6

Waste management

6.1

Introduction

The Project involves the demolition of existing

facilities and retrofitting of emissions control facilities to four existing

677MW generating units of CPB. This

section identifies the potential wastes arising from the Project and assesses

the potential environmental impacts associated with waste handling and

disposal. The main issues are:

· disposal of

dredged sediments;

· handling and

treatment of contaminated soil;

· disposal of

construction and demolition (C&D) materials () arising from the

demolition, excavation and construction works; and

· management of

by-products produced from the FGD process.

Opportunities for waste minimisation, recycling,

storage, collection, transport and disposal have been examined and procedures

for waste reduction and management have been proposed.

6.2

Legislative

Requirements and Evaluation Criteria

The following discussion on legislative

requirements and evaluation criteria applies to both the construction and

operational phases of the Project.

The criteria and guidelines for evaluating

potential waste management implications are laid out in Annexes 7 and 15 of the EIAO-TM under the EIAO.

The following legislation covers, or has some

bearing upon, the handling, treatment and disposal of wastes in Hong Kong, and will also be considered in the assessment.

· Waste Disposal Ordinance (Cap 354);

· Waste Disposal (Chemical Waste) (General) Regulation (Cap 354C);

· Land (Miscellaneous Provisions) Ordinance (Cap 28);

· Public Health and Municipal Services Ordinance (Cap 132) - Public Cleansing and Prevention of Nuisances Regulation; and

· Dumping at Sea Ordinance (Cap 466).

6.2.1

Waste Disposal Ordinance (Cap

354)

The Waste

Disposal Ordinance (WDO) prohibits the unauthorised disposal of wastes,

with waste defined as any substance or article, which is abandoned. Under the WDO, wastes can only be disposed of at a licensed site. A breach of these regulations can lead

to the imposition of a fine and/or a prison sentence. The WDO

also provides for the issuing of licences for the collection and transport

of wastes. Licences are not,

however, currently issued for the collection and transport of construction

waste or trade waste.

The Waste

Disposal (Charges for Disposal of Construction Waste) Regulation defined

construction waste as any substance, matters or things that is generated from

construction work and abandoned, whether or not it has been processed or

stockpiled before being abandoned, but does not include any sludge, screening

or matter removed in or generated from any desludging,

desilting or dredging works.

The Construction Waste Disposal

Charging Scheme entered into operation on 1 December 2005. Starting from 1 December 2005, the main

contractor who undertakes construction work under a contract with value of $1

million or above is required to open a billing account solely for the

contract. Application should be

made within 21 days after the contract is awarded.

For construction work under a contract with value less than $1 million,

such as minor construction or renovation work, any person such as the owner of

the premises where the construction work takes place or his/her contractor can

open a billing account; the account can also be used for contracts each with

value less than $1 million. The

premises owner concerned may also engage a contractor with a valid billing

account to make arrangement for disposal of construction waste.

Under the new construction waste charging scheme, charging for disposal

of construction waste started on 20 January 2006 and therefore will apply to

this Project.

Depending on the percentage of inert materials in the construction

waste, construction waste can be disposed at public fill, sorting facilities, landfills

and outlying islands transfer facilities where different disposal cost would be

applied. The scheme encourages

reducing, reusing and sorting of construction waste such that the waste

producer can minimise their disposal fee.

Table 6.1 presents a summary

of the government construction waste disposal facilities, types of waste

accepted and disposal cost.

Table 6.1 Government

Waste Disposal Facilities for Construction Waste

|

Government Waste Disposal Facilities

|

Type of Construction Waste Accepted

|

Charge Per Tonne

|

|

Public fill reception facilities

|

Consisting entirely of inert construction

waste

|

$27

|

|

Sorting facilities

|

Containing more than 50% by weight of

inert construction waste

|

$100

|

|

Landfills

|

Containing not more than 50% by weight of

inert construction waste

|

$125

|

|

Outlying Islands

Transfer Facilities

|

Containing any percentage of inert

construction waste

|

$125

|

6.2.2

Waste Disposal (Chemical Waste)

(General) Regulation (Cap 354C)

Chemical waste as defined under the Waste Disposal (Chemical Waste) (General)

Regulation includes any substance being scrap material, or unwanted

substances specified under Schedule 1

of the Regulation, if such a substance

or chemical occurs in such a form, quantity or concentration so as to cause

pollution or constitute a danger to health or risk of pollution to the

environment.

A person should not produce,

or cause to be produced, chemical wastes unless he is registered with the

EPD. Producers of chemical wastes

must treat their wastes, utilising on-site plant licensed by the EPD or have a

licensed collector take the wastes to a licensed facility. For each consignment of wastes, the

waste producer, collector and disposer of the wastes must sign all relevant

parts of a computerised trip ticket.

The system is designed to allow the transfer of wastes to be traced from

cradle-to-grave.

The Regulation

prescribes the storage facilities to be provided on site including labelling

and warning signs. To minimise the

risks of pollution and danger to human health or life, the waste producer is

required to prepare and make available written procedures to be observed in the

case of emergencies due to spillage, leakage or accidents arising from the

storage of chemical wastes as well as provide employees with training in such

procedures.

6.2.3

Land (Miscellaneous

Provisions) Ordinance (Cap 28)

The inert portion of C&D materials (also

called public fill) may be taken to public filling facilities. Public filling areas usually form part

of land reclamation schemes and are operated by the Civil Engineering and

Development Department (CEDD) and others.

The Land (Miscellaneous

Provisions) Ordinance requires that individuals or companies who deliver

public fill to the public filling facilities obtain Dumping Licences from the

CEDD.

Under the licence conditions, public filling

areas will accept only inert building debris, soil, rock and broken

concrete. There is no size limit on

rock and broken concrete, and a small amount of timber mixed with inert

material is permissible. The

material should, however, be free from marine mud, household refuse, plastic,

metal, industrial and chemical wastes, animal and vegetable matter and any

other materials considered unsuitable by the public filling supervisor.

6.2.4

Public Health and Municipal

Services Ordinance (Cap 132) - Public Cleansing and Prevention of Nuisances

Regulation

This Regulation

provides a further control on the illegal dumping of wastes on unauthorised

(unlicensed) sites. The illegal

dumping of wastes can lead to a fine and imprisonment.

6.2.5

Dumping at Sea Ordinance (Cap

466)

This Ordinance

came into operation in April 1995 and empowers the Director of

Environmental Protection to control the disposal and incineration of substances

and articles at sea for the protection of the marine environment. Under the Ordinance, a permit from the Director of Environmental Protection

is required for the disposal of regulated substances within and outside the

waters of the Hong Kong SAR. The

permit contains terms and conditions that includes the following

specifications:

· Type and quantity

of substances to be dumped;

· Location of the

disposal grounds;

· Requirements of

equipment for monitoring the disposal operations; and

· The need for

environmental monitoring.

Management of

Dredged/Excavated Sediments for Marine Disposal

Marine disposal of any dredged/excavated sediment is subject to control

under the Dumping at Sea Ordinance

1995. The Ordinance has replaced the Dumping

at Sea Act 1974 (Overseas

Territories) Order 1975

(App. III p. DK1) in its application in Hong Kong SAR. In addition, dredged/excavated sediment destined

for marine disposal is classified based on its contaminant levels with

reference to the Chemical Exceedance Levels (CEL), as stipulated in ETWBTC No. 34/2002: Management of Dredged/Excavated Sediment. This Technical Circular includes a set

of sediment quality criteria, as presented in Table 6.2, which includes heavy metals and metalloids, organic

pollutants and a class of contamination level for highly contaminated sediment

not suitable for marine disposal.

Table 6.2 Dredged/Excavated

Sediment Quality Criteria for the Classification under the ETWBTC No 34/2002

|

Contaminants

|

Lower Chemical

Exceedance Level (LCEL)

|

Upper Chemical

Exceedance Level (UCEL)

|

|

Metals

(mg kg-1 dry weight)

|

|

Cd

|

1.5

|

4

|

|

Cr

|

80

|

160

|

|

Cu

|

65

|

110

|

|

Hg

|

0.5

|

1

|

|

Ni (a)

|

40

|

40

|

|

Pb

|

75

|

110

|

|

Silver (Ag)

|

1

|

2

|

|

Zinc (Zn)

|

200

|

270

|

|

Metalloid

(mg kg-1 dry weight)

|

|

Arsenic (As)

|

12

|

42

|

|

Organic-PAHs (mg

kg-1 dry weight)

|

|

Low Molecular Weight (LMW) PAHs

|

550

|

3,160

|

|

High Molecular Weight (HMW) PAHs

|

1,700

|

9,600

|

|

Organic-non-PAHs (mg

kg-1 dry weight)

|

|

Total PCBs

|

23

|

180

|

|

Organometallics

(mgTBT l-1 in interstitial water)

|

|

Tributyl-tin (a)

|

0.15

|

0.15

|

|

Note:

(a)

The

contaminant level is considered to have exceeded the UCEL if it is greater

than the value shown.

|

In accordance with ETWBTC 34/2002, the sediment is classified

into three categories based on its contamination levels:

Category L : Sediment

with all contaminant levels not exceeding the LCEL. The material must be dredged,

transported and disposed of in a manner which minimises the loss of

contaminants either into solution or by re-suspension.

Category M : Any one or more contaminants in the sediment exceed the - the LCEL

and none exceeding the UCEL. The

material must be dredged and transported with care, and must be effectively

isolated from the environment upon final disposal unless appropriate biological

tests demonstrate that the material will not adversely affect the marine

environment.

Category H : Any one or more contaminants in the sediment exceed the

exceeding the UCEL. The material

must be dredged and transported with great care, and must be effectively

isolated from the environment upon final disposal.

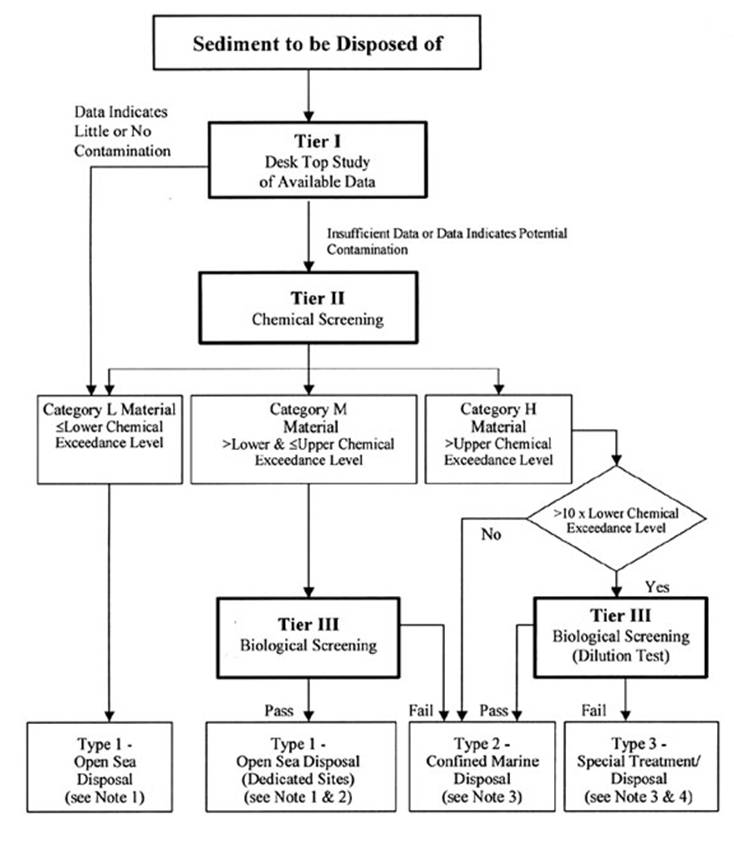

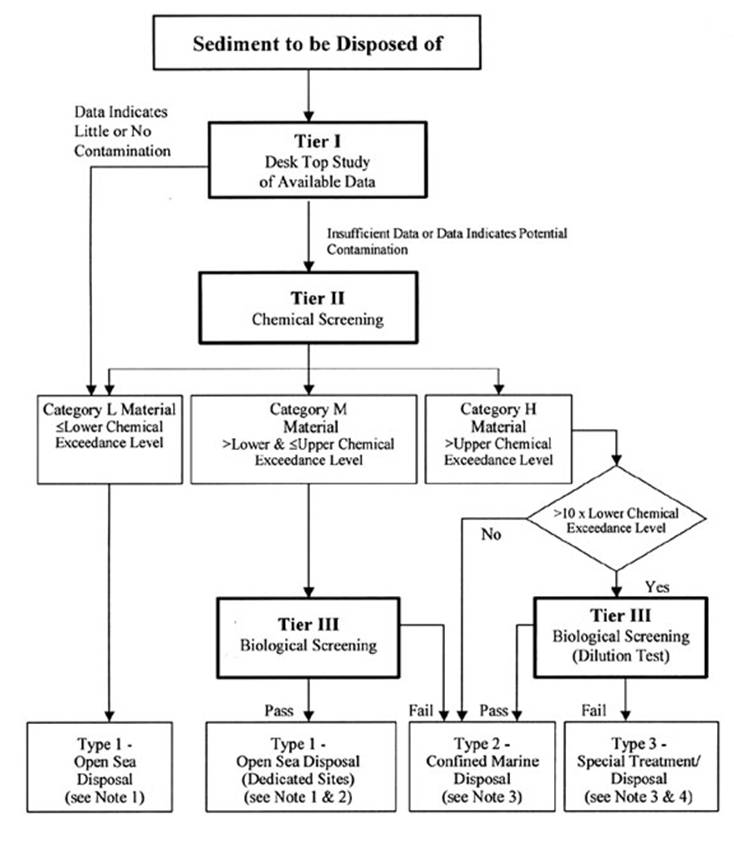

Figure 6.1 summarises the sediment classification and disposal

arrangements. EPD will base on the

sediment and biological test results to determine the most appropriate disposal

site (eg open sea or confined marine disposal site).

Figure 6.1 Management

Frameworks for Dredged/Excavated Sediment

Notes:

(a) Most open

sea disposal sites are multi-user facilities and as a consequence their management

involves a flexibility to accommodate varying and unpredictable circumstances.

Contract documents should include provisions to allow the same degree of

flexibility should it be necessary to divert from one disposal site to another

during the construction period of a contract.

(b) Dedicated

Sites will be monitored to confirm that there is no adverse impact.

(c) For

sediment requiring Type 2 or Type 3 disposal, contract documents should state

the allocation conditions of Marine Fill Committee (MFC) and DEP. At present,

East Sha Chau Mud Pits are

designated for confined marine disposal.

(d) If any

sediment suitable for Type 3 disposal (Category H sediment failing the

biological dilution test) is identified, it is the responsibility of the

project proponent, in consultation with DEP, to identify and agree with

him/her, the most appropriate treatment and/or disposal arrangement. Such a

proposal is likely to be very site and project specific and therefore cannot be

prescribed. This will not preclude treatment of this sediment to render it

suitable for confined marine disposal.

(e) The

allocation of disposal space may carry a requirement for the project proponent

to arrange for chemical analysis of the sediment sampled from 5% of the vessels

en-route to the disposal site. For Category M and certain Category H sediment,

the chemical tests will be augmented by biological tests. Vessel sampling will

normally entail mixing five samples to form a composite sample from the vessel

and undertaking laboratory tests on this composite sample. All marine disposal

sites will be monitored under the general direction of the CEDD. However,

exceptionally large allocations might require some additional disposal site

monitoring. These will be stipulated at the time of allocation.

(f)

Trailer suction hopper dredgers disposing

of sediment at the East Sha Chau

Mud Pits must use a down-a-pipe disposal method, the design of which must be

approved in advance by Director of the CEDD. The dredging contractor must

provide equipment for such disposal.

Source: Appendix C, ETWBTC 34/2002

6.2.6

Other Relevant Guidelines

Other ‘guideline’ documents, which detail how

the works contractor should comply with the WDO and its associated regulations,

are as follows:

· Waste Disposal Plan for Hong Kong (December 1989),

Planning, Environment and Lands Branch Government Secretariat, Hong Kong Government;

· Chapter 9 Environment (1999), Hong Kong Planning

Standards and Guidelines, Hong Kong

Government;

· New Disposal Arrangements for Construction Waste (1992), EPD &

CEDD, Hong Kong Government;

· Code of Practice on the Packaging, Labelling and

Storage of Chemical Wastes (1992), EPD, Hong Kong

Government.

· Works Branch Technical Circular (WBTC) No. 32/92, The

Use of Tropical Hard Wood on Construction Site; Works Branch, Hong Kong Government;

· WBTC No. 2/93, Public Dumps. Works Branch, Hong Kong Government;

· WBTC No. 2/93B, Public Filling Facilities, Works Branch, Hong Kong Government;

· WBTC No. 16/96, Wet Soil in Public Dumps; Works Branch, Hong Kong Government;

· WBTC Nos. 4/98 and 4/98A, Use of Public Fill in Reclamation and Earth Filling Projects;

Works Bureau, Hong Kong SAR Government.

· Waste Reduction Framework Plan, 1998 to 2007, Planning,

Environment and Lands Bureau, Government Secretariat, 5 November 1998;

· WBTC Nos. 25/99, 25/99A and 25/99C, Incorporation of Information on Construction and Demolition

Material Management in Public Works Sub-committee Papers; Works Bureau, Hong Kong SAR Government;

· WBTC No. 12/2000, Fill Management; Works Bureau, Hong Kong SAR Government;

· WBTC No. 19/2001, Metallic Site Hoardings and

Signboards; Works Bureau, Hong Kong SAR Government;

· WBTC Nos. 6/2002 and 6/2002A, Enhanced Specification for Site Cleanliness and Tidiness. Works

Bureau, Hong Kong SAR Government;

· WBTC No. 11/2002, Control of Site Crusher. Works Bureau, Hong Kong SAR Government;

· WBTC No. 12/2002, Specification Facilitating the Use

of Recycled Aggregates. Works Bureau, Hong Kong

SAR Government;

· ETWBTC No. 33/2002, Management of Construction and

Demolition Material Including Rock; Environment,

Transport and Works Bureau, Hong Kong SAR

Government;

· ETWBTC No. 34/2002, Management of Dredged/Excavated

Sediment; Environment, Transport and Works

Bureau, Hong Kong SAR Government;

· ETWBTC No. 31/2004, Trip Ticket System for Disposal of

Construction & Demolition Materials, Environment, Transport and

Works Bureau, Hong Kong SAR Government; and

· ETWBTC No. 19/2005, Environmental Management on

Construction Sites; Environment, Transport and Works Bureau, Hong Kong SAR Government.

6.3

Expected

Waste Sources

6.3.1

Construction Phase

During the construction phase, the main activities,

which will result in generation of waste, include demolition, site formation,

dredging, filling and concreting.

The typical waste types associated with these

activities include:

· Dredged marine sediment;

· Contaminated soil;

· C&D materials;

· Chemical waste;

· Sewage; and

· General refuse.

Proper waste management is important to prevent and

mitigate potential environmental impacts.

6.3.2

Operational Phase

The following wastes are expected to be generated

during the operational phase:

· Gypsum generated from FGD

processes;

· Sludge from FGD wastewater

treatment;

· Industrial waste; and

· General refuse.

6.4

Assessment

Methodology

The potential environmental impacts associated

with the handling and disposal of waste arising from the construction and

operation of the Project are assessed in accordance with the criteria presented

in Annexes 7 and 15 of the EIAO-TM, which

are summarised as follows:

· estimation of the

types and quantities of the wastes to be generated;

· assessment of the

secondary environmental impacts due to the management of waste with respect to

potential hazards, air and odour emissions, noise, wastewater discharges and

traffic; and

· assessment of the

potential impacts on the capacity of waste collection, transfer and disposal

facilities.

6.5

Waste

Management Assessment

6.5.1

Construction Phase

Dredged Marine Sediment

The existing Heavy Load Berth along the north-western

waterfront of the Castle Peak Power Station will be extended to form a

multi-purpose wharf and to provide the additional berthing facility required

for future loading and unloading of the reagent and by-products of the new

emission control system. Dredging

will be required for the development of the additional berthing facility. The dredging works are

expected to be carried out within about six weeks in early to mid 2007. The exact extent and boundary of the dredging works

is still being streamlined but the total area required to be dredged is

currently estimated to be approximately 30,000 m2. Due to the small dredging area, one

dredger is expected to be employed for the dredging works. The existing seabed level is about -6 mPD and the dredged level is

expected to be up to a depth of –8.2 mPD with the

estimated total dredged volume to be about 80,700 m3. The proposed dredged area is shown in Figure 2.3.

Based on the existing sediment quality data published by EPD for the

monitoring stations at Pillar Point and Urmston Road (NS3 and NS4), the

sediment quality in the area is considered to be not contaminated. To confirm no contamination of the

marine sediment, vibrocore samples of sediment were

taken at three locations evenly distributed within the area to be dredged based

on the total area expected to be dredged.

The sampling locations are presented in Figure 2.3. Detailed sampling plan and

sampling method are presented in Sediment Quality Plan (SQP) which has been

submitted to EPD (Annex D).

The results of the chemical analyses of the marine sediment are

presented in Table 6.3.

As shown in Table

6.3, all the results are below their respectively LCEL/reporting limit at

all sampling locations and all sampling depths. The findings indicate that the marine

sediment within the dredged area is likely to be uncontaminated but further

sampling and testing in accordance with the detailed requirements of ETWBTC No. 34/2002 will be required for

the actual allocation of sediment disposal site and the application for a dumping

permit under the Dumping at Sea Ordinance

(Cap 466) prior to the commencement of the dredging activities. In the event that these further tests

show the sediment to be uncontaminated, it would be suitable for disposal at

open sea. Should the sediment be

found to be contaminated, confined marine disposal would be appropriate. Based on a maximum daily dredging rate

of about 5,200m3, about 8 barge trips per day will be required,

assuming a carrying capacity of about 700 m3 per barge, for the

disposal of the dredged sediment.

Contaminated Soil

To accommodate the new development, demolition

works are required to demolish or relocate a number of existing facilities

including:

· CPB Fuel Oil Day

Tank (FODT);

· Dangerous Goods

(DG) Store to the south of the FOPH;

· Oil interceptor

for FODT and APS Transformer Compound (West & East Ends);

· Pipe works in

trenches connecting between FODT to FOTPH;

· Pipe works

connecting with FOPH and oil interceptor;

· Intermediate

pressure reduction station (IPRS), LPG compound and CO2 storage

tanks.

Potential leakage and/or spillage (if any) of

oil from the operation of these facilities may cause land contamination to the

underlying soil.

A Contamination Assessment Plan (CAP) has been prepared, submitted to

and was approved by EPD in April 2006 (see Annex E). It

reviewed the historical land uses and existing conditions of the site and

recommended a site investigation programme to determine if the site is

contaminated and if so, the types and degree of contamination. Site investigation was conducted at four

trial pits and eight drillholes. Based on the finding of the site

investigation, total petroleum hydrocarbon (TPH) was found at 0.9 m below

ground level at TP3. However, since

no contamination were found at the adjacent trail pits/boreholes, it is

anticipated that the TPH contamination is localized at TP3. The estimated amount of potentially

contaminated soil within the Project boundary is 50 m3 (with a

bulking factor of 1.2 applied to the in-situ

volume). Details of the finding of

the site investigation were reported in the Annex E1 – Contamination Assessment Report (CAR).

The excavated contaminated soil will be treated

onsite using bioremediation method.

The remediation actions involve excavation, testing, on-site treatment

(i.e., biodegradation) and verification sampling and analysis. The treated soils will be reused within

the Project as far as possible or disposed of at the public fill bank at Tuen Mun Area 38.

The Remediation

Action Plan (RAP) in Annex E details

the measures required.

C&D Materials

Demolition

Materials

Facilities to be demolished to provide space for

installing FGD plants in this Project have been discussed above.

The demolition and relocation works will take about

6.5 months and are scheduled to commence in the first half of 2007.

A total of about 835 tonnes of scrap metals will

be produced from the demolition of FODT, LPG and CO2 tanks, pumps

and the associated fixtures/ appendages such as pipeline, spiral stair and

catwalk attached to the oil tanks.

The steel sheet of the circular roof and sidewall will be cut into small

panels in regular size for easy transportation. All the scrap steel will be transported

off-site by barge/trucks for recycling.

A total of about 1,830 m3

uncontaminated reinforced concrete (after applying a bulking factor of 1.4)

will be generated from demolition of the retaining walls of FODT, DG stores,

LPG switch room and vaporiser room and LPG tank foundation. These materials are not contaminated and

will be separated from other wastes to avoid contamination. The reinforced concrete (public fill)

can be reused on-site or sent to public filling area at Tuen

Mun Area 38 and/or other reclamation site for reuse.

Excavated

Materials

Excavation works would be

required for the construction of the foundations to support the new

facilities. A total of

approximately 30,000 m3 (with a bulking factor of 1.2 applied) of

non-contaminated excavated materials (assumed to be mainly soft materials) will

be generated from the excavation for the foundations of new facilities. The excavated soil will be temporarily

stockpile onsite at the existing coal yard located to the north of the Stacker Reclaimer and is expected to be reused for the filling

activities in this Project.

The portion of the existing coal yard to be used

for the new FGD facilities (located south of existing ash sump and ACP Plant

House) will need to be raised from the existing level of +5 to +6mPD to an

approximate level of +7mPD. Public fill

material will still need to be imported even after reusing the excavated

materials generated from the Project and therefore no surplus excavated

materials is expected from the Project.

C&D Materials Arising from New Building

Construction

C&D materials consisting of packing

materials, plastics, metal, concrete, wood etc will be generated from the new

building construction. The main

structures to be constructed at the site would be the CO2 tank, LPG

tank, IPRS, FGD and SCR equipment, limestone and gypsum storage facilities and

urea storage area. The majority of

these new facilities are steel structures and also pre-fabricated, and

therefore the quantity of C&D materials generated is expected to be small. These materials should be sorted on-site

in order to minimise the amount of construction waste to be disposed of at

landfills and the cost for disposal of the C&D materials arising from the

Project. Recyclables could be

reused on site or sold to recyclers/recycling facilities. Construction waste will be disposed of

at the refuse transfer station at North

West New Territories or directly to the WENT

landfill by trucks.

Chemical Wastes

Chemical waste, as defined under the Waste Disposal (Chemical Waste) (General)

Regulation, includes any substance being scrap material, or unwanted

substances specified under Schedule 1

of the Regulation. A complete list of such substances is

provided under the Regulation;

however, substances likely to be generated from the construction of the SCR and

FGD plants and the associated building will, for the most part, arise from the

maintenance of construction plant and equipment. These may include, but need not be

limited to the following:

· Scrap batteries or

spent acid/alkali from their maintenance;

· Used paint, engine

oils, hydraulic fluids and waste fuel;

· Contaminated oily

water from the flushing and cleaning of the light oil tanks and the oil/water

separation sump prior to their demolition;

· Spent mineral

oils/cleaning fluids from mechanical machinery; and

· Spent

solvents/solutions, some of which may be halogenated, from equipment cleaning

activities.

Chemical wastes may pose environmental, health

and safety hazards if not stored and disposed of in an appropriate manner as

outlined in the Waste Disposal (Chemical

Waste) (General) Regulation and the Code

of Practice on the Packaging, Labelling and Storage of Chemical Wastes. These hazards may include:

· Toxic effects to

workers;

· Adverse effects on

air, water and land from spills; and

· Fire hazards.

Oily water and oily sludge will be generated

from the cleaning of the FODT and oil transfer pipelines to be demolished. The amount of chemical waste that will

arise from other construction activities will be highly dependent on the

Contractor’s on-site maintenance activities and the quantity of plant and

equipment utilised. With respect to

the nature of construction works, the number of construction plant and

equipment to be used on site, it is estimated that about a few hundred litres

of used lubricant oil will be generated during the construction period. It is anticipated that the quantities of

waste solvent and waste paint will be minimal.

With the incorporation of suitable arrangements

for the storage, handling, transportation and disposal of chemical wastes under

the requirements stated in the Code of

Practice on the Packaging, Labelling and Storage of Chemical Waste, no

adverse environmental and health impacts will result from the handling,

transportation and disposal of chemical waste arising from the Project.

Sewage

Sewage will arise from the construction

workforce and site office’s sanitary facilities. These wastes should be managed properly

to avoid any adverse water quality impact, odour and potential health risks to

the workforce by attracting pests and other disease vectors.

It is estimated that about

900 construction workers will be working on site at the peak of the construction programme. With a sewage generation rate of 0.15 m3

per worker per day, about 135 m3 of sewage will be generated per

day. It is expected that portable

toilets will be provided for site workers and the existing sanitary facilities

at the CPPS will not be used by any of the site workers. A licensed contractor should be employed to remove

the sewage and dispose of it to sewage treatment works operated by Drainage

Services Department. With the

implementation of these waste management practices on-site, adverse

environmental impacts are not expected.

General Refuse

The presence of a construction site with workers

and associated site office will result in the generation of a variety of

general refuse requiring disposal.

General refuse will mainly consist of food waste, aluminium cans and

waste paper.

The storage of general refuse has the potential

to give rise to adverse environmental impacts. These include odour if the waste is not

collected frequently (for example, daily), windblown litter, water quality

impacts if waste enters water bodies, and visual impact. The site may also attract pests, vermin,

and other disease vectors if the waste storage areas are not well maintained

and cleaned regularly. In addition,

disposal of wastes at sites other than approved landfills, can also lead to

similar adverse impacts at those sites.

During the peak of construction programme, about

900 construction workers will be worked on site at any one time and the amount

of general refuse to be generated is expected be about 585 kg per day based on

a general refuse generation rate of 0.65 kg per worker per day.

Recyclable materials (i.e. paper, plastic bottle

and aluminium can) should be separated and disposed of at the recycling bins in

order to minimise the amount of general refuse to be disposed of at

landfills. General refuse generated

from the construction workforce will be collected together with other general

refuse generated from the existing CPB by contractor and subsequently sent to

the refuse transfer station in North

West New Territories or directly to WENT landfill

for disposal. With respect to the

small quantity of general refuse to be generated, it is anticipated that no

additional traffic will be generated due to its disposal.

Provided that the mitigation measures

recommended in Section 6.6 are adopted, the environmental impacts caused by the storage, handling,

transport and disposal of general refuse are expected to be minimal.

Summary

Table

6.4

summarised the waste arising during construction of the Project.

Table 6.4 Waste

Arising During Construction Phase

|

Type

|

Estimated Quantity

|

Disposal / Treatment Site

|

|

Dredged Sediment

|

·

80,700 m3

(likely to be uncontaminated)

|

·

Disposal to open

sea (if confirmed by further tests in accordance with ETWBTC No. 34/2002 to be uncontaminated); or

·

confined marine

disposal (if confirmed by further tests to be contaminated)

|

|

Contaminated Soil

|

·

50 m3

(bulk)

|

On-site treatment

(bioremediation) and the treated soil will be reused as fill materials with

the Project or disposal of at public fill bank in Tuen

Mun Area 38

|

|

Scrap Steel

|

·

835 tonnes

|

Off-site recycling

|

|

Public Fill

|

·

1,830 m3

(uncontaminated concrete)

·

30,000 m3

(bulk) (excavated soil)

|

Reuse on-site for site

formation and backfilling

|

|

Construction Waste

|

·

minor

|

Refuse transfer station in North West New Territories

or WENT Landfill

|

|

Chemical Waste

|

·

fuel oil day tank

and oil separator sump demolition.

·

Less than one

hundred litres per month from all construction activities.

|

Chemical Waste Treatment

Centre and/or other licensed lube oil recycling facility

|

|

Sewage

|

·

135 m3/day

(on average)

|

Provision of portable toilets

and regular collection by contractor for off-site treatment

|

|

General Refuse

|

·

585 kg/day (on

average)

|

Transported together with

other general refuse generated from the existing CPPS to refuse transfer

station in North West

New Territories

or WENT Landfill

|

6.5.2

Operational Phase

Gypsum Generated from FGD

Processes

The limestone FGD processes will generate two

principal types of by-product or waste.

They are the gypsum and the sludge from treatment of the FGD wastewater.

Gypsum is a non-hazardous and non-toxic

substance. It is produced in the

form of fine, white, crystalline powder consisting predominantly of calcium

sulphate. The quantity of gypsum

generated will depend on a number of factors including the sulphur content of

the fuel used and the operational profile of CPB.

Gypsum is a useful construction material in

building industry and the demand for gypsum is high in both Hong Kong and

Mainland China.

About 240,000 tonnes of commercial grade gypsum

will be produced per year in addition to a small amount of lower grade gypsum

at about 17,000 tonnes per year (i.e., 6.6% of the total gypsum generated).

Commercial

Grade Gypsum : The commercial grade gypsum produced could be used for a number of

purposes such as the production of plasterboard, cement, etc. CAPCO can liaise with the overseas

limestone supplier to take back the gypsum generated from the limestone FGD

system at CPB. Currently, the Hongkong Electric Company has entered into a

buyback agreement with the overseas limestone supplier to take back the gypsum

generated from the FGD process at the Lamma Power

Station. It is likely that the

buyback agreement could also be feasible for the limestone FGD system at CPB.

Another feasible way to reuse the gypsum is to

sell to cement manufacturers in PRD and East-Asia region. The demand for gypsum from the cement

and plasterboard sectors in Guangdong

Province is likely to

exceed the supply. Many

multi-national cement manufacturers have acquired sizable cement production plants

in the East-Asia region and their potential demand for gypsum is therefore well

in excess of the level of supply by CAPCO.

It is therefore likely that multi-national cement manufacturers could

take all the FGD gypsum to be produced at CPB under a long-term arrangement to

supply various cement plant around the region.

Barges will be employed to transport the

commercial grade gypsum offsite.

One to two barge trips per week are anticipated for gypsum transport.

Lower Grade Gypsum: A small amount of lower

grade gypsum (about 17,000 tonnes per year or 6.6% of the total gypsum

generated) will also be generated as a result of the FGD process. Despite its lower grade, the gypsum can

still be reused for cement production.

Similar to the case of commercial grade gypsum, CAPCO can liaise with

the limestone supplier to take back also the lower grade gypsum. As a fallback option in the rare event

of the lack of demand for lower grade gypsum, it can be disposed of at a

designated area of the Tsang Tsui Ash Lagoons. The dewatered gypsum will be transported

by trucks. Assuming 365 working

days per year, 47 tonnes of lower grade gypsum (or about 20 m3 of

lower grade gypsum based on a density of 2.3 tonne per cubic metre) will be

generated per day. Based on a carrying

capacity of 7 m3 for each truckload, about three additional truck

trips will be generated per day from the Project on the Lung Kwu Tan Road

and Nim

Wan Road for the transportation of lower grade

gypsum.

Sludge from FGD Wastewater

Treatment

The dewatered gypsum cake will need to be washed

with fresh water to remove the soluble chlorides to meet the specification for

commercial grade gypsum. The wash

water, containing excessive chlorides, will be treated in a chloride purge

treatment system to remove the suspended solids and trace elements, to reduce

the residual COD and to adjust the pH before it is discharging with the cooling

water of the CPB to Urmston Road.

About 60 tonnes of sludge dry solids per day (or

about 180 tonnes per day at 30% dry solids) will be generated from the chloride

purge treatment system. The typical

quality of the sludge is presented in Table

6.5.

Table 6.5 Typical

Chemical Composition of Chloride Purge Treatment Sludge

|

Component

|

Content

|

|

Calcium sulphate

|

40%

|

|

Calcium sulphite

|

1%

|

|

Calcium carbonate

|

4%

|

|

Inerts

|

20%

|

|

Flyash

|

5%

|

|

Others (surplus

sludge from biological treatment system)

|

30%

|

Design optimisation of the FGD wastewater

treatment system has commenced. One

of the key design optimisation objective is to minimise the influent throughput

to the wastewater treatment system which would result in a lower quantity of

sludge arising. This would help to

reduce the amount of sludge requiring disposal. In addition, the feasibility of other

disposal options such as off-take by the limestone supplier and gypsum

off-taker to minimise the quantity of sludge to be disposed of at landfills

would be further explored in the detailed design stage.

Industrial

Waste

Most of the industrial waste generated from the

maintenance of the limestone FGD system will be scrap metal, which can be

recycled. It is therefore

anticipated that no adverse environmental impacts will result from the handling

and disposal of the industrial waste to be generated from the operation of the

FGD system.

General

Refuse

CAPCO will deploy the existing CPB staff to

manage the new emission control system and it is not anticipated to have

significant increase of number of staff.

Hence, no additional general refuse will be generated from the

workforce.

Summary

Table

6.6

summarises the waste arising during the operation of the Project.

Table 6.6 Waste

Arising During Operational Phase

|

Type

|

Estimated Quantity

|

Disposal / Treatment Site

|

|

Gypsum

|

·

Commercial grade

gypsum : 240,000 tonnes per year

·

Lower grade

gypsum : 17,000 tonnes per year

|

·

Commercial grade

gypsum : To be collected by the limestone supplier or sold to plasterboard

and/or cement manufacturers

·

Lower grade

gypsum : To be collected by the limestone supplier or sold to cement

manufacturers. As a fall-back

option, disposal at a designated area of Tsang Tsui

Ash Lagoons may be considered

|

|

Sludge

|

·

60 tonnes dry

solid per day or about 180 tonnes per day at 30% dry solids

|

·

Minimising the

influent throughput to the wastewater treatment system which would result in

a lower quantity of sludge arising;

·

Feasibility of

other disposal options to be further explored in detailed design stage

|

|

Industrial waste

|

·

Few kg of scrap

metal per month

|

·

To be collected

by recyclers/recycling facilities

|

6.6

Mitigation

Measures

There are no major waste management issues

associated with the operation of the new emission control system. This section recommends the mitigation measures

to avoid or minimize potential adverse environmental impacts associated with

handling, collection and disposal of waste arising from the construction of the

new emission control system.

It is the Contractor’s responsibility to ensure

that only licensed chemical waste collectors are used for collection and

transportation of chemical waste to the licensed disposal facility and that

appropriate measures are taken to minimize adverse environmental impacts,

including windblown litter and dust from the transportation of wastes. In addition, the Contractor must ensure

that all the necessary waste permits are obtained for the construction and

operational phases.

6.6.1

Dredged Sediments

According to the requirements stipulated in ETWBTC No. 34/2002, the dredged sediment

should be disposed of only at designated disposal sites allocated by the Marine

Fill Committee (MFC) based on the findings of further sediment quality

tests. A dumping licence should

also be obtained from EPD prior to the commencement of the dredging works.

Regardless of the sediment disposal method and

site, the Contractor should:

· Dredge the

sediments using closed grabs;

· Use split barges

of not less than 750 m3 capacity when transporting the sediment to

the disposal site;

· Regularly maintain

the barge hoppers to ensure that they are capable of rapid opening and

discharge at the designated disposal site; and

· Monitor the barge

load against loss of materials during transportation.

6.6.2

Contaminated Soil

For excavated contaminated soil, mitigation

measures recommended in the RAP, Annex E should be implemented.

6.6.3

Excavated Materials

Wherever practicable, excavated materials should

be segregated from other wastes to avoid contamination thereby ensuring that it

can be re-used onsite avoiding the need for disposal at landfills.

Management

of Waste Disposal

Construction Waste Disposal Charging Scheme was

launched on 1 December 2005 and the charging for disposal of construction waste

was commenced on 20 January 2006.

The Contractor should open a billing account

with EPD in accordance with the Waste

Disposal (Charges for Disposal of Construction Waste) Regulation for the

payment of disposal charges. Every

waste load transferred to Government waste disposal facilities such as public

fill, sorting facilities, landfills or transfer station would required a valid

“chit” which contains the information of the account holder to facilitate waste

transaction recording and billing to the waste producer. A trip-ticket system will be established

in accordance with the ETWBTC No. 31/2004

to monitor the reuse of surplus excavated materials offsite and disposal of

C&D waste and general refuse at transfer station/landfills, and to control

fly-tipping. The billing “chit” and

trip-ticket system will be included as one of the contractual requirements and

implemented by the contractor.

CAPCO will also conduct regular audits of the waste management measures

implemented on site as described in the Waste Management Plan.

A recording system (similar to summary table as

shown in Annex 5 and Annex 6 of Appendix G of ETWBTC No. 19/2005) for the amount of waste generated, recycled and

disposed of (including the disposal sites) should be established during the

construction stage.

Measures

for the Reduction of C&DM Generation during Planning and Design Stages

The various waste management options can be

categorized in terms of preference from an environmental viewpoint. The options considered to be more

preferable have the least impacts and are more sustainable in the long term. Hence, the waste management hierarchy is

as follows:

· Avoidance and

minimization, that is, reduction of waste generation through changing or

improving practices and design;

· Reuse of

materials, thus avoiding disposal (generally with only limited reprocessing);

· Recovery and

recycling, thus avoiding disposal (although reprocessing may be required); and

· Treatment and

disposal, according to relevant law, regulations, guidelines and good practice.

This hierarchy should be used to evaluate the

waste management options, thus allowing maximum waste reduction and reduced

disposal costs. Records of

quantities of wastes generated, recycled and disposed (locations) shall be

kept.

Measures

for the Reduction of C&DM Generation during Construction

All C&D materials will be reused within the

Project. Public fill and

construction waste should be segregated and stored in different containers or

skips to facilitate reuse or recycling of materials and their proper disposal

of construction waste. Specific areas

of the work site should be designated for such segregation and temporary

storage if immediate use is not practicable.

The construction waste should be collected by

Contractor and transported to landfills for disposal.

The use of wooden hoardings

should not be allowed. An

alternative material, which can be reused or recycled, for example, metal

(aluminium, alloy, etc) should be used.

To reduce the potential dust

impact, C&D materials should be wetted as quickly as possible during

excavation works.

6.6.4

Chemical Waste

The Contractor should register as a chemical

waste producer with the EPD.

Chemical waste, as defined by Schedule

1 of the Waste Disposal (Chemical

Waste) (General) Regulation, should be handled in accordance with the Code

of Practice on the Packaging, Handling and Storage of Chemical Wastes as

follows:

Containers used for storage

of chemical wastes should:

· be suitable for

the substance they are holding, resistant to corrosion, maintained in a good

condition, and securely closed;

· have a capacity of

less than 450 L unless the specifications have been approved by the EPD; and

· display a label in

English and Chinese in accordance with instructions prescribed in Schedule 2 of

the Regulations.

The storage area for chemical wastes should:

· be clearly labelled

and used solely for the storage of chemical waste;

· be enclosed on at

least 3 sides;

· have an

impermeable floor and bunding, of capacity to

accommodate 110% of the volume of the largest container or 20% by volume of the

chemical waste stored in that area, whichever is the greatest;

· have adequate

ventilation;

· be covered to

prevent rainfall entering (water collected within the bund must be tested and

disposed of as chemical waste, if necessary); and

· be arranged so

that incompatible materials are appropriately separated.

Disposal of chemical waste should be:

· via a licensed

waste collector; and

· to a facility

licensed to receive chemical waste, such as the Chemical Waste Treatment Centre which also offers a chemical

waste collection service and can supply the necessary storage containers.

6.6.5

Sewage

The sewage sludge from

the portable toilet should be collected by a reputable collector on a regular

basic.

6.6.6

General Refuse

General refuse should be stored in enclosed bins

or compaction units separately from construction and chemical wastes. General refuse should be removed from

the site, separately from construction and chemical wastes, on a daily basis to

minimise odour, pest and litter impacts.

Burning of refuse on construction site is prohibited by law.

Aluminium cans are often recovered from the

waste stream by individual collectors if they are segregated and made easily

accessible. As such, separate,

labelled bins for their deposit should be provided if feasible. Materials recovered will be re-used on

site or sold for recycling.

6.6.7

Staff Training

Training will be provided to workers on the

concepts of site cleanliness and on appropriate waste management procedures,

including waste reduction, reuse and recycling at the beginning of the

Contract.

6.7

Residual Environmental Impacts

With the implementation of the recommended

mitigation measures, no residual impacts are anticipated from the construction

and operation of the Project.

6.8

Environmental Monitoring and Audit

6.8.1

Construction Phase

Joint site audits by the CAPCO and the contractor should be undertaken

on a weekly basis. Particular

attention should be given to the contractor’s provision of sufficient spaces,

adequacy of resources and facilities for on-site sorting and temporary storage

of C&D materials. The C&D

materials to be disposed of from the site should be visually inspected. The C&D waste to be disposed of at

refuse transfer stations or landfills should contain no as practicable

observable inert or reusable/recyclable C&D materials (e.g. soil, broken

rock, metal, and paper/cardboard packaging, etc). Any irregularities observed during the

weekly site audits should be raised promptly to the contractor for

rectification.

6.8.2

Operational Phase

No adverse environmental impact will arise with the implementation of

good waste management practices and therefore, no environmental monitoring and

audit programme is required.

6.9

Conclusion

6.9.1

Construction Phase

The key potential impacts during the construction

phase are related to management of dredged sediments, demolition materials,

excavated materials and construction waste.

About 80,700 m3 of

marine sediment will be dredged in connection with the provision of the

additional berthing facility. The

final disposal site for the material will be determined by the MFC and a

dumping licence will be obtained from EPD prior to the commencement of the

dredging works with reference to the results of further tests to be undertaken

in accordance with the detailed requirements of ETWBTC No. 34/2002.

An estimated total of 50 m3

total petroleum hydrocarbon (TPH) contaminated soil will be excavated and the material should be remediated by using bioremediation method, as discussed in Section 7 and the RAP in Annex E. The treated soil will be reused within

the Project or disposed of at the public fill bank in Tuen

Mun Area 38.

A total of about 835 tonnes of scrap steel will

be produced during demolition of oil tanks and the associated fixtures/

appendages. All the scrap steel

will be delivered off-site by barge/truck for recycling.

A total of about 30,000 m3

of uncontaminated excavated soil will be generated from the demolition and

construction works. All excavated

soil will be reused for the backfilling on-site.

Small quantities of chemical

wastes (less than 100 litres per month), sewage (a maximum of 135 m3

per day) and general refuse (a maximum of 585 kg per day) will be generated

during the construction phase.

With the implementation of the recommendations

in Section 6.6, the potential

environmental impacts arising from storage, handling, collection, transport and

disposal of wastes should be able to meet the criteria specified in the EIAO-TM. No unacceptable waste management impact

is anticipated.

6.9.2

Operational Phase

Commercial grade gypsum (about 240,000 tonnes

per year) can be recycled in PRD and East-Asia regional market. Similarly the lower grade gypsum (about

17,000 tonnes per year) can also be reused for cement production. The sludge from FGD wastewater treatment

(about 180 tonnes at 30% dry solids per day) will be generated. Design optimization of FGD wastewater

system has been commenced and one of the key objectives is to minimize the

influent throughput to the wastewater treatment system as a result in lowering

the quantity of sludge arising.

This would help to reduce the amount of sludge requiring disposal. Alternative disposal options such as

off-take by the limestone supplier and gypsum off-taker and incineration of the

sludge will be explored in the detailed design stage.

With the implementation of the recommended

mitigation measures, the potential environmental impacts associated with the

storage, handling, collection, transport and disposal of a small quantity of

industrial waste and general refuse arising from the operation of the Project

will meet the criteria specified in the EIAO-TM

and no unacceptable waste management impact is anticipated.