Table 6.4 EPD River Water Quality

Monitoring Data in 2012

|

Parameter |

Tin Sum Nullah |

River

WQO |

|

TR20B |

||

|

Dissolved Oxygen (mg/L) |

8.2 (7.8 – 9.6) |

No

less than 4 mg/L |

|

pH |

7.9 (7.7 – 8.4) |

6.5

– 8.5 |

|

Suspended Solids (mg/L) |

<1 (<1 – 6) |

Not

to cause more than 20 mg/L change |

|

5-day Biochemical Oxygen

Demand (mg/L) |

<1 (<1 – <1) |

Not

to cause more than 5 mg/L change |

|

Chemical Oxygen Demand

(mg/L) |

4 (<2 – 5) |

Not

to cause more than 30 mg/L change |

|

Oil & grease (mg/L) |

<0.5 (<0.5 – 0.5) |

Not

available |

|

Faecal coliforms (cfu/100mL) |

1 (<1 – <1) |

Not

available |

|

E.coli (cfu/100mL) |

1 (<1 – <1) |

1000 counts per 100ml |

|

Ammonia-nitrogen (mg/L) |

0.02 (<0.01 – 0.28) |

0.5

mg/L at any time |

|

Nitrate-nitrogen (mg/L) |

1.80 (0.67 – 2.50) |

Not

available |

|

Total Kjeldahl Nitrogen (mg/L) |

0.13 (0.05 – 0.51) |

Not

available |

|

Ortho-phosphate (mg/L) |

0.01 (<0.01 – 0.02) |

Not

available |

|

Total Phosphorus (mg/L) |

<0.02 (<0.02 – 0.03) |

Not

available |

|

Total Sulphide (mg/L) |

<0.02 (<0.02 – <0.02) |

Not

available |

|

Aluminium (µg/L) |

90 (<50 – 470) |

Not

available |

|

Cadmium (µg/L) |

<0.1 (<0.1 – 0.1) |

Not

available |

|

Chromium (µg/L) |

<1 (<1 – 1) |

Not

available |

|

Copper

(µg/L) |

2 (<1 – 8) |

Not

available |

|

Lead

(µg/L) |

<1 (<1 – 2) |

Not

available |

|

Zinc (µg/L) |

20 (<10 – 40) |

Not

available |

Notes:

1.

Data source: 2012 River Water Quality in Hong

Kong

2.

Except as specified, data presented are

depth-averaged values calculated by taking the means of three depths: surface,

mid-depth, bottom.

3.

Data presented are annual arithmetic means of

depth-averaged results except for E.coli

and faecal coliforms that are annual geometric means.

4.

Data in brackets indicate the ranges.

6.3.4

Full compliance with the river WQOs were

achieved at the monitoring station (TR20B) in Tin Sum Nullah for pH, suspended

solids (SS), dissolved oxygen (DO), COD and BOD5. The water quality

of this minor stream was reported to be excellent.

Water Sensitive Receivers

6.3.5

In order to evaluate potential water quality

impacts arising from the Project, water sensitive receivers (WSR) within 500 m

of the Project site boundary are considered. Two natural streams / nullah flow

along the Project site boundary. One is located to the northwest of the Project

boundary and the other one named Tin Sum Nullah is located along the southeast

of the Project boundary. The ecological value of these two watercourses is

generally low with low species diversity (refer to Section 8). No ecologically

important species susceptible to water pollution were recorded. However, any

pollutants generated by the Project activities could be discharged into these inland

water courses if uncontrolled, and hence may affect aquatic communities.

Locations of these WSRs are shown in Figure 6.1.

6.4

Assessment Methodologies

6.4.1

According to the EIA Study Brief, the

assessment area for water quality impact assessment will cover all areas within

a distance of 500 m from the boundary of the Project site. The water sensitive

receivers which may be affected by the Project have been identified. Potential

sources of water quality impact that may arise during the construction and

operational activities were described. Possible mitigation measures were also

identified to reduce adverse impacts on water quality.

6.5

Identification of Environmental Impacts

Construction

Phase

6.5.1

The proposed construction works for

reprovisioning of Sha Tin WTW would include demolition of the existing

facilities of the South Works and common facilities for both the North and the

South Works in phases as below; reprovisioning of the South Works; and construction of

new common facilities for both the North and the South Works. Details of the

construction works are described in Section 2. The construction sequence of the major

facilities is:

·

Construction

of retaining wall and new access road;

·

Construction

of new chemical house;

·

Demolition

of existing South Works;

·

Construction

of washwater equalization facilities;

·

Demolition

of existing chemical house (named as Water Treatment Works Logistics Centre);

·

Demolition

of existing washwater recovery tanks;

·

Construction

of Administration Building cum Mainland East Laboratory with visitor

facilities;

·

Construction

of the South Works (except Stage 2 filters);

·

Demolition

of existing administration building;

·

Construction

of Stage 2 filters; and

·

Paving

of access road.

6.5.2

No marine work including dredging would be

required for this Project. No construction activities would be conducted within

the natural streams / nullah within and adjacent to the Project Site. Also,

there would be no canteen or kitchen in the construction site. Potential

sources of water quality impact associated with the land-based construction of

the Project include:

·

General construction activities;

·

Construction site runoff;

·

Accidental spillage; and

·

Sewage effluent from construction workforce.

General Construction Activities

6.5.3

The land-based construction works could have

the potential to cause water pollution.

Various types of construction activities may generate wastewater. These include general cleaning and polishing,

wheel washing, and dust suppression.

These types of wastewater would contain high concentrations of suspended

solids (SS). There is no public sewer available for wastewater discharge

on-site. If uncontrolled, these effluents could lead to deterioration in water

quality.

Construction Site Runoff and Drainage

6.5.4

Construction site run-off would cause

potential water quality impacts.

Potential pollution sources of site run-off may include:

·

Runoff and erosion from exposed soil

surfaces, earth working areas and stockpiles;

·

Release of any bentonite slurries, concrete

washings and other grouting materials with construction run-off, storm water or

ground water dewatering process;

·

Wash water from dust suppression sprays and

wheel washing facilities; and

·

Fuel, oil and lubricants from maintenance of

construction vehicles and equipment.

6.5.5

During rainstorms, site run-off would wash

away the soil particles on unpaved lands and areas with the topsoil

exposed. The run-off is generally

characterized by high concentrations of SS.

Release of uncontrolled site run-off would increase the SS levels and

turbidity in the nearby water environment.

Site run-off may also wash away contaminated soil particles and

therefore cause water pollution.

6.5.6

Wind blown dust would be generated from

exposed soil surfaces in the works areas.

It is possible that wind blown dust would fall directly onto the nearby

water bodies when a strong wind occurs.

Dispersion of dust within the works areas may increase the SS levels in

surface run-off causing a potential impact to the nearby sensitive receivers.

Accidental Spillage

6.5.7

A large variety of chemicals may be used

during construction activities. These

chemicals may include petroleum products, surplus adhesives, spent lubrication

oil, grease and mineral oil, spent acid and alkaline solutions/solvent and

other chemicals. Accidental spillage of

chemicals in the works areas may contaminate the surface soils. The contaminated soil particles may be washed

away by construction site run-off or stormwater drainage which in turn causes

water pollution.

Sewage Effluent from Construction Workforce

6.5.8

During the construction of the Project, the

workforce on site will contribute to the local population of the area, although

the number of workers will vary over the construction period. Potential impacts

may arise from wastewater generated from sanitary facilities and waste disposal

areas.

6.5.9

Deep excavation would be required for

construction of water tanks and the associated facilities. Since potentially

contaminated areas at the Project site were identified in the Contamination

Assessment Plan (CAP), any groundwater pumping out or from dewatering process

during excavation works could be potentially contaminated. Discharge / recharge of potentially

contaminated groundwater generated may affect the surface / groundwater

quality, if uncontrolled.

Operational

Phase

6.5.10

The Sha Tin WTW is to treat raw water mainly imported

from Dongjiang and to provide water supply to territory. The treated water

would comply with the latest standards as specified by WSD. The existing treated water quality standards

as specified by WSD, the authority in

Hong Kong, is based on the World Health Organization (WHO)’s Guidelines for

Drinking-water Quality 2008, supplemented by an additional 10 parameters not

included in the Guidelines. Upon decommissioning for the South Works, it would

then move to the construction phase. Similarly upon completion of the

construction, it would move to the operation phase. No water quality

impact would be expected from switching the existing facilities to the upgraded

facilities. Potential sources of water quality impacts on the nearby water

courses due to the Sha Tin WTW operation would be:

·

Washwater effluent; and

·

Overflow from Treatment Works Components.

Washwater Effluent

6.5.11

During operational phase of the Project, cleansing

of the treatment works components such as filter beds would be required. Washwater

may contain various chemicals, such as polymer, ammonium sulphate, sodium

phosphate, and chlorine, and any impurities removed by the filters. Direct

discharge of such washwater could deteriorate water quality in the receiving

water bodies, if uncontrolled.

Overflow from Treatment Works Components

6.5.12

Possible failure of treatment works

components or interruption of the electrical power supply could cause Sha Tin

WTW operational failures, which could result in an overflow of water. If uncontrolled,

overflow of water would be discharged to the surrounding area and adjacent

water courses.

6.6

Cumulative Impacts from Concurrent Project

6.6.1

The construction works for Shatin to Central

Link – Tai Wai to Hung Hom Section would be conducted concurrently with this

Project. The construction for the railway alignment near the Sha Tin WTW will

be land-based only. Provided that all mitigation measures as recommended in the

EIA Report will be implemented properly, the potential water quality impact

from the Project is expected to be localized and therefore no cumulative water

quality impacts would be expected.

6.7

Prediction and Evaluation of Environmental Impacts

Construction

Phase

General Construction Activities

6.7.1

Land-based construction activities would

generate wastewater and cause water pollution. Their impacts are likely to be

minimal, provided that good construction practices and proper site management

would be observed. Effluent discharge from temporary site facilities should be

controlled to prevent direct discharge to the neighbouring water environment.

It is anticipated that water quality impacts caused by general construction

activities would be insignificant with adequate implementation of recommended

mitigation measures (as given in Section

6.8).

Construction Site Run-off and Drainage

6.7.2

Construction site run-off and drainage may

cause local water quality impacts.

Increase in SS arising from the construction site could block the

drainage channels and may result in local flooding when heavy rainfall

occurs. As a good site practice,

mitigation measures should be implemented to control construction site runoff

and drainage from the works areas, and to prevent runoff and drainage water

with high levels of SS from entering the nearby water bodies. With the implementation of appropriate

measures to control run-off and drainage from the construction site,

disturbance of water bodies would be avoided and deterioration in water quality

would be minimal. Unacceptable impacts on the water quality are not expected,

provided that the recommended measures described in Section 6.8 are properly implemented.

Accidental Spillage

6.7.3

The use of engine oil and lubricants, and

their storage as waste materials has the potential to create impacts on the

water quality if spillage occurs and enters adjacent water environment. Waste oil may infiltrate into the surface

soil layer, or run-off into nearby water environment, increasing hydrocarbon

levels. The potential impacts could

however be mitigated by practical mitigation measures and good site practices

(as given in Section 6.8).

Sewage Effluent from Construction Workforce

6.7.4

Domestic sewage would be generated from the

workforce during the construction phase. Provided that sewage is not discharged

directly into stormwater drains or natural streams / nullah adjacent to the

construction site and this temporary sewage will be properly treated by interim

sewage treatment facilities, such as portable chemical toilets which are

properly maintained with the employment of licensed collectors for the

collection and disposal on a regular basis, it is unlikely that sewage

generated from the site would have a significant water quality impact. Mitigation measures and good site practices

given in Section 6.8 should be

implemented.

Groundwater

6.7.5

Deep excavation would be required for

construction of water tanks and the associated facilities. Since potentially

contaminated areas at the Project site were identified in the CAP, any groundwater

pumping out or from dewatering process during excavation works could be

potentially contaminated. Prior to the

excavation works, the baseline groundwater quality in these potentially

contaminated areas should be reviewed with reference to the relevant site

investigation data and any additional groundwater quality measurement

results. The review results should be

submitted to EPD for examination. If the results indicate contamination for the

groundwater to be generated from the excavation works, this contaminated

groundwater would either be properly treated or properly recharged into the

ground in compliance with the requirements of the TM-DSS. No direct discharge of contaminated

groundwater would be allowed. Provided that all the mitigation measures and

monitoring requirements as recommended in Sections

6.8 and 6.10 are followed properly, no adverse water quality impact would

be envisaged.

Operational

Phase

Washwater Effluent

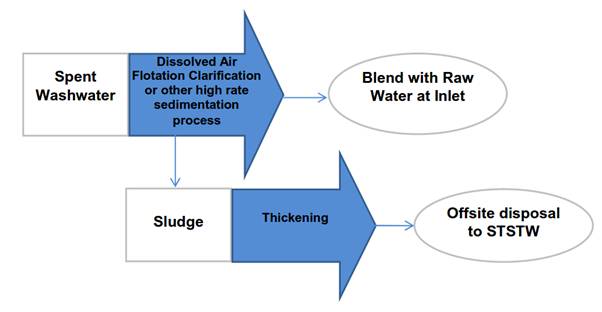

6.7.6

During operational phase, cleansing of the

treatment works components would be required. The washwater would firstly be

captured by the washwater

equalization tanks, the washwater would then be treated using dissolved air

flotation (DAF) clarification at the DAF clarifiers or other high rate

sedimentation process and finally flow to the Inlet Works to be blended with

raw water. The treatment of sludge generated from the DAF clarification or

other high rate sedimentation process is detailed in the waste management

section. A flow chart for the

treatment of spent washwater is given below in Plate 1. No washwater would be discharged off-site and thus no

adverse impacts upon the nearby watercourses arising from the washwater effluent

would be anticipated.

Plate 1 Flow Chart for Spent

Washwater

Overflow from Treatment Works Components

6.7.7 Overflow

of raw water and process water may occur in the event of equipment failure or

interruption of the electrical power supply. Potential overflow would come from

raw water (which comes from local reservoir and Guangdong) and well process /

treated water (which contains low level of chemicals that used to removed

pollutants and enhance the drinking water quality). The discharge of overflow

in case of equipment failure or power failure is not expected to result in

significant impact on water quality of receiving waters. Provision of standby

units and dual power supply could minimise occurrence of overflow. Discharge of

overflow into the surrounding area and nearby water courses would be avoided

and hence no adverse water quality impact would be anticipated.

6.8

Mitigation of Adverse Environmental Impacts

Construction

Phase

Construction Site Run-off and General Construction

Activities

6.8.1

The site practices outlined in ProPECC PN

1/94 “Construction Site Drainage” should be followed to minimise surface

run-off and the chance of erosion.

Effluent discharged from the construction site should comply with the

standards stipulated in the TM-DSS. The following measures are recommended to

protect water quality and sensitive uses of the inland and coastal waters, and

when properly implemented should be sufficient to adequately control site

discharges so as to avoid water quality impacts:

6.8.2

Surface run-off from construction sites

should be discharged into storm drains via adequately designed sand/silt

removal facilities such as sand traps, silt traps and sedimentation

basins. Channels or earth bunds or sand

bag barriers should be provided on site to properly direct stormwater to such

silt removal facilities. Perimeter

channels at site boundaries should be provided where necessary to intercept

storm run-off from outside the site so that it will not wash across the

site. Catchpits and perimeter channels

should be constructed in advance of site formation works and earthworks.

6.8.3

Silt removal facilities, channels and

manholes should be maintained and the deposited silt and grit should be removed

regularly, at the onset of and after each rainstorm to prevent local

flooding. Any practical options for the

diversion and re-alignment of drainage should comply with both engineering and

environmental requirements in order to provide adequate hydraulic capacity of

all drains. Minimum distances of 100 m should be maintained between the

discharge points of construction site run-off and the existing saltwater

intakes. While the locations of the discharge points of construction site

run-off have not been confirmed at the current stage, the discharge points are

confirmed to be located within the construction site boundary. The nearest

seawater intake from the construction site within the same watershed would be

the Sha Tin WSD flushing water intakes, which is located at Sha Tin Hoi (5 km

away). It is anticipated that the minimum separation between the discharge

points of construction site effluent and the existing seawater intakes would be

satisfied.

6.8.4

Construction works should be programmed to

minimize soil excavation works in rainy seasons (April to September) as far as

practicable. If excavation in soil

cannot be avoided in these months or at any time of year when rainstorms are

likely, for the purpose of preventing soil erosion, temporary exposed slope

surfaces should be covered e.g. by tarpaulin, and temporary access roads should

be protected by crushed stone or gravel, as excavation proceeds. Intercepting channels should be provided

(e.g. along the crest / edge of excavation) to prevent storm run-off from

washing across exposed soil surfaces.

Arrangements should always be in place in such a way that adequate

surface protection measures can be safely carried out well before the arrival

of a rainstorm.

6.8.5

Earthworks final surfaces should be well

compacted and the subsequent permanent work or surface protection should be

carried out immediately after the final surfaces are formed to prevent erosion

caused by rainstorms. Appropriate

drainage like intercepting channels should be provided where necessary.

6.8.6

Measures should be taken to minimize the

ingress of rainwater into trenches. If excavation of trenches in wet seasons is

necessary, they should be dug and backfilled in short sections. Rainwater pumped out from trenches or

foundation excavations should be discharged into storm drains via silt removal

facilities.

6.8.7

Open stockpiles of construction materials

(e.g. aggregates, sand and fill material) on sites should be covered with

tarpaulin or similar fabric during rainstorms.

6.8.8

Manholes (including newly constructed ones)

should always be adequately covered and temporarily sealed so as to prevent

silt, construction materials or debris from getting into the drainage system.

6.8.9

Good site practices should be adopted to

remove rubbish and litter from construction sites so as to prevent the rubbish

and litter from spreading from the site area.

It is recommended to clean the construction sites on a regular basis.

Wheel

Washing Water

6.8.10

All vehicles and plant should be cleaned

before they leave a construction site to minimize the deposition of earth, mud,

debris on roads. A wheel washing bay

should be provided at every site exit if practicable and wash-water should have

sand and silt settled out or removed before discharging into storm drains. The section of construction road between the

wheel washing bay and the public road should be paved with backfall to reduce

vehicle tracking of soil and to prevent site run-off from entering public road

drains.

Wastewater

from Building Construction

6.8.11

Before commencing any demolition works, all

drainage connections should be sealed to prevent building debris, soil, sand

etc. from entering drains.

6.8.12

Wastewater generated from building

construction activities including concreting, plastering, internal decoration,

cleaning of works and similar activities should not be discharged into the

stormwater drainage system. If the

wastewater is to be tankered off site for disposal into foul sewers, it should

undergo the removal of settleable solids in a silt removal facility, and pH

adjustment as necessary.

Acid

Cleaning, Etching and Pickling Wastewater

6.8.13

Acidic wastewater generated from acid

cleaning, etching, pickling and similar activities should be neutralized to

within the pH range of 6 to 10. The neutralized wastewater should be tankered

off site for disposal into foul sewers or treated to a standard acceptable to

storm drains and the receiving waters.

Effluent

Discharge

6.8.14

There is a need to apply to EPD for a

discharge licence for discharge of effluent from the construction site under

the WPCO. The discharge quality must meet the requirements specified in the discharge

licence. All the run-off and wastewater generated from the works areas should

be treated so that it satisfies all the standards listed in the TM-DSS. Minimum

distances of 100 m should be maintained between the discharge points of

construction site effluent and the existing seawater intakes. The nearest

seawater intake from the construction site within the same watershed would be

the WSD flushing water intakes, which is located at Sha Tin Hoi (5 km away). It

is anticipated that the minimum separation between the discharge points of

construction site effluent and the existing seawater intakes would be

satisfied. The beneficial uses of the treated effluent for other on-site

activities such as dust suppression, wheel washing and general cleaning etc., can

minimise water consumption and reduce the effluent discharge volume. If

monitoring of the treated effluent quality from the works areas is required

during the construction phase of the Project, the monitoring should be carried

out in accordance with the relevant WPCO licence which is under the ambit of

regional office of EPD.

Accidental Spillage

6.8.15

Contractor must register as a chemical waste

producer if chemical wastes would be produced from the construction activities.

The Waste Disposal Ordinance (Cap 354) and its subsidiary regulations in

particular the Waste Disposal (Chemical Waste) (General) Regulation should be

observed and complied with for control of chemical wastes.

6.8.16

Any service shop and maintenance facilities

should be located on hard standings within a bunded area, and sumps and oil

interceptors should be provided. Maintenance of vehicles and equipment

involving activities with potential for leakage and spillage should only be

undertaken within the areas appropriately equipped to control these discharges.

6.8.17

Disposal of chemical wastes should be carried

out in complian ce with the Waste Disposal Ordinance. The

Code of Practice on the Packaging, Labelling and Storage of Chemical Wastes

published under the Waste Disposal Ordinance details the requirements to deal

with chemical wastes. General requirements are given as follows:

·

Suitable containers should be used to hold

the chemical wastes to avoid leakage or spillage during storage, handling and

transport.

·

Chemical waste containers should be suitably

labelled, to notify and warn the personnel who are handling the wastes, to

avoid accidents.

·

Storage area should be selected at a safe

location on site and adequate space should be allocated to the storage area.

Sewage Effluent from Construction Workforce

6.8.18

The construction workforce on site will

generate sewage. It is recommended that

all the sewage generated from the workforce should be properly treated by

interim treatment facilities, such as chemical toilets which are properly

maintained with the employment of licensed collectors for the collection and

disposal on a regular basis. Interim treatment facilities should be

properly maintained to avoid adverse impact upon the nearby water environment.

6.8.19

Notices should be posted at conspicuous

locations to remind the workers not to discharge any sewage or wastewater into

the surrounding environment. Regular

environmental audit of the construction site will provide an effective control

of any malpractices and can encourage continual improvement of environmental

performance on site. It is anticipated

that sewage generation during the construction phase of the project would not

cause water pollution problem after undertaking all required measures.

Construction Works in Close Proximity of Inland

Water

6.8.20

Construction works would be carried out in

close proximity of inland water courses along Project site. To minimize the

potential water quality impacts from the construction works near any water

courses, the practices outlined in ETWB TC (Works) No. 5/2005 “Protection of Natural

Streams/rivers from Adverse Impacts arising from Construction Works” should be

adopted where applicable. Relevant mitigation measures are listed

below:

·

Temporary storage of materials (e.g.

equipment, filling materials, chemicals and fuel) and temporary stockpile of

construction materials should be located well away from any water courses

during carrying out of the construction works.

·

Stockpiling of construction materials and

dusty materials should be covered and located away from any water courses.

·

Shoring should be properly erected as

appropriate to prevent soil/ mud from slipping into the watercourses. Stockpiles should be properly covered.

·

Construction debris and spoil should be

covered up and/or disposed of as soon as possible to avoid being washed into

the nearby water receivers.

·

Construction activities, which generate large

amount of wastewater, should be carried out in a distance away from the

waterfront, where practicable.

·

Hoarding should be erected along the site

boundary to protect the nearby watercourses.

Groundwater

6.8.21

No direct discharge of groundwater from

contaminated areas should be adopted.

Prior to any excavation works within the potentially contaminated areas,

the baseline groundwater quality should be reviewed based on the relevant site

investigation data and groundwater quality measurements with reference to

Guidance Note for Contaminated Land Assessment and Remediation and the review

results should be submitted to EPD for examination. If the review results

indicate contamination for the groundwater to be generated from the excavation

works, this contaminated groundwater should either be properly treated or

properly recharged into the ground in compliance with the requirements of the

TM-DSS. If wastewater treatment is to

be deployed for treating the contaminated groundwater, the wastewater treatment

unit shall deploy suitable treatment processes (e.g. oil interceptor /

activated carbon) to reduce the pollution level to an acceptable standard and

remove any prohibited substances to an undetectable range. All treated effluent

from the wastewater treatment plant shall meet the requirements as stated in

TM-DSS and should be tankered away for proper disposal.

6.8.22

If deployment of wastewater treatment is not

feasible for handling the contaminated groundwater, groundwater recharging

wells should be installed as appropriate for recharging the contaminated

groundwater back into the ground. The recharging wells should be selected at

places where the groundwater quality would not be affected by the recharge

operation as indicated in Section 2.3 of the TM-DSS. The baseline groundwater quality

should be determined prior to the selection of the recharge wells, and a

working plan should be submitted to EPD for agreement. Pollution levels of groundwater to be

recharged shall not be higher than pollutant levels of ambient groundwater at

the recharge well. Groundwater monitoring wells should be installed near the

recharge points to monitor the effectiveness of the recharge wells and to

ensure that no likelihood of increase of groundwater level and transfer of

pollutants beyond the site boundary. Prior to recharge, free products should be

removed as necessary by installing the petrol interceptor. The Contractor should apply for a discharge

licence under the WPCO through the Regional Office of EPD for groundwater

recharge operation or discharge of treated groundwater.

Operation

Phase

Emergency Overflow

6.8.23

Standby treatment facilities, such as

parallel trains in flash mixing basins, backwash pumps and pumps in the

inter-stage booster pumping station, would be provided to prevent the

occurrence of overflow as a result of equipment failure or maintenance.

6.8.24

Dual power supply should be provided. Dual

power supply could be in the format of ring main, or an automatic-operated

emergency generator with sufficient capacity to cope with the demand loading of

the essential plant equipment. Inlet valve feeding raw water would be closed

manually within 30 minutes by the operator-in-charge in case of equipment or

power failure.

Summary

of Mitigation Measures

6.8.25

The recommended mitigation measures are

summarized as below:

Construction Phase

·

The site practices outlined in ProPECC PN

1/94 “Construction Site Drainage” should be followed to minimise surface

run-off and the chance of erosion.

Effluent discharged from the construction site should comply with the

standards stipulated in the TM-DSS.

·

The Waste Disposal Ordinance (Cap 354) and

its subsidiary regulations in particular the Waste Disposal (Chemical Waste)

(General) Regulation should be observed and complied with for control of

chemical wastes.

·

All the sewage generated from the workforce

should be properly treated by interim treatment facilities, such as chemical

toilets.

·

The practices outlined in ETWB TC (Works) No.

5/2005 “Protection of Natural Streams/rivers from Adverse Impacts arising from

Construction Works” should be adopted where applicable, to minimize the

potential water quality impacts from the construction works near any water

courses,

·

Contaminated groundwater, if any, should

either be properly treated or properly recharged into the ground in compliance

with the requirements of the TM-DSS.

Operation Phase

·

Standby treatment facilities and dual power

supply should be provided to prevent the occurrence of overflow.

·

Inlet valve feeding raw water would be closed

manually within 30 minutes by the operator-in-charge in case of equipment or

power failure.

6.9

Evaluation of Residual Environmental Impacts

6.9.1

With the full implementation of the

recommended mitigation measures for the construction and operation phases of

the proposed Project, no adverse impact on water quality is anticipated.

6.10

EM&A Requirements

Construction Phase

6.10.1

Minimisation of water quality deterioration

from land-based construction activities could be achieved through implementing

adequate mitigation measures. To ensure

no adverse water quality impact to the nearby water courses due to the

discharge of surface runoff and drainage from the works areas, water quality

monitoring of the two water courses along the Project boundary is recommended

during site clearance and foundation works. Details of the recommended water quality

monitoring requirements are provided in the stand-alone EM&A Manual for the

Project. It is also recommended that regular site inspections should be undertaken

to inspect the construction activities and works areas in order to ensure the

recommended mitigation measures are properly implemented.

Operational

Phase