Advanced Incineration Technology

Incineration is a thermal treatment technology used to reduce the volume of waste requiring final disposal. Incineration can typically reduce the waste volume by over 90% and it is one of the widely used technologies for treating municipal solid waste prior to disposal at landfills. Most modern incineration plants incorporate heat recovery as well as power generation facilities to recover the heat energy in the waste.

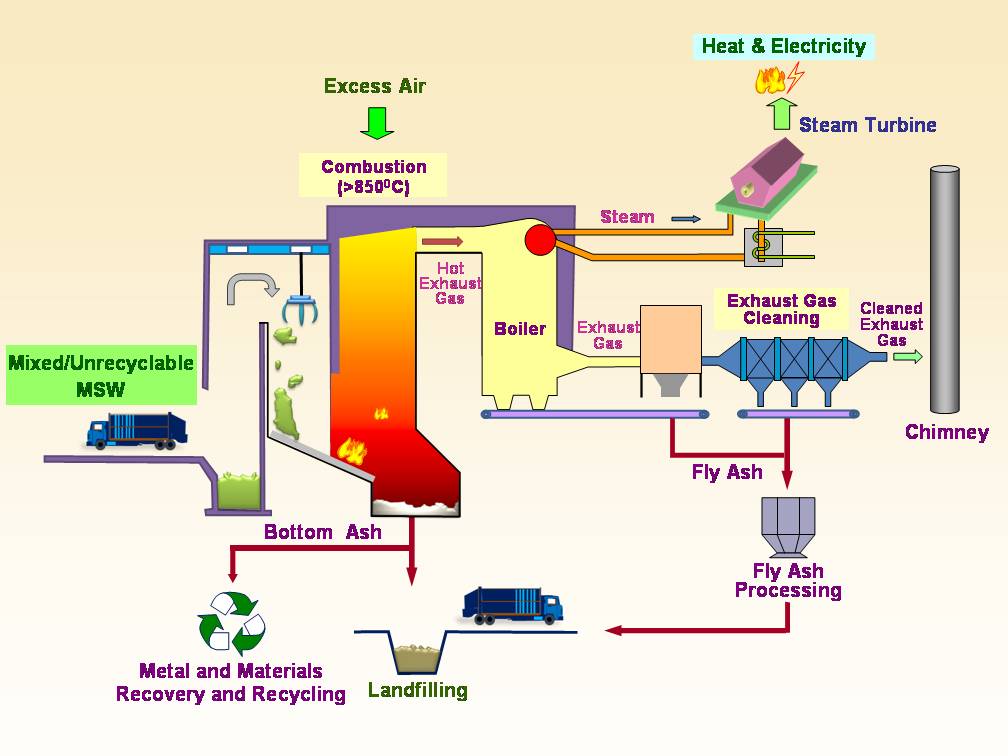

To ensure that the gas emissions meet the stringent standards imposed by regulatory bodies (e.g. EU Waste Incineration Directive) for public health and environmental protection, modern incineration plants adopt a number of advanced design and process controls as well as exhaust gas cleaning measures as illustrated by the flow chart below:

Typical incineration flow chart

Combustion - Waste is continuously fed into the furnace by an overhead crane. In the specially designed furnace, municipal solid waste will be combusted at high temperature of 850oC or above with the sufficient supply of air. Flue gas should also be combusted at this high temperature for at least 2 seconds. The above measures are to ensure complete combustion of municipal solid waste and to breakdown organic compounds (including dioxins).

Boiler/ steam turbine - The heat from the combustion is used to generate steam in the boiler. The steam then drives the turbine which is coupled to the electricity generator. The excess heat generated can also be used for other purposes, e.g. heat for swimming pool.

Exhaust gas cleaning - The exhaust gas from the boiler is typically cleaned by the following advanced pollution control systems to ensure compliance with the stringent environmental standards:

l Dry or Wet scrubbers – to spray lime powder or fine atomized slurry into the hot exhaust gas to neutralize and remove the polluted acidic gases (sulphur oxides, hydrogen chloride)

l Activated Carbon Injection – to adsorb and remove any heavy metal and organic pollutants (e.g. dioxins) in the exhaust gas

l Bag house filter - to filter and remove dust and fine particulates

l Selective Non-Catalytic Reduction - to remove nitrogen oxides (which is a cause of urban smog) by reacting them with ammonia or urea.

Ash residues handling - The ash residues from incineration generally include bottom ash from the furnace and fly ash from the exhaust gas cleaning units. The bottom ash is either reused as construction material or disposed of at landfills. Fly ash is typically stabilized and solidified by reagents (e.g. cement) and disposed of at dedicated landfill with continuous environmental monitoring. Ash melting that use the heat energy in the incinerator to melt the ash residues at a high temperature is a technology used in some place. The melted products are inert and contain no hazardous materials so that they may be re-used (e.g. as construction material). Comparatively ash melting is more expensive but it has the advantages of further volume reduction and fixation of any hazardous materials in the fly ash.