |

2013 |

6,000 |

375 |

42,000 |

|

|

||||

|

HKCEC Stage 1 |

2010 |

1,500 |

94 |

10,500 |

|

HKCEC Stage 2 |

2012 |

6,000 |

375 |

42,000 |

|

HKCEC Stage 3 |

2012 |

1,500 |

94 |

10,500 |

|

Dredging along pipelines |

||||

|

Cross Harbour Water Mains |

2010 –2011 |

1,500 |

94 |

10,500 |

|

Wan Chai East Submarine Sewage Pipeline |

2010 |

1,500 |

94 |

10,500 |

Note:

1. Dredging to be carried out by closed grab dredger (16 hours per day).

2. Silt curtains to be deployed around seawall dredging and seawall trench filling in NPR, WCR and HKCEC areas.

3. Reduced dredging rates of 1,500 m3 per day are applicable to construction of the western seawall of WCR Stage 1 which is close to the WSD Wan Chai intake. For construction of the remaining seawalls of WCR Stage 1, the maximum dredging rate of 6,000 m3 per day will be applied.

Dredging Works for Proposed Cruise Terminal at Kai Tak (CT Dredging)

11.106

Development of the proposed Kai Tak Cruise

Terminal would require dredging at the existing seawall at the southern tip of

the former

11.107

The maximum dredging rate recommended during the

Stage 1 dredging period would be 8,000 m3 per day (including the dredging

of 4,000 m3 per day at or near the seawall for berth construction

using 2 closed grab dredgers plus the dredging of 4,000 m3 per day