4

Air Quality

Assessment

4.1

Introduction

This Section presents an assessment of the

potential air quality impacts associated with the construction and operation of

the proposed biodiesel plant at Tseung Kwan O

Industrial Estate (TKOIE).

Dust nuisance and

stack emissions are the potential air quality impacts during the construction

and operation phases, respectively. Air

Sensitive Receivers (ASRs) have been identified and potential air quality

impacts were evaluated. Where necessary,

mitigation measures are recommended to minimize the impacts and ensure

compliance with the air quality criteria.

4.2

Legislation Requirements and Evaluation Criteria

4.2.1

Air Pollutants Covered by Hong Kong Air Quality Objectives (HKAQOs)

The principal legislation for the

management of air quality in

Table 4.2a Hong

Kong Air Quality Objectives (mg m-3) (a)

|

Air Pollutant |

Averaging Time |

|||

|

|

1 Hour (b) |

24 Hour (c) |

3 Months (d) |

1 Year (d) |

|

Total Suspended Particulates (TSP) |

- |

260 |

- |

80 |

|

Respirable Suspended Particulates (RSP) (e) |

- |

180 |

- |

55 |

|

|

800 |

350 |

- |

80 |

|

Nitrogen Dioxide (NO2) |

300 |

150 |

- |

80 |

|

Carbon Monoxide (CO) |

30,000 |

- |

- |

- |

|

Photochemical Oxidants (as ozone (O3))

(f) |

240 |

- |

- |

- |

|

Lead (Pb) |

- |

- |

1.5 |

- |

|

Notes: (a)

Measured

at 298K (25°C) and 101.325 kPa (one

atmosphere) (b)

Not

to be exceeded more than three times per year (c)

Not

to be exceeded more than once per year (d)

Arithmetic

means (e)

Suspended

airborne particulates with a nominal aerodynamic diameter of 10 micrometres

or smaller (f)

Photochemical

oxidants are determined by measurement of ozone only |

||||

In addition, the Technical Memorandum of Environmental Impact

Assessment Ordinance (EIAO-TM) stipulates an hourly TSP criterion of 500 mg m-3 for construction dust impact assessment and an odour criterion of 5 Odour Unit

(OU) in 5-second averaging time for the odour impact

assessment.

The measures stipulated in the Air Pollution Control (Construction Dust)

Regulations should be followed to reduce dust impacts.

Should the fuel consumption rate of a

premises/process with a chimney emission exceed the specified fuel consumption

rates stated in the Air Pollution Control

(Furnaces, Ovens and chimneys) (Installation and Alternation) Regulations,

an approval for chimney installation/alternation should be obtained from the

EPD prior to the operation.

Should the total quantity of organic

liquid to be stored in tanks exceed 100 tonnes per annum, a licence must be

obtained under the Air Pollution Control

(Specified Process) Regulation and the control measures set out in the Guidance Note on the Best Practicable Means

for Organic Chemical Works (Bulk Storage of Organic Liquids) (BPM 25/2)

should be followed.

4.2.2

Air Pollutants Not Covered by HKAQOs

For those pollutants not covered by the HKAQOs, health risk criteria recommended in the

international guidelines, such as those promulgated by the World Health

Organisation (WHO), the United States Environmental Protection Agency

(US EPA) and the California Air Resources Board (CARB) have been

considered. The criteria/guideline

values were selected in the following order of preference:

·

WHO;

·

·

CARB.

Cancer Health Risk Assessment

Of the non-criteria substances emitted

during the operation, acetaldehyde is considered carcinogenic. Table 4.2b shows the Unit Risk Factors

(URFs) for the carcinogenic substances considered in

this assessment.

Table 4.2b Guideline

Unit Risk Factor for Carcinogenic Substance

|

Substance |

Unit Risk Factor (mg m-3)-1 |

|

Acetaldehyde |

2.7x10-6 (a) |

|

Note: (a)

The unit risk factor (URF) of acetaldehyde [i.e. (1.5-9 x 10-7) (mgm-3)-1] is available in

Guidelines for Air Quality,

WHO, |

|

The risk assessment guidelines for

assessing the carcinogenic health risk from exposure to air toxic are

summarised in Table 4.2c.

Table 4.2c Risk

Assessment Guidelines for the Assessment of Carcinogenic Health Risks

|

Acceptability of Cancer Risk |

Estimated Individual Lifetime Cancer Risk Level |

|

Significant |

> 10-4 |

|

Risk should be reduced to

As Low As Reasonably Practicable (ALARP) |

> 10-6 – 10-4 |

|

Insignificant |

£ 10-6 |

Non-Cancer Health Risk Assessment

Acetaldehyde has the potential to cause

chronic impacts from long term exposure whereas methanol has the potential to

cause both acute and chronic impacts to humans from short term and long term

exposures. The chronic reference

concentration of acetaldehyde and the acute and chronic reference

concentrations of methanol are summarised in Table 4.2d.

Table 4.2d Guideline

Values for Chronic and Acute Reference Concentrations

|

Substance |

Chronic Reference Concentration (RCc) (Annual Average in mg m-3) |

Acute Reference Concentration (RCA) (Hourly in mg m-3) |

|

Acetaldehyde |

9 (a) |

- (b) |

|

Methanol |

4,000 (c) |

2.8x104 (d) |

|

Notes: (a)

The RCcs for

acetaldehyde are both 9 mgm-3 with

reference to the USEPA-IRIS - online

data as in Sept 2008 (http://www.epa.gov/iriswebp/iris/subst/0290.htm)

and California Environmental Protection Agency, Air

Resources Board (ARB)/Office of Environmental Health Hazard Assessment

(OEHHA) – On-line data as in Sept 2008 (http://www.oehha.org/air/hot_spots/pdf/TSDlookup2002.pdf).

RCc for acetaldehyde (ie, 50

mg m-3)

is available in Guidelines

for Air Quality, WHO, (b)

No

acute reference concentrations of acetyldehyde are

available in WHO, CARB/OEHHA or USEPA-IRIS database. (c)

The

RCc for methanol is 4,000 mgm-3 with

reference to California Environmental Protection Agency, Air

Resources Board (ARB)/Office of Environmental Health Hazard Assessment

(OEHHA) – On-line data as in Sept 2008 (http://www.oehha.ca.gov/air/chronic_rels/AllChrels.html).

No RCc for methanol is available in USEPA-IRIS database

and WHO guidelines. (d)

The

RCA for methanol is 2.8x104 mgm-3 with

reference to California Environmental Protection Agency, Air

Resources Board (ARB)/Office of Environmental Health Hazard Assessment

(OEHHA) – On-line data as in Sept 2008

(http://www.oehha.ca.gov/air/acute_rels/allAcRELs.html).

No RCA for methanol is available in USEPA-IRIS database and

WHO guidelines. |

||

The risk assessment guidelines also

recommend criteria to assess the acceptability of chronic and acute non-cancer

health risks and these are summarised in Tables 4.2e and 4.2f,

respectively.

Table 4.2e Acceptability

of Chronic Non-Cancer Health Risks

|

Acceptability |

Assessment Results (a) |

|

Chronic non-cancer risks are considered

“Insignificant” |

ACA £ RCc |

|

Chronic non-cancer health risks are

considered “Significant”. A

more detailed assessment of the control requirements and further mitigation

measures are needed. |

ACA > RCc |

|

Note: (a)

ACA

and RCc represent annual average

concentration and chronic reference concentration, respectively. |

|

Table 4.2f Acceptability

of Acute Non-cancer Health Risks

|

Acceptability |

Assessment Results (a) |

|

Acute non-cancer risks are considered “Insignificant” |

ACHM £ RCA |

|

Acute non-cancer health risks are considered “Significant”. A more detailed assessment of the control

requirements and further mitigation measures are needed. |

ACHM > RCA |

|

Note: (a)

ACHM

and RCA represent hourly average and acute reference

concentrations, respectively. |

|

4.3

Baseline Conditions and Identification of Air Sensitive Receivers

4.3.1

Baseline

Conditions

The Site is

located at the southwest of the TKOIE on

There is no EPD

Air Quality Monitoring Station (AQMS) operating the in Tseung

Kwan O area. The nearest EPD’s AQMS is located at Kwun

Tong. The means of the annual average

air pollutant concentrations recorded at the Kwun

Tong AQMS from 2003 to 2007 are adopted to establish the background air quality

of the Study Area (see Table 4.3a).

Table 4.3a Background

Air Pollution Concentrations

|

Air Pollutant |

Background Concentration |

|

TSP |

79 (a) |

|

RSP |

56 (a) |

|

NO2 |

63 (a) |

|

SO2 |

19 (a) |

|

CO |

1,181 (b) |

|

Notes: (a) Annual average data on air pollutant

concentrations measured at the EPD Kwun Tong AQMS

from 2003 – 2007 (http://www.epd-asg.gov.hk/english/report/aqr.php). (b) Since no CO data is recorded at EPD Kwun Tong AQMS, therefore, the annual average CO data

recorded at Mongkok AQMS from 2003-2007 is used. |

|

4.3.2

Identification of

Air Sensitive Receivers

Within the Study Area (ie 500m from the Site

boundary), the land uses are all industrial.

No residential

dwellings have been identified within 500m of the site boundary. The nearest residential use (

Table 4.3b Representative

Air Sensitive Receivers (ASRs)

|

ASR |

Location |

Type of Uses (a) |

Approx. Distance from the nearest Project Site Boundary (m) |

Approx. Max. Height of Building |

|

A1 |

Gammon Skanka |

I |

30 |

30 |

|

A2 |

Proposed

Industrial Sites (No committed uses at the time of preparation of EIA) |

I |

25 |

30 |

|

A3 |

Hong Kong

Trade Development Council Exhibition Services & Logistic Centre |

C |

140 |

30 |

|

A4 |

|

I |

310 |

30 |

|

A5 |

HAECO |

I |

440 |

30 |

|

A6-1 |

Asia Netcom

HK Limited |

I |

255 |

30 |

|

A6-2 |

Asia Netcom

HK Limited |

I |

345 |

30 |

|

A7 |

Mei Ah

Centre |

I |

420 |

30 |

|

A8 |

Wellcome Co. Ltd (Storage) |

I |

345 |

30 |

|

A9 |

|

I |

450 |

30 |

|

A10 |

Next Media

Apple Daily |

I |

450 |

30 |

|

A11 |

Hong Kong

Oxygen Acetylene Co. Ltd |

I |

355 |

30 |

|

A12-1 |

|

I |

510 |

30 |

|

A12-2 |

|

I |

550 |

30 |

|

A12-3 |

|

I |

560 |

30 |

|

A13 |

|

I |

515 |

30 |

|

A14 |

Next Media

Apple Daily |

I |

530 |

30 |

|

A15 |

Avery

Dennison |

I |

540 |

30 |

|

A16 |

Varitronix Limited |

I |

530 |

30 |

|

A17 |

Committed

HSBC Office |

C |

700 |

30 |

|

A18 |

Eastern

Pacific Electronics |

I |

780 |

30 |

|

A19 |

Committed

Tung Wah Group of Hospital Aided Primary &

Secondary School |

G/IC |

820 |

30 |

|

A20-1 |

|

CDA |

800 |

200 |

|

A20-2 |

|

CDA |

820 |

200 |

|

A20-3 |

|

CDA |

930 |

200 |

|

A21 |

Chiaphua-Shinko Centre |

I |

1,300 |

30 |

|

Note: (a)

I = Industrial premises, C = Commercial premises, G/IC =

Government/Institution/Community and CDA = Comprehensive Development Area |

||||

4.4

Potential Sources of Impacts

4.4.1

Construction Phase

The Project Site

is currently a vacant lot which has been formed by reclamation as part of the

TKOIE development. The construction

works will last for about 13 months from March 2009, tentatively. Foundation works will last for about 3

months. A detailed construction programme is presented in Figure 3.2f.

The total site area is about 18,000 m2. Since the site has been formed, no major

earthworks will be required for site formation.

Minor excavation works will be required for the construction of foundation

works and site utilities. Driven steel H piles with reinforced

concrete pile caps will be used for the foundations of the buildings. All excavated materials generated from

foundation works and site levelling works will be reused on site. The storage tanks and process equipment will be

pre-fabricated off-site and assembled on-site using hydraulic and tower cranes and hence minimal

dust will be generated from this activity.

About 4 to 5 trucks will be operating on site at the same time during the

foundation works, and building and civil works.

According to the construction programme, there

is no overlapping of the foundation works, and building and civil works.

Dust generated

from the excavation works and gaseous emissions from diesel-driven construction

equipment are the major concerns during the construction phase. As only minor excavation works will be

required, the potential dust emissions will be minimal with the implementation

of the dust control measures stipulated in the Air Pollution Control (Construction Dust) Regulation. The reinforced concrete buildings will be

constructed on site using ready-mix concrete and conventional construction

methods. Limited dust will be emitted

from the concreting works and assembling of the pre-fabricated units of the

storage tanks and processing system.

Due to the small

site area, the number of diesel-driven construction plant and equipment

operating simultaneously on-site will be limited. The potential gaseous emissions from these

plant and equipment are expected to be minimal and unlikely to cause adverse

air quality impacts.

The jetty for the reception of marine

vessels during the operation phase will be constructed by piled deck (see Figure 2.2b) and no dredging of marine

sediment will be required. Marine piles

will be drilled through the existing rubble mound seawall to competent bearing

strata by a piling rig mounted barge.

The bored piles will be filled with concrete prior to placement of

trellis beam and pre-cast concrete panels.

The dust and air emissions generated from the marine works will be

minimal.

With the

implementation of dust suppression measures stipulated under the Air Pollution Control (Construction Dust)

Regulation and the adoption of good site practices, the potential dust

impacts will be controlled to within the relevant standards as stipulated in

Section 1 of Annex 4 of the EIAO-TM. No adverse impacts are anticipated.

4.4.2

Operation Phase

Potential air

pollution sources from the biodiesel plant during the operation phase include

the following:

·

Emissions from fuel combustion in the boilers;

·

Emissions from the standby biogas flare (if in

operation);

·

Organic emissions from the

·

Odour from final air scrubber

which will scrub all the pre-treated exhaust gas from the unloading and

treatment of Grease Trap Waste (GTW) and the on-site wastewater treatment

plant; and

·

Vehicular emissions due to additional traffic

associated with the operation of the biodiesel plant.

To assess

potential cumulative air quality impacts, the emissions from the adjacent major

stacks within the TKOIE were also considered.

Emissions from

Fuel Combustion

The boilers are a

dual-fuel fired boiler (which could utilise gas (eg

biogas) or fuel oil (eg gas oil, or a mixture of gas

oil and bio-heating oil (hereafter called oil mixture) ([1])) for production of steam for the

biodiesel process and thermal oil system.

The Project Proponent is committed to use an appropriate fuel or a mixture

of fuels which will comply with the new emission limits stipulated in the Air Pollution Control (Fuel Restriction)

(Amendment) Regulation taking effect on 1 October 2008. About 21.5 tonnes of the oil mixture will be

required per day (which is equivalent to about 920 m3 of biogas per

hour). Under normal operation, biogas (a

high

energy value, 36.44 MJ Nm-3) generated from the IC Reactor of the wastewater

treatment plant (an average of

about 80 m3 hr-1

of biogas generated) will be used as the priority fuel which will be

supplemented by oil mixture or gas oil.

The

major air pollutants from the combustion of biogas and oil mixture (or gas oil)

are expected to be carbon monoxide (CO), nitrogen dioxide (NO2) and

a limited quantity of non-methane organic compounds (NMOCs)

(if biogas is combusted) and sulphur dioxide (SO2). The air pollutants will be emitted at a

minimum exit velocity of 7 m s-1 and temperature of 100°C through a 31m stack with a diameter of 0.75m.

With reference

to the emission factors for NO2, CO, SO2 and NMOCs established for biogas and oil mixture, a comparison

of the emission rates from the boiler is summarised in Table 4.4a.

Table 4.4a Comparison

of NO2, CO, SO2 and NMOCs

Emissions from Combustion of Biogas and Oil Mixture at Boiler

|

Parameter |

Boiler |

|||

|

|

Biogas |

Oil Mixture

(Mixture of Gas Oil (80%) and Bioheating Oil (20%)) |

||

|

Stack

Height (m above ground) |

31 |

|||

|

Stack

Diameter (m) |

0.75 |

|||

|

Exhaust

Velocity (m s-1) |

7 (minimum) |

|||

|

Exhaust

Temperature (°C) |

100 (minimum) |

|||

|

Exhaust

Flow Rate (m3hr-1) |

11,133 |

|||

|

Fuel

Consumption (tonnes day-1) |

- |

21.5 |

||

|

Maximum

Volume of Biogas (equivalent) & Oil Mixture Consumed (m3 hr-1) |

920.7 (a) |

0.995 (b) |

||

|

Emission

Factor for Biogas at Exhaust Temperature (mg m-3) (c) (d) |

NOx |

109.8 |

- |

|

|

|

CO |

36.6 |

- |

|

|

|

H2S |

10 (i) |

- |

|

|

|

NMOCs |

3.7 |

- |

|

|

Emission

Factor for Oil Mixture (kg m-3) (f) |

NOx |

- |

2.4 |

|

|

|

CO |

- |

0.6 (e) |

|

|

|

SO2 |

- |

0.864 |

|

|

Emission

Rate (g s-1) (g) (h) |

NOx |

0.34 |

0.66 |

|

|

|

NO2 |

0.07 |

0.13 |

|

|

|

CO |

0.11 |

0.17 |

|

|

|

SO2 |

0.01(j) |

0.24 |

|

|

|

NMOCs |

0.01 |

- |

|

|

Notes: (a)

Equivalent to oil mixture consumed. Under normal operation, the actual biogas

consumption is only about 80

m3 hr-1 produced from the IC Reactor based on the design

capacity. (b)

The density of oil mixture is about 900 kg m-3. (c)

Due to the nature of biogas, the emission factor of biogas

is assumed to be similar to that of landfill gas. (d)

The emission factors of biogas were converted to

that under exhaust gas condition. The

original emission factors of biogas used are reference to (e)

Reference to USEPA AP-42, Section

1.3, Table 1.3-1 (http://www.epa.gov/ttn/chief/ap42/ch01/final/c01s03.pdf). (f)

Reference to Amendment

of Air Pollution Control (Fuel Restriction) Regulation in June 2008. (g)

The emission rate of air pollutants from combustion

of oil mixture were calculated based on the volume of oil consumed. The emission rate of air pollutants from

combustion of biogas were calculated based on the exhaust flow rate. Emission rate of air pollutant from

combustion of oil mixture = emission factor (oil mixture) x volume of oil

mixture consumed. For example, NOx emission rate from combustion of oil

mixture = (2.4x106 mg m-3) x (0.995 m3 hr-1)

/ (1,000 x 3,600) = 0.66 g s-1.

Emission rate of air pollutant from combustion of biogas = emission

factor (biogas) x exhaust flow rate.

For example, NOx emission rate

from combustion of biogas = (109.8 mg m-3) x (11,133 m3 hr-1)

/ (1,000 x 3,600) = 0.34 g s-1 (h)

Refer to Annex

A1 for detailed emission rate calculation. (i)

The emission factor of H2S (in ppm) in biogas is measured at

30°C and given by

the plant design engineer. (j)

The emission rate of SO2 from is

calculated based on the equivalent biogas consumption rate of about 920.7 m3

hr-1. |

||||

It should be noted that there have been a

number of research studies determine the NOx

emissions from biodiesel compared with petroleum based diesel oil. There is no commonly-agreed NOx emission factor for the combustion of

biodiesel.

Testing emissions from the combustion of

biodiesel in a similar boiler was conducted by BDI. A summary of the testing results is presented

in Annex A2. The testing results show that the NOx emissions range from 0.83 kg hr-1

to 1.01 kg hr-1 (ie, 0.23 g s-1

to 0.28 g s-1). Compared to

the emission factors given in Table 4.4a

(which are based on the emission rates of petroleum based diesel oil), the NOx emissions analysed from the emission test

are much lower. Therefore, the

assessment is considered conservative.

Comparing the pollutant emission rates of

biogas and oil mixture (see Table 4.4a),

it is evident that the emission rates for the combustion of oil mixture are

higher. As a conservation assumption, it

is assumed that the boilers will consume only oil mixture.

Emissions from

Standby Biogas Flare

Under normal

operation, all the biogas generated from the IC reactor will be used as fuel

for the boilers. However, when the

boilers are under maintenance, all the biogas generated will be flared. The stack of the flare will be installed at

about 12.5m above ground and located at to the on-site wastewater treatment

plant. The diameter of stack is about

0.96m and the flue gas flow rate is 1,407 m3 hr-1.

An air scrubber

will be installed to remove the majority of the hydrogen sulphide

(H2S) in the biogas (down to a maximum of 10 ppm)

prior to combustion in the flare or boilers.

NO2, CO, SO2 (from destruction of H2S

at high temperature) and NMOCs will be the key air

pollutants from the emissions from the biogas flare.

As a conservative assumption, it was assumed that the flare will be

operating at its maximum capacity (ie 150 m3 hr-1

of biogas), the emission rates of NO2, CO, SO2 and NMOCs are summarised in Table 4.4b.

Table 4.4b Emission

of NO2, CO, SO2 and NMOCs from

Standby Biogas Flare

|

Parameters |

Standby

Biogas Flare |

|

|

Stack

Height (m above ground) |

12.5 |

|

|

Stack

Diameter (m) |

0.96 |

|

|

Exhaust

Flow Rate (m3 hr-1) |

1,407 |

|

|

Exhaust

Temperature (°C) |

815 |

|

|

Volume

of Biogas to be flared off (Designed flare capacity) |

150 (a) |

|

|

Emission

Factor of Biogas at Exhaust Temperature |

NOx |

37.6 |

|

|

CO |

12.5 |

|

|

H2S |

10 ppm (c) |

|

|

NMOCs |

1.3 |

|

Emission

Rate (g s-1) (b) |

NOx |

0.015 |

|

|

NO2 |

0.003 |

|

|

CO |

0.005 |

|

|

SO2

|

1.07x10-3 (d) |

|

|

NMOCs |

4.9x10-4 |

|

Notes: (a)

The design capacity of the flare is 150 m3 hr-1

of biogas. (b)

Reference to Annex

A1 for detailed calculation. (c)

The emission factor of H2S in biogas is

measured at 30°C and given by

the plant design engineer. (d)

SO2 is estimated from the H2S concentration

in the biogas. Reference to Annex A1 for detailed calculation. |

||

Organic Emissions

from Process Building

The biodiesel

production is carried out inside the

Among of these organics, only acetyldehyde is classified as carcinogenic and has the

potential to lead to chronic heath effects.

Methanol has also the potential to cause both chronic and acute health

effects.

The emission inventory and exhaust vent

pipe design parameters are summarized in Table

4.4c.

Table 4.4c Emission

of Acetyldehyde and Methanol from

|

Parameters |

Exhaust

Pipe of |

|

|

|

Acetyldehyde |

Methanol |

|

Stack

Height (m above ground) |

22.8 |

|

|

Stack

Diameter (m) |

0.15 |

|

|

Exhaust

Flow Rate (m3 hr-1) |

50 |

|

|

Exhaust

Temperature (°C) |

35 |

|

|

Maximum

Concentration at Stack (mg m-3) |

2,000 (a) |

2,000 |

|

Emission

Rate (g s-1) (b) |

0.028 |

0.028 |

|

Notes: (a)

Since the percentage of acetyldehyde

in the impurities of methanol is not known, it is assumed that all the

impurities of methanol are acetyldehyde for the

worst case assessment. (b)

Refer to Annex

A1 for detailed emission rate calculation. |

||

Odour from Unloading and

Treatment of GTW and On-site Wastewater Treatment Plant

The unloading and

storage of GTW and operation of the wastewater treatment plant have the

potential to cause odour nuisance if not properly

managed.

Unloading and

Treatment of GTW

GTW will be delivered

to the biodiesel plant by sealed road tankers.

After weighing, the tankers will be directed to the unloading bays. GTW will be discharged from the tanker

directly to the underground storage tanks in a closed system (via a flexible

hose). The GTW received will be screened in the Belt Filter

Room adjacent to the unloading bays to remove food residues and other large

objects. The screenings will be stored

in containers inside the Technic Room. The Belt Filter Room and the Technic Room will be enclosed and provided with a

ventilation system which will maintain a slight negative pressure to prevent

odour emissions. The exhaust air from

these rooms will be treated by an air scrubbing system (with a removal efficiency

of >99.5% ([3])). The

scrubbed air will be diverted to the on-site wastewater treatment plant as the

ventilation air for the enclosed wastewater treatment tanks.

All biodiesel

process tanks ([4]), including the

GTW storage tanks will be enclosed and the exhaust air will be treated by an

air scrubbing system (with a

removal efficiency of >99.5%). The

scrubbed exhaust air will be diverted to the on-site wastewater treatment plant

as part of the air intake for the aeration process and ventilation air for the

enclosed wastewater treatment tanks. Any

residual odorous components in the exhaust air will be scrubbed by the

wastewater. The vent gas of the aeration

tank will be cleaned by the final air scrubber (with a removal efficiency of >99.5%) prior to discharge

to the atmosphere.

On-site Wastewater Treatment Plant

All wastewater

storage and treatment tanks will be enclosed.

After the anaerobic digestion process in the IC Reactor, the Biochemical

Oxygen Demand (BOD) of the wastewater will be significantly reduced (by about

80%) and hence the potential for odour nuisance is

significantly reduced. The vent air from

the wastewater storage and treatment tanks will be cleaned by the final air

scrubber prior to discharge to the atmosphere.

Summary

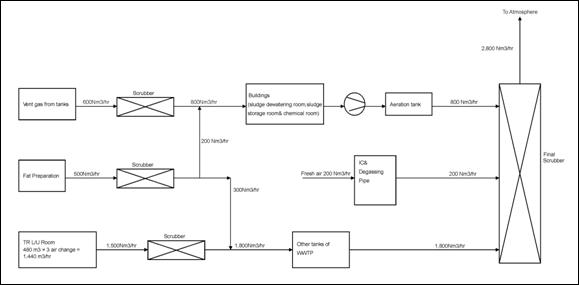

Figure 4.4a shows the flow rates of the

scrubbed exhaust air from the GTW unloading and pre-treatment facilities and

on-site wastewater treatment plant.

Figure 4.4a Exhaust Air Flow Chart

There is only one emission point for the air scrubbers (which is the

final air scrubber of the wastewater treatment plant). The odour

concentration after treatment at the final air scrubber will be controlled at a

limit of 257.6 OUm-3. The

exhaust air from the final air scrubber will be dispersed at ambient

temperature with a flow rate of 2,800 m3 hr-1. The details of the stack and odour emission rate are summarised in Table

4.4d.

Table 4.4d Odour

Emission from Final Scrubber

|

Parameters |

Final

Scrubber |

|

Stack

Height (m above ground) |

13.8 |

|

Stack

Diameter (m) |

1.2 |

|

Exit

Flow Rate (m3 hr-1) |

2,800 |

|

Exit

Temperature (°C) |

ambient |

|

Maximum

Odour Concentration at Exhaust Point (OU m-3) (a) |

257.6 |

|

Odour

Emission Rate (OU s-1) (b) |

200.3 |

|

Notes: (a)

Monitoring will be performed to ensure the odour concentration

emitted from the exhaust point will not exceed the maximum odour

concentration. This will be included

in the Contract Specification. (b)

Refer to Annex

A1 for detailed odour emission rate calculation. |

|

Emissions from

Delivery Trucks

Vehicular

emissions induced from the Project are expected to be negligible since

additional traffic associated with the operation of the biodiesel plant only

constitutes a very small percentage (0.47%) of the total background traffic on

Wan Po Road (ie 93 trucks per day compared to AADT of

19,860 in 2006, refer to Section 5.4.2). It is therefore considered that the potential

air quality impact due to additional traffic is negligible and will not cause

an adverse air quality impact.

Emissions from Marine

Vessels during Berthing

According to Section 3.2.2 and Table 3.2b, PFAD, biodiesel and methanol will be delivered by

barge. It is estimated that about 4

barges will be berthed per week and it takes less than 15 minutes for the

marine vessel to travel fro 500m from the approach channel to the jetty and

berth. Therefore, the potential air

quality impact during maneuvering of the marine vessel will be transient and

negligible. PFAD and methanol delivered to the Site by barge will

be pumped to the storage tanks using dedicated pipelines. Flexible hoses will be used to connect

storage the tanks of the barge to the pipelines at the jetty. During berthing, the main engine and the

auxiliary engine of the vessels will be switched off to minimize the emissions. The power supply to the marine vessels will

be provided by an on-site power supply.

Therefore, no emission is anticipated from the marine vessels during

berthing.

4.4.3

Cumulative Impacts

Construction Phase

The operation of

TKO Area 137 Fill Bank and existing SENT Landfill and the construction of the

TKO Further Development works are identified as concurrent projects during the

construction of the biodiesel plant (see Section

3.3).

TKO Area 137 Fill

Bank and existing SENT Landfill are located at south and east of the biodiesel

plant, respectively and the nearest distance from the existing SENT Landfill to

the Project Site is about 700m. The TKO

Area 137 Fill Bank is further away.

Given the large separation distances and different worst case wind

directions, it is not anticipated that these concurrent projects will cause

adverse cumulative dust impacts.

The TKO Further

Development – Infrastructure works site is located at more than 2 km from the

biodiesel plant. It is therefore, not

anticipated that it will cause cumulative dust impact to the identified ASRs.

Operation Phase

A chimney survey within the TKOIE was

conducted in January 2008 and the major emissions sources within 500m from the

Project Site boundary are HAESL and

Interviews with

According to the information provided by

With reference to

the EIA Report of HAECO/HAESL Aircraft

Engine Test Cell Facility at TKO, NO2, CO and SO2 are

the key air pollutants to be emitted during engine testing. These emission rates and stack

characteristics are summarized in Table

4.4e.

Table 4.4e Stack

and Emission Characteristics of HAESL (a)

|

Stack ID |

No.

of Stacks |

Efflux

Velocity |

Stack

Diameter (m) |

Stack

Height Above Ground (m) |

Exit

Temp. (°C) |

Emission

Rate (g s-1) |

||

|

|

NO2 |

CO |

SO2 |

|||||

|

HAECO

/ HAESL (b) |

1 |

16.4 for NO2 & SO2; |

14.7 |

40 |

52 |

21.2 |

23.9 |

1.92 |

|

Notes: (a)

Reference to the EIA Report of HAECO Aircraft Engine Test Cell Facility at TKO. (b)

It is the equivalent diameter. The stack is in square shape with an area

of 13m x 13m. |

||||||||

These data have been confirmed by

HAESL. The emissions of NO2,

CO and SO2 from HAESL are included to assess the cumulative air

quality impact during the operation phase.

To assess the

potential cumulative air quality impact due to other minor emission sources in

TKOIE, the Consultant has made reference to the emission sources and data

adopted in the approved EIA Report of Fill Bank at TKO Area 137. The estimation of the emissions from these

sources has taken account of the total fuel consumption of the whole TKOIE

which includes potential future emission sources. The assessment is therefore considered

conservative. The facilities were

assumed to operate for 10 hours a day on an annual basis, as detailed in the

reference report. Emission rates of NO2

from the potential sources were similar to those in the TKO 137 Fill Bank EIA,

while emission rates of CO and SO2 were calculated with reference to

the USEPA Compilation

of Air Pollutants Emission Factors, 5th Edition (AP42) (1995) and

the SO2 emission limit stipulated in the Air Pollution Control (Fuel Restriction) Regulation Amendment 2008,

respectively. Calculation details of

respective emission rates are presented in Annex

A1.

No similar odour source is identified

within 500m of the Project site boundary and hence, no cumulative odour impact

is expected.

4.5

Assessment Methodology (Operational Air Quality Impact)

Stack Emissions

from Boiler Stack, Biogas Flare, Process

Building

An emission

inventory for the boiler stack,

Table 4.5a Summary

of Stack Information and Emission Inventory

|

Parameter |

Boiler Stack |

Biogas Flare |

|

HAESL Stack |

TKOIE Stacks(f) |

|

|

Operating Hours |

24 |

24 |

24 |

24 |

10 |

|

|

No. of Stack |

1 |

1 |

1 |

1 |

21 |

|

|

Stack Height (m above ground) |

31 |

12.5 |

22.8 |

40 |

10 |

|

|

Stack Diameter (m) |

0.75 |

0.96 |

0.15 |

14.7 |

1.2 |

|

|

Flue Gas Exit Temperature (°K) |

373 |

1,088 |

308 |

325 |

463.15 |

|

|

Flue Gas Exit Velocity (m s-1) |

7 |

0.54 |

0.79 |

16.4 |

9.00 |

|

|

Emission Rates (g s-1) (a) |

NOx |

0.66 |

0.015 |

- |

106 |

|

|

NO2 (b) |

0.13 |

0.003 |

- |

21.2 |

0.043 (c) |

|

|

|

CO |

0.17 |

0.005 |

- |

23.9 |

0.042(d) |

|

|

SO2 |

0.24 |

1.07x10-3 |

- |

1.9 |

0.06(e) |

|

|

Acetyldehyde |

- |

|

0.028 |

- |

|

|

|

Methanol |

- |

|

0.028 |

- |

|

|

Notes: (a) As shown in Table 4.4a,

burning of mixture of gas oil/bioheating oil

generates higher emission rates of air pollutants than burning of biogas. (b) It is assumed that 20% of NOx emitted

from the stacks will be converted to NO2. (c) Reference has been made to NO2 emission rates in the Fill Bank at

TKO Area 137 EIA Report (EIA – 076/2002) (d) CO emission rate is calculated with reference to the USEPA Compilation of Air Pollutants Emission Factors,

5th Edition (AP42) (1995) (e) SO2

emission rate is calculated with reference to the SO2

limit stipulated in the Air Pollution Control (Fuel Restriction) Regulation Amendment 2008 (f) With reference to approach adopted in the approved TKO Area 137 Fill Bank

EIA Report |

||||||

Hourly, daily and annual average NO2, CO and SO2

concentrations, hourly methanol concentration and annual average acetyldehyde and methanol concentrations at different elevations

(1.5m to 120m) of the identified ASRs were predicted using an EPD approved air

dispersion model, Industrial Source Complex Short-Term (ISCST3). The meteorological data recorded at the TKO

Weather Station in 2003 ([5])

and

“rural” mode were used for the model runs as the Project Site is located along

the waterfront.

Two scenarios were

established for the model run:

Scenario 1 : Under

Scenario 2 : Under Emergency

Operation (Emission from Biogas Flare)

In each scenario,

emissions from HAESL and other emission sources in TKOIE are also included in

the model to assess the cumulative impact.

Background air pollutant concentrations (refer to Table 4.3a) were added to the modelled

cumulative results to assess the total air quality impacts at the ASRs.

Odour Emission from

Final Air Scrubber

Table 4.5b summarises the odour

emission inventory of the exhaust air after treatment by the final scrubber.

Table 4.5b Odour Emission Inventory

|

Parameter |

Final

Scrubber Exhaust Stack |

|

Operating Hours |

24 |

|

No. of Stacks |

1 |

|

Vent Duct Height (m above ground) |

13.8 |

|

Vent Duct Diameter (m) |

1.2 |

|

Exhaust Air Exit Temperature (°K) |

Ambient temperature |

|

Exhaust Air Exit Velocity (m s-1) |

0.7 |

|

Odour Concentration at Exhaust Duct (OU m-3) |

257.6 |

|

Odour Emission Rate (OU s-1) |

200.3 |

An EPD approved

air dispersion model, ISCST3, was used to predict the odour

concentration at different elevations of the identified ASRs. Other modeling parameters are similar to

those adopted in the stack emission assessment.

The model output

corresponds more closely to a maximum 15-minute average concentration. This matter relates to the Pasquill-Gifford vertical dispersion parameter used in the

ISCST model which is fully documented in the Workbook on Atmospheric Dispersion Estimates.

In order to

convert the model outputs to maximum 5-second average concentrations, a

two-step conversion process has been defined.

Step 1:

Conversion of the

model output to a maximum 3-minute average, using the power law formula

proposed by Duffee et al ([6]), which is

reproduced below:

![]()

Where:

Xl = concentration for the longer

averaging time;

Xs = concentration for the shorter

averaging time;

ts =

shorter averaging time;

tl =

longer averaging time; and

p = power law exponent, which depends on the Pasquill stability class, and is detailed in Table 4.5c.

Table 4.5c Power

Law Exponents

|

Pasquill Stability

Class |

p |

|

A |

0.5 |

|

B |

0.5 |

|

C |

0.333 |

|

D |

0.2 |

|

E |

0.167 |

|

F |

0.167 |

Step 2:

To convert

3-minute average to maximum 5-second average concentration, the approach

suggested by the Warren Spring Laboratory ([7])

was

adopted:

“Typical

maximum or peak 5-second average concentrations within any 3-minute period

appear to be of the order of 5 times the 3-minute average. During very unstable conditions larger

ratios, perhaps 10:1, are more appropriate…..”

The resulting factors for converting the

model outputs to 5-second averages are presented in Table 4.5d.

Table 4.5d Factors

for Converting Model Outputs to Maximum 5-second Mean Odour Concentration

|

Pasquill Stability Class |

Conversion 15-minute to 3-minute Average |

Conversion 3-minute to 5-second Average |

Overall Conversion Factor |

|

A |

2.23 |

10 |

22.3 |

|

B |

2.23 |

10 |

22.3 |

|

C |

1.70 |

5 |

8.50 |

|

D |

1.38 |

5 |

6.90 |

|

E |

1.31 |

5 |

6.55 |

|

F |

1.31 |

5 |

6.55 |

The overall

conversion factors under different stability classes are applied to the model

so that the predicted outputs are in 5-second averages.

Isopleths showing

5-second odour levels are plotted at the different

assessment heights.

4.6

Evaluation of Impacts

Stack Emissions

from Boiler Stack, Standby Flare, Process

Building

NO2, CO

and SO2

The maximum hourly, daily and annual average concentrations of NO2

and SO2 and maximum hourly and 8-hour average CO concentrations were

predicted at various heights at the identified ASRs. The highest cumulative maximum hourly, daily

and annual average concentrations of NO2 and SO2 and

maximum hourly and 8-hour average CO concentrations, taking account of the

background air quality, are summarised in Table

4.6a for both scenarios. The predicted concentrations of these air

pollutants at different ASR elevations are summarized in Annex A4.

Table 4.6a Predicted

Highest Cumulative Air Pollutant Concentrations at ASRs

|

ASR |

Highest Hourly

Concentration (µg m-3) |

Highest 8-hour

Concentration (µg m-3) |

Highest Daily Average

Concentration (µg m-3) |

Annual Average

Concentration |

||||

|

|

NO2 |

CO |

SO2 |

CO |

NO2 |

SO2 |

NO2 |

SO2 |

|

Scenario 1 : |

||||||||

|

A1 |

96.5 |

1,224 |

79.5 |

1,200 |

72.3 |

35.7 |

65.5 |

23.24 |

|

A2 |

99.0 |

1,227 |

84.5 |

1,205 |

74.0 |

39.1 |

65.2 |

22.75 |

|

A3 |

77.2 |

1,200 |

45.2 |

1,186 |

65.3 |

23.1 |

63.6 |

19.76 |

|

A4 |

84.1 |

1,202 |

48.4 |

1,191 |

66.6 |

24.0 |

64.1 |

20.45 |

|

A5 |

71.2 |

1,189 |

30.4 |

1,184 |

64.7 |

20.7 |

63.6 |

19.57 |

|

A6-1 |

80.3 |

1,198 |

43.1 |

1,186 |

65.0 |

21.7 |

63.5 |

19.62 |

|

A6-2 |

209.9 |

1,324 |

224.0 |

1,253 |

94.2 |

62.5 |

65.4 |

22.24 |

|

A7 |

97.8 |

1,216 |

68.4 |

1,191 |

66.9 |

23.7 |

63.4 |

19.52 |

|

A8 |

89.0 |

1,207 |

54.6 |

1,191 |

66.9 |

23.8 |

63.6 |

19.80 |

|

A9 |

69.3 |

1,189 |

30.5 |

1,184 |

64.4 |

21.1 |

63.4 |

19.42 |

|

A10 |

71.7 |

1,192 |

35.1 |

1,186 |

65.1 |

21.5 |

63.4 |

19.52 |

|

A11 |

77.0 |

1,195 |

39.3 |

1,190 |

66.2 |

24.4 |

63.9 |

20.24 |

|

A12-1 |

79.9 |

1,197 |

42.5 |

1,190 |

66.4 |

23.8 |

63.9 |

19.92 |

|

A12-2 |

84.7 |

1,202 |

49.3 |

1,191 |

67.2 |

24.9 |

64.0 |

20.39 |

|

A12-3 |

110.3 |

1,227 |

85.0 |

1,208 |

74.6 |

35.2 |

64.2 |

20.61 |

|

A13 |

74.7 |

1,192 |

35.4 |

1,185 |

64.9 |

21.3 |

63.4 |

19.47 |

|

A14 |

68.3 |

1,188 |

28.8 |

1,185 |

64.6 |

21.0 |

63.3 |

19.37 |

|

A15 |

72.0 |

1,193 |

35.6 |

1,184 |

64.6 |

21.3 |

63.3 |

19.39 |

|

A16 |

73.5 |

1,194 |

37.2 |

1,185 |

65.0 |

22.0 |

63.5 |

19.65 |

|

A17 |

103.9 |

1,221 |

76.0 |

1,195 |

68.7 |

27.0 |

64.4 |

20.89 |

|

A18 |

79.3 |

1,201 |

47.2 |

1,188 |

67.0 |

25.4 |

63.6 |

19.89 |

|

A19 |

91.1 |

1,209 |

58.3 |

1,201 |

72.3 |

32.2 |

64.0 |

20.39 |

|

A20-1 |

104.1 |

1,249 |

92.1 |

1,196 |

69.0 |

26.5 |

63.4 |

19.54 |

|

A20-2 |

90.8 |

1,225 |

51.0 |

1,196 |

68.7 |

24.1 |

63.5 |

19.61 |

|

A20-3 |

128.4 |

1,291 |

86.2 |

1,216 |

72.7 |

29.1 |

63.9 |

20.08 |

|

A21 |

75.4 |

1,198 |

39.4 |

1,189 |

66.1 |

23.8 |

63.4 |

19.56 |

|

Scenario 2

: Emergency Operation (Emission from Biogas Flare) |

||||||||

|

A1 |

80.8 |

1,198 |

43.8 |

1,189 |

66.5 |

23.9 |

63.8 |

19.97 |

|

A2 |

70.0 |

1,188 |

28.8 |

1,184 |

64.6 |

20.6 |

63.7 |

19.82 |

|

A3 |

74.0 |

1,192 |

34.3 |

1,185 |

65.0 |

21.7 |

63.5 |

19.62 |

|

A4 |

84.1 |

1,202 |

48.4 |

1,191 |

66.6 |

24.0 |

64.1 |

20.42 |

|

A5 |

71.2 |

1,189 |

30.4 |

1,184 |

64.7 |

20.4 |

63.6 |

19.52 |

|

A6-1 |

80.3 |

1,198 |

43.1 |

1,186 |

65.0 |

21.7 |

63.5 |

19.57 |

|

A6-2 |

209.9 |

1,324 |

224.0 |

1,253 |

94.2 |

62.5 |

65.4 |

22.18 |

|

A7 |

95.7 |

1,213 |

64.6 |

1,191 |

66.7 |

23.5 |

63.4 |

19.46 |

|

A8 |

89.0 |

1,207 |

54.6 |

1,191 |

66.9 |

23.8 |

63.6 |

19.77 |

|

A9 |

67.6 |

1,188 |

24.1 |

1,184 |

64.4 |

20.4 |

63.3 |

19.39 |

|

A10 |

69.0 |

1,190 |

25.6 |

1,185 |

64.5 |

20.3 |

63.4 |

19.47 |

|

A11 |

77.0 |

1,195 |

38.5 |

1,187 |

65.8 |

22.9 |

63.6 |

19.81 |

|

A12-1 |

79.9 |

1,197 |

42.5 |

1,190 |

66.4 |

23.8 |

63.9 |

19.84 |

|

A12-2 |

84.7 |

1,202 |

49.3 |

1,191 |

67.2 |

24.9 |

64.0 |

20.29 |

|

A12-3 |

110.3 |

1,227 |

85.0 |

1,208 |

74.6 |

35.2 |

64.2 |

20.58 |

|

A13 |

74.7 |

1,192 |

35.4 |

1,185 |

64.9 |

21.3 |

63.4 |

19.43 |

|

A14 |

67.5 |

1,185 |

25.2 |

1,185 |

64.6 |

21.0 |

63.3 |

19.35 |

|

A15 |

67.1 |

1,187 |

24.7 |

1,184 |

64.4 |

20.5 |

63.3 |

19.34 |

|

A16 |

70.3 |

1,192 |

27.1 |

1,185 |

64.5 |

20.3 |

63.4 |

19.52 |

|

A17 |

103.9 |

1,221 |

76.0 |

1,195 |

68.7 |

27.0 |

64.4 |

20.84 |

|

A18 |

76.1 |

1,196 |

36.6 |

1,188 |

65.6 |

21.0 |

63.4 |

19.40 |

|

A19 |

90.9 |

1,208 |

57.9 |

1,201 |

71.4 |

30.5 |

63.9 |

20.11 |

|

A20-1 |

104.1 |

1,249 |

45.4 |

1,196 |

68.8 |

21.7 |

63.3 |

19.31 |

|

A20-2 |

90.8 |

1,225 |

51.0 |

1,196 |

68.3 |

22.1 |

63.4 |

19.39 |

|

A20-3 |

128.4 |

1,291 |

86.2 |

1,216 |

72.6 |

28.4 |

63.9 |

19.93 |

|

A21 |

75.3 |

1,198 |

34.6 |

1,188 |

65.0 |

21.5 |

63.3 |

19.35 |

|

AQO |

300 |

30,000 |

800 |

10,000 |

150 |

350 |

80 |

80 |

|

Notes: (a) Background concentrations (NO2 of 63 µg m-3, CO

of 1,181 µg m-3 and SO2 of 19 µg m-3) have

been included. (b) The predicted concentrations of these

air pollutants at different ASR elevations are summarized in Annex A4. |

||||||||

The predicted cumulative maximum NO2, CO and SO2

concentrations under different averaging times at various heights at ASRs A1 –

A19 and A21 are well within the respective AQOs. The worst affected height is at 30m above

ground. The highest cumulative maximum

NO2, CO and SO2 concentrations, including the background

air quality, are predicted at 30m above ground; the ASR that is affected the

most varies depending on the averaging period.

The maximum

contribution of hourly NO2 concentration at the identified ASRs from

the operation of the biodiesel plant alone is at ASR A2, which is located immediately at the south

of the Project Site. It is about 34%of

the total predicted concentration at A2 (34 µgm-3 contributed from

the biodiesel plant operation during normal condition).

The predicted cumulative maximum NO2,

CO and SO2 concentrations under different averaging times at various

heights at LOHAS Park (A20) are also well within the respective AQOs.

Referring the predicted results presented in Table A4-1 of Annex A4,

the maximum hourly NO2 concentration at LOHAS Park due to the

operation of the biodiesel plant, (ie 39.6 µg m-3, which is about

13.2% of the hourly AQO criterion for NO2), is predicted at 60m above

ground. The predicted hourly NO2

concentrations at this ASR due to the operation of the biodiesel plant reduce

with increasing height and at 120m above ground the hourly NO2

concentration reduced to 2.8

µg m-3, which is about 0.9% of the hourly AQO criterion for NO2. This suggests that at level higher than 120m,

the Project contribution to the total hourly NO2 concentrations at

The highest predicted cumulative maximum hourly NO2

concentrations (including background) at

Figures 4.6a to 4.6e and 4.6h to

4.6j present the isopleths of the cumulative maximum average hourly NO2

concentrations at 1.5m to 30m above ground and 60m, 90m and 120m at

The assessment indicates that the

operation of the proposed biodiesel plant in the TKOIE will not cause adverse

air quality impacts to the identified ASRs at TKOIE, Areas 85 and 86.

Acetyldehyde and Methanol

Non-cancer

Health Risk Assessment: The predicted hourly methanol

concentration and annual average acetyldehyde and

methanol concentrations at different ASR elevations are presented in Annex A4 and the highest predicted

results are summarized in Table 4.6b.

Table 4.6b Predicted

Highest Hourly Concentration of Methanol and Annual Average Concentrations of Acetyldehyde and Methanol

|

ASR |

Predicted Highest Hourly

Concentrations (µg m-3) |

Predicted Highest Annual

Average Concentrations (µg m-3) |

|

|

|

Methanol |

Methanol |

Acetyldehyde |

|

A1 |

15.5 |

1.27 |

1.27 |

|

A2 |

58.9 |

2.90 |

2.90 |

|

A3 |

10.6 |

0.32 |

0.32 |

|

A4 |

5.2 |

0.10 |

0.10 |

|

A5 |

6.8 |

0.10 |

0.10 |

|

A6-1 |

7.1 |

0.08 |

0.08 |

|

A6-2 |

6.3 |

0.08 |

0.08 |

|

A7 |

5.4 |

0.06 |

0.06 |

|

A8 |

7.0 |

0.05 |

0.05 |

|

A9 |

6.2 |

0.04 |

0.04 |

|

A10 |

3.0 |

0.04 |

0.04 |

|

A11 |

7.7 |

0.16 |

0.16 |

|

A12-1 |

6.4 |

0.16 |

0.16 |

|

A12-2 |

4.0 |

0.07 |

0.07 |

|

A12-3 |

5.8 |

0.07 |

0.07 |

|

A13 |

5.8 |

0.05 |

0.05 |

|

A14 |

6.2 |

0.04 |

0.04 |

|

A15 |

3.3 |

0.03 |

0.03 |

|

A16 |

6.5 |

0.06 |

0.06 |

|

A17 |

2.2 |

0.05 |

0.05 |

|

A18 |

5.1 |

0.11 |

0.11 |

|

A19 |

5.7 |

0.10 |

0.10 |

|

A20-1 |

3.9 |

0.02 |

0.02 |

|

A20-2 |

4.6 |

0.05 |

0.05 |

|

A20-3 |

1.3 |

0.03 |

0.03 |

|

A21 |

4.7 |

0.06 |

0.06 |

|

Reference

Concentration : |

2.8x104 |

4,000 |

9 |

The results indicate that the predicted

hourly concentration of methanol and annual average concentrations of acetyldehyde and methanol at the identified ASRs are well

below the respective reference chronic and acute concentrations. Hence, the chronic and acute health impacts

of acetyldehyde and methanol are considered to be

insignificant.

Cancer

Health Risk Assessment: The calculated individual cancer health risk

levels of acetyldehyde at different elevations of the

identified ASRs are presented in Annex A4

and the highest individual risk level of ASRs are summarized in Table 4.6c.

Table 4.6c Individual

Cancer Risk of Acetyldehyde

|

ASR |

Predicted Highest

Individual Cancer Risk of Acetyldehyde (a) |

|

A1 |

3.43E-06 |

|

A2 |

7.82E-06 |

|

A3 |

8.61E-07 |

|

A4 |

2.78E-07 |

|

A5 |

2.83E-07 |

|

A6-1 |

2.28E-07 |

|

A6-2 |

2.05E-07 |

|

A7 |

1.67E-07 |

|

A8 |

1.37E-07 |

|

A9 |

9.65E-08 |

|

A10 |

1.10E-07 |

|

A11 |

4.31E-07 |

|

A12-1 |

4.19E-07 |

|

A12-2 |

1.86E-07 |

|

A12-3 |

1.76E-07 |

|

A13 |

1.30E-07 |

|

A14 |

9.77E-08 |

|

A15 |

7.00E-08 |

|

A16 |

1.52E-07 |

|

A17 |

1.44E-07 |

|

A18 |

3.00E-07 |

|

A19 |

2.61E-07 |

|

A20-1 |

5.27E-08 |

|

A20-2 |

1.32E-07 |

|

A20-3 |

7.48E-08 |

|

A21 |

1.63E-07 |

|

Note: (a)

Unit risk factor of acetyldehyde (as presented

in Table 4.2b) was used for the

calculation. The individual risk level

is calculated by the predicted annual average concentration of acetyldehyde multiplying the unit risk factor. |

|

The calculated

individual cancer risk levels of acetyldehyde at different

elevations at the identified ASRs are lower than 10-6 except at A1

and A2. For A1 and A2, the risk should

be reduced to As Low As Reasonably Practicable (ALARP). It should be noted that the assessment

conservatively assumed that all the impurities of methanol are acetyldehyde (see Section

4.4.2) and it is expected that the actual risk will be lower than predicted

in this assessment.

Odour Emission from

Final Scrubber

The predicted

maximum 5-second odour levels at different elevations

of ASRs are presented in Annex A4 and

the highest predicted odour levels at ASRs are

summarized in Table 4.6d.

The predicted

5-second average odour levels at various heights at

the identified ASRs are well within the odour

criterion (ie 5 OU in 5-second averaging time).

Figures 4.6k to 4.6o present the isopleths of the predicted maximum

5-second odour levels at different heights of the identified ASRs. The isopleths show that the odour impacts are

localized and comply with the EIAO-TM

assessment criterion. Hence, no adverse

odour impact is anticipated.

Table 4.6d Highest

Predicted Maximum 5-second Odour Levels

|

ASR |

Predicted Maximum 5-second Odour Level (Odour Unit) |

|

A1 |

2.7 |

|

A2 |

2.2 |

|

A3 |

1.0 |

|

A4 |

1.2 |

|

A5 |

0.9 |

|

A6-1 |

0.6 |

|

A6-2 |

1.1 |

|

A7 |

0.9 |

|

A8 |

0.6 |

|

A9 |

0.5 |

|

A10 |

0.3 |

|

A11 |

0.5 |

|

A12-1 |

0.7 |

|

A12-2 |

0.5 |

|

A12-3 |

0.2 |

|

A13 |

0.3 |

|

A14 |

0.2 |

|

A15 |

0.3 |

|

A16 |

0.4 |

|

A17 |

0.4 |

|

A18 |

0.1 |

|

A19 |

0.1 |

|

A20-1 |

0.1 |

|

A20-2 |

0.3 |

|

A20-3 |

0.3 |

|

A21 |

0.1 |

|

5-second Odour Criterion : |

5 |

4.7

Mitigation Measures

4.7.1

Construction Phase

Although the construction dust impact is expected to be

minimal, the following dust control measures stipulated in the Air Pollution Control (Construction Dust)

Regulation will be implemented to further reduce the fugitive dust emission

as much as possible:

·

Dust

control measures such as water spaying on roads and dusty areas, covering of

lorries by impervious sheets and controlling of the falling height of fill

materials will be implemented;

·

Effective

dust screens, sheeting or netting will be provided to enclose the scaffolding

from the ground level of the facility during the building construction;

·

All

debris and materials will be covered or stored in a sheltered debris collection

area;

·

Hoarding

from ground level will be provided along the entire length of the site boundary

except for a site entrance or exit;

·

Every

stockpile of dusty materials will be covered entirely by impermeable sheeting

or placed in an area sheltered on the top and the 3 sides.

Good site practices such as regular

maintenance and checking of the diesel powered mechanical equipment will be

adopted to avoid any black smoke emissions and to minimize gaseous emissions.

4.7.2

Operation Phase

No mitigation

measures will be required.

4.8

Residual Impacts

4.8.1

Construction Phase

No adverse residual impact is anticipated after

the implementation of the recommended mitigation measures described in Section 4.7.1.

4.8.2

Operation Phase

No adverse residual impact is anticipated.

4.9

Environmental

Monitoring and Audit

4.9.1

Construction Phase

As the scale of construction works is small,

no dust monitoring (in terms of TSP) is required. However, regular site audit (ie monthly) will be performed to ensure the implementation

of suitable dust control measures and good site practices recommended in Section 4.7.1.

4.9.2

Operation Phase

Odour concentration at the stack of the

final air scrubber will be monitored on monthly basis for the first two years

of the operation. Exhaust gas

temperature and exhaust gas velocity of the final scrubber will also be

monitored at the same frequency.

Odour patrol will be carried out along the

Project Site boundary on

monthly basis during the first year of the operation of the biodiesel

plant. If there is no exceedance of action limit or there is no substantiated

odour compliant during the first year of operation, the monitoring frequency

will be reduced to quarterly intervals in the second year of the operation.

During the second year of operation, if the action level is triggered,

the frequency will be resumed to monthly until compliance with the action level

for three consecutive months is obtained and the frequency will be reduced to

quarterly interval thereafter. If the

action level is not triggered for four consecutive quarterly monitoring, the

monitoring can be terminated

Detailed monitoring programme and

requirements are presented in Section 9.2.

4.10

Conclusions

4.10.1

Construction Phase

The Site has been

formed and is currently vacant. No major

earthworks will be required for the site formation works and only minor

excavation works will be required for the construction of the foundation works

and site utilities. The storage tanks

and process equipment will be pre-fabricated off-site and assembled on site using hydraulic and tower cranes and hence minimal

dust will be generated from this activity.

Dust generated from the minor excavation works and concreting works for

the construction of site buildings will be minimal. The dust and air emissions generated from the marine works will be

minimal.

The jetty will be constructed by piled

deck and no dredging of marine sediment will be required. Marine piles will be drilled through the

existing rubble mound seawall to competent bearing strata by a piling rig

mounted barge. The bored piles will be

filled with concrete prior to placement of trellis beam and pre-cast concrete

panels. The dust and air emissions

generated from the marine works will be minimal.

With the

implementation of dust suppression measures stipulated under the Air Pollution Control (Construction Dust)

Regulation and the adoption of good site practices, no adverse construction

dust impact is anticipated. Dust

monitoring during the construction phase is therefore considered not necessary.

Monthly site

audits will be conducted to ensure the implementation of suitable dust control

measures and good site practices during the construction phase.

4.10.2

Operational Phase

The stacks of the boiler and biogas flare (if in operation), and the

exhaust of the

The potential odour impact due to the discharge of exhaust air from the

final air scrubber of the on-site wastewater treatment plant has been

evaluated. After scrubbing, the odour concentration will be significantly reduced and will

not cause adverse odour impacts to the identified

ASRs.

The concentrations

of

Odour concentration at the stack of the

final air scrubber will be monitored for the first two years of operation of

the biodiesel plant and odour patrols along the Project Site boundary will also

be carried out to confirm that the operation of biodiesel plant will not cause

adverse odour impacts.

With the implementation

of proper design, the recommended mitigation measures and monitoring programme, it is concluded that the construction and

operation of the biodiesel plant will not cause adverse air quality impacts and

will comply with the EIAO-TM

requirements.