4 Tier 2 - Confirmation of Environmental Acceptability

1 Before chlorination and UV radiation are short-listed for further evaluation in Tier 3, an assessment of the fundamental acceptability of the technologies is conducted with respect to the key aspects of marine water quality and human/ecological health.

2 As mentioned earlier in Section 1.3.5, the SCI outfall is near optimal for discharge of treated effluent. This also helps to avoid or minimise the impacts of any disinfection-by-products, as elaborated below.

1 The two key concerns associated with chlorination are:

· Total residual chlorine (TRC)

· Formation of chlorination-by-products (CBPs)

1 While the fundamental objective of chlorination is to destroy the pathogens in the effluent, it is important that excessive levels of the residual chlorine compounds (TRC) must not enter the receiving waters, because chlorine residue is toxic to certain species of fish and aquatic life.

2 To overcome this concern, it is common practice to de-chlorinate the disinfected effluent using a de-chlorination agent (e.g., sodium bisulphite) to remove completely the TRC from the effluent.

4.1.2 Chlorination-By-Products (CBPs)

1 The other environmental concern with chlorination is the formation of chlorinated organic compounds (generally termed chlorination-by-products), some of which are potentially carcinogenic.

2 The formation of CBPs is related to the strength of the sewage and the dosage of chlorine added to the wastewater. However, in the case of HATS, formation of CBPs is greatly reduced for several reasons:

· HATS sewage is of primarily domestic origin, where there are little CBP precursors (as one would expect to find from industrial effluents).

· Enforcement of the licensing controls under the Water Pollution Control Ordinance helps to keep toxic industrial effluents from entering the sewerage system.

· For chlorination of primary or CEPT effluent, due to the presence of ammonia in the effluent, the formation of chlorinated organic compounds is substantially suppressed.

· For secondary effluent, the level of organics in the effluent is generally low; this means that the level of CBPs would be low.

3 As part of the EIA study, chemical tests of HATS effluents were conducted. These have confirmed that there are few CBPs in the HATS chlorinated effluent and the detected CBPs are of very low concentrations. In addition, none of the detected CBPs is known to be of significant concern with respect to bioaccumulation.

1 In addition to the source control measures mentioned above for TRC and CBPs, the concentrations of any potential contaminants of concern are further reduced through mixing.

2 As the effluent is discharged through the outfall diffusers into the sea, it is mixed thoroughly within close proximity of the discharge point in what is commonly referred to as the zone of initial dilution (ZID). For the SCI outfall, computer modelling has suggested that the effluent would be diluted typically about 40 times at the edge of the ZID.

3 Then, the effluent is further diluted as it is dispersed beyond the ZID into the far field in what is termed the “mixing zone”. Eventually, the effluent will be diluted to such an extent by ambient waters that the effect of the effluent will be unidentifiable.

4 In the case of SCISTW outfall, the ZID is generally restricted within a few hundred metres of the discharge point, where there are no water sensitive receivers or uses (i.e., no sensitive marine ecological resources or fish culture zones). In addition, this part of the harbour, being close to the container terminals, is heavily trafficked. The opportunities for swimming (or other water sports) or recreational fishing are limited.

1 The combined effect of source control measures (e.g., de-chlorination), effective initial dilution/far field mixing, and absence of water sensitive receivers or uses in the near field is that there should be no or negligible risk to human health or aquatic lives due to the HATS discharge.

2 To confirm this, two risk assessments (see Sections 6 and 7 of this EIA Report for details) were conducted:

· Human Health Risk Assessment

· The objective was to assess the potential human health risks/impact associated with exposure to CBPs from HATS effluent discharges. It was acknowledged that, as the SCI outfall is located in the inner harbour remote from likely human receivers or uses of the water, the chance of prolonged exposure to the effluent would be very low.

· Nevertheless, for the purposes of the risk assessment, a very conservative approach was taken, involving consideration of several unlikely exposure pathways. These included (a) accidental drop into the harbour (at edge of ZID) and daily consumption of contaminated seafood from the inner harbour; (b) frequent swimming at the edge of mixing zone and daily consumption of contaminated seafood; and (c) frequent swimming at Tsuen Wan beaches and daily consumption of contaminated seafood.

· As expected, it was found that the risk to human health under all of assessed pathways under the different exposure scenarios would be low and well within acceptable limits (see Section 6 of this EIA Report for details).

· Ecological Health Risk Assessment

· The objective was to assess the adverse chronic effects to aquatic life and marine mammals associated with the exposure to CBPs from HATS effluent discharges

· Again, the ecological risk assessment followed well-established procedures and adopted a conservative approach. It was found that the risk to the ecological resources would be acceptable.

· Compliance with the established water quality criteria with respect to acute and chronic toxicity was confirmed based on results of the Whole Effluent Toxicity Test[3] (WETT).

· In addition, it was found that there was no statistical difference between the toxicity (as measured by WETT) of raw CEPT effluent and chlorinated/de-chlorinated effluent. This means that chlorination of HATS effluents would not increase risk to aquatic lives compared to current conditions (where raw CEPT effluent is being discharged from SCISTW under HATS Stage 1).

3 In conclusion, based on the risk assessments, it is concluded that:

· Risks to human health and ecological resources are low and within acceptable limits

· No adverse impact on aquatic lives due to acute and chronic toxicity

· Chlorination disinfection is an environmentally acceptable option for HATS, with respect to water quality, human and ecological health risks

1 Certain chemical compounds in sewage can be altered by UV radiation. However, there is relatively little information on disinfection-by-products (DBPs) from UV radiation.

2 Nevertheless, aldehydes and other oxidation by-products were found to exhibit a UV-dose response increase in previous pilot studies using both low- and high-intensity UV system, although the elevated levels were found to be within the acceptable limits. Further, effective dilution of the disinfected effluent in the receiving waters would reduce the concentrations of any DBPs.

3 For the purpose of this assessment, it has been assumed that no or insignificant level of potentially toxic DBPs from UV radiation would enter the receiving water body. Therefore, the risk on human or ecological health due to UV radiation of effluent is insignificant or negligible.

4 Overall, UV disinfection is also an environmentally acceptable option for HATS, with respect to water quality, human and ecological health risks.

5 It is proposed to include both chlorination and UV radiation into the short-list of technologies for further evaluation in Tier 3, which will consider the full spectrum of environmental aspects in addition to water quality and ecological/human health risks.

5 Conceptualisation of Short-listed Disinfection Options

1 Chlorination and UV radiation are generic technology groups. Before proceeding to Tier 3 evaluation, it is necessary to identify the most appropriate scheme for each of the two technologies. These are elaborated below.

5.2.1 Options for Effecting Chlorination

1 Chlorine can be supplied in many forms[4], which include chlorine gas, hypochlorite solutions, and other chlorine compounds in solid or liquid form.

2 The key considerations for selecting the most appropriate method of chlorination include safe and easy handling, storage, and shipping, as well as affordable capital and operation and maintenance costs.

3 The advantages and disadvantages of each key chlorination option in the context of these considerations are discussed below:

· Option 1 - Chlorine gas is an extremely volatile and highly toxic chemical that requires specific precautions for it to be transported, stored, and used safely. In treatment plants where chlorine gas is used, chlorine is supplied as a liquefied gas under high pressure in containers. Because of the significant safety risks due to its extremely toxicity and reactivity, use of chlorine gas is being phased out overseas. For SCISTW, which is near a densely populated urban environment, use of chlorine gas will pose significant risks. Therefore, this option is not considered further.

· Option 2 - Sodium hypochlorite (or commonly called bleach) is a liquid form of chlorine that achieves results similar to chlorine gas disinfection. As a liquid, it is much safer than chlorine gas to handle. Sodium hypochlorite can be commercially supplied or generated on-site. In on-site generation, seawater is passed through an electrolytic cell to form sodium hypochlorite. Sodium hypochlorite is used in many large STWs. It warrants further consideration.

· Option 3 - Calcium hypochlorite is essentially a solid that is used in place of liquid sodium hypochlorite. Because it is a solid, calcium hypochlorite is safer to handle than chlorine gas or sodium hypochlorite. However, it is corrosive and hygroscopic (i.e., readily absorbs moisture), reacting slowly with moisture in the air to form chlorine gas if not stored in airtight containers, with potentially significant health and safety concerns. It also poses excessive maintenance problems resulting from the deposition of the calcium ion throughout the system. In addition, chemical costs for calcium hypochlorite are relatively high, typically 1.5 to 2.5 times of liquid sodium hypochlorite, due to the energy intensive nature of the production process. Overall, this option does not appear to offer any significant advantages over sodium hypochlorite. Calcium hypochlorite is therefore not considered further.

· Option 4 - Chlorine dioxide has the key advantage that it produces lower levels of THMs than other chlorine alternatives. However, chlorine dioxide is a gas that is explosive at above 10% by volume in air. Chlorine dioxide must be generated on-site because it is an unstable compound. Use of chlorine dioxide is not considered suitable for SCISTW because of significant explosion risks due to the manufacturing, handling, and storage of vast quantity of this gas near a densely populated urban environment. This option is therefore not considered further.

4 The above analysis suggests that sodium hypochlorite (bleach) would be the most suitable medium for effecting chlorination at SCISTW. In turn, sodium hypochlorite may be obtained by either:

· On-site generation of hypochlorite by electro-chlorination of seawater; or

· Direct purchase of sodium hypochlorite

5.2.2 Evaluation of Short-listed Chlorination Options

1 To select the most appropriate method, an evaluation of the relative advantages and disadvantages of on-site generation and direct purchase of sodium hypochlorite has been conducted.

2 The evaluation is based on four broad headings, each with sub-criteria reflecting the key issues of concern and serving to differentiate the performance of the two options :

· Technical considerations

· Reliability of supply

· Flexibility

· Land/Space requirement

· Environmental considerations

· Hazards to public

· Cost

· Capital cost

· Recurrent cost

· Lifecycle cost

· Miscellaneous

· Implementation timeframe

3 Options are rated against each criterion as follows:

· Desirable (ü)

· Neutral (¡)

· Undesirable (û)

4 The outcome is summarized in Table 5‑1.

Table 5‑1 On-site Generation vs. Purchase of Sodium Hypochlorite

|

|

On-site generation |

Purchase |

Comment |

|

Technical Considerations |

|||

|

Reliability of supply |

¡ |

¡ |

On-site generation using electro-chlorination has the advantage that supply of sodium hypochlorite would be independent of external suppliers. However, operation and maintenance efforts of the proposed electro-chlorination system at the anticipated (large) scale are complex and demanding, given that seawater (which could give rise to corrosion, biofouling, etc) is involved. In addition, seawater conditions (salinity) vary seasonally, requiring careful operator management to maintain adequate production of sodium hypochlorite throughout the year.

The “purchase” option does not involve complex site operation to produce sodium hypochlorite, but will rely on external suppliers. While it is expected that there are or will be adequate number of suppliers in the region to respond to the demand by SCISTW, and that supply reliability will not be a critical concern, this option nevertheless has the disadvantage that supply is affected by commercial factors outside the control of the SCISTW operators.

Overall, both options are rated equal against this criterion.

|

|

Flexibility |

û |

ü |

This refers to the flexibility of the chlorination system to cope with changing operational requirements, including, for example, variations in effluent quality and quantity. If on-site generation were adopted, the system would be designed on a conservative basis consistent with good engineering practice. However, this means the system could be under-utilised if flow build up is slower than expected due to slower population growth, or if lower dosage is required than expected due to better than expected effluent quality. On the other hand, the purchase option would be more flexible in that the quantity to be purchased could be varied according to actual requirements.

|

|

Land /space requirements |

û |

ü |

The on-site generation system will take up more space or land than the purchase option, due to the need to site the electro-chlorination system and associated facilities (e.g., seawater pumping station, power supply facilities, etc). As the existing SCISTW site will need to accommodate the Stage 2A expansion works, it is desirable to minimise footprint of process units or treatment systems.

|

|

Environmental Considerations |

|||

|

Hazards to public |

¡ |

¡ |

The purchase option would involve transport, storage, and handling of sodium hypochlorite solution. Sodium hypochlorite solution (bleach solution) is not flammable or explosive, but is classified as a Category 4 Dangerous Goods (DG) under the Dangerous Goods Ordinance as it is corrosive. The Fire Services Department (FSD) requirements for handling and transport of CAT 4 DG will be followed, and this is considered adequate to safeguard public health and safety.

The on-site generation option would not involve transport to site of sodium hypochlorite. However, generation of hydrogen gas during electrolysis of seawater will occur. Hydrogen is a highly flammable gas, burning at concentrations as low as 4% hydrogen in air. Careful control of hydrogen is needed.

In summary, both options could pose hazards to the public. However, these hazards are considered low and acceptable, with adoption of FSD requirements. They are ranked equal against this criterion. |

|

Cost |

|||

|

Capital Cost

|

û |

ü |

On-site generation will require capital investment in the form of an electro-chlorination system to be built at SCISTW. This is not the case for direct-purchase.

|

|

Recurrent Cost

|

ü |

û |

Recurrent cost for the direct purchase option is the cost of the sodium hypochlorite solution, which is higher than the cost of operating and maintaining the electro-chlorination system.

|

|

Life-cycle Cost (15 years)

|

Similar order |

On a life-cycle cost basis, the two options have been found to be similar. That is, the higher capital cost of the electro-chlorination system is offset by its lower recurrent cost, compared to the direct purchase option (which has a lower capital cost but higher recurrent cost).

|

|

|

Miscellaneous |

|||

|

Timeframe |

û |

ü |

The current target is to commission the advance disinfection facilities by 2009. The on-site generation system will involve construction and installation of an electro-chlorinator requiring time and effort. This option is therefore less desirable than the purchase option. |

5 The above analysis suggests that there are advantages and disadvantages with respect to reliability of supply for either option. Both options could pose hazards to the public that need to be and can be controlled.

6 The on-site generation would be preferable to the purchase option in terms of a lower recurrent cost (though the total life cost of the two options is similar). On the other hand, the purchase option is preferable in terms of flexibility to deal with variations in flow quantity and quality, lower land/space requirement, lower capital cost (though the total life cost of the two options is similar), and requiring less time to implement.

7 Overall, given the strengths of the purchase option with respect to a higher degree of flexibility, lesser operation and maintenance efforts, lesser land/space requirements, and shorter timeframe for implementation, it is proposed that this should be adopted as the preferred scheme for chlorination.

1 UV disinfection relies on the transference of electromagnetic energy from a source to the cellular material of an organism. The germicidal effects of UV light involve photochemical damage to RNA and DNA within the cells of an organism. The micro-organism becomes unable to maintain metabolism or reproduce itself and subsequently perishes. The germicidal effects of UV light are greatest at wavelengths from 240 to 260 nanometres (nm).

2 However, as the UV radiation does not kill (or destroy) the organisms, reactivation of the organisms has been known to occur. For example, coliform concentrations as measured in the disinfected effluent may increase under particular conditions, due to reactivation in the receiving water.

3 The principal components of a UV disinfection system include the UV lamps, the quartz sleeves in which the UV lamps are placed, the UV module for holding/supporting the UV lamps and quartz sleeves, the ballasts used to regulate power supply to the UV lamps, and the power supply panels for supplying power to the UV disinfection system.

1 For a given UV dose, the pathogen reductions achieved vary from effluent to effluent, influenced by the concentration of suspended solids, the particle size of these solids, the UV (254mm) transmission of the effluent, the iron content and other factors which remain unknown or ill defined. Further, the maximum reductions achievable are limited by the concentration of suspended solids. This is particularly true for viruses that strongly associate with particulate matter.

2 An important parameter for UV disinfection process is the UV transmittance (or UV absorbance/demand) of wastewater, which measures the ability of UV light to penetrate wastewater and is hence a critical factor in designing the UV disinfection system. Generally, the lower the UV transmittance (UVT) of wastewater, the less UV radiation would be effective for disinfection, and hence the more UV lamps would be required.

3 Examples of UV absorbing compounds include humic materials, oil and grease, suspended solids, iron compound, manganese compound and proteins. In practice, a UV radiation system commonly incorporates fine screens as a pre-treatment step to improve the quality of the effluent as much as possible before being treated by UV radiation.

4 For UV disinfection of CEPT effluent, it will be preferable to avoid coagulants made of iron compounds (or compounds that are known to interfere with the transmittance of UV radiation). In Hong Kong, alum is commonly used as coagulant for CEPT effluent subject to UV radiation (e.g., Sham Tseng STW).

1 For disinfection applications, UV energy is artificially generated by striking an electric arc through mercury vapour. UV light can be produced from high intensity or low intensity mercury lamps. High intensity systems are more compact than low intensity ones. For SCISTW, owing to space constraints, it is suggested that high intensity lamps should be considered.

2 Further, UV lamps can be low-pressure or medium-pressure, with the difference in terminology indicating the relative pressure of the mercury vapour within the lamp. While the low-pressure lamps emit approximately 90 percent of their light at 254nm, the medium-pressure lamps emit higher-intensity radiation across a broader spectrum of radiation and therefore require fewer lamps but more power. On the other hand, low-pressure systems would require more lamps and occupy more space, but consume less power.

3 Either low- or medium-pressure high intensity UV lamps are suitable for application at SCISTW. These would be considered as the preferred scheme for UV radiation at SCISTW for the purposes of evaluation in Tier 3.

6 Tier 3 Evaluation

1 The environmental acceptability of the two short-listed disinfection options (chlorination and UV radiation) with respect to water quality, human heath, and ecological health has been considered in Section 4. It has been concluded that both options would be acceptable in these respects for HATS.

2 The objective of Tier 3 evaluation is to compare performances of the two short-listed disinfection schemes, in the context of HATS, against a broader range of environmental criteria, in addition to water quality, human health, and ecological health.

1 The water quality and related aspects of the options have been evaluated as part of the Tier 2 evaluation. For completeness, however, it is intended to reiterate the gist of these assessments in the Tier 3 evaluation.

2 Overall, the following criteria are proposed for Tier 3 evaluation, which include several non-water quality aspects:

· Pathogen reduction

· Human health

· Marine ecology (ecological health)

· Fisheries

· Air quality

· Noise

· Solid waste management implications

· Landscape and visual impacts

· Hazard to Life

3 For the purposes of this exercise, the longer-term effects would be of primary interest. Therefore, the evaluation will refer to operational rather than construction stage impacts.

4 Further, it is recognised that while the two disinfection options may be similarly categorised as acceptable under certain environmental aspects, they may be different in terms of their level of impact (or risk[5]) and hence the extent to which they are preferred under the concerned aspect.

5 To address this, it is proposed to assess the two options based on a system of qualitative impact/risk categorisation, based on the following considerations:

· Is the effect on the environmental aspect of concern is positive (i.e., beneficial) or negative (i.e., adverse)?

· If adverse, would the impact/risk be negligible (i.e., non-detectable)?

· If detectable, could it be controlled to within acceptable limits with standard measures or generally accepted good practice?

· If specific mitigation measures are required to control the impact/risk to within acceptable levels, are we highly confident that the mitigation measures would perform as expected. At the same time, how confident are we with the predicted impact/risk in the first place?

· Finally, if the impact/risk is high, and there are significant doubts with the available mitigation measures, the option would be judged unacceptable.

1 The relative performance of the two options against each criterion is summarised in Table 6‑1 to Table 6‑9.

Table 6‑1 Tier 3 Evaluation Matrix (Pathogen reduction)

|

Option |

Comments |

|

Sodium Hypochlorite

|

Effluent disinfection by chlorination (use of sodium hypochlorite solution) would have the beneficial effect of reducing effluent pathogen levels (measured as E. coli) thereby helping to protect water quality at the water sensitive receivers (e.g., beaches). In the context of HATS, chlorination by purchase of sodium hypochlorite solution could be implemented quickly (by 2009). This is because the sodium hypochlorite dosing system can be installed relatively easily. Overall, it is assessed that disinfection by use of sodium hypochlorite solution would have beneficial effect on water quality (with respect to reduction of pathogen levels) in the shortest possible time.

|

|

UV radiation

|

Effluent disinfection by UV radiation also would have the beneficial effect of controlling pathogen levels (measured as E. coli). In the context of SCISTW, however, implementation of an UV disinfection system would take more time and effort, due to the need to secure additional land to accommodate the large-scale UV plant, to build, install, and commission the plant, and to upgrade the existing power supply to the SCISTW. In comparison with the sodium hypochlorite dosing system, the UV plant would take much longer to implement. According to current estimate, the UV plant probably will be able to commence operation in 2013/14 (at the same time as completion of HATS Stage2A).

Overall, it is assessed that disinfection by UV radiation would have beneficial effect on water quality (with respect to reduction of pathogen levels) in the longer term (compared to the more immediate water quality improvement with chlorination by purchase of sodium hypochlorite solution). |

Table 6‑2 Tier 3 Evaluation Matrix (Human Health)

|

Option |

Comments |

|

Sodium Hypochlorite |

The environmental acceptability of chlorination, in the context of HATS, with respect to human health has been confirmed through a human health risk assessment (as discussed in Section 4.1.4.) This evaluation further considers the chlorination option for the purposes of option rating.

Hazard/Pollutant Identification The key concerns of chlorination on human health are (a) toxicity generated by total residual chlorine (TRC), and (b) formation of chlorination-by-products (CBPs). As discussed in Section 4.1.1, TRC can be effectively removed from the effluent by de-chlorination, a standard control practised at many STWs adopting chlorination worldwide.

With respect to CBPs, their concentrations in chlorinated effluent are related to the strength of the sewage and the dosage of the chlorine. For HATS, laboratory trials have confirmed that the HATS effluents would contain few CBPs at very low levels. In addition, none of the detected CBPs is known to be of significant concern with respect to bioaccumulation. This is because of several reasons, including:

· Absence of CBP precursors in the raw sewage, due to the predominantly domestic nature of the HATS catchment and effective licensing controls on any industrial discharges · In the case of CEPT effluent, suppression of CBP formation due to presence of ammonia · In the case of secondary effluent, the generally low level of organics in the sewage · Effect of de-chlorination, which also helps to reduce CBP levels

It is expected that effective operation of the chlorination system can be achieved by the SCISTW to control or minimise formation of CBPs. There is ample international experience to be drawn upon with operation of large STWs employing chlorination (e.g., Deer Island STW in Boston, USA) for disinfecting sewage effluent.

Likelihood of occurrence (exposure pathway) This is concerned with the way human receivers may be exposed to the CBPs. For the SCI outfall, human receivers are unlikely to be exposed to the effluent directly or indirectly, under normal conditions:

· The waters off SCI are dominated by marine traffic, where swimming, fishing, or other water-based recreational activities are not normally practised. · Ingestion of contaminated seafood harvested from the affected sea area would be very unlikely, given that the waters off SCI are not fishing grounds and do not have fish farms.

Consequence This is the effect of exposure to human receivers of the CBPs. Key considerations include duration of exposure, dosage, etc. Again, given the setting of the SCI discharge, it is highly unlikely any human receivers would be subjected to frequent, large doses of the chlorinated effluent or for a sustained long period.

Conclusion On consideration of the above factors and results of the human health risk assessment (see Section 4.1.4), it is concluded that, in the context of HATS, impacts/risks on human health are acceptable without mitigation measures over and above generally accepted good practice or standard engineering controls (e.g., de-chlorination, near optimal location of SCI outfall with respect to harbour hydrodynamics and remoteness from human receivers, etc)

|

|

UV radiation

|

Hazard/Pollutant Identification Two groups of contaminants of concern are associated with UV radiation: · Certain chemical compounds in sewage can be altered by UV radiation. However, there is relatively little information on disinfection-by-products (DBPs) from UV radiation. Nevertheless, aldehydes and other oxidation by-products were found to exhibit a UV-dose response increase in previous pilot studies using both low- and high-intensity UV systems, although the elevated levels were within the acceptable limits. · The other potential hazard is the mercury present in UV lamps.

Likelihood of occurrence (exposure pathway) · At this stage, the only well documented DBP is cyanide, which can be treated (e.g., oxidised with hydrogen peroxide) such that no cyanide will be released into the receiving waters. · If a UV lamp and its sleeve break in the effluent channel, mercury could be released into the wastewater. This is a very unlikely occurrence. UV lamp breakage would more likely occur during the chemical cleaning process, which is conducted outside of the channels. UV operation manuals typically include procedures for properly handling such breakages and properly disposing of the mercury. · Overall, it is assumed that no significant levels of contaminants of concern (i.e., neither mercury, cyanide, nor any DBPs) will be discharged into receivers. · Further, for the SCI outfall, human receivers are unlikely to be exposed to the effluent directly or indirectly, under normal conditions: o The waters off SCI are dominated by marine traffic, where swimming, fishing, or other water-based recreational activities are not normally practised. o Ingestion of contaminated seafood harvested from the affected sea area would be very unlikely, given that the waters off SCI are not fishing grounds and do not have fish farms.

Consequence This is the effect of exposure to human receivers of the potential DBPs. Key considerations include duration of exposure, dosage, etc. Again, given the setting of the SCI discharge, it is highly unlikely any human receivers would be subjected to large doses of the disinfected effluent or for any significant period.

Conclusion While it may be argued that UV disinfection of sewage effluent is not “risk free” with respect to DBPs, in the case of SCI outfall, even if any DBPs were discharged into the sea, they would be diluted and dispersed rapidly. Further, human receivers are unlikely to be exposed to the effluent directly or indirectly, under normal conditions.

Overall, it is concluded that, in the context of HATS, impacts/risks on human health are acceptable without mitigation measures over and above generally accepted good practice or standard engineering controls (e.g., near optimal location of SCI outfall with respect to harbour hydrodynamics and remoteness from human receivers, etc) |

Table 6‑3 Tier 3 Evaluation Matrix (Marine Ecology)

|

Option |

Comments |

|

Sodium Hypochlorite |

Similar to human health, the key concerns on marine ecology (or aquatic lives) are TRC and CBP. Similarly, given the near-optimal location of the SCI outfall with respect to harbour hydrodynamic conditions and remoteness from the sensitive marine ecological resources, an ecological risk assessment (see section 4.1.4) has confirmed that the established ecological risk criteria could be met. It is expected that the same standard practice (e.g., de-chlorination to remove TRC, source control of CBP precursors, etc) could be applied effectively to safeguard ecological health.

Overall, for the purposes of Tier 3 evaluation, it is concluded that, in the context of HATS, impacts/risks on marine ecology are acceptable without mitigation measures over and above generally accepted good practice or standard engineering controls.

|

|

UV radiation

|

It may be argued that UV disinfection of sewage effluent is not risk free with respect to DBPs. However, it is concluded that, in the context of HATS, impacts/risks on marine ecology are acceptable without mitigation measures over and above generally accepted good practice or standard engineering controls (e.g., near optimal location of SCI outfall with respect to harbour hydrodynamics and remoteness from sensitive receivers; etc). |

Table 6‑4 Tier 3 Evaluation Matrix (Fisheries)

|

Option |

Comments |

|

Sodium Hypochlorite |

Similar to human health and marine ecology, the key concerns on fisheries are TRC and CBP. Nevertheless, given the hydrodynamic conditions of the receiving waters and absence of fisheries resources (e.g., fish culture zones) within close proximity of the SCI outfall, it is considered that no adverse impact on fisheries resources would occur. Overall, for the purposes of Tier 3 evaluation, it is considered that impacts/risks on fisheries from effluent chlorination are acceptable without mitigation measures over and above generally accepted good practice (e.g., de-chlorination). |

|

UV radiation

|

Similarly, it may be argued that UV disinfection of sewage effluent is not risk free with respect to DBPs. However, it is concluded that, in the context of HATS, impacts/risks on fisheries are acceptable without mitigation measures over and above generally accepted good practice or standard engineering controls (e.g., near optimal location of SCI outfall with respect to harbour hydrodynamics and remoteness from fisheries resources, etc).

|

Table 6‑5 Tier 3 Evaluation Matrix (Air Quality)

|

|

Comments |

|

Sodium Hypochlorite |

Neither chlorination (using sodium hypochlorite solution) nor UV radiation would generate any significant emissions to air during operation. Therefore, either option is considered to have no material impact on any air sensitive receivers. |

|

UV radiation |

Table 6‑6 Tier 3 Evaluation Matrix (Noise)

|

|

Comments |

|

Sodium Hypochlorite

|

Neither the sodium hypochlorite dosing system nor the UV radiation system would generate significant noise emissions during operation. Therefore, either option is considered to have no material impact on noise sensitive receivers. |

|

UV radiation

|

Table 6‑7 Tier 3 Evaluation Matrix (Waste Management Implications)

|

|

Comments |

|

Sodium Hypochlorite |

The chlorination process does not generate solid waste or residues. |

|

UV radiation

|

Sludge The UV radiation process itself does not generate solid waste or residues. However, if UV radiation were adopted for Stage 2A SCISTW Upgrading, it would be necessary to use alum (instead of ferric chloride) as coagulant in the CEPT process. This is because iron (ferric) compounds have a relatively high absorbance of UV radiation, thereby making the disinfection process ineffective. Alum has a lower absorbance of UV radiation compared to ferric chloride, and would be preferred if disinfection by UV radiation were to follow. However, compared to using ferric chloride, use of alum would increase the quantity of sludge generated from the CEPT process by about 10% each day (i.e., approximately 100 to 130 wet tpd). This is highly undesirable from a waste management perspective, as the capacity for co-disposal of sewage sludge (with general solid wastes) in the existing strategic landfills is already depleting faster than anticipated. Any further increase in sewage sludge production would exacerbate the already worsening situation. In the worst situation, it may be necessary to treat the sludge to a condition that can be disposed of at landfills directly (rather than co-disposed with other general solid wastes).

If UV radiation were adopted for Stage 2B, which would be for disinfection of secondary (biologically treated) effluent, no additional sludge is expected. There would be no need to replace ferric chloride by alum as coagulant at the primary treatment stage.

Hazardous Waste Stage 2A (for disinfection of CEPT effluent) would have the largest number of installed UV lamps. When SCISTW moves to Stage 2B, where biological treatment is provided, the number of UV lamps needed to disinfect the biologically treated effluent would be less than that installed for Stage 2A. It is estimated that the over-provision at Stage 2B would be about 70% compared to number of lamps installed for Stage 2A.

For stage 2A, depending on whether medium- or low-pressure units are used, it has been estimated that the number of UV lamps to be installed would be between 10,400 and 47,500. These UV lamps contain mercury. At the end of their lives, these would have to be disposed of as a hazardous waste at a designated facility (currently the Chemical Waste Treatment Facility at Tsing Yi) or returned to the manufacturer for re-processing or disposal. Medium-pressure lamps have a design life of 3,000 hours (or 0.34 year). Low-pressure lamps have a design life of 12,000 hours (1.37 year). That means, on average about 30,000 to 35,000 spent UV lamps would be generated each year.

Conclusion Overall, use of UV radiation would have implications on solid waste management, requiring application of specific mitigation or safeguards over and above standard practice. For example, additional sludge would be generated due to use of alum as coagulant in the CEPT process. The sludge may require special processing before it is delivered to the landfills. Irrespective of sludge, special measures are also needed for disposal of the spent UV lamps (which are a hazardous waste).

|

Table 6‑8 Tier 3 Evaluation Matrix (Landscape and Visual Impacts)

|

Option |

Comments |

|

Sodium Hypochlorite |

The project would involve some aboveground structures, including a sodium hypochlorite storage tank farm (comprising five 12m-high, 10m-diameter tanks) within the SCISTW site and a sodium bisulphate tank farm (comprising two 6.2m-high, 6m-diameter tanks) off-site on Container Port Road South.

Given the general industrial setting of the area, and the scale of the storage tanks relative to the SCISTW facilities, it is assessed that the landscape or visual impacts would be detectable but acceptable without mitigation measures over and above generally accepted good practice (e.g., sympathetic architectural design).

|

|

UV radiation

|

The UV radiation plant would be located off-site on Container Port Road South and occupy up to 11,000 m2. It probably would be housed in a single storey building. Given the general industrial setting of the area, and the scale of the plant relative to the SCISTW facilities, it is assessed that the landscape or visual impacts would be detectable but acceptable without mitigation measures over and above generally accepted good practice (e.g., sympathetic architectural design).

|

Table 6‑9 Tier 3 Evaluation Matrix (Hazards to Public)

|

|

Comments |

|

Sodium Hypochlorite |

Hazards, in this context, refer to events that could pose a danger to the public (not the workers on the site).

The two chemicals of concern are sodium hypochlorite solution and sodium bisulphite solution. Sodium hypochlorite is common household bleach. It is neither flammable nor explosive. It is corrosive, and is classified as Category 4 dangerous goods (DG) in Hong Kong. Sodium bisulphite is normally stable. It is only toxic when swallowed or inhaled. These two substances are routinely used in many sewage treatment works in the world, including the Deer Island Sewage Treatment Plant in Boston, USA, which has a comparable capacity and scale to SCISTW. The maximum quantity of sodium hypochlorite solution stored on-site at SCISTW is estimated to be about 2,500m3. The maximum quantity of sodium bisulphite solution stored on-site would be about 150m3. These chemicals will be handled and stored according to standard well-proven practices and codes of practice at SCISTW. Given the nature of the chemicals, and the location of SCISTW (which is isolated and remote from population centres), storage or handling of these chemicals in SCISTW are not expected to pose ant material hazards to the public.

The potential hazards to the public would be related primarily to the transportation of sodium hypochlorite solution and sodium bisulphite solution to the SCISTW site. Sodium hypochlorite solution would be delivered to SCISTW normally by purpose-built marine vessels. Delivery would be 2 to 3 times a week. Delivery by road tankers would occur only on occasions when chemicals delivery by sea is not feasible (e.g., severe adverse weather conditions, etc). This mode of delivery would pose very low hazards to the public. Sodium bisulphite solution (the de-chlorination agent) would be delivered to SCISTW by road tankers at an interval of 2 to 3 times a week. Standard HK Fire Services Department requirements will be followed during transportation of these materials.

Overall, impacts/risks with respect to hazards to public are acceptable with specific precautionary design measures (e.g., relevant FSD codes of practice), and high levels of confidence are associated with the available precautionary design measures.

|

|

UV radiation

|

The UV radiation plant would be located on Container Port Road in a designated area. Access by the public to the plant will not be allowed. No transportation of DG is involved during operation stage of the UV radiation plant. However, about 30,000 to 35,000 spent UV lamps containing mercury would need to be transported offsite for disposal each year. It is expected that transportation of the spent UV lamps would be managed properly to prevent any breakage and release of mercury. Therefore, risks are considered acceptable without mitigation measures (over and above generally accepted good practice).

|

1 With respect to pathogen reduction, chlorination (purchase of sodium hypochlorite) would be preferred to UV radiation. This is because the chlorination system could be implemented much sooner than the UV system, with the potential to bring about earlier improvement to water quality (reduction of pathogens) at the Tsuen Wan beaches.

2 On human health, marine ecology, and fisheries:

· The key concerns of chlorination are toxicity generated by TRC and formation of CBPs.

· TRC can be removed from the effluent by de-chlorination such that it would not pose a significant concern to human health, marine ecology, or fisheries.

· The formation of CBPs is related to the strength of the sewage and the dosage of chlorine added to the wastewater. However, in the case of HATS, formation of CBPs is greatly reduced for several reasons[6]. Chemical tests have confirmed that there are few CBPs in the HATS effluents, and that the detected CBPs are of relatively low concentrations.

· Further, hydrodynamic conditions are favourable to effective mixing and dilution of the discharged effluent from SCISTW, while the SCI outfall is located well away from human receivers, sensitive marine resources, and fisheries resources.

· The project-specific human and ecological health risk assessments (based on conservative approaches) conducted as part of the EIA study have demonstrated that the risks are low and well within acceptable criteria.

· In conclusion, in the context of HATS, effluent disinfection by chlorination poses low and therefore acceptable risk to human health, marine ecology, and fisheries without mitigation measures over and above generally accepted good practice (e.g., de-chlorination, effective outfall discharge, etc).

· Two groups of contaminants of concerns are associated with UV radiation: mercury from the UV lamps and DBPs.

· With respect to mercury, this could be released into the effluent if the UV lamps break during operation or maintenance activities. This is unlikely, however, given that proper procedures will be in place.

· Regarding DBPs from UV radiation of sewage, there is relatively little information as this subject is being researched. Aldehydes and other oxidation by-products were found to exhibit a UV-dose response increase in previous pilot studies using both low- and high-intensity UV systems, although the elevated levels were within the acceptable limits.

· Nevertheless, hydrodynamic conditions are favourable to effective mixing and dilution of the discharged effluent from SCISTW, while the SCI outfall is located well away from human receivers, sensitive marine resources, and fisheries resources.

· Again, in the context of HATS, effluent disinfection by UV radiation is considered to pose low and therefore acceptable risk to human health, marine ecology, and fisheries without mitigation measures over and above generally accepted good practice (e.g., cyanide removal, effective outfall discharge, etc).

3 With respect to air quality and noise, neither disinfection option would generate any significant air and noise emissions during operation. Therefore, either option is considered to have no material air quality or noise impact.

4 Concerning landscape and visual impacts, given the industrial setting of the area and the scale of disinfection plant (either chlorination or UV radiation) relative to the SCISTW, it is considered that either option would be acceptable without mitigation measures over and above generally accepted good practice (e.g., sympathetic architectural treatment).

5 Regarding waste management implications, chlorination is preferred to UV radiation. This is because:

· Application of UV radiation to CEPT effluent (Stage 2A) would require switching the coagulant to alum (from ferric chloride) in the CEPT process. This, in turn, would lead to about 10% extra sludge each day (about 100 to 130 wet tpd) requiring disposal at landfills.

· The capacity available for co-disposing sewage sludge (with other solid wastes) at landfills is depleting rapidly. The extra 10% of alum sludge is not an insignificant amount. To overcome this problem, it may be necessary to pre-process the sludge to a condition that is suitable for direct disposal at landfills.

· UV lamps contain mercury, and spent UV lamps are hazardous wastes requiring special disposal practice or re-processing by the manufacturer. It has been estimated that on average tens of thousands of spent UV lamps would generated each year under Stage 2A.

· For Stage 2B, where biologically treated effluent is involved, no extra sludge would be generated (as there would be no need to use alum in the upstream CEPT process). However, spent UV lamps will continue to be managed or disposed of as a hazardous waste.

6 With respect to hazards to public:

· The chlorination option would involve sodium hypochlorite and sodium bisulphate solutions. Given the nature of the chemicals (neither substance is explosive or flammable), and the location of SCISTW (which is isolated and remote from population centres), storage and handling of these chemicals in SCISTW are not expected to pose any material hazards to the public. Transportation of these substances to SCISTW will be by purpose-built marine vessel or road tankers, and will follow standard HK Fire Services Department requirements. Overall, it is expected that the hazard posed to public during transportation of these substances would be low with adoption of relevant Fire Services Department codes of practices.

· The UV option would also pose a certain degree of hazard to the public during transportation of spent UV lamps (which contain mercury, a hazardous waste) from the disinfection plant to the disposal site (e.g., the Chemical Waste Treatment Facility at south Tsing Yi). Nevertheless, risks are considered acceptable without mitigation measures over and above generally accepted good practice.

1 The above analysis suggests that both disinfection options would be environmentally acceptable.

2 The relative strengths (benefits) of chlorination over UV radiation are:

· earlier improvement of water quality (in terms of reduction of pathogens)

· lesser waste management issues, due to additional sludge from UV disinfection of CEPT effluent and hazardous mercury wastes from spent UV lamps

3 The relative strength (benefit) of UV radiation over chlorination (purchase of sodium hypochlorite solution) is the perceived higher level of hazard associated with transport of chlorination and de-chlorination chemicals than transport of hazardous mercury wastes.

4 Overall, while both chlorination and UV radiation are preferred from an environmental perspective, neither is superior to the other on all of the environmental aspects considered in the Tier 3 evaluation.

5 To select a disinfection option for HATS, it is proposed to proceed to Tier 4 evaluation, which will consider a broader range of criteria (other than environmental aspects).

7 Tier 4 Evaluation

1 For this evaluation, it is proposed to consider the following non-environmental criteria:

· Cost, i.e., lifecycle cost, covering both capital, and operating and maintenance components. The option with the lower the total lifecycle cost is preferred.

· Flexibility of the disinfection system to cater for project risks or uncertainties, including, for example, sewage flow and quality variations, delay to overall HATS programme, etc. The more flexible option would be preferred.

· Implementation issues, in terms of impact on existing SCISTW operations, and time required to build and commission the disinfection facility.

· Scale-Up Factor is the capacity of the HATS disinfection plant relative to that of the largest known and established plant using either UV radiation or chlorination for CEPT/secondary effluent. The option with a smaller scale up factor would be preferred, as the technical risks and operational challenges to be managed or overcome would be smaller.

2 Options will be ranked based on qualitative or quantitative assessment, as follows:

· Preferred (ü)

· Not preferred (o)

1 The relative performances of the two options against each Tier 4 criterion are summarised in 錯誤! 找不到參照來源。 Table 7‑1 to Table 7‑3.

Table 7‑1 Tier 4 Evaluation Matrix (Cost)

|

Option |

Comments |

Ranking |

|

Sodium Hypochlorite

|

The lifecycle costs (based on a 15-year equipment life), at 4% discount rate, 2006 1st Q price level, of the options have been estimated in the order of:

This shows that chlorination (purchase of sodium hypochlorite) has a lower lifecycle cost than UV radiation disinfection. This may be explained by the relatively high capital cost of the UV system compared to the chlorination (storage and dosing) system.

The capital cost of a chlorination plant (based on purchase of sodium hypochlorite solution) for Stage 2A/B has been estimated at $0.29 billion. This is much lower than the estimated capital cost of an equivalent capacity UV disinfection plant (which ranges from $0.72 billion to $0.94 billion). The reason for this is that the chlorination plant will be essentially a chemical storage and dosing system requiring relatively little capital investment.

The operation and maintenance (O&M) costs have been estimated:

For either disinfection option, the O&M cost is higher for Stage 2A than Stage 2B, because the CEPT effluent (2A) is of lower quality than secondary effluent (2B). The O&M cost of chlorination is comparable to UV radiation, as the chlorination cost includes the purchase of sodium hypochlorite solution.

Overall, the chlorination system is preferred to the UV system in terms of cost.

|

ü |

|

UV radiation

|

o |

Table 7‑2 Tier 4 Evaluation Matrix (Flexibility)

|

OPTION |

COMMENTS |

RANKING |

|

Sodium Hypochlorite

|

The chlorination system is more flexible than the UV system to cater for project risks such as lower (than expected) rate of population growth leading to slower flow build-up, delays to project implementation due to for example socio-economic or political factors, uncertainty in selection of the ultimate biological treatment technology in Stage 2B, variable effluent quality, etc. This is because:

· Sodium hypochlorite can effectively treat both CEPT and secondary effluent, and is more versatile than UV radiation as a disinfectant for sewage effluent. · Chlorination can cater better for effluent quality uncertainties associated with the future biological treatment technology options. The quantity of sodium hypochlorite to be purchased can be varied to meet the required dosage in light of actual requirements. For the UV system, the maximum capacity is set for the ultimate flow conditions under design conditions (e.g., assumed UV transmittance value). There is therefore less flexibility to cater for effluent quality variations. · Sodium hypochlorite will be better positioned to deal with any delay to implementation of Stage 2B, since it can be reliably depended upon to continue to treat CEPT effluent for as long as it takes. · Owing to uncertainties in population growth and consequently sewage flow build-up, it is possible that the installed treatment capacity could be excessive to actual demand in the early years. For this reason, it is better from a financial point of view to minimise initial capital investment as much as possible if return (i.e., environmental improvement) on investment were to be maximised. This will favour the chlorination option, as much lower capital investment will be made for the chlorination system than for the UV system. · As the chlorination (purchase option) would not involve significant capital investments, it could be easily discarded to allow introduction of any more advanced or suitable disinfection technologies in the future.

|

ü |

|

UV radiation

|

o |

Table 7‑3 Tier 4 Evaluation Matrix (Implementation Issues)

|

Option |

Comments |

Ranking |

|

Sodium Hypochlorite

|

The SCISTW will be operating while the Stage 2A works (including the disinfection system) is incorporated into the facility. The chlorination system, consisting of a storage system and a dosing system, can be integrated into the existing effluent discharge system with relative ease. For the UV radiation system, more construction activities will be involved, due to the need for installation of more complicated mechanical and electrical plant and equipment.

In addition, it has been found that the existing power supply to SCISTW is not sufficient to meet the power demand of the UV radiation disinfection system. To serve the new UV system, a new primary 132kV electrical substation will be needed. This will take time (possibly up to 3 to 4 years) from planning to actual commissioning of the substation. In addition, operation and maintenance efforts of the UV disinfection system would be relatively high.

For disinfection to be achievable by 2009, chlorination (purchase of sodium hypochlorite) would be preferred, as the initial storage and dosing system can be accommodated within the existing SCISTW.

Overall, it would be quicker and simpler to install a chlorination system (purchase of sodium hypochlorite) than a UV radiation system at SCISTW. This would have the benefit of effecting disinfection of the effluent at the earliest possible time, thereby helping to improve beach water quality sooner rather than later.

|

ü |

|

UV radiation

|

o |

Table 7‑4 Tier 4 Evaluation Matrix (Scale Up Factor)

|

Option |

Comments |

Ranking |

|

Sodium Hypochlorite

|

As HATS Stage 2 will be implemented in phases, the scale up factor is most critical for disinfecting the type of effluent encountered at the initial stage of HATS, i.e., CEPT effluent under the ADF and Stage 2A.

For HATS ADF and Stage 2A, developing a chlorination plant at SCISTW would involve a smaller scale-up factor than UV radiation for the CEPT effluent. This is elaborated below: · There is some experience[7] with applying UV radiation to disinfect CEPT effluent at several STWs in Hong Kong, e.g., Siu Ho Wan Phase 1 (96,000m3/d), Cyberport (10,800m3/d), and Sham Tseng (16,850m3/d). · Internationally, the largest known CEPT plant using UV radiation disinfection is the Sand Island STW, Honolulu, USA (320,000m3/d), which is being commissioned at the moment. · The proposed ADF or Stage 2A CEPT disinfection plant at SCISTW (up to 2.5million m3/d) would be one to two orders of magnitude larger than these local or overseas CEPT STWs. Therefore, applying UV radiation to HATS CEPT effluent would involve scaling up the UV system by the corresponding orders of magnitude to deal with the challenges of the local situation (e.g., effluent UV transmittance profile[8]). · On the other hand, chlorination has been applied to treat CEPT effluent at many large STWs, e.g., Deer Island[9] STW, Boston, USA (1.8million m3/d) and Newtown Creek[10] STW, New York, USA (1.2million m3/d). This scale of application of chlorination (to CEPT effluent) is of the same order of magnitude as HATS. · Overall, on a comparative basis, chlorination would involve a much lower scale up factor. Hence, it is a relatively more proven technology than UV radiation for disinfecting CEPT effluent for HATS.

|

ü |

|

UV radiation

|

o |

1 The performances of the two options against the Tier 4 evaluation criteria are summarised in Table 7‑5.

Table 7‑5 Summary of Tier 4 Evaluation

|

Criterion |

Chlorination (purchase of sodium hypochlorite) |

UV radiation |

|

Cost

|

Preferred |

Not preferred |

|

Flexibility

|

Preferred |

Not preferred |

|

Implementation Issues |

Preferred |

Not preferred |

|

Scale Up Factor

|

Preferred |

Not preferred |

2 This shows that, for the Tier 4 evaluation criteria, chlorination (purchase of sodium hypochlorite solution) would be preferred to UV radiation. In summary:

· Chlorination (purchase of sodium hypochlorite) is preferred to UV radiation in terms of cost. Compared to UV radiation, chlorination has much lower capital cost, but comparable operation and maintenance cost, resulting in lower overall lifecycle cost. The saving over a 15-year lifecycle of the chlorination option over the UV option is estimated at about $0.6billion.

· Chlorination, using purchase option, is more flexible than UV radiation to cater for project risks. These include, for example, lower (than expected) rate of population growth leading to slower flow build-up, delays to project implementation due to for example socio-economic or political factors, uncertainty in selection of the ultimate biological treatment technology in Stage 2B, variable effluent quality, future advancement in disinfection technologies, etc. It also avoids excessive over-provision of disinfection facility when Stage 2B comes in operation, at which time the disinfection requirement would be much reduced due to better quality effluent being produced.

· A chlorination system (purchase of sodium hypochlorite) would be quicker and simpler to implement at the SCISTW than a UV radiation system. It will also need lesser operation and maintenance efforts. This would have the benefit of effecting disinfection of the effluent at the earliest possible time, thereby helping to improve beach water quality sooner rather than later.

· Given the mega-size of SCISTW (2.5million m3/d), and its pivotal role in marine water quality protection, it would be prudent to minimise the technical risks and operational challenges associated with system scale up.

3 Overall, chlorination (purchase of sodium hypochlorite solution) is preferred to UV radiation against the Tier 4 evaluation criteria.

7.4 Conclusions on Disinfection Alternatives and Preferred Option

7.4.1 Consideration of Alternatives

1 As concluded from the Tier 1 evaluation, the feasible sewage disinfection options for the ADF (the Project) are chlorination and UV radiation.

2 Based on the outcome of Tiers 2 evaluation, it is concluded that both chlorination (purchase of sodium hypochlorite) and UV radiation are environmentally acceptable for HATS. Water quality and ecological impacts can be mitigated or controlled to well within established criteria (contained in the Technical Memorandum of EIA Process).

3 A comparison of the environmental benefits and disbenefits of chlorination (purchase of sodium hypochlorite) and UV radiation has been made in the Tier 3 evaluation. It is concluded that:

· Neither chlorination nor UV radiation is superior to the other on all of the environmental aspects. Nevertheless, neither option would result in adverse environmental effects (or impacts exceeding the relevant criteria in the TM).

· Therefore, both chlorination (purchase of sodium hypochlorite) and UV radiation are preferred from an environmental perspective.

7.4.2 Selection of Preferred Option

1 As discussed earlier, a multi-tier multi-criteria option evaluation has been conducted to recommend a preferred disinfection technology for HATS. The Tier 1 evaluation was a screening test, and served to identify only those disinfection options that would be technically feasible for HATS.

2 Environmental considerations have played a key part in the technology selection process for HATS. These included:

· In Tier 2 evaluation, the environmental acceptability of both technically feasible options (UV radiation and chlorination) in terms of water quality, human health, and ecological health was confirmed before these were taken forward to the next stage of the evaluation.

· In Tier 3 evaluation, both UV radiation and chlorination were assessed against nine environmental criteria, i.e., fisheries, air quality, noise, landscape and visual impacts, waste management implications, hazards to public, in addition to water quality improvement (pathogen reduction), human health, and marine ecology.

3 The Tier 3 evaluation has concluded that, from an environmental perspective, both chlorination (purchase of sodium hypochlorite) and UV radiation would be preferred. Neither option would result in any adverse environmental effects.

4 Nevertheless, neither disinfection option would be superior to the other on all of the nine environmental criteria. There were relative environmental benefits and disbenefits, depending on the criteria under consideration, as elaborated in Section 6.3.

5 On non-environmental considerations, chlorination does have advantages over UV radiation in the context of HATS (including the ADF), in terms of a lower total lifecycle cost, a higher level of flexibility to deal with uncertainties and project risks, easier and speedier implementation at SCISTW, and lower technology scale-up factors. In particular,

· Adoption of UV radiation for the ADF (and Stage 2A), where CEPT effluent is involved, will result in substantial abortive works (hence capital investment) at Stage 2B when biological treatment is implemented.

· Early commissioning of the disinfection plant at SCISTW would bring about water quality improvement (pathogen reduction) at the earliest opportunity.

· Further, given the mega-size of SCISTW (2.5million m3/d), and its pivotal role in marine water quality protection, it would be prudent to minimise the technical risks and operational challenges associated with system scale up.

6 On balance, it is recommended that chlorination (purchase of sodium hypochlorite solution) should be adopted as the disinfection technology for HATS in preference to UV radiation.

7 In arriving at the above conclusion, environmental factors have played a significant role, as manifested in the conduct of Tiers 2 and 3 evaluations. .

8 Review of Local and International Disinfection Practices

1 A review of local and international effluent disinfection practices has been conducted in parallel with the “HATS disinfection option evaluation” presented in the preceding sections.

2 As discussed earlier, selection of sewage disinfection technology is necessarily a project-specific exercise that must consider a wide range of technical and non-technical constraints and issues unique to the situation at hand.

3 With this in mind, the objective of the review of local and international disinfection practices is to provide supplementary information for general reference by the project team. It is not intended that the outcome of the local and international review should drive the option selection for HATS.

1 In Hong Kong, there are over 260 sewerage facilities. Eleven of these are municipal STWs employing primary, secondary, or tertiary treatment. Most of these municipal STWs are less than 100,000m3/day, with the exception of SCISTW and Shatin STW.

2 The existing SCISTW constructed under Stage 1 of HATS has the largest capacity at 1.7million m3/day. Currently, the effluent is not disinfected. It is now proposed to provide disinfection facilities at SCISTW, which is the subject of this EIA study.

3 Shatin STW is the second largest, at 0.34million m3/day. It is a secondary plant. Currently, the effluent is not disinfected. However, there is a plan to provide effluent disinfection using UV radiation.

4 UV radiation is used for effluent disinfection at Shek Wu Hui (80,000m3/day; secondary treatment), Sai Kung (22,0000m3/day; secondary), Sham Tseng (16,850m3/day; CEPT), Cyberport (10,800m3/day; CEPT), and Ngong Ping (3,000m3/day; tertiary). The UV disinfection system at Siu Ho Wan Phase 1 (96,000m3/day; CEPT) is to be commissioned. Chlorination is used at Stanley (11,600m3/day; secondary).

8.2.2 Disinfection of Secondary Effluent

1 UV disinfection (e.g., Shek Wu Hui and Sai Kung STWs) and chlorination (e.g., Stanley STW) of secondary effluent have been practiced in Hong Kong for some time. Either technology is satisfactory for secondary effluent.

8.2.3 Disinfection of Primary/CEPT Effluent

1 Recently, UV disinfection has been adopted at the newer CEPT plants. These provide opportunities where experience with use of UV radiation on local CEPT effluent may be gained.

2 The Cyberport CEPT STW and Sham Tseng CEPT STW were commissioned in 2000 and 2003, respectively. It was reported that there were initial operational problems with the UV disinfection systems at both plants, due to the variable UV transmittance[11] (UVT) of the CEPT effluents. These were resolved eventually by installation of additional UV lamps, more frequent UV lamp replacements, and higher power consumption.

3 At the time of writing, the UV system at Siu Ho Wan STW has not been fully commissioned. Nevertheless, initial problems related to CEPT effluent quality (with respect to UVT) were also encountered at Siu Ho Wan CEPT STW (Phase1). Further studies are being carried out to investigate the UVT profile at Siu Ho Wan STW. The selection of disinfection technology for Phase 2 of the STW will be reviewed in light of the study findings and operational experience.

4 Overall, local experience with UV disinfection of CEPT effluent shows that the performance of the UV disinfection system was not without problems initially. However, it is anticipated that as more experience with UV disinfection operation under local conditions is gained, understanding of UVT with respect to local CEPT effluent will be improved.

1 In Hong Kong, disinfection of secondary effluent by either chlorination or UV radiation has been practised for some time. For CEPT effluent, there is some recent experience with UV radiation disinfection on several small STWs.

2 For HATS Stage 2A, which involve a mega-size CEPT plant of around 2.5 million m3/day capacity, the approach to selection of disinfection technology must necessarily be robust, as the consequence of technology non-performance would be significant.

3 The outcome of the above review of local experience has been taken into account in the option evaluation process.

1 The general objective of the survey was to gather information on the current practices and the trend of disinfection technologies in other coastal cities that discharge their treated effluents in marine waters.

2 However, it is cautioned that the conditions that led to the adoption of a particular disinfection scheme or technology by an overseas sewage treatment plant could be complex and might include a multitude of technical and non-technical (e.g., social, political, etc) considerations. As such, the review is to provide a general reference, and it should not be taken as a definitive account of overseas trends or practices.

8.3.2 Selection of Coastal Cities for Survey

1 The survey was focused on the disinfection methods adopted in municipal sewage treatment works (STW) in other coastal cities. There are altogether about 230 coastal cities in North America (total: 24), Asia/Australia/New Zealand (total: 149) and Europe (total: 57) each having more than 200,000 inhabitants.

2 In order to contain the survey within a manageable scale and in a cost-effective manner, the following criteria were used in short-listing these coastal cities for the purpose of the survey:

· Coastal cities with significant population

· Coastal cities with well-established requirements for wastewater treatment and disinfection

· Coastal cities with well-developed sewage treatment and disposal systems

· Coastal cities with ocean discharge of the treated effluents

3 In addition to the above criteria, some practical constraints, such as language, availability of local contacts and so on were also considered in the selection process.

4 Eventually, 24 coastal cities were selected for the survey, including eight (8) in North America, nine (9) in Asia/Australia/New Zealand and seven (7) in Europe:

· North America (8)

· Halifax, Canada

· Vancouver, Canada

· Miami, United States

· New York, United States

· Boston, United States

· Seattle, United States

· Los Angeles, United States

· Honolulu, United States

· Asia/Australia/New Zealand (9)

· Melbourne, Australia

· Sydney, Australia

· Auckland, New Zealand

· Tokyo, Japan

· Singapore

· Kaohsiung, Taiwan

· Guangzhou, China

· Shanghai, China

· Bangkok, Thailand

· Europe (7)

· Hamburg, Germany

· Bremen/Bremerhaven, Germany

· Dublin, Ireland

· Cardiff, Wales

· Swansea, Wales

· Edinburgh, Scotland

· London, England

1 For each of the cities selected, key information that was collected includes:

· City’s sewage treatment system including no of treatment plants, design capacity and treatment process of each plant

· Current disinfection practices and years of commissioning

· Disinfected effluent standards

· Discharge location of disinfected effluent

· Any upgrading plan in next five years

2 Questionnaires were sent to the management and the operation and maintenance (O&M) authorities of the STW in the selected coastal cities. Telephone conversation and email communications with plant operators were conducted to clarify the collected survey information, as necessary.

3 Supplementary information on the disinfection installation at these STWs was also gathered from the internet and from the consultants’ sister companies at the selected cities. In addition, the installation lists from the major disinfection equipment suppliers were collected and reviewed.

8.3.4 Current Disinfection Practices in the Surveyed Cities

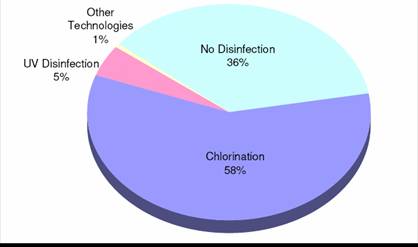

1 In these 24 cities, 132 sewage treatment works (total capacity 38,688,000m3/day) were surveyed. Of the total effluent, 36% of it is discharged into receiving waters without disinfection, 58% uses chlorination, 5% uses UV disinfection, and less than 1% uses other technologies.

Figure 8‑1

Disinfection Technologies for the Surveyed STWs

Total Flow of 132 STWs = 38,688,000m3/day

Primary STWs

2 Of these 132 STWs, 13 were primary or CEPT STWs, collectively treating about 6.8 million m3 of effluent each day.

3 With respect to the disinfection practices adopted in the 13 surveyed primary or CEPT STWs, it is observed that:

· The majority (69.4%, by volume) of the effluent is discharged to receiving waters (mostly marine waters except two were rivers) without disinfection.

· About 30.3% (by volume) of the effluent is disinfected by chlorination, with the capacity of the largest STW at about 1.2million m3/day.

· One small CEPT plant (capacity of 0.024million m3/day) uses UV radiation, accounting for about 0.4% of the amount of effluent treated.

4 The capacity of the largest primary treatment plant is 1,173,000m3/day in Newtown Creek, New York, USA (currently being upgraded to secondary treatment). One small chemically enhanced primary treatment plant, Bellambi STW in Sydney, Australia, with a capacity of 24,000m3/day, is disinfected by UV radiation.

Secondary/Tertiary STWs

5 With respect to the disinfection practices adopted in the 119 surveyed secondary or tertiary STWs (totalling 31.9million m3 of effluent each day), it is observed that:

· About 29% (by volume) of the treated secondary/tertiary effluent is discharged to receiving waters without disinfection.

· The majority (65%, by volume) of the effluent is disinfected by chlorination, with the capacity of the largest STW (which is in Deer Island, Boston, USA) at 1.8million m3/day. Deer Island STW was previously a primary treatment works with chlorination for disinfection before upgrading to a secondary treatment plant in 1999.

· UV radiation is used to disinfect about 5% (by volume) of the effluent, with the capacity of the largest plant (which is Ringsend STW, Dublin, Ireland) at 0.64million m3/day.

· One plant in Japan (capacity 0.3million m3/day) uses a combined chlorination and ozonation process to disinfect the treated effluent, prior to discharging it to the upstream of water gathering catchments.

Figure 8‑2

Disinfection Technologies for the Surveyed 13 Primary and 119 Secondary STWs

|

Large STWs

6 The statistics may also be presented in terms of STW size. Of the 132 surveyed STWs, 48 were considered “large” (i.e., having a treatment capacity higher than 100,000m3/day). Collectively, these 48 large STWs treat about 36.6million m3 of effluent each day. The disinfection practices adopted in these large STWs are summarised below:

· About 36% (by volume) of the effluent is discharged to receiving waters without disinfection.

· Chlorination is used to disinfect about 60% (by volume) of the effluent, with the capacity of the largest STW (which is a secondary STW in the USA) at 1.8million m3/day.

· UV radiation is used to disinfect about 4% (by volume) of the effluent, with the capacity of the largest plant (which is a secondary/tertiary STW in Ireland) at 0.64million m3/day.

· One plant in Japan uses a combined chlorination and ozonation disinfection process, as noted above.

7 In conclusion, the review has found that effluent disinfection is not practised at all of the surveyed STWs. Where disinfection is employed, chlorination is the major technology (in terms of volume of effluent treated) for either primary/CEPT, secondary, or tertiary effluent.

8 UV radiation is the next major disinfection technology after chlorination. The review shows that it is applied more to secondary/tertiary effluent than to primary/CEPT effluent.

1 Of the disinfection facilities commissioned in the surveyed cities in the last 10 years, some 75% of the installed capacities use chlorination/dechlorination, whilst the remaining 25% use UV radiation for disinfecting mostly secondary or tertiary effluents.

2 For those facilities to be commissioned in the coming five years, the total flow capacity of the new UV radiation installations is similar with that of new chlorination facilities.

3 Most of the UV facilities installed/to be installed are used to disinfect secondary/tertiary effluents. The application of UV radiation in primary effluents is rarely adopted.

4 Examples of some large UV radiation facilities recently commissioned / to be commissioned include:

· The Ringsend STW in Dublin, Ireland - commissioned in 2003 with a flow capacity of 638,000m3/day

· The Megere STW in Auckland, New Zealand - commissioned in 2003 with a flow capacity of 300,000m3/day

· The Longhua STW in Shanghai, China - commissioned in 2003 with a total flow capacity of 105,000m3/day

5 As for chlorination, notable new installations include:

· The South STW in Seattle, US - commissioned in 2002 with a flow capacity of 435,000 m31day

· The Da Tan Sha STW and Lie De STW in Guangzhou - commissioned in 2004 with a total capacity of 1,020,000m3/day