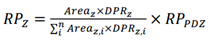

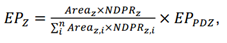

12.1.1

ERM-Hong Kong Ltd (ERM) has been commissioned

to conduct a Hazard to Life Assessment (HA) for the In-Situ Reprovisioning of

Sha Tin Water Treatment Works (Sha Tin WTW) South Works Project (hereinafter

referred to as “the Project”). The hazard assessment is a part of the

Environmental Impact Assessment for the Project conducted under the EIAO. The

EIA Study Brief is registered as "In-situ Reprovisioning of Sha Tin Water

Treatment Works – South Works” (Reference No. ESB-220/2011) and was issued on 9

March 2011.

12.1.1

Requirements for assessment of hazards to

life are presented in Section 3.4.3 of the Study Brief. Section 3.4.3.2

stipulates that:

The Applicant shall investigate alternative construction methods to

avoid the use of explosives. If there is use of explosives for the construction

activities and the storage or blasting location is in close proximity to

populated areas and/or Potentially Hazardous Installation site (i.e. STWTW),

the Applicant shall carry out hazard assessment as follows:

(i) Identify hazardous scenarios associated with the transport, storage

and use of explosives (including possible damage scenarios to gas and chlorine

facilities) and then determine a set of relevant scenarios to be included in a

Quantitative Risk Assessment (QRA);

(ii) Execute a QRA of the set of hazardous scenarios determined in (i),

expressing population risks in both individual and societal terms;

(iii) Compare individual and societal risks with the criteria for

evaluating hazard to life stipulated in Annex 4 of the TM; and

(iv) Identify and assess practicable and cost-effective risk mitigation

measures.

The methodology to be used in the hazard assessment should be consistent

with previous studies having similar issues (e.g. Shatin-to-Central Link (Tai

Wai to Hung Hom Section) (ESB-191/2008), and Central Kowloon Route

(ESB-156/2006).

12.1.2

Section 3.4.3.3 of the Study Brief stipulates

that:

The Applicant shall investigate methods to

avoid and/or minimize chlorine risks. The Applicant shall carry out hazard

assessment to evaluate potential hazard to life during construction and

operation stages of the Project due to STWTW. The hazard assessment shall

include the following:

(i) Identify hazardous scenarios

associated with the transport, storage and use of chlorine at STWTW (including

possible damage scenarios associated with construction activities, storage of

liquid oxygen) and then determine a set of relevant scenarios to be included in

a QRA;

(ii) Execute a QRA of the set of hazardous

scenarios determined in (i), expressing population risks in both individual and

societal terms;

(iii) Compare individual and societal

risks with the criteria for evaluating hazard to life stipulated in Annex 4 of

the TM; and

(iv) Identify and assess practicable and

cost-effective risk mitigation measures.

The methodology to be used in the hazard

assessment should be consistent with previous studies having similar issues

(e.g. Shatin-to-Central Link (Tai Wai to Hung Hom Section) (ESB-191/2008), and

Integration of Siu Ho Wan and Silver Mine Bay Water Treatment Works

(ESB-150/2006)).

12.1.3

The scope section of the Study Brief also

states (Section 3.2.2 (vi)):

Potential hazard to life on construction

workers, operational staff and other sensitive receivers to be identified, with

STWTW is Potentially Hazardous Installations (PHI) due to the use of liquid

chlorine on site and the Beacon Hill North Offtake Station and its associated

750mm diameter high pressure gas pipeline that runs through the old Beacon Hill

Tunnel, and the possible use of explosives for blasting if applicable.

12.1.4

As required by the Study Brief, this

assessment concerns hazards related to transport, storage and use of chlorine

at Sha Tin WTW (STWTW) during the Construction Phase (South Works reprovisioning

works) and Operational Phase of the Project (after the project completion). The

approach adopted follows that of previous studies having similar issues.

12.1.5

Hazards relating to liquid oxygen are not

included in the assessment as it has been confirmed that there will be no

storage of liquid oxygen at Sha Tin WTW. Also, there will be no use of

explosives and hence this is not considered further in the assessment. Further,

it has been confirmed by HKCG that there are no high pressure gas pipelines

running through the old Beacon Hill Tunnel.

12.1.6

Additional hazard to life requirements are

also formulated in Section 2.1 (v) of the Study Brief, which as one of the

objectives of the EIA Study specifies:

To identify and assess the potential risk to

human life due to the construction works impact on the operation of the

existing PHI (Chlorine Store), the 400kV overhead power line and other notifiable gas installations

(NGIs), e.g. Beacon Hill North Offtake Station present or in the vicinity of

Project site and to propose measures to

mitigate these impacts.

These

issues are also addressed in relevant sections of this assessment.

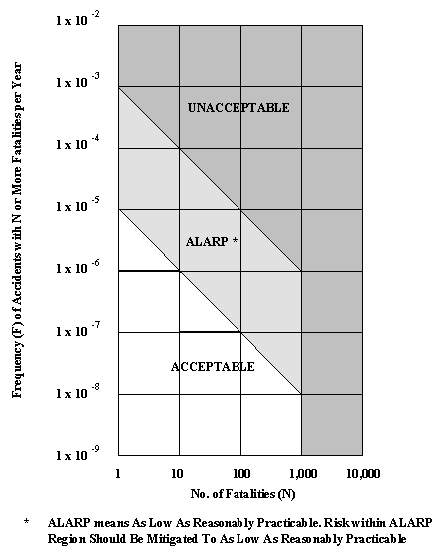

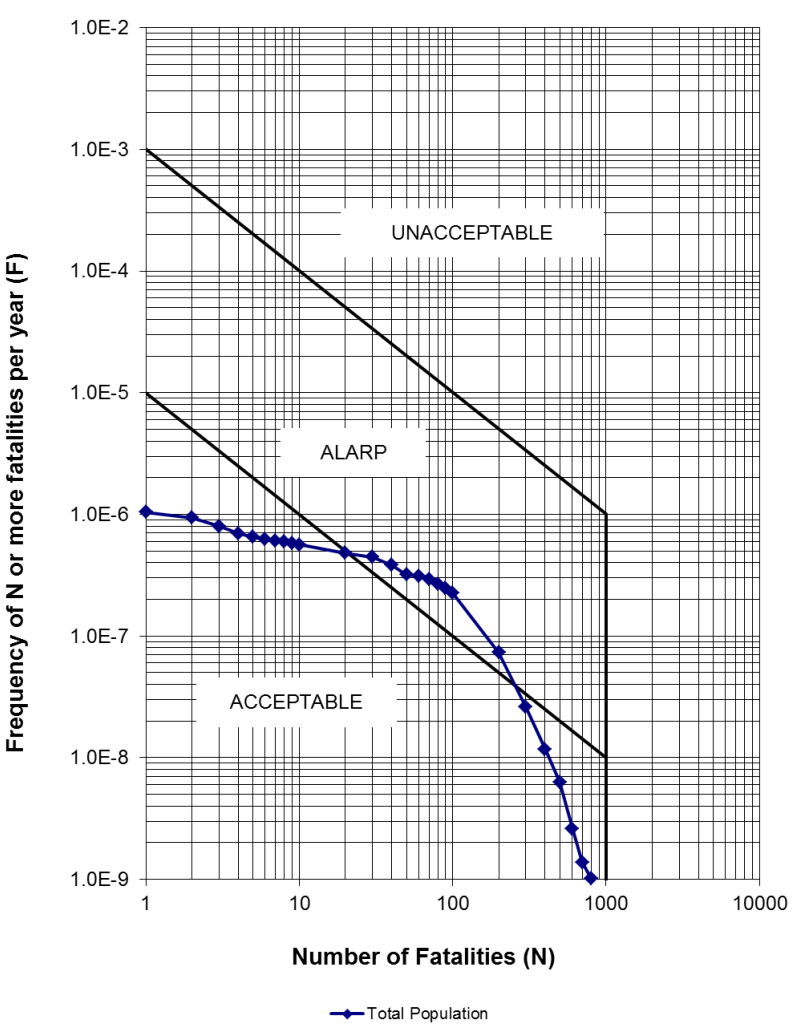

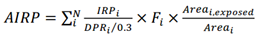

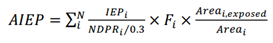

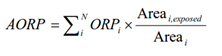

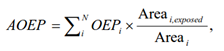

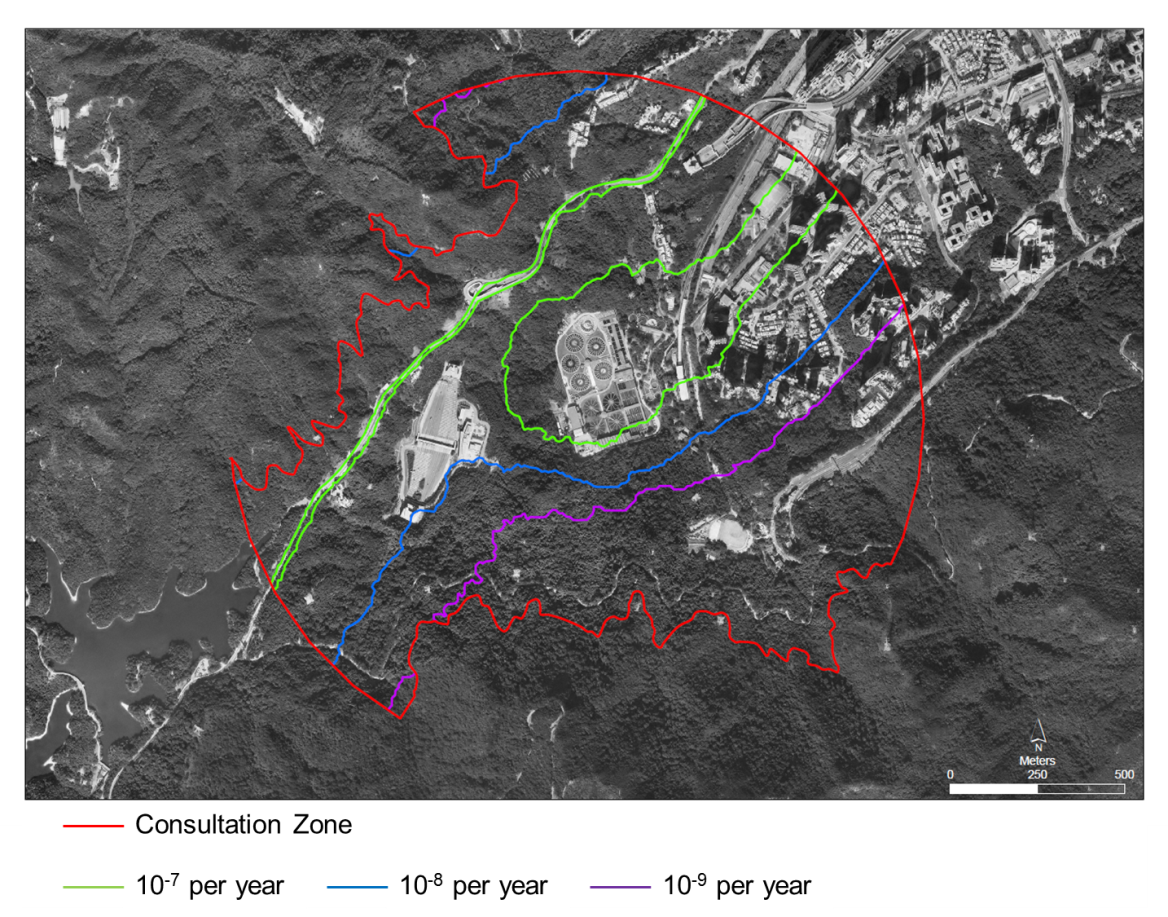

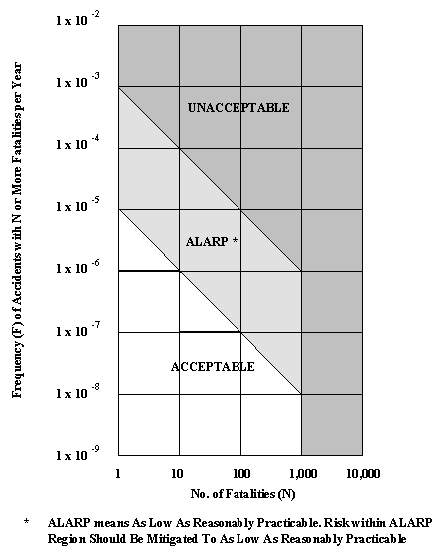

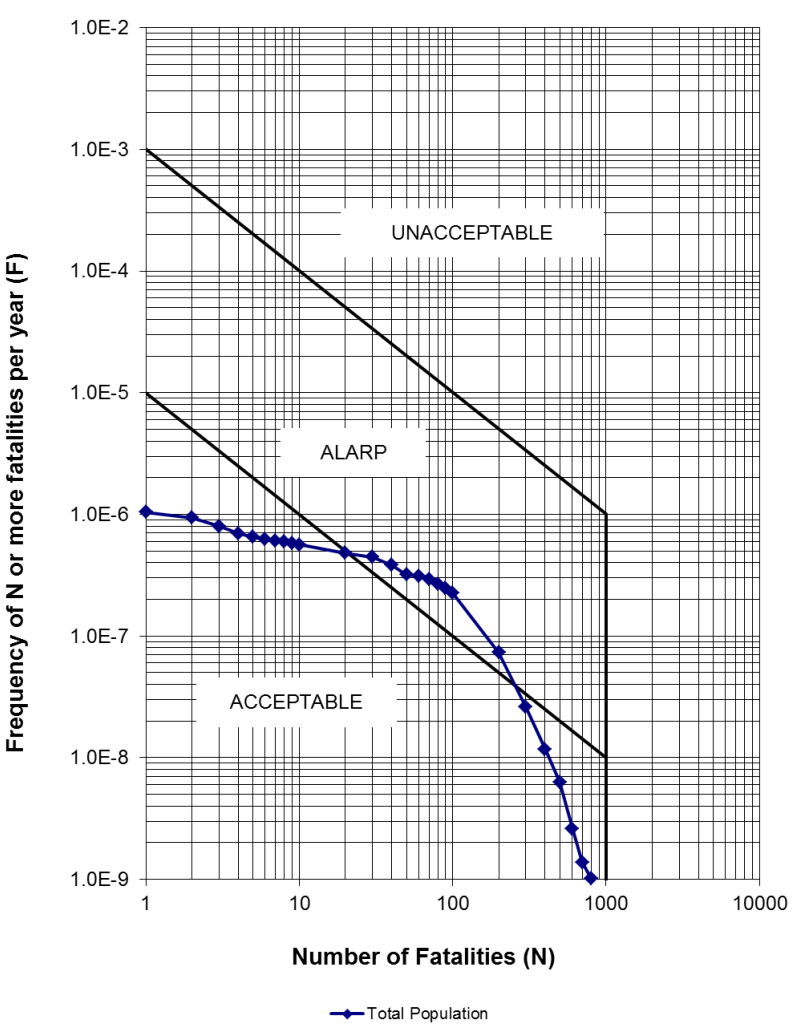

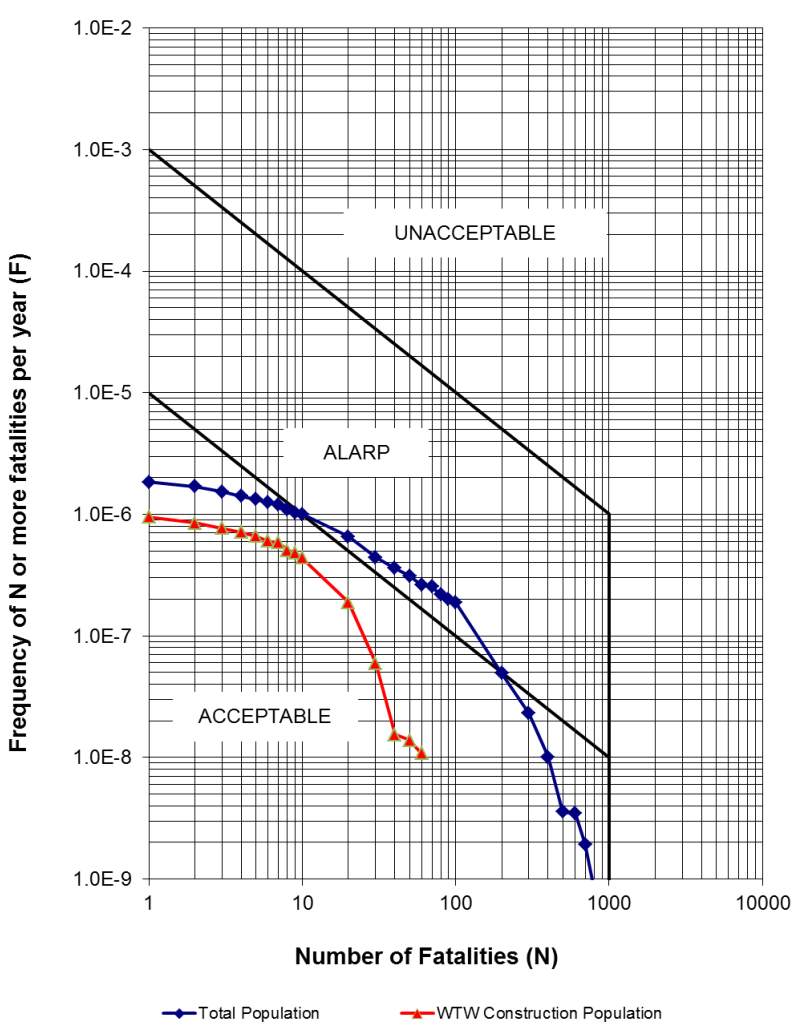

12.2.1

Hong Kong Risk Guidelines (HKRG) for

Designated Projects are defined in Annex

4 of the Technical Memorandum to

Environmental Impact Assessment Process (EIAO-TM) in terms of individual

and societal risks as follows:

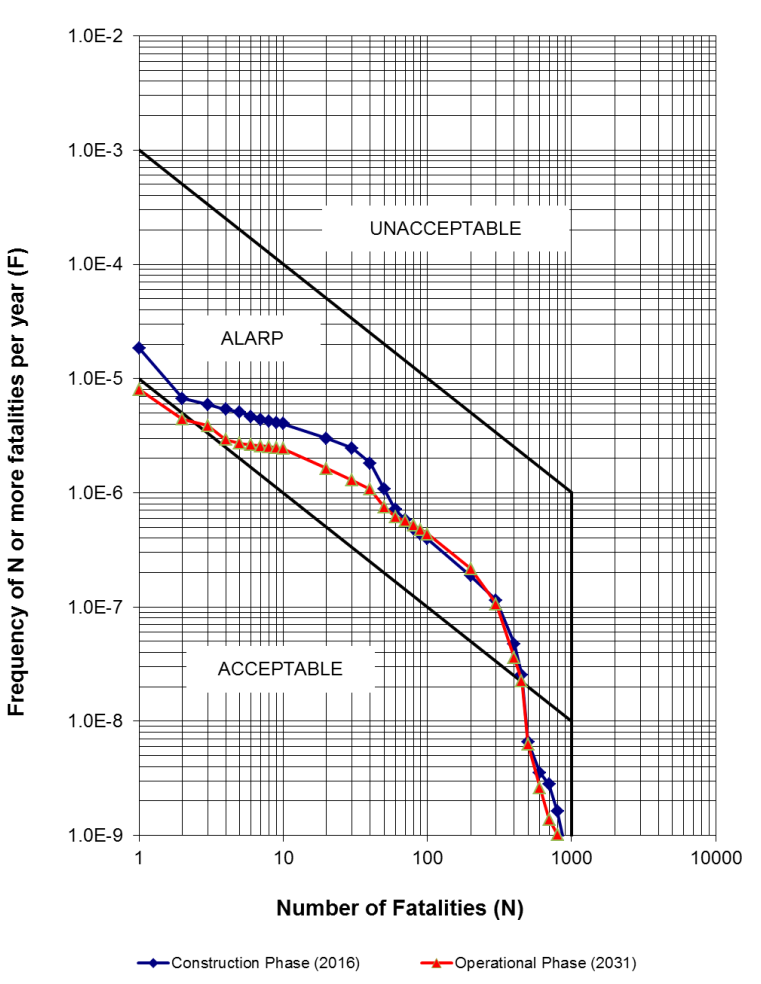

·

Maximum level of off-site individual risk

should not exceed 1 in 100000 per year, i.e. 1 × 10-5 per year; and

·

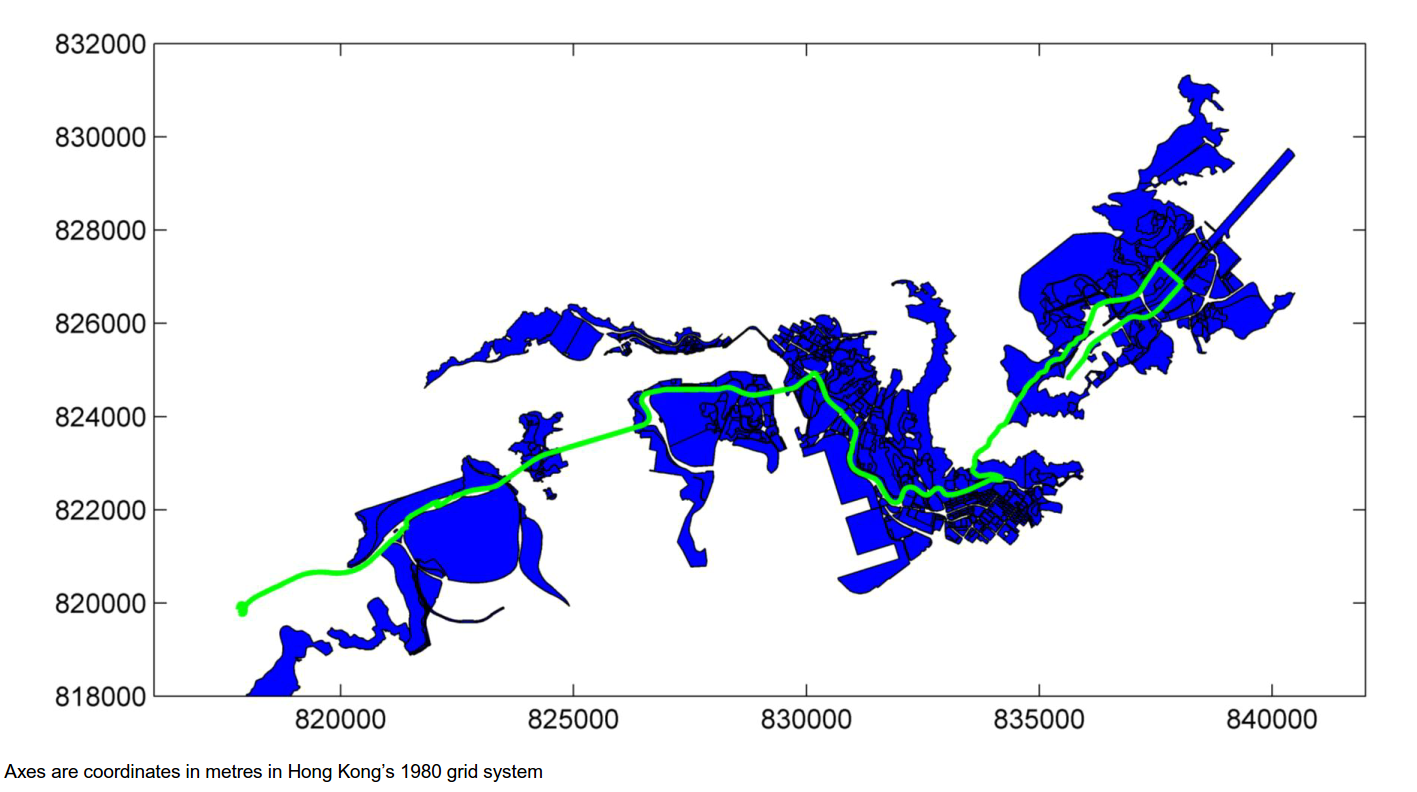

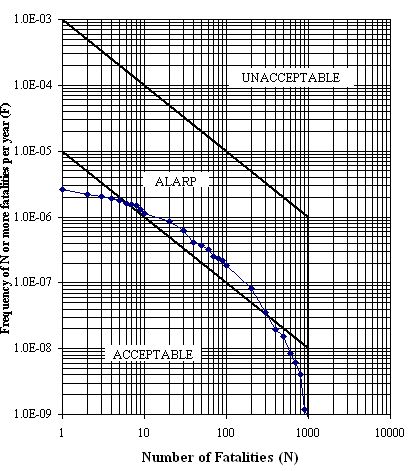

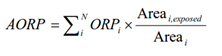

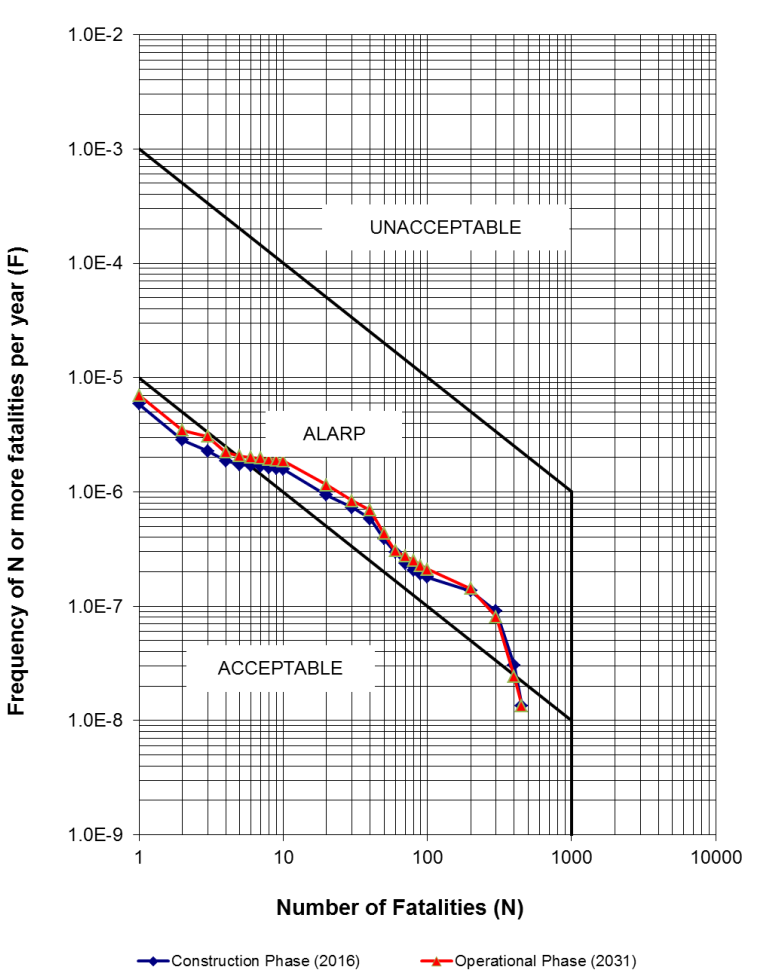

Societal Risk Guidelines as stipulated in

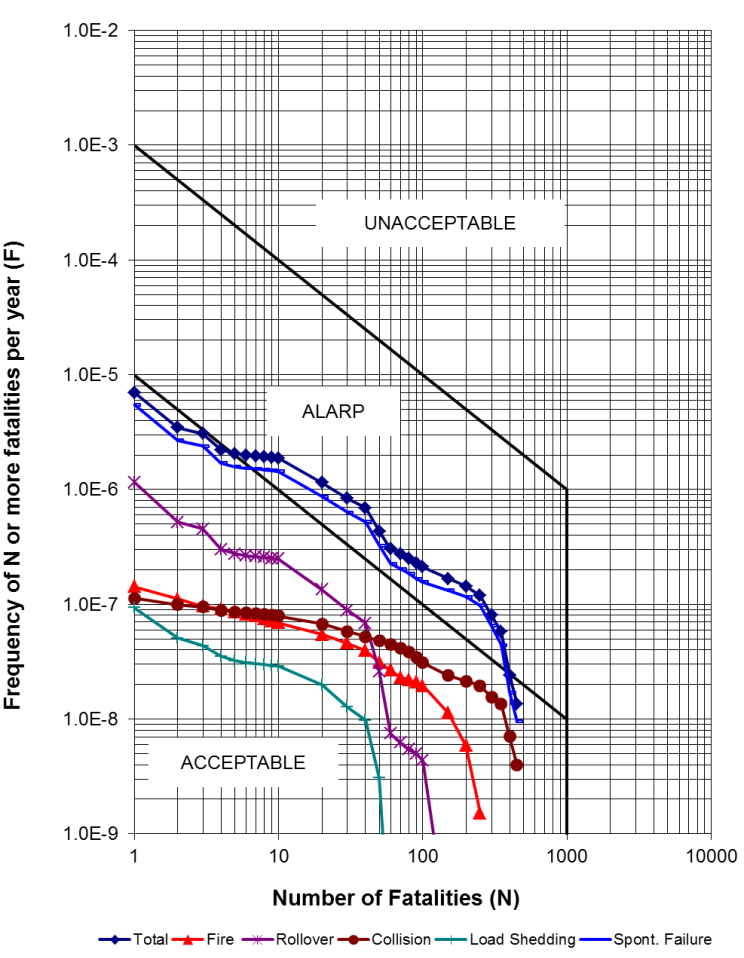

EIAO-TM are shown in Figure 12.1. For definitions of the individual and

societal risk measures see Section 12.12.

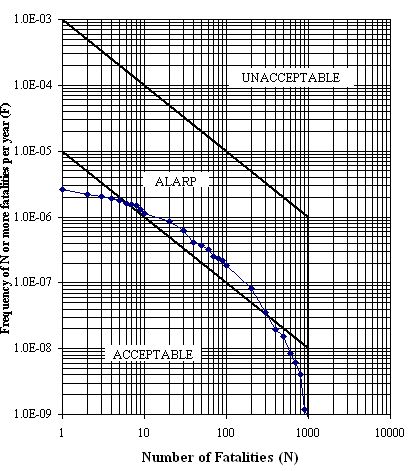

Figure 12.1 Societal Risk

Guidelines for Acceptable Risk Levels (EIAO-TM)

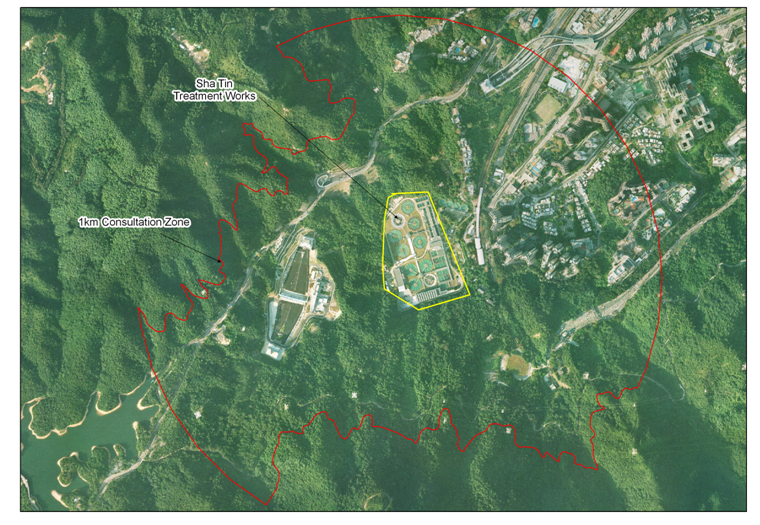

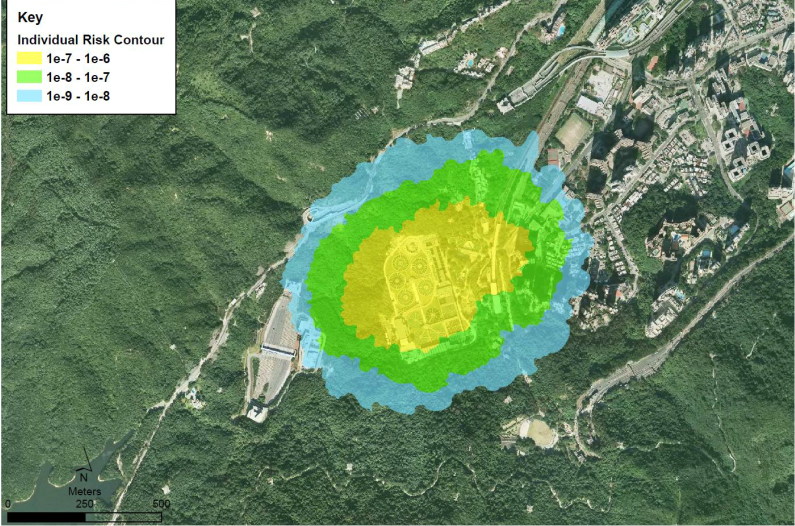

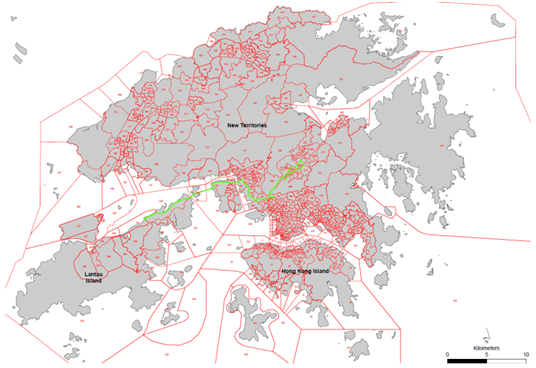

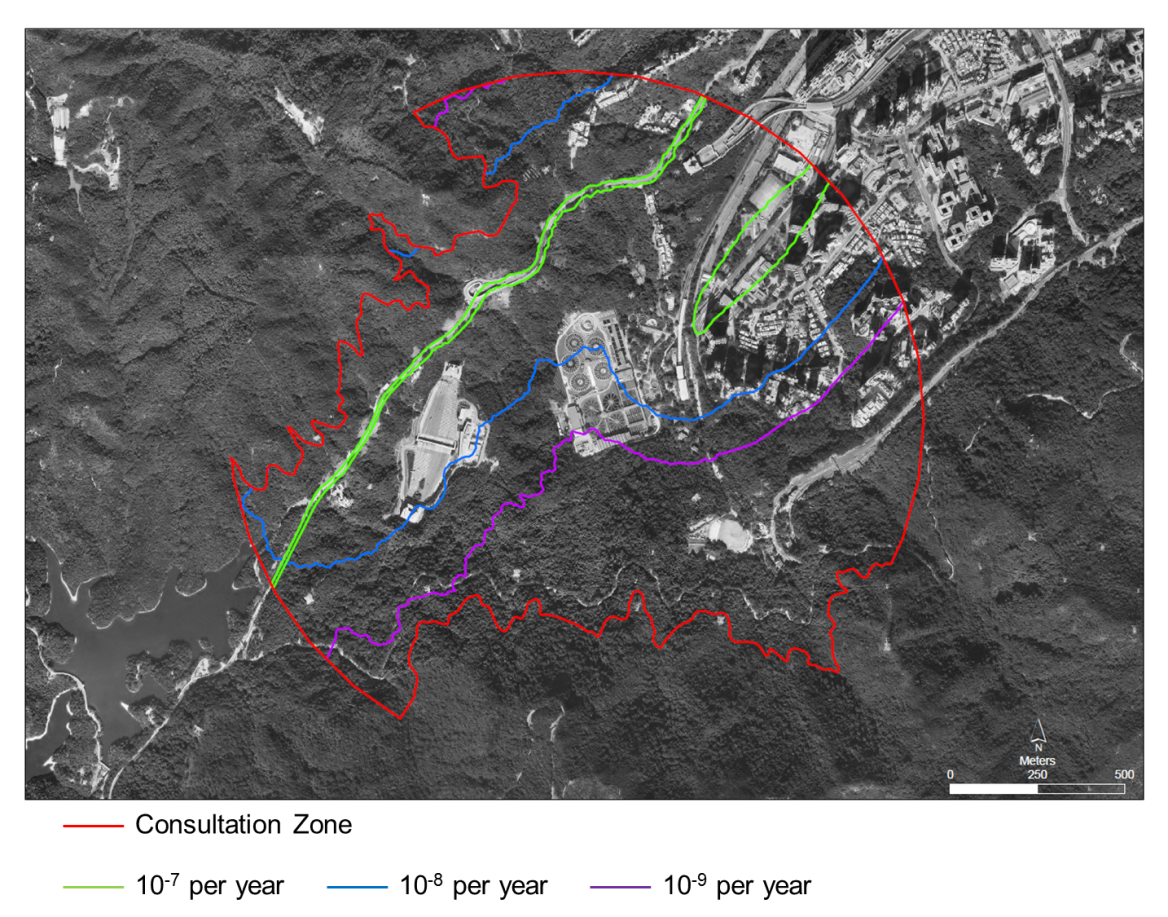

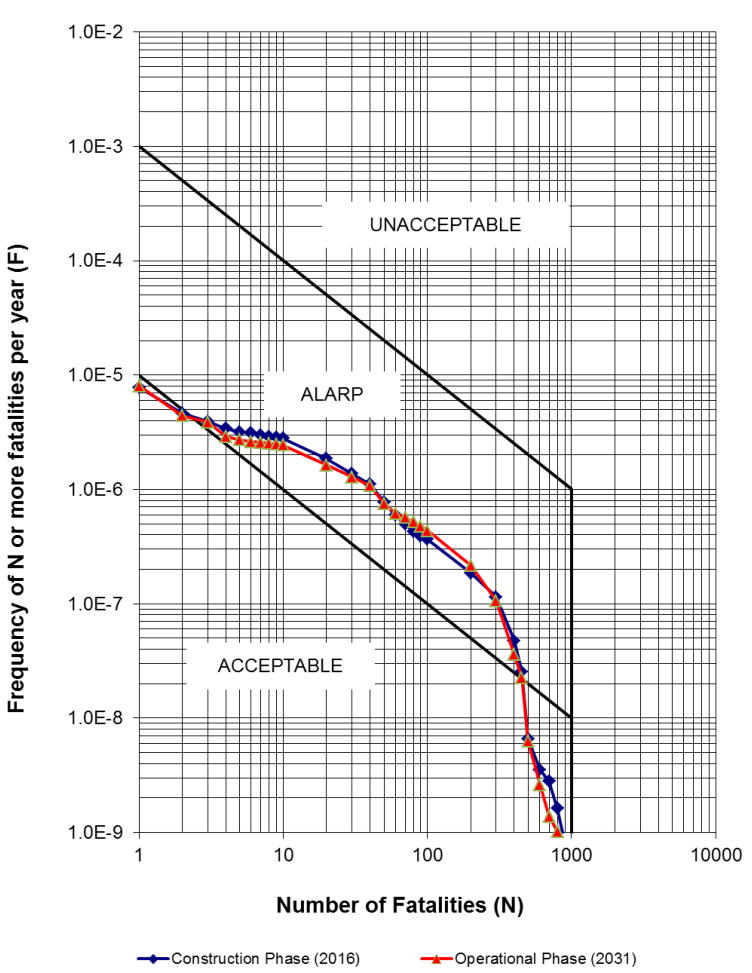

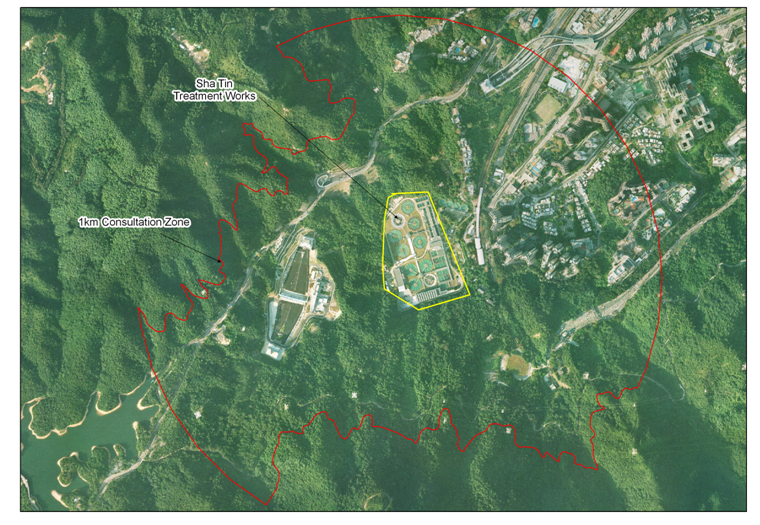

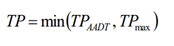

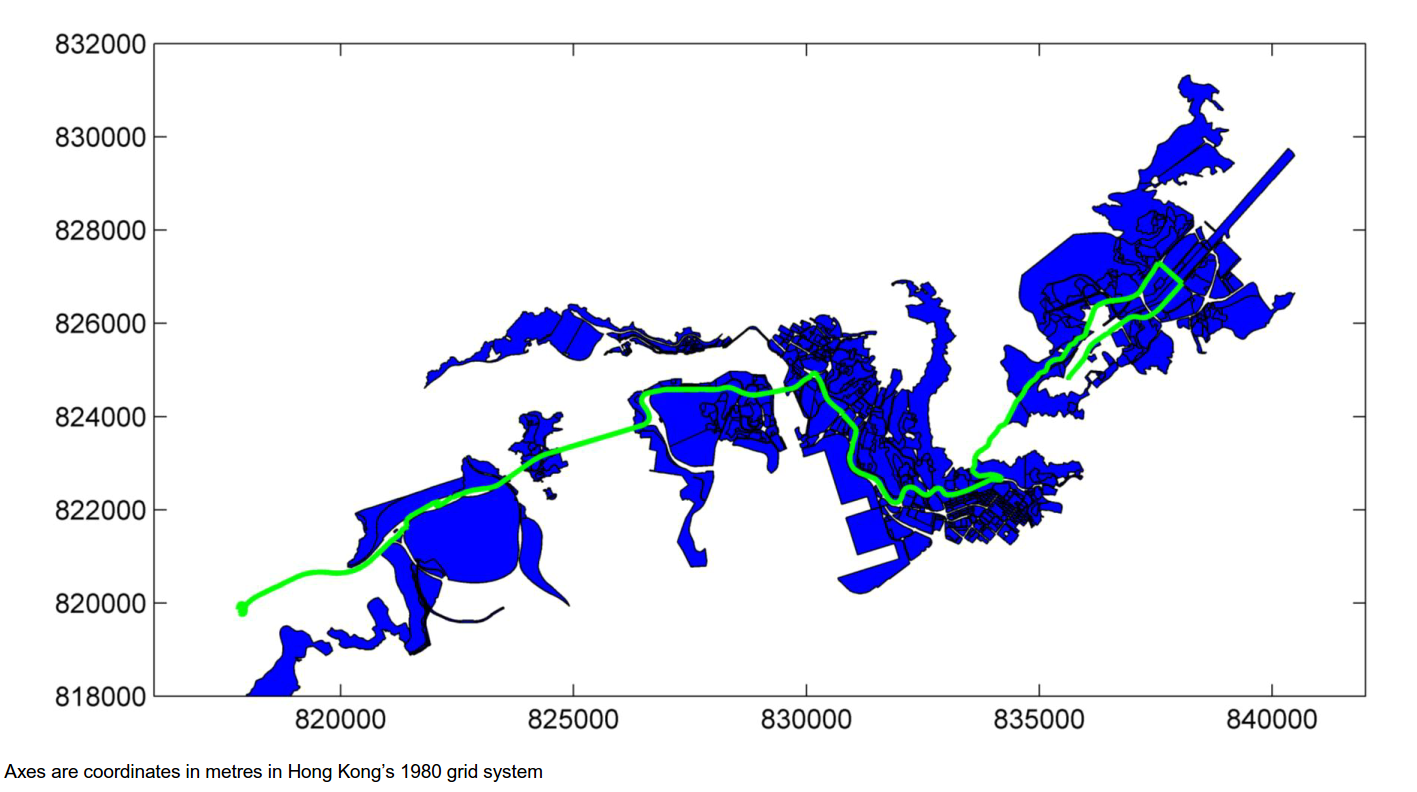

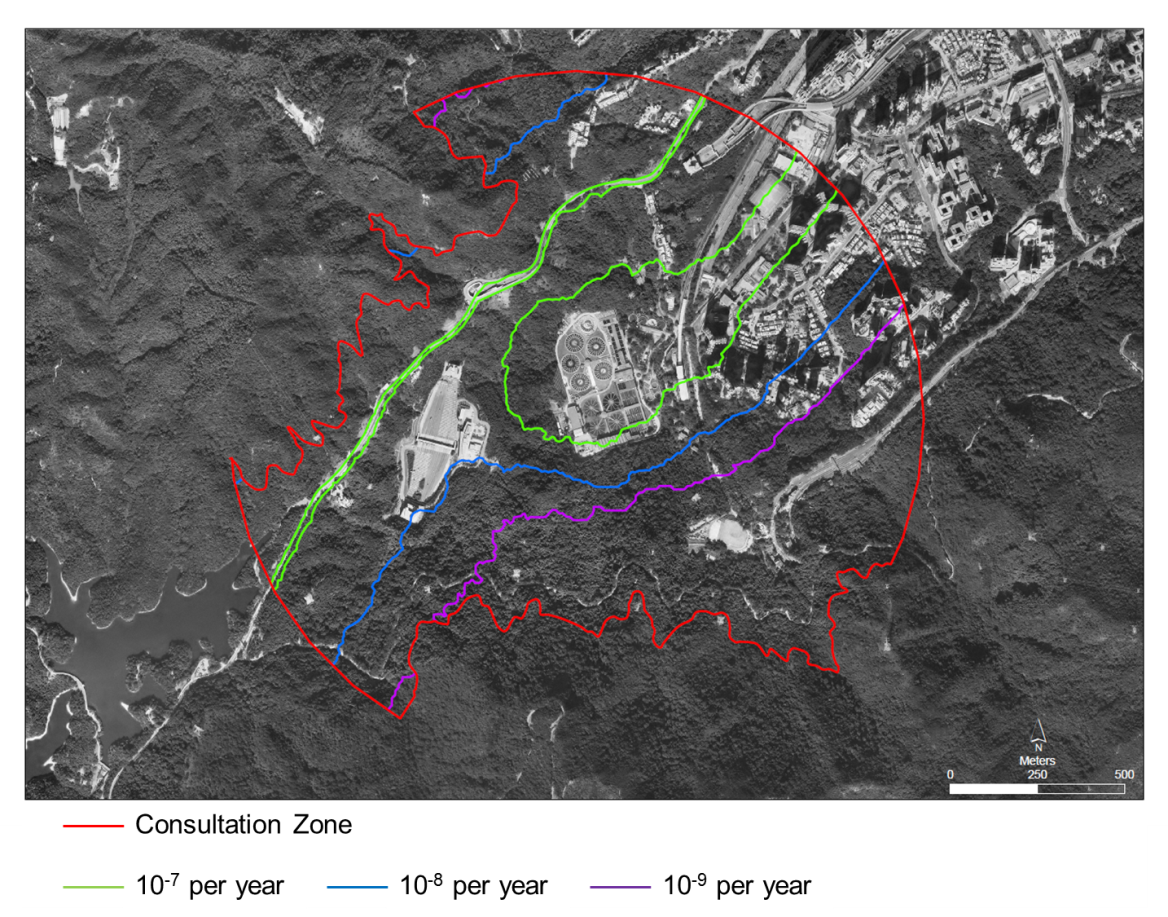

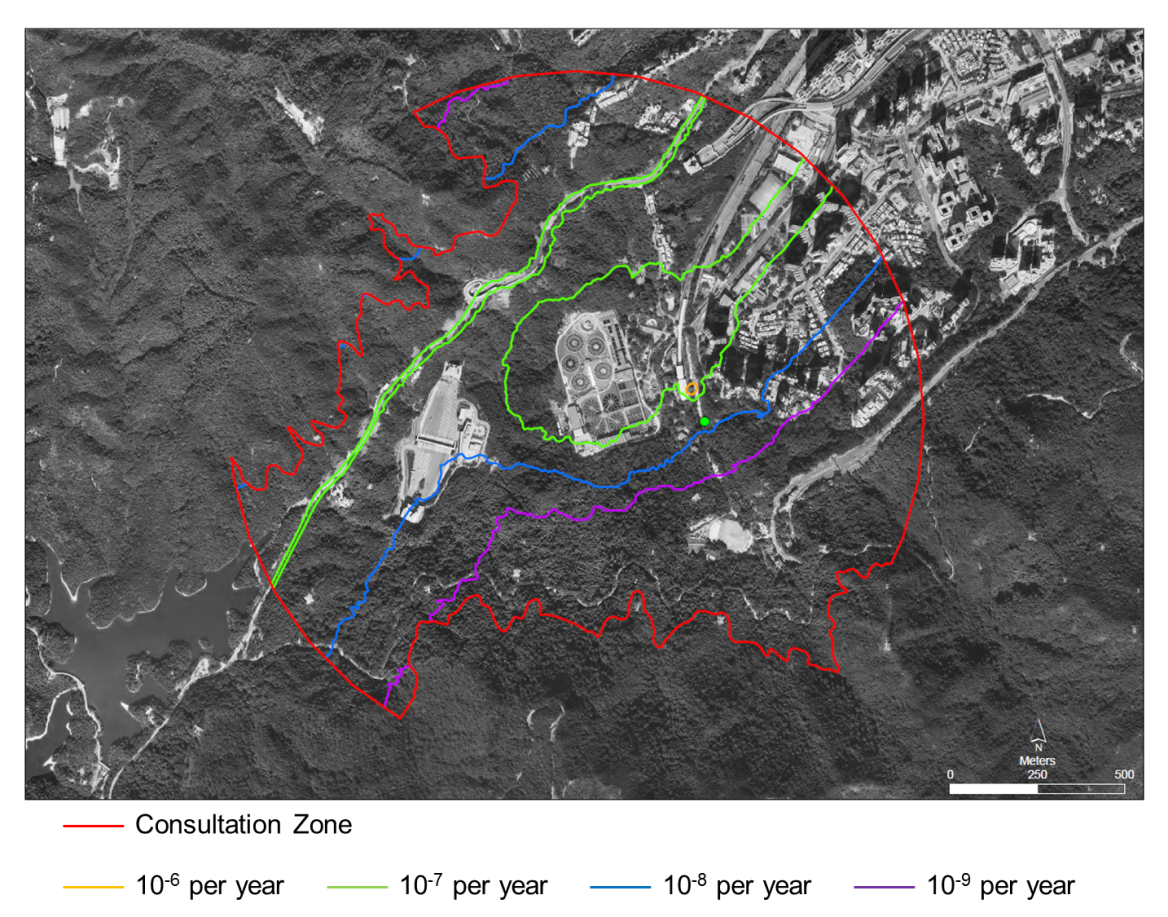

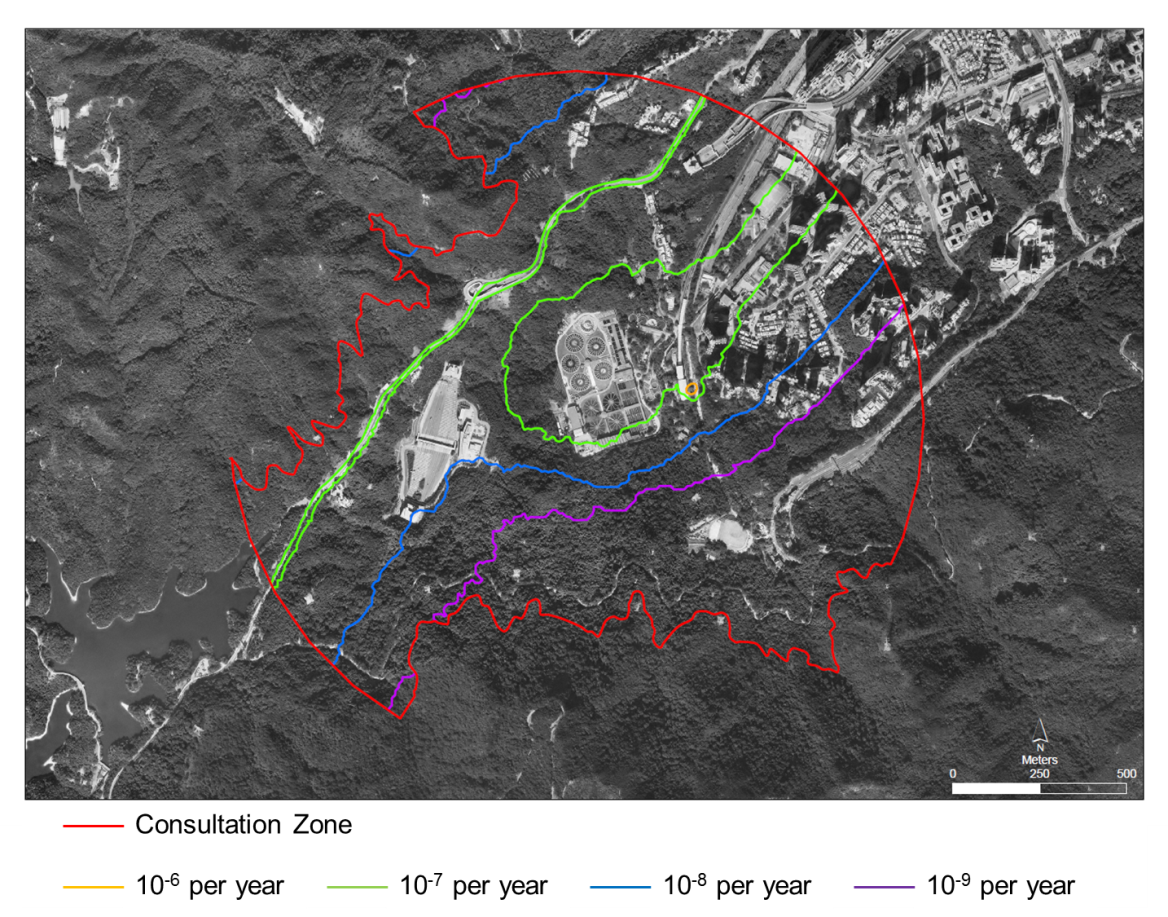

12.2.2

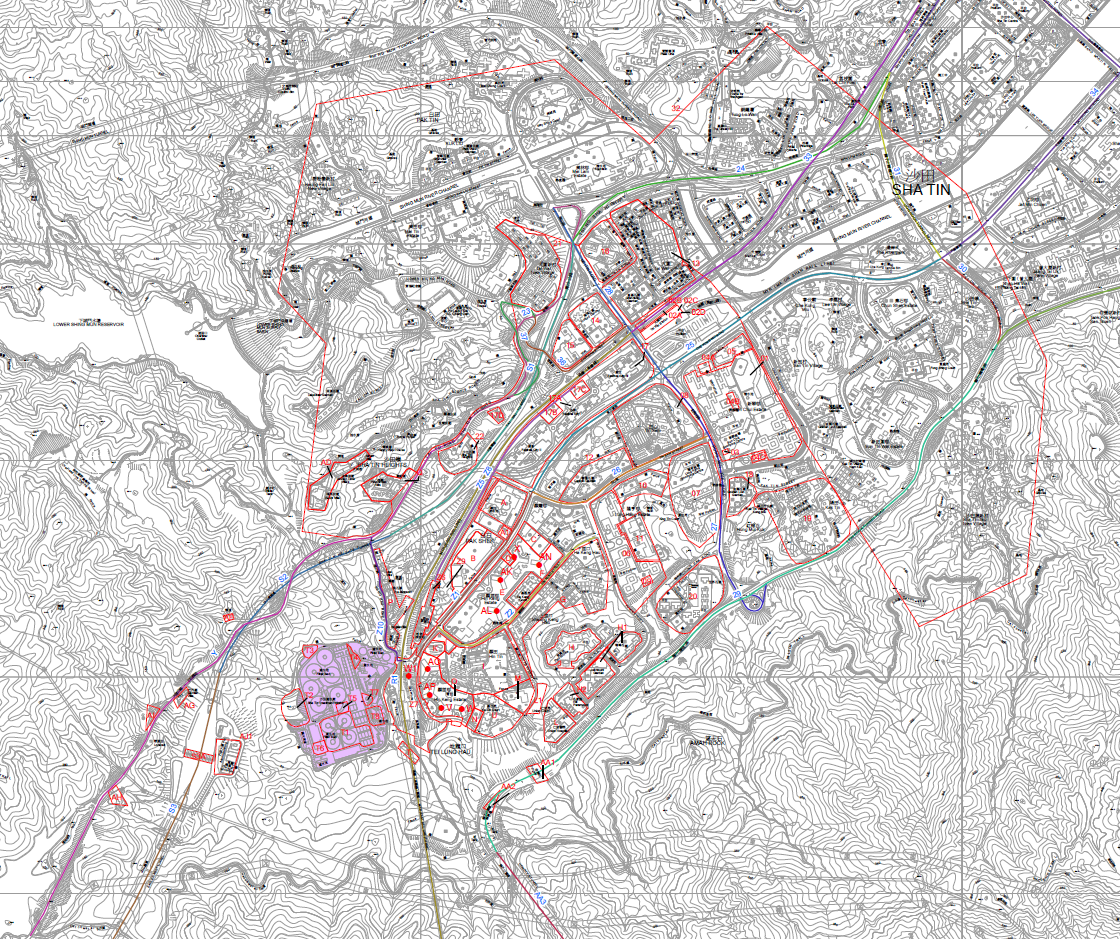

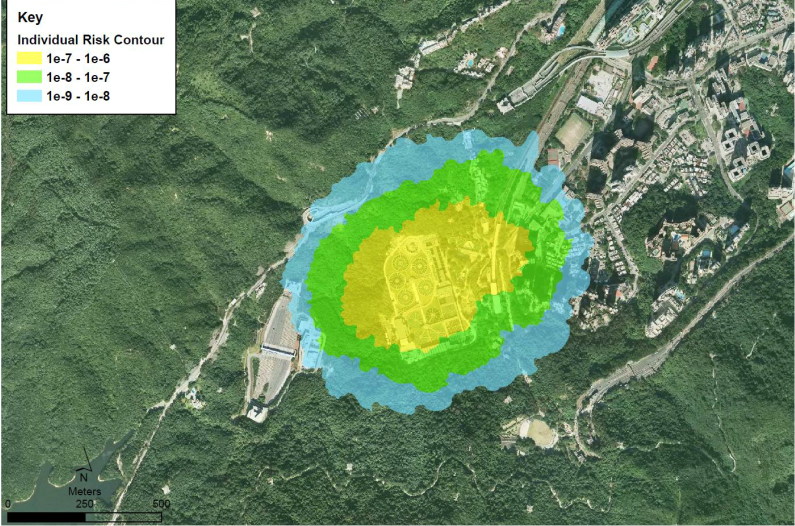

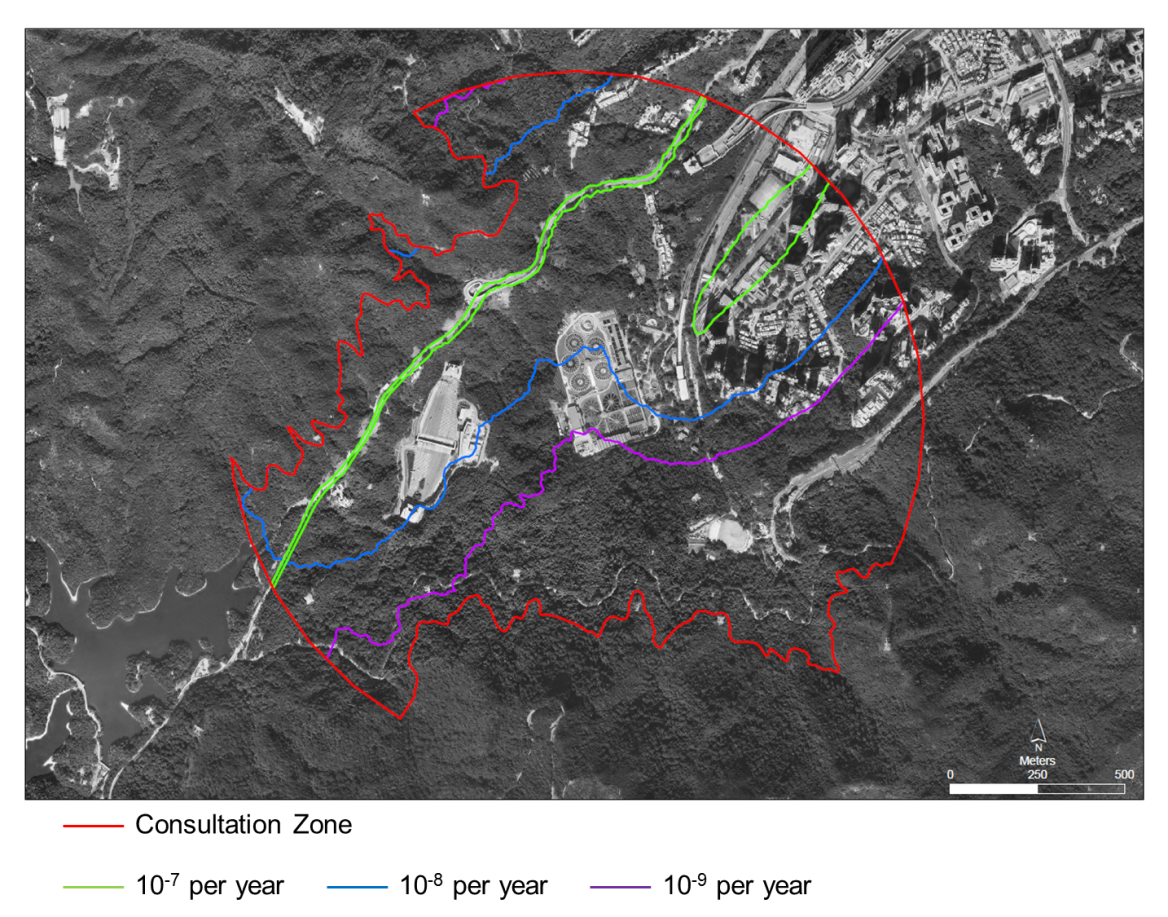

The Sha Tin WTW is designated as a

Potentially Hazardous Installation (PHI) owing to its use and storage of

chlorine in 1-tonne (1t) drums. A Consultation Zone (CZ), centred at the Chlorination

House, of 1000m radius but excluding the areas located at over 150 m above sea

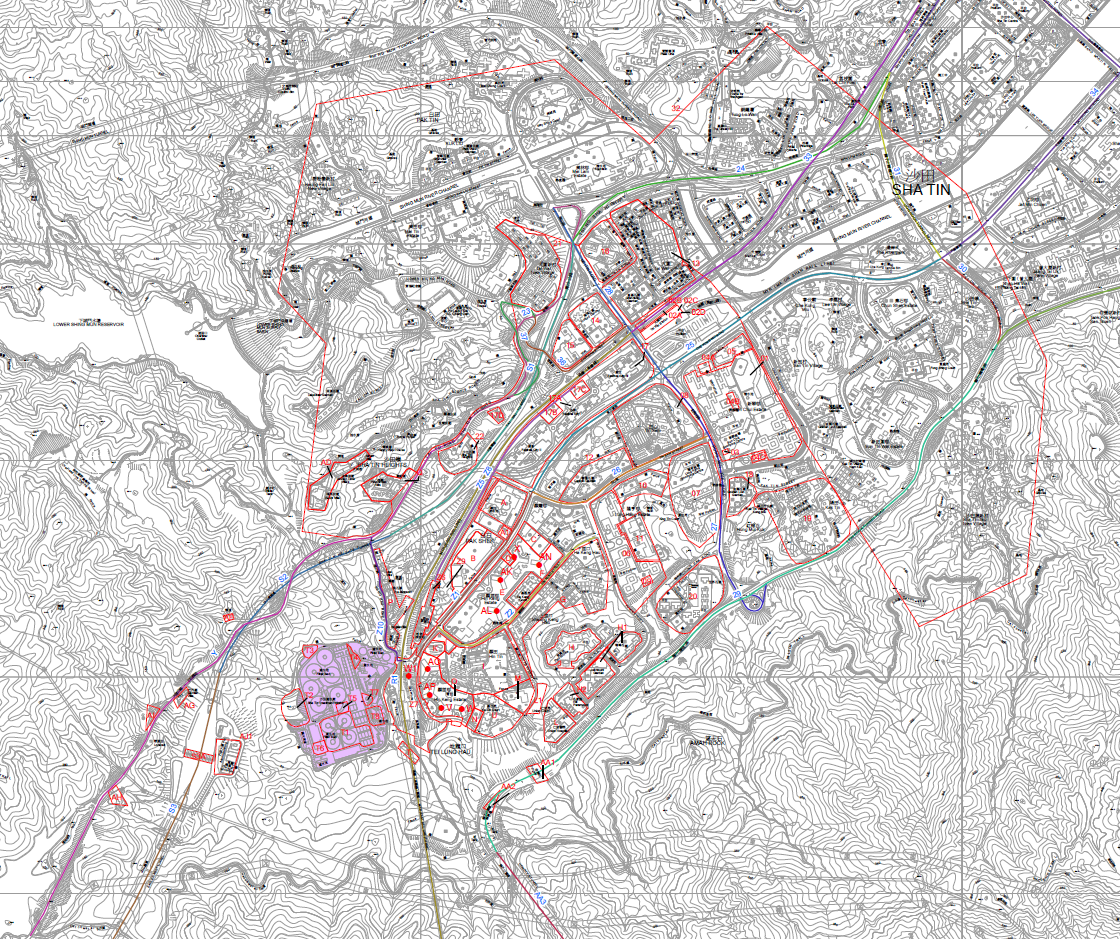

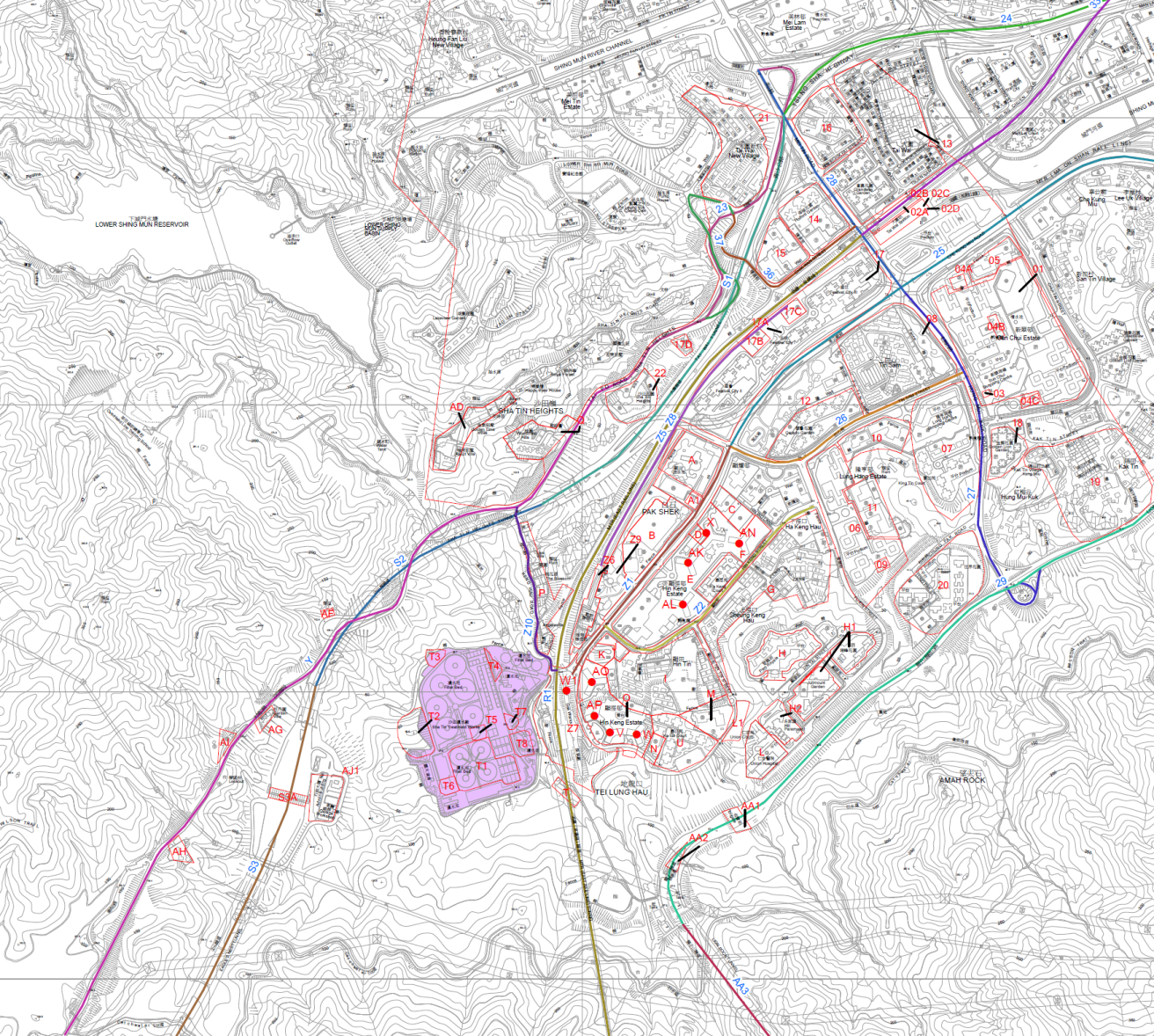

level is established around the WTW (Figure 12.2). The Hong Kong Planning Standards and Guidelines

(HKPSG), Chapter 12, require that PHIs comply with Hong Kong Risk Guidelines as

described above.

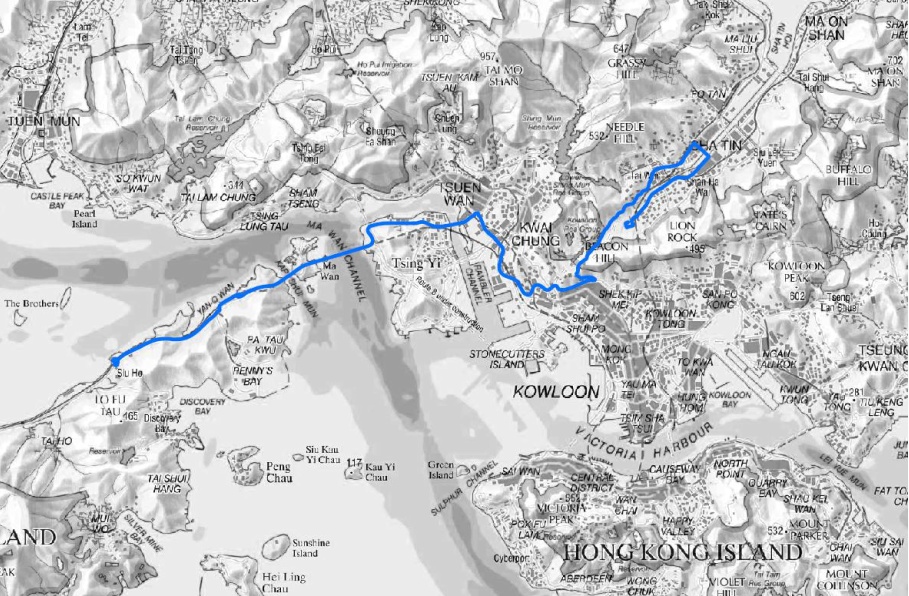

Figure 12.2 Sha Tin WTW

Location and Consultation Zone

12.3

Sha Tin Water Treatment Works: Location and Operations

Location

12.3.1

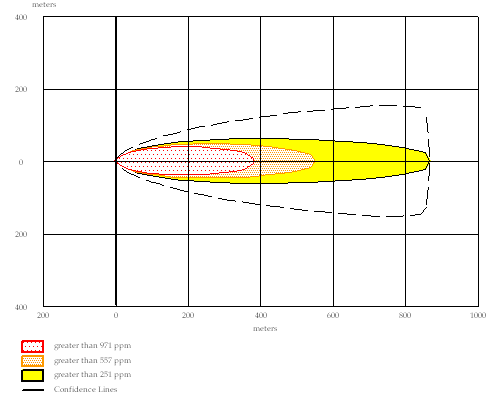

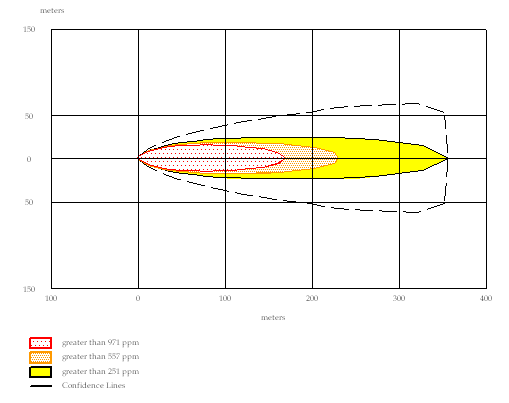

Sha Tin WTW lies at the head of a valley on

Keng Hau Road, Hin Tin to the south-west of Sha Tin new town. The site is

approximately rectangular in shape and measures 400 m north to south by 300 m

east to west. The treatment plant comprises a South Works and a North Works.

The Chlorination House is located in the south-west corner of the site. The

site location is shown in Figure 12.2 and the existing

site layout in Figure 12.3.

12.3.2

Sha Tin WTW is located at 30 m above the

Principal Datum (PD) and is surrounded on three sides by hills rising to

approximately 300 m. To the north-east the land slopes gently downwards towards

the town of Sha Tin. The topography is of particular relevance; since chlorine

is a dense gas, the spread of a chlorine cloud from any large release would be

restricted by the neighbouring hills and directed towards the populated areas.

The topography of the site is shown in Figure 12.4.

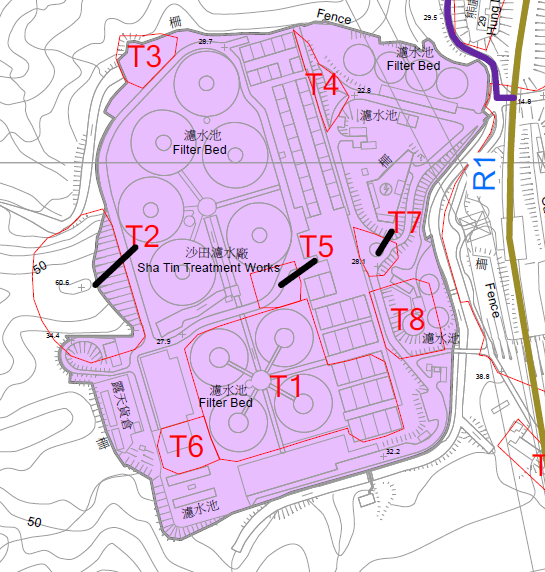

Figure 12.3 Existing Layout of Sha Tin WTW

Figure 12.4 Topography of the Sha Tin WTW Area (not to scale)

Delivery, Storage and Handling of

Chlorine

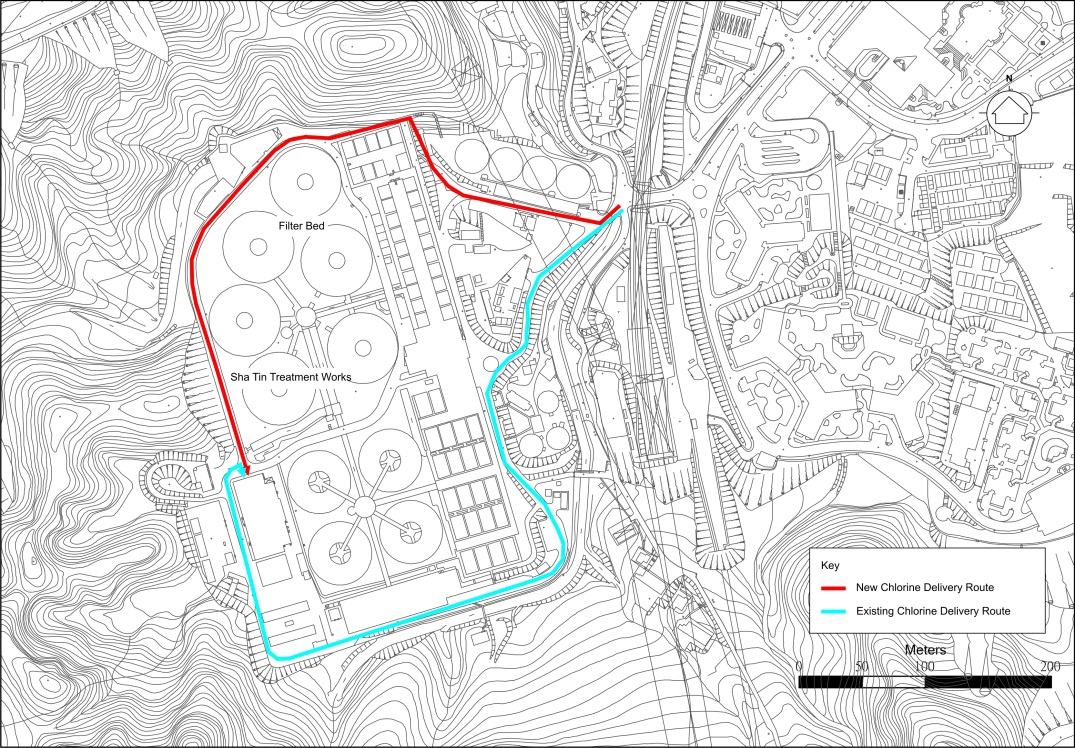

12.3.3

Chlorine is delivered to Sha Tin WTW in

batches of up to 6×1-tonne drums. Unloading takes place inside the Chlorination

House, with the doors closed, in a designated truck unloading bay. The movement of drums

within the storage area and ‘drive-through’ unloading bay is carried out using

a hoist/monorail system with a purpose-built lifting beam. Prior to usage, the

drums are stored on cradles within the chlorine storage area.

12.3.4

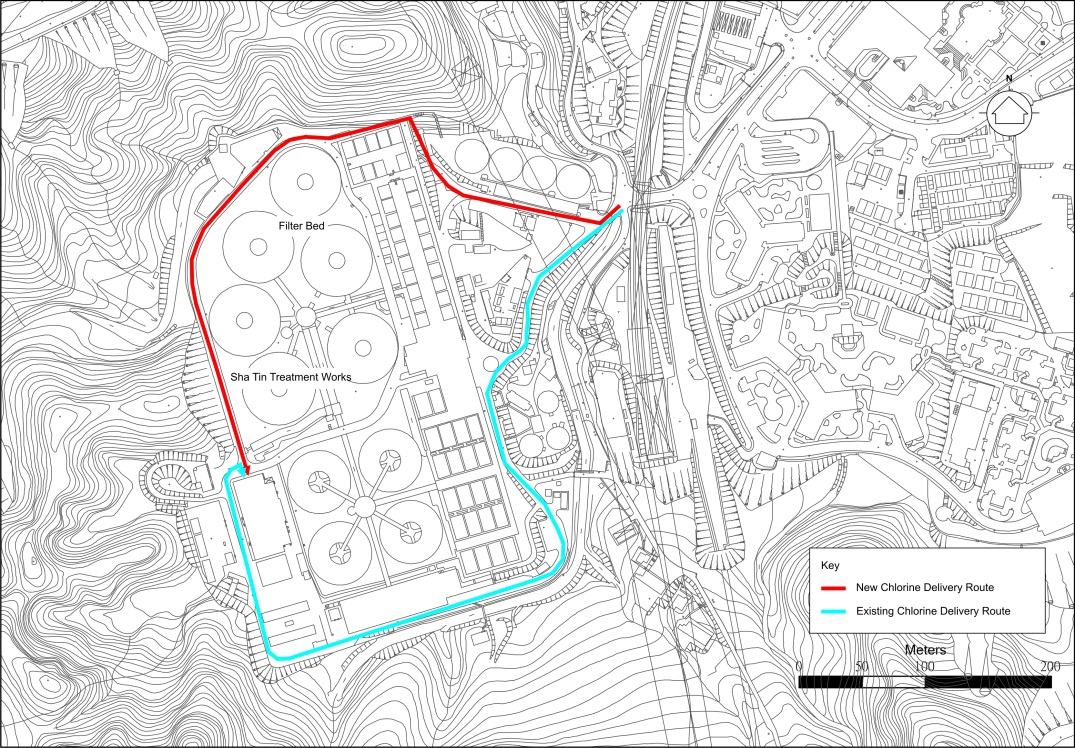

The on-site chlorine delivery route is shown

in Figure 12.6.

Chlorination System

12.3.5

The draw-off units comprise of pairs of

drums, one drum on duty, the other serving as standby. The number of drums on

line is subject to the raw water quality. Changeover panels automatically

change the draw-off from duty to standby when the draw-off pressure falls below

a preset level. The changeover is achieved by electrically-actuated isolating

valves provided for each drum.

12.3.6

Liquid chlorine is drawn from the 1-tonne

drums and is passed to the evaporators for conversion into the gaseous state. The

gaseous chlorine passes through the chlorinators and dissolves in water at

ejectors to form chlorinated water for feeding into the bulk water stream

during the treatment process.

12.3.7

The chlorinators are of vacuum venturi type

and thus the section of line between the regulator and the chlorinator is at

negative pressure. This reduces the chances of chlorine leaks. Double non

return valves are provided within the chlorinator units.

Ventilation System

12.3.8

The chlorine drum storage area, evaporator

and chlorinator rooms are normally ventilated via a supply of fresh air at high

level which is extracted at low level. On detection of chlorine levels above 3

ppm there are visual and audible alarms, the ventilation fans stop and the

normally-open motorised louvres shut.

Chlorine Scrubbing System

12.3.9

An emergency chlorine scrubbing system is

installed to remove any leaked chlorine in the chlorine handling and storage

areas. The system is a packed tower utilising sodium hydroxide as the

neutralising agent. The plant and equipment are installed in a separate

scrubber room.

12.3.10

On detection of chlorine at a concentration

of 3 ppm or above in the chlorine handling or storage areas, the scrubbing

system will activate automatically. The air/chlorine mixture in the affected

areas is drawn into the scrubber by the scrubber fan via ducting connected to

the normal ventilation system. An electrically-operated isolating damper is

provided in the scrubber intake which opens automatically when the scrubber fan

starts up.

12.3.11

The scrubber system is normally set at auto

standby mode and is activated if the chlorine concentration rises above 3 ppm. A

continuous chlorine monitor is installed at a point downstream of the packed

tower and upstream of the vent/recycle changeover dampers to monitor the

scrubber performance; a “Chlorine concentration high” alarm will be initiated

if the concentration of chlorine in the tower exhaust exceeds the preset value.

12.3.12

The sodium hydroxide solution is of 10-12%

concentration and is held in a solution tank beneath the packed tower. When the

system is in operation, the sodium hydroxide is re-circulated by a pump to the

distributor at the top of the packed tower to provide adequate irrigation to

the packing. Sufficient solution is provided to absorb 1 tonne of chlorine. A

mist eliminator is provided at the top of the packed tower to prevent

entrainment of liquid into the treated air.

12.3.13

The scrubber is provided with the following

additional features: a sampling point, a top entry mixer (for preparation of the

sodium hydroxide solution), a direct reading transparent level gauge, an

inspection window and level indication with high and low level alarms and a

temperature measurement device for monitoring the temperature of caustic

solution during the preparation process.

Emergency Repair/Stoppage Kit for Chlorine

Spillage/Leakage

12.3.14

According to the Fire Services Department’s

fire safety requirements, an emergency repair/stoppage kit for chlorine

spillage/leakage is provided and maintained in good working condition at all

times for use by the trained persons and stowed adjacent to but outside the

store/plant room. Regular drills are conducted to train personnel on the proper

use of the breathing apparatus and protective clothing.

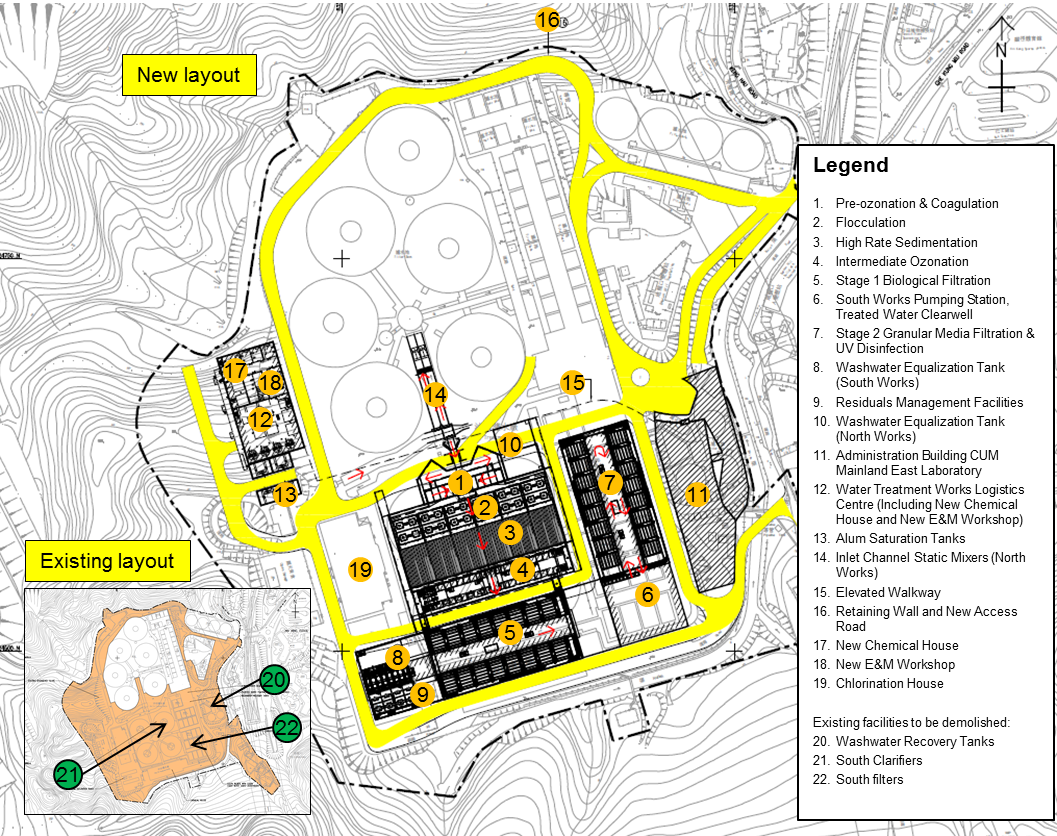

12.4.1

This project concerns a major reprovisioning

of the Sha Tin WTW South Works. During the reprovisioning, since parts of the

plant (i.e. the South Works) will have to be temporarily shut down, the water

throughput will decrease and accordingly, chlorine storage and usage levels will

be significantly reduced. Following completion of the reprovisioning water

throughput will return to 1,227 Mld.

12.4.2

The reprovisioning will involve introduction

of new treatment technologies for the South Works and construction of a number

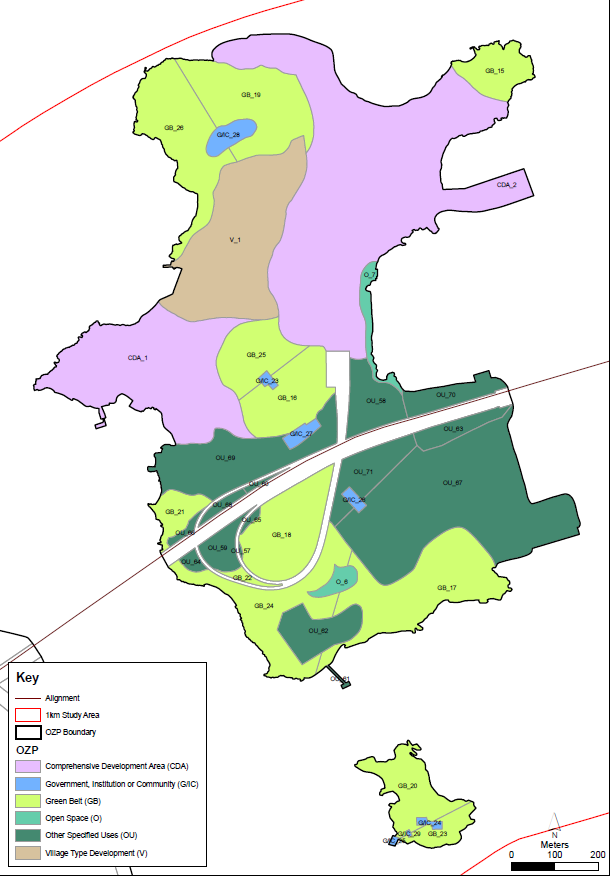

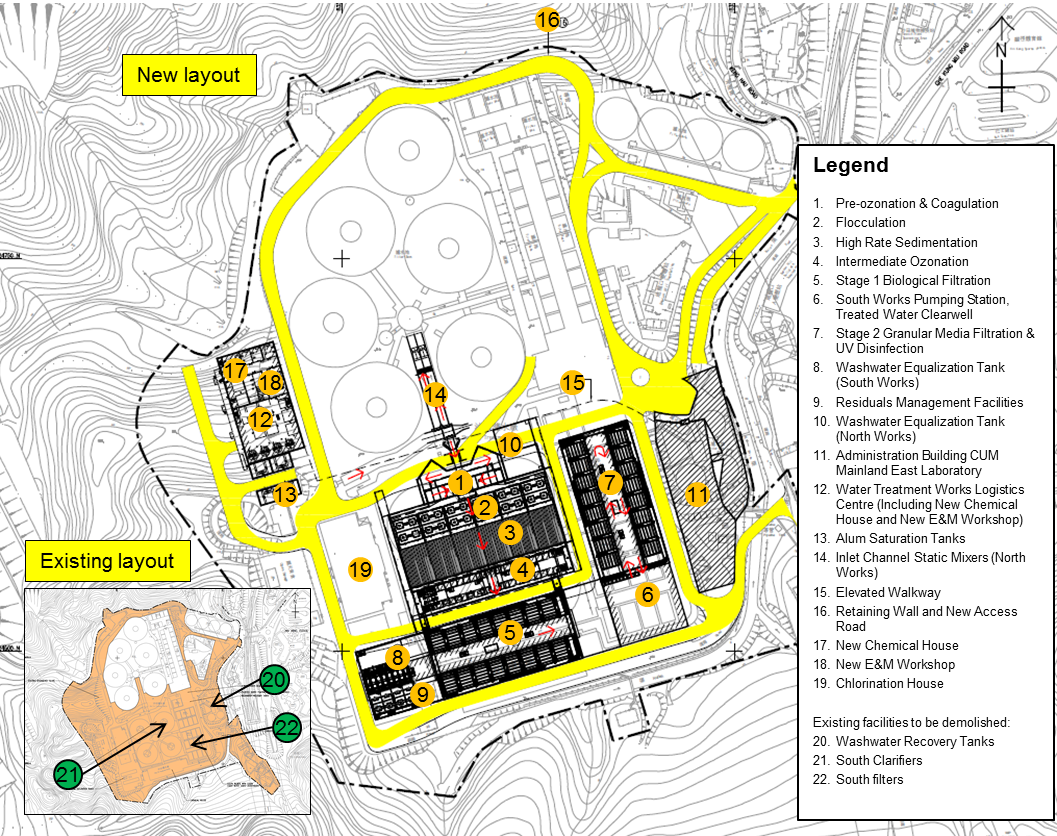

of new facilities. Details are shown in Figure 12.5.

12.4.3

The current chlorine dosage levels are at or

below 2 mg/l. This will be reduced to 1.7 mg/l following the reprovisioning,

due to the introduction of new treatment technologies. This will result in a

permanent reduction in chlorine usage once reprovisioning is completed. Therefore,

it is worth highlighting that this is an improvement project that will lead to

a reduction in risks associated with the Sha Tin WTW. The operational parameters

of the WTW during and after the reprovisioning are presented in Table 12.1.

12.4.4

Before the start of the construction of

reprovisioning of South Works, 31 excess storage castors for storage of

chlorine drums will be carefully selected and to be removed from the

chlorination house (i.e. reduced from 221 castors to 190 castors before the

start of the construction works).

12.4.5

During and after the reprovisioning, the

existing on-site chlorine delivery route along the east & south & west

boundaries of the site will be replaced by the route along the east & north

& west site boundaries. Details are shown in Figure 12.6. The purpose of this is to separate the

existing North Works and the construction activities in order to maintain

continuous operation, maintenance and security of the existing North Works and

in particular to separate chlorine deliveries from the construction activities.

12.4.6

Details of the construction programme are provided

in Appendix

2.1. In general, the existing on-site chlorine delivery

route along the east & south & west boundaries of the site will be used

during Stage 1 of the reprovisioning and that along the east & north &

west boundaries of the site as shown in Figure 12.6 will be used for Stage 2; the intent being

to segregate chlorine delivery trucks from construction activities. Description

and locations of different construction activities are also provided in Appendix

12.8.

Figure 12.5 New Treatment

Facilities and Sha Tin WTW Layout following the Reprovisioning of South Works

Figure

12.6 Existing Chlorine Delivery Route at Sha Tin WTW and the New

Route to be used during and after the Reprovisioning of South Works

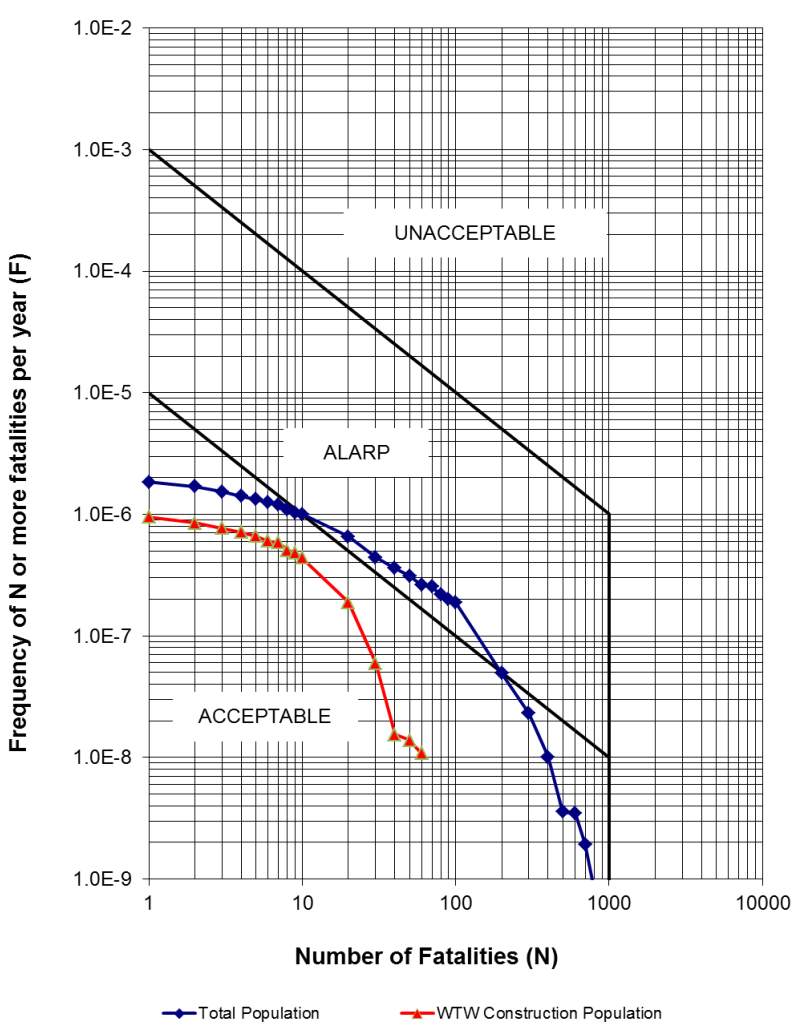

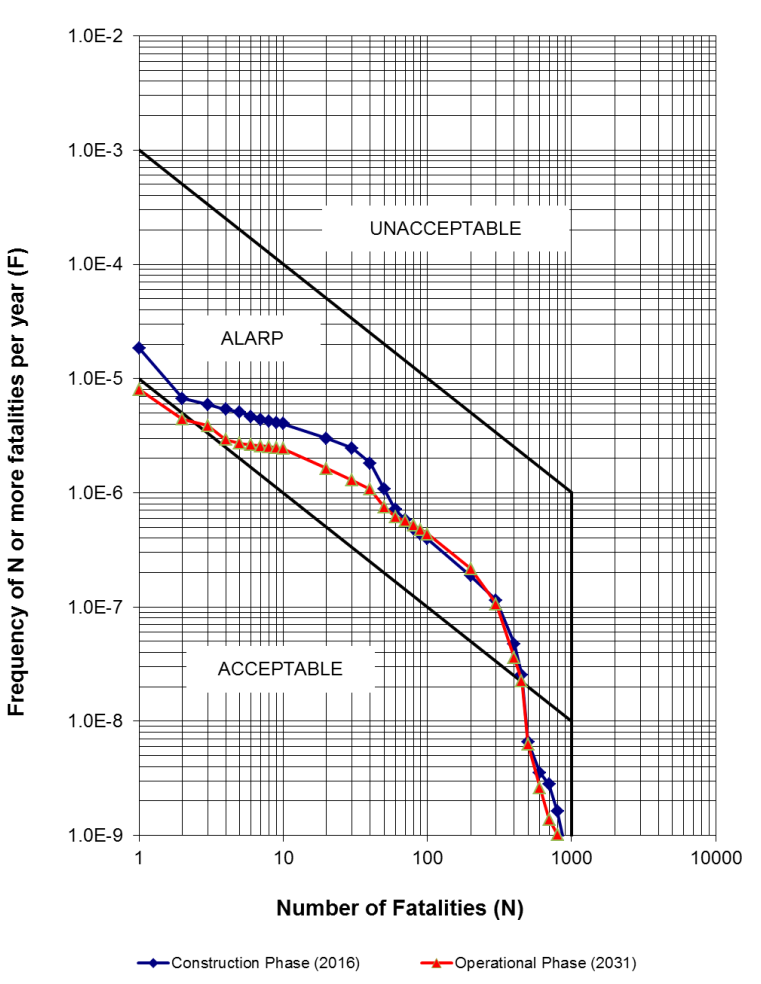

12.5.1

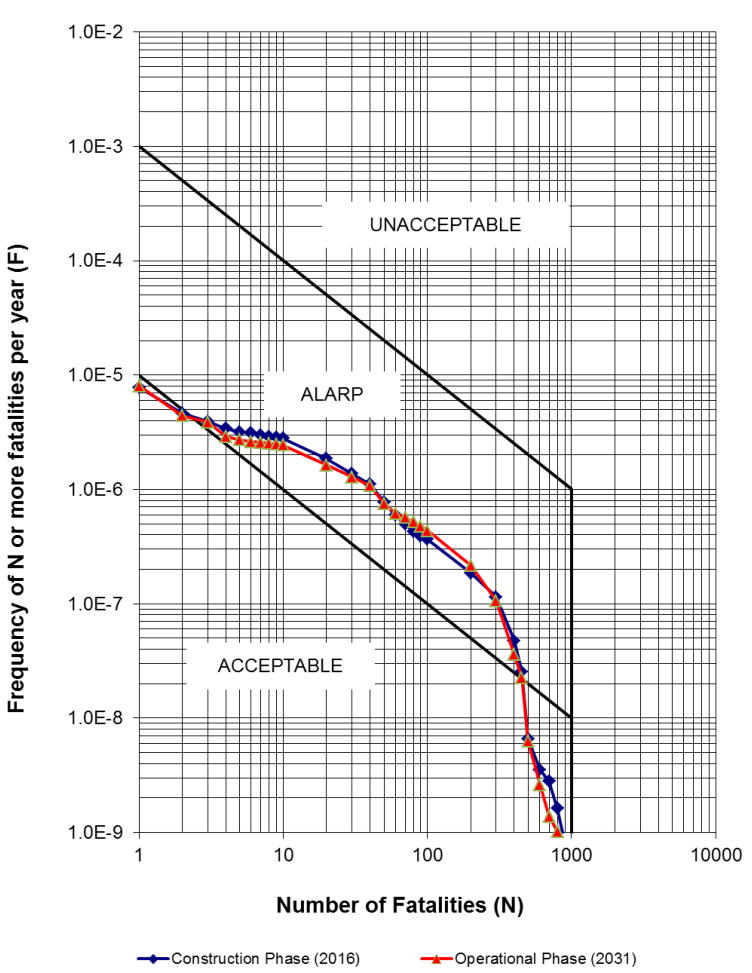

Based on the South Works reprovisioning

schedule, two scenarios have been considered in the QRA. These are the Construction

Phase of this project and the Operational Phase following the completion of the

reprovisioning. The main assumptions used for each scenario, based on WTW

operational data provided by WSD, are listed in Table 12.1. Population data for the construction and

operational phase scenarios are projected to years 2016 and 2031, respectively.

Details of the population data for each assessment year are provided in Section 12.8 and Table 12.3.

12.5.2

The WTW operating data for these two

scenarios are consistent with Scenarios 2 and 4 of ERM (2011a).

Table 12.1 Scenarios

Considered in the QRA

|

Scenario

|

Assessment year

|

Maximum Chlorine Storage at WTW (tonnes)

|

Chlorine Storage Time Distribution Assumed in the QRA

(tonnes, % of time)

|

Average Chlorine Usage at WTW (tonnes per

year)

|

|

Scenario

1: Construction Phase

|

2016

|

158

|

158 (100%)

|

642

|

|

Scenario

2:

Operational

Phase

|

2031

|

190

|

190 (20%)

150 (80%)

|

761

|

2001 QRA

12.6.1

In 1997, the Water Supplies Department (WSD)

commissioned ERM to carry out a Reassessment

of Chlorine Hazards for Eight Existing Water Treatment Works. The WTWs

considered were:

·

Au Tau WTW;

·

Pak Kong WTW;

·

Sha Tin WTW;

·

Sheung Shui WTW;

·

Tai Po Tau WTW;

·

Tsuen Wan WTW;

·

Tuen Mun WTW; and

·

Yau Kom Tau WTW.

12.6.2

The approved methodology for the above QRA

studies is detailed in the 8 WTW Study Methodology

Report (ERM, 1997).

12.6.3

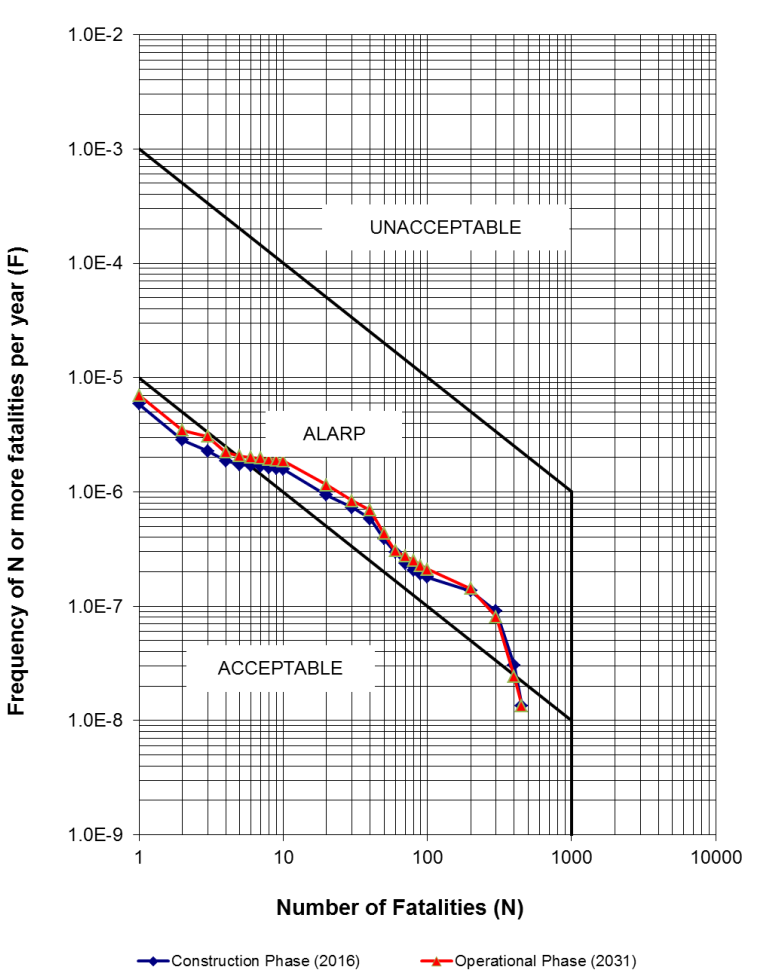

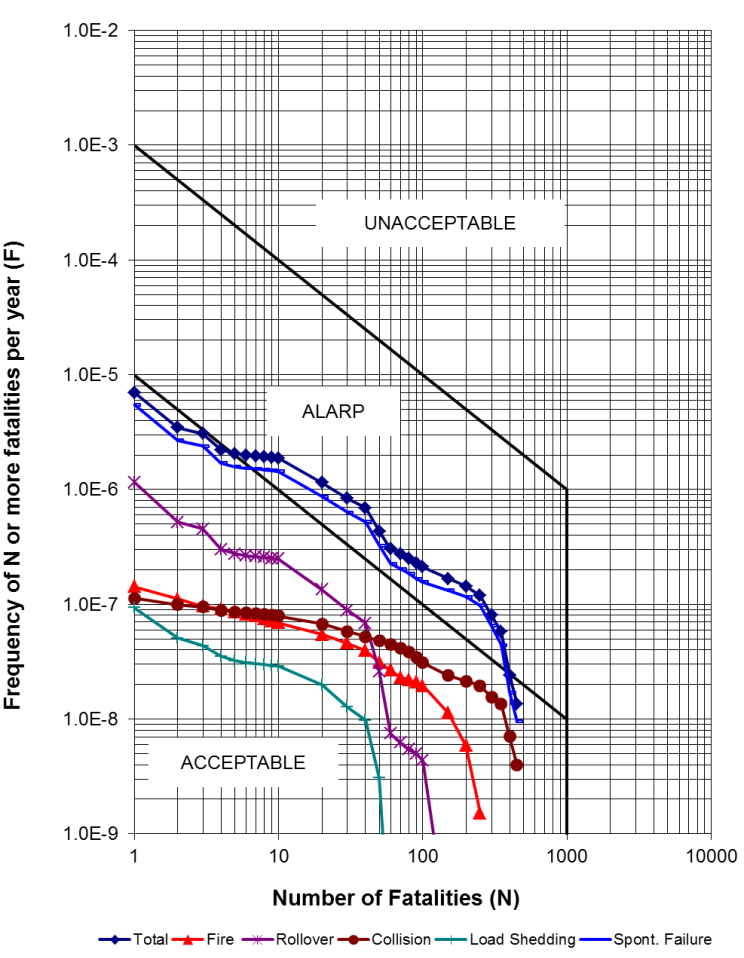

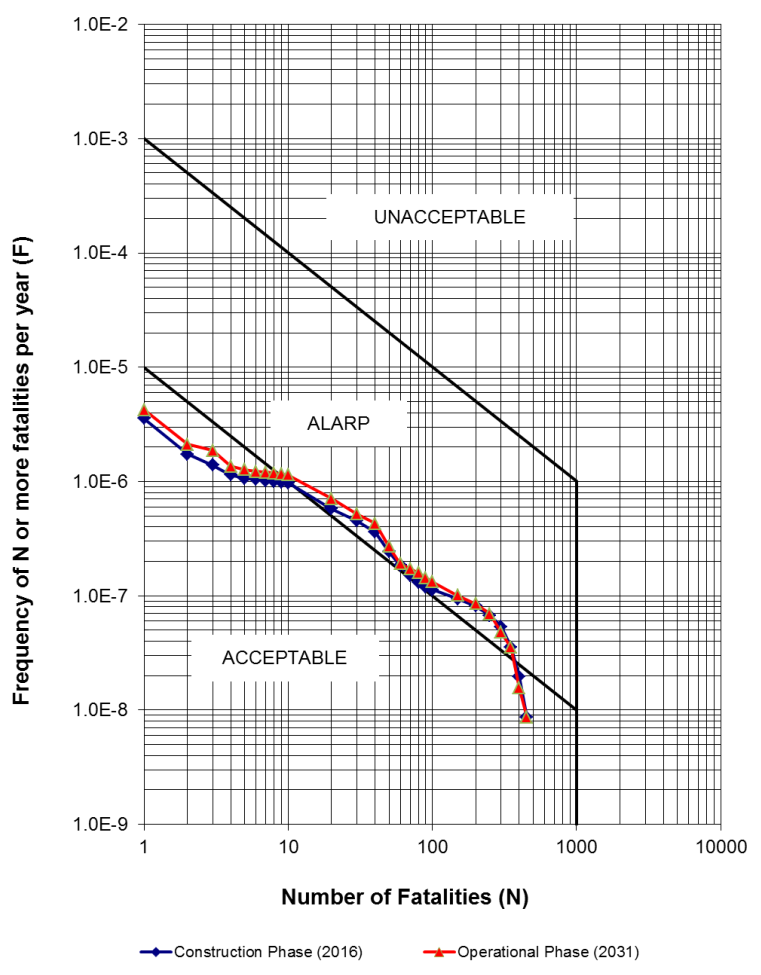

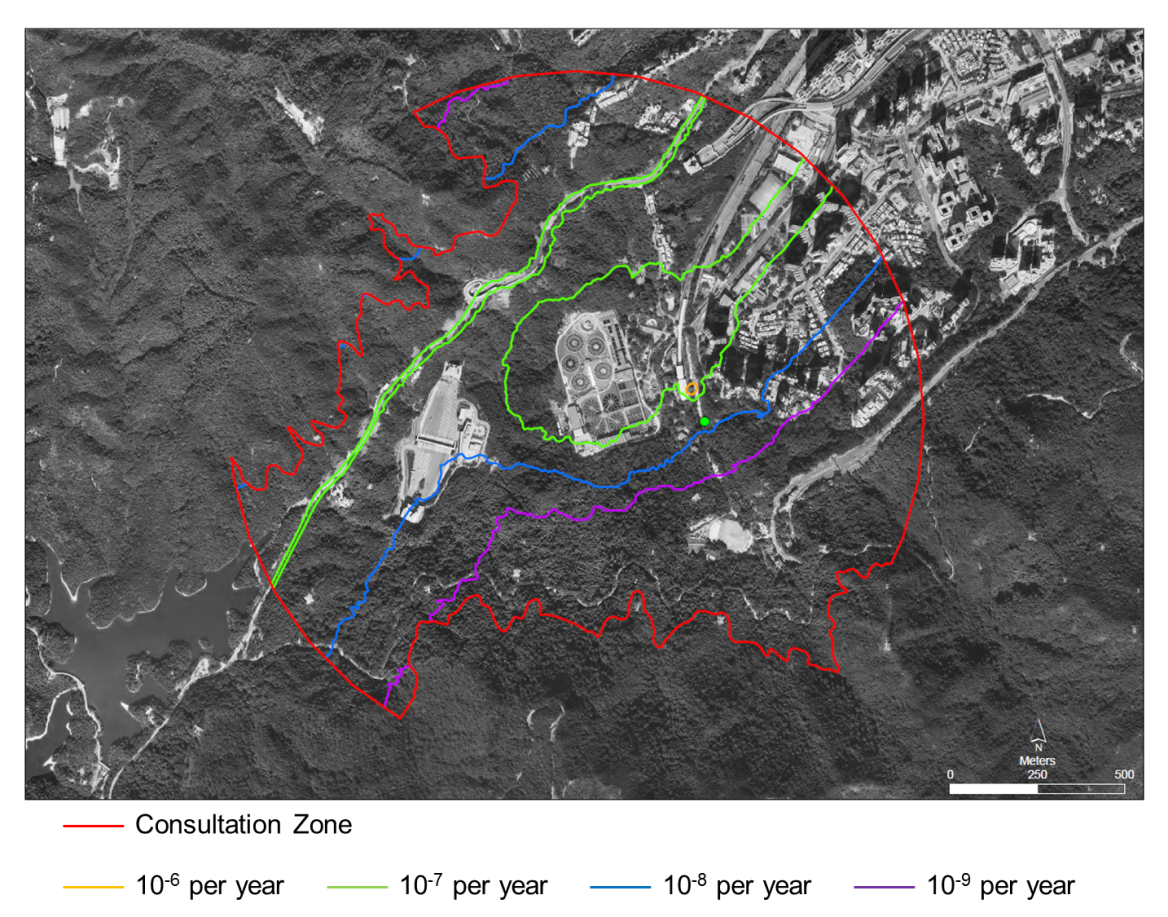

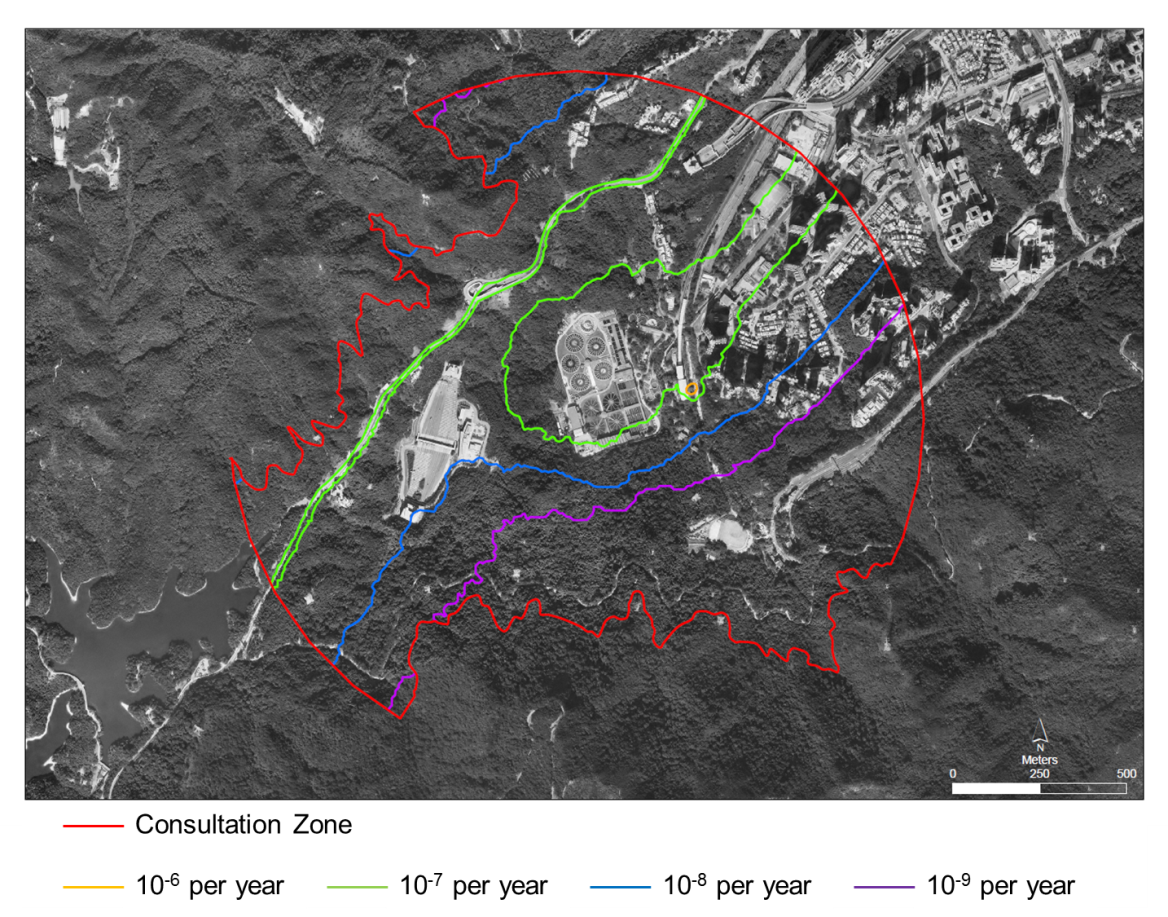

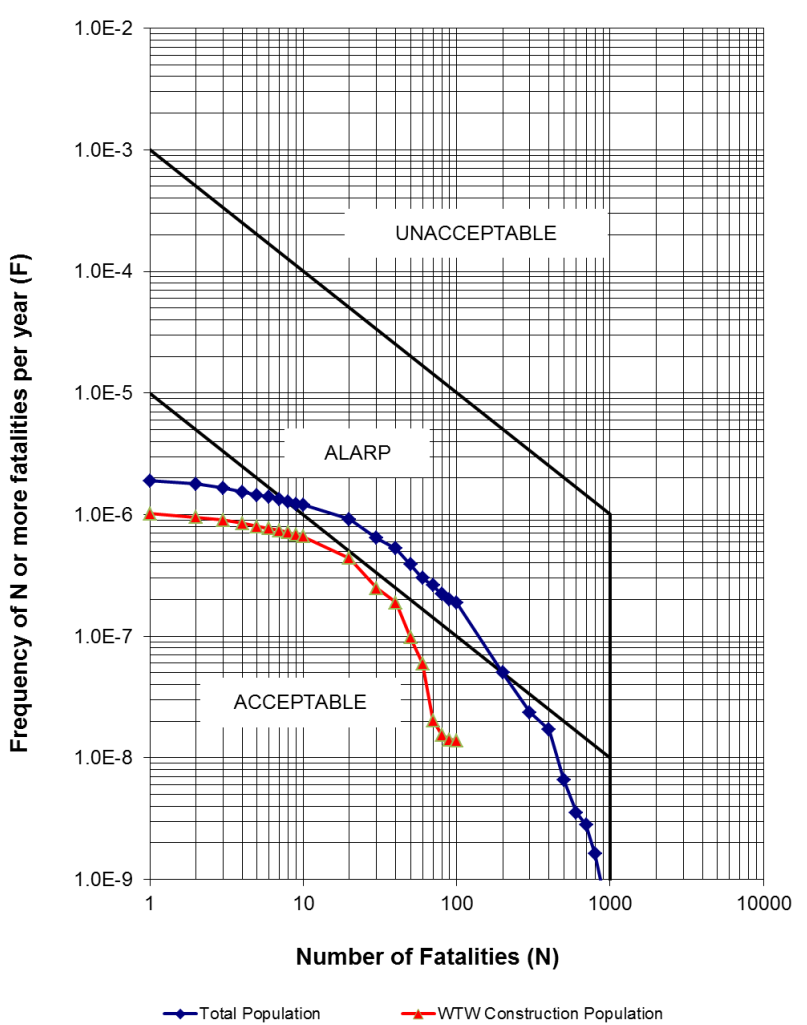

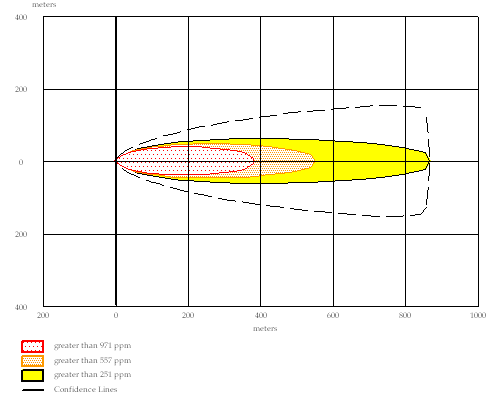

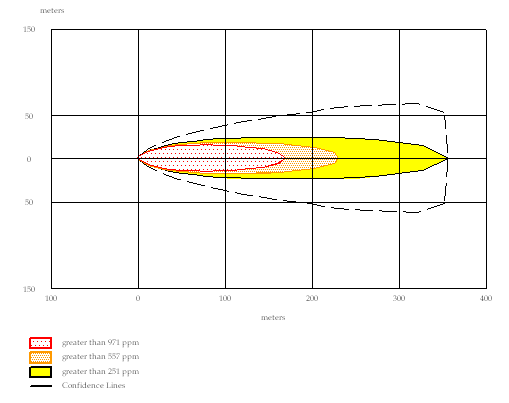

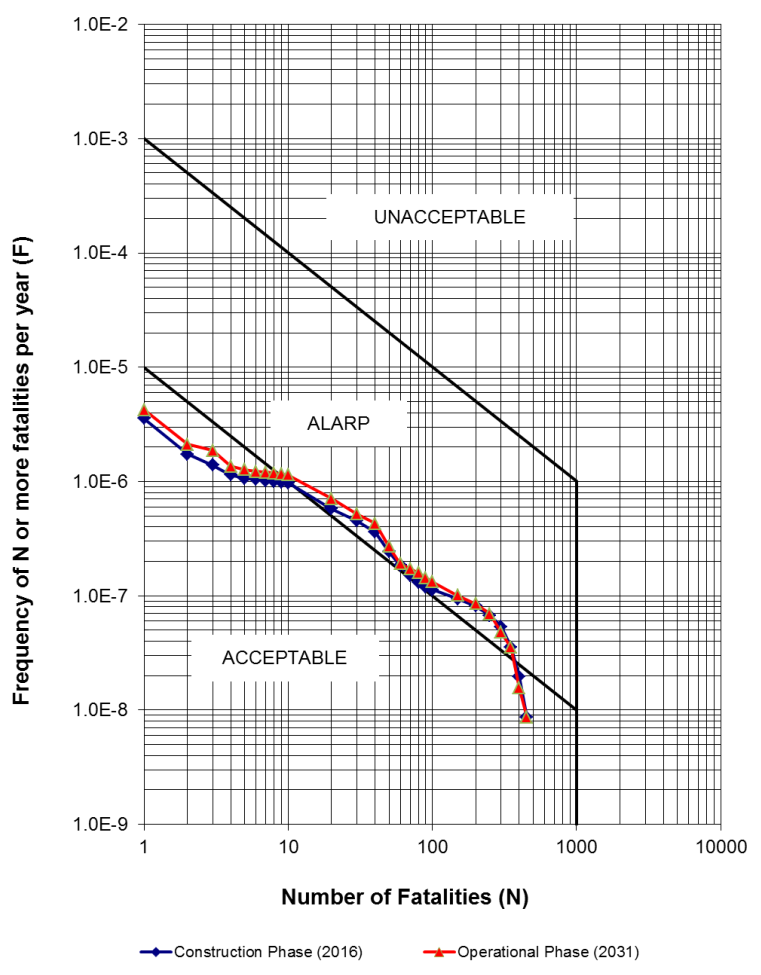

Results for the Sha Tin WTW (ERM, 2001),

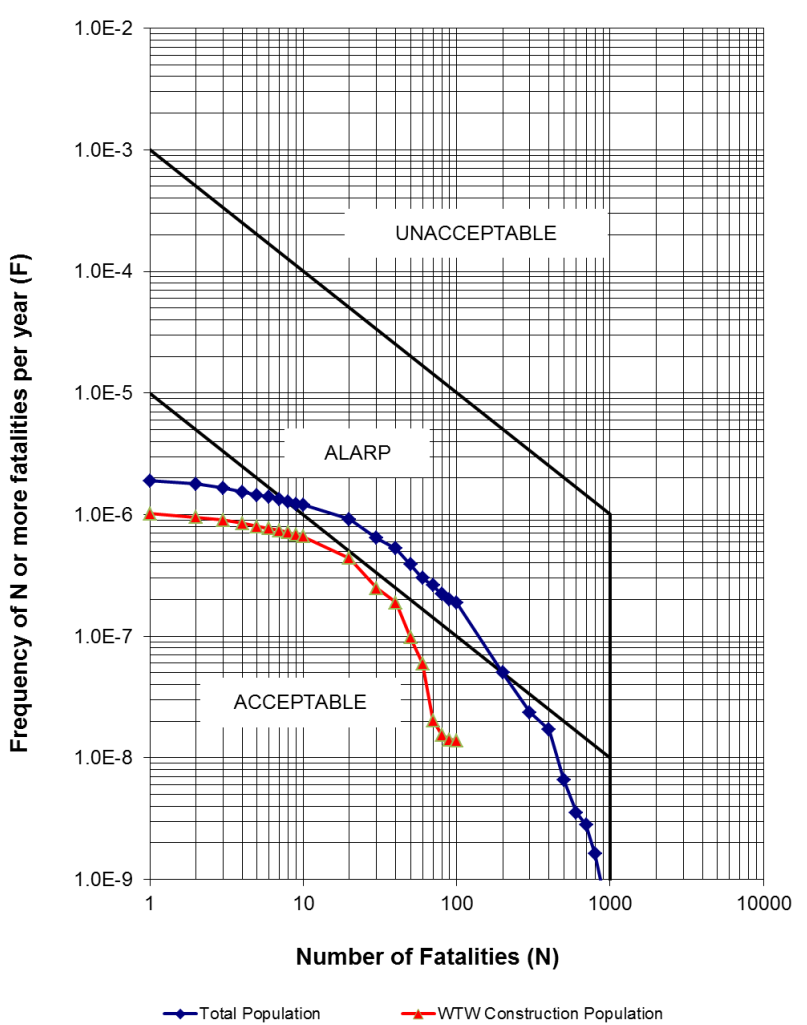

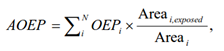

illustrated here in Figure 12.7 showed that:

·

The risk was in the ‘ALARP

region’; and

·

The maximum number N of fatalities was

assessed at over 900.

Figure

12.7 FN curve from the 2001 Sha Tin WTW Hazard

Assessment (ERM, 2001)

2011 QRA for Hin Keng Station and SCL Alignment

12.6.4

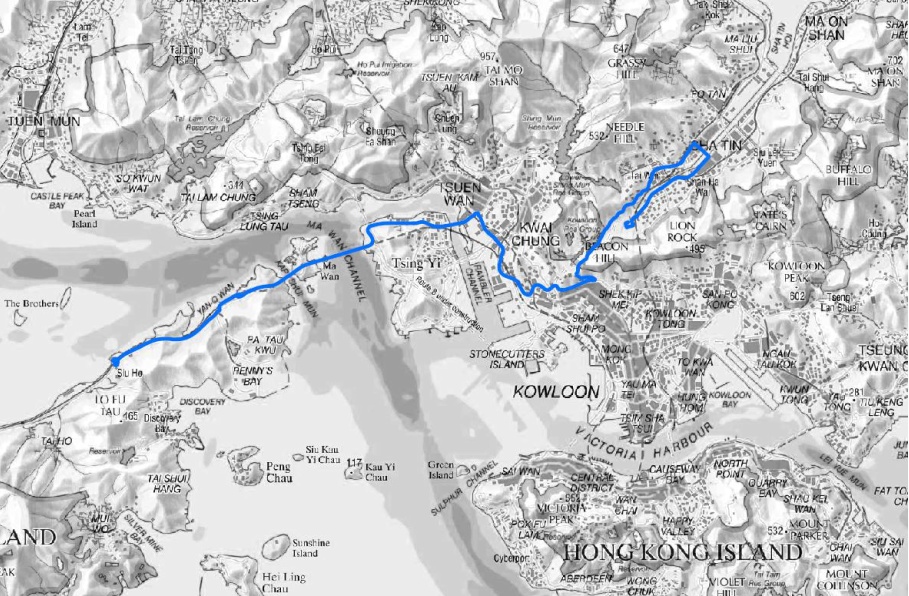

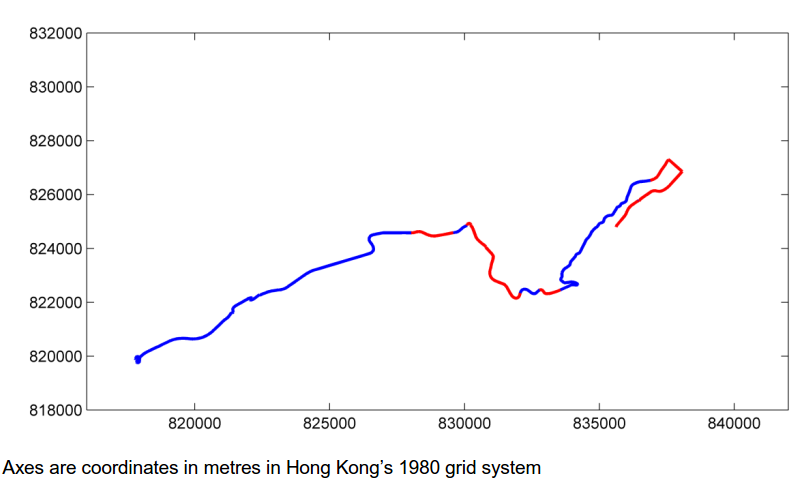

In 2008–2011, ERM conducted a QRA study on

behalf of MTRCL to assess the chlorine hazards related to the Sha Tin WTW

operations in connection with the proposed Sha Tin to Central Link (SCL)

project. This study assessed the impact of increased population from SCL work

areas, future SCL alignment and the proposed Hin Keng Station that will be

located within the Sha Tin WTW Consultation Zone (ERM, 2011a). The SCL QRA also

took into account the South Works reprovisioning that will proceed concurrently

with the SCL construction and the modified WTW operational parameters (chlorine

usage and storage quantities) during the reprovisioning and after its

completion.

12.6.5

The present QRA for the on-site transport,

storage and handling of chlorine at Sha Tin WTW follows the methodology of both

previous studies.

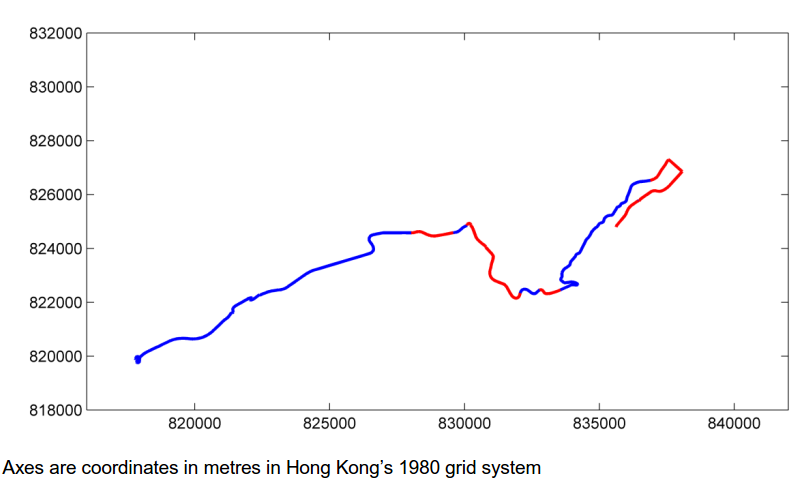

12.7.1

For the sake of consistency, this study uses

the same meteorological data set as was used in the previous QRAs (ERM 2001, 2011a),

i.e. the data recorded at the Sha Tin weather station in the year 1996 by the

Hong Kong Observatory.

12.7.2

The weather data have been rationalised into

different combinations of wind direction, speed and atmospheric stability

class. The probabilities of occurrence of each combination during day and night

are presented in Table 12.2. The

Pasquill-Gifford stability classes range from A through F. Class A represents

extremely unstable conditions which typically occur under conditions of strong

daytime insolation. Class F on the other hand represents stable conditions

which typically arise on clear nights with little wind. Turbulent mixing, which

affects the dispersion of a chlorine cloud, increases through the stability

class range from F to A.

Table 12.2 Meteorological Data for Sha Tin Water Treatment Works

|

|

|

DAY Probability

|

NIGHT Probability

|

|

|

Direction

|

Wind Speed

(m/s):

|

2.3

|

1.5

|

3.5

|

1.5

|

1.5

|

3.5

|

1.5

|

TOTAL

|

|

|

Atmospheric

Stability :

|

B

|

D

|

D

|

F

|

D

|

D

|

F

|

|

|

N

|

|

0.0509

|

0.0380

|

0.0120

|

0.0153

|

0.0224

|

0.0045

|

0.0761

|

0.2191

|

|

NE

|

|

0.0458

|

0.0228

|

0.0253

|

0.0149

|

0.0107

|

0.0239

|

0.0529

|

0.1963

|

|

E

|

|

0.0450

|

0.0200

|

0.0299

|

0.0115

|

0.0116

|

0.0173

|

0.0774

|

0.2126

|

|

SE

|

|

0.0146

|

0.0065

|

0.0059

|

0.0027

|

0.0023

|

0.0029

|

0.0233

|

0.0581

|

|

S

|

|

0.0171

|

0.0106

|

0.0125

|

0.0042

|

0.0029

|

0.0050

|

0.0346

|

0.0868

|

|

SW

|

|

0.0247

|

0.0113

|

0.0429

|

0.0050

|

0.0034

|

0.0103

|

0.0528

|

0.1504

|

|

W

|

|

0.0023

|

0.0020

|

0.0004

|

0.0017

|

0.0018

|

0.0000

|

0.0139

|

0.0220

|

|

NW

|

|

0.0038

|

0.0048

|

0.0059

|

0.0039

|

0.0036

|

0.0032

|

0.0294

|

0.0546

|

|

Total

|

|

0.2042

|

0.1160

|

0.1346

|

0.0590

|

0.0587

|

0.0671

|

0.3604

|

1.0000

|

12.8

Population Data

General

Approach

12.8.1

The approach to the population data for this

study is the same as in the QRA for Sha Tin WTW for the SCL Project (ERM, 2011a).

The population data from the 2011 study were updated where applicable based on

more recent information.

12.8.2

The population data used in this study is

summarised in Table 12.3. A

definition of the time periods included in Table 12.3 is

provided in Appendix

12.6.

Sources

of Information

12.8.3

Population data for the South Works reprovisioning

workforce and Sha Tin WTW staff quarters were provided by WSD.

12.8.4

Railway-specific data such as SCL train and

station loadings for the Operational Phase, population of the Tai Wai MTR

Depot, number and locations of the SCL construction workers etc. were obtained

from MTRCL.

12.8.5

The Planning Department provided the GIS

coverage of Tertiary Planning Units (TPUs) further divided into Street Blocks

(SB). Detailed TPU-based population data and their projections to the future

are publicly available from the Plan-D website.

12.8.6

The Territory Population and Employment Data

Matrix (TPEDM) population projections for different Planning Data Zones (PDZ)

were also obtained from PlanD. These were used to obtain population projections

up to the year 2031 and the average household size for different areas.

12.8.7

Hong Kong conducts a population census once

every ten years and a by-census in the middle of the intercensal period. By-census

differs from a full census in not having a complete headcount but enquiring on

the detailed characteristics of the population on the basis of a large sample.

Census data is presented on Centamap website ([1]) for most

building groups and the population is further updated based on Territory

Planning Unit (TPU) Large Street Block (SB) population from 2011 Census.

12.8.8

If the population data was not directly

available, data on the number of floors and units of the residential

developments were obtained from the Centamap website and, together with the

TPEDM data on average household size, were used to estimate the current

population of these developments.

12.8.9

The Centamap website was also used to verify

the locations and/or further existence of the population units assumed in the

previous assessments and to check for any new developments that may have been recently

constructed.

12.8.10

Daily attendance data at Hin Tin Swimming

Pool and the highest and average daily usage data for the Hin Tin Playground

were obtained from Leisure and Cultural Services Department (LCSD).

12.8.11

Most of the road populations were estimated

based on the Annual Average Daily Traffic (AADT) data from the Transport

Department’s (TD) Annual Traffic Census 2013 () which is the

latest available data.

12.8.12

Recent data for the Tsing Sha Highway and

Lion Rock Tunnel, such as Staff in administration building, toll plaza, etc.

were obtained from TD in 2014 ().

12.8.13

A site survey covering a large part of the

area within the 1-km CZ considered in the study was conducted by ERM personnel

on 28 April 2009. An additional site survey of the areas to be affected by the

SCL project site was conducted in July 2011. Another site survey was conducted

in Jan 2014 to further update the population.

12.8.14

Although site surveys indicated no population

at the Beacon Hill North Offtake Station, Towngas has since advised that a

number of their staff are located on this site from time to time. This

population has therefore been included in this assessment taking into

consideration both the site surveys and the Towngas information. However, this

has no significant impact on the results.

12.8.15

For most kindergartens, primary and secondary

schools and colleges, data from the Education Bureau website () was used.

This included the number of classrooms and the capacity of each classroom.

12.8.16

For cases where population data were not

available from publicly available data sources, the required information was

obtained by telephone interviews and e-mail inquiries.

12.8.17

The percentages of the maximum population

present (occupancy) at different times of the day and the indoor/outdoor

fractions for the total unit population are consistent with those used in the

previous QRA (ERM, 2011a).

Population

Units

12.8.18

The population units are defined for the QRA

purposes in the form of GIS-based polygons, points and lines. Outside the WTW

site the units used in this study are the same as in the previous QRA (ERM, 2011a)

however more detailed population units for different South Works reprovisioning

work areas are considered.

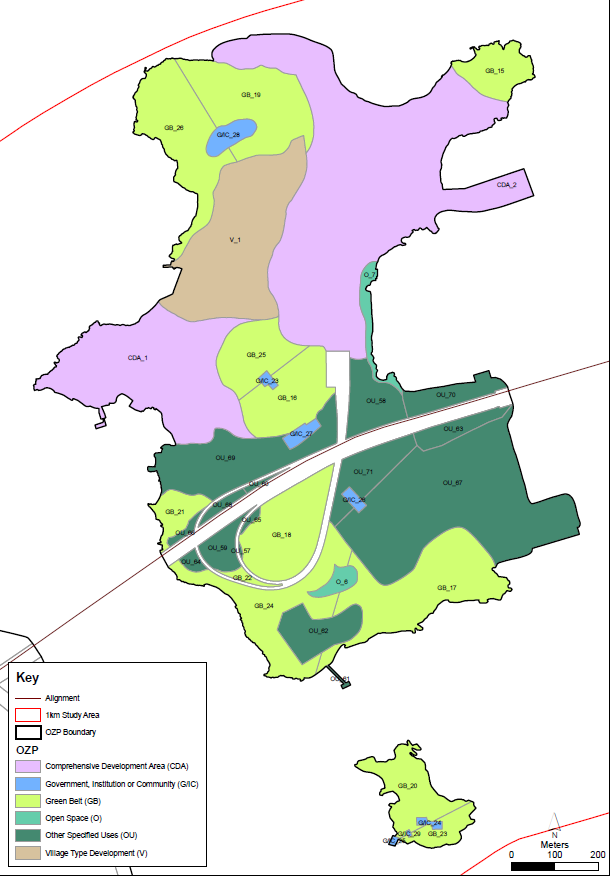

12.8.19

The full list of population units considered

is provided in Table 12.3 and their

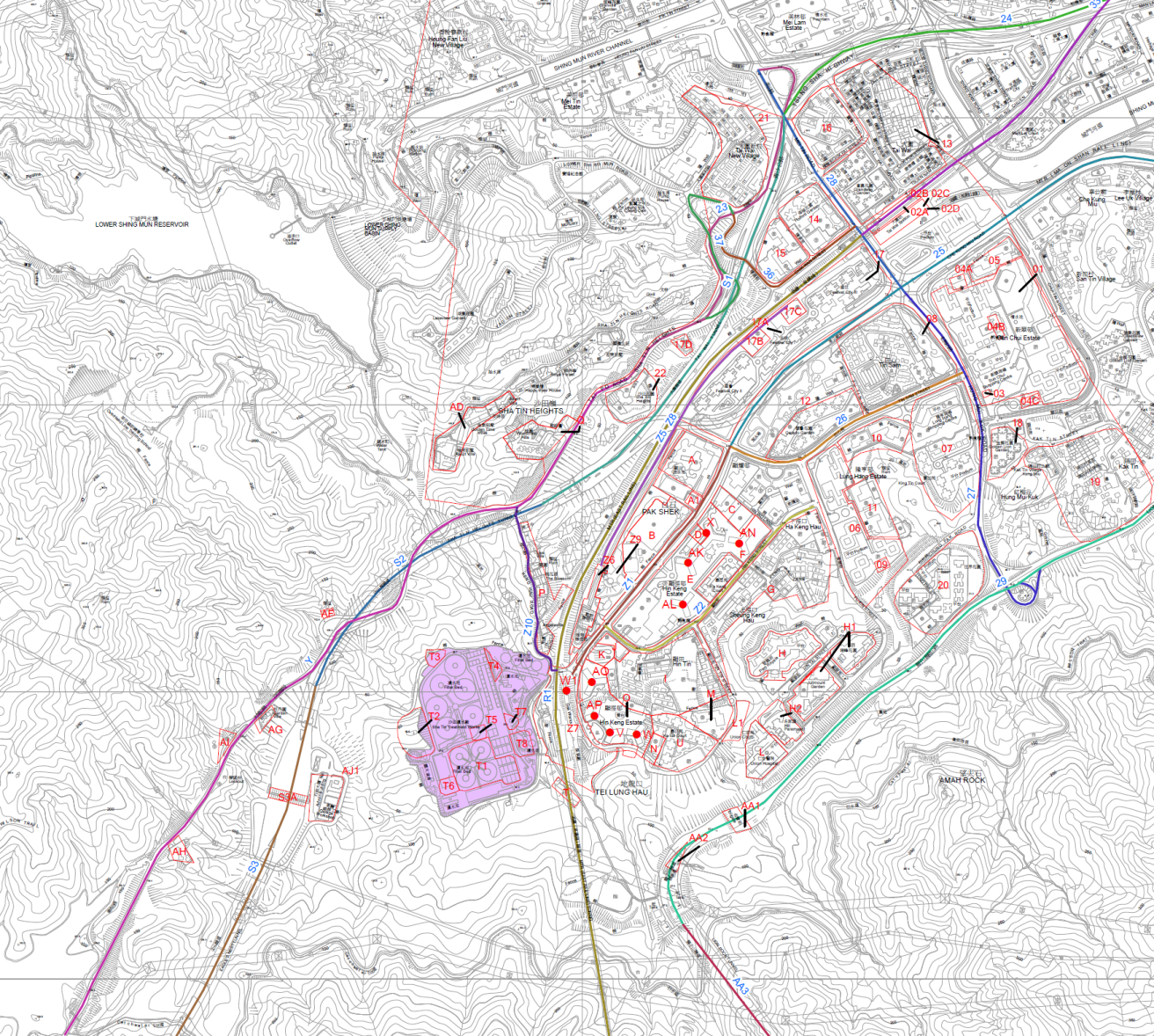

locations shown in Figure 12.8 and Figure 12.9. The

population units within the 1-km Consultation Zone of the WTW are referenced

with letters while those outside the CZ are denoted by numbers.

South

Works Reprovisioning Work Areas and Workforce Population Data

12.8.20

Based on information provided by WSD, eight population

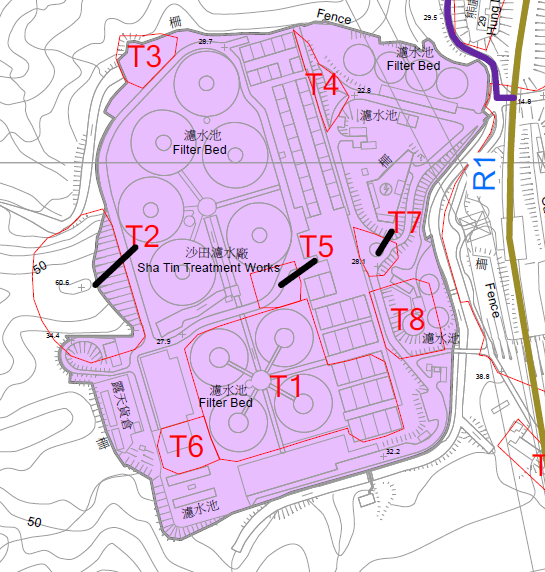

polygons, T1 to T8 (see Figure 12.8, Figure 12.9 and Figure 12.10) have

been defined for different project work areas at the WTW. Details on the

construction activities within each of these areas are provided in Appendix

12.8.

12.8.21

Since a different number of workers will be

needed for each construction activity and the activities at different site

areas will occur at different times, the total number of workers on site will

be changing and there will be no period when the workforce will be present

simultaneously in all locations. A conservative case was therefore selected

with a relatively high total population of 198 construction workers and

resident site staff (RSS) for supervision of the construction activities

simultaneously present at areas T1, T2 and T5. The resulting total numbers of

people at each site for this representative period are shown in Table 12.3. These

198 construction and RSS workers are conservatively assumed to be present year

round.

12.8.22

It is assumed that 10% of the 85 construction

workers and 50% of the 113 RSS will be located indoors. Thus, at each site, the

average proportion of people indoors can be estimated at (8.5 + 56.5)/(85 + 113)

= 33%.

12.8.23

It may be noted that the spatial distribution

of the reprovisioning workers and number of workers are different from those

assumed in the SCL QRA (ERM, 2011a). These have been revised based on updated

information provided by WSD. The SCL QRA assumed a uniform density of workers

over the southern works area whereas a more detailed spatial distribution is

now available as adopted in the current assessment. The estimated number of

workers has increased based on the latest project schedule. These changes,

however, do not have a significant impact on the analysis.

12.8.24

The WTW has a reception facility for visitors

as an integrated part of the WTW. The

visitor reception facility is located within the boundary fence of the WTW,

which walk-in visitors are not allowed.

Only visitors permitted by WSD are allowed to enter into the boundary of

the WTW. In addition, visitors will be

briefed on the safety and emergency procedures in case of fire and chlorine

leak. Visitors will also be escorted by

WSD staff when they are within the WTW.

Figure 12.8 Population Units used in QRA (figure 1 of 2)

Figure 12.9 Population Units used in QRA (figure 2 of 2)

Figure 12.10 Population Units for the Reprovisioning Works

Population Forecast

12.8.25

The residential population levels determined as

described above have been scaled up or down according to the population trends

determined from the area-specific TPEDM PDZ-based projections. For construction

phase, the maximum population between 2011 and 2016 will be used. For

operational phase, the maximum population between 2011, 2016 and 2031 will be

used. Relevant scaling factors are listed in Appendix

12.6.

12.8.26

The methodology of this scaling is consistent

with that used in the SCL Project QRA (ERM 2011a) except population is update

based on the latest available data.

12.8.27

As no information on the future traffic

trends was available for the road population and the examination of past

traffic data shows no significant upward traffic trend over recent years, the

road population numbers derived from the 2013 Traffic Census were not further

projected to the future years.

Table 12.3 Detailed Population Data

|

Ref.

(see

Fig

12.8)

|

Name

|

Base data/ data used previously

|

Const.

Phase

(2016)

|

Oper. Phase

(2031)

|

Occupancy

|

Fraction

Indoors

|

Vulner-ability Factor

|

No.

of Floors

|

Remarks

|

|

Night

|

Jammed

Peak

|

Peak

Hour

|

Weekend

Day

|

Working

Day

|

|

01

|

Sun Chui Estate

|

18937

|

18937

|

20673

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

35

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

02A

|

East Rail Tai Wai Station

|

2000

|

2000

|

2083

|

20%

|

100%

|

100%

|

50%

|

50%

|

0%

|

1

|

1

|

Based on MTRCL

data. SCL is under construction under Year 2014 and will operate at Year 2018

(1).

|

|

02B

|

East Rail Train at Tai Wai Station

|

1304

|

1304

|

1464

|

20%

|

100%

|

100%

|

50%

|

50%

|

100%

|

1

|

1

|

Based on MTRCL

data. SCL is under construction under Year 2014 and will operate at Year 2018

(1).

|

|

02C

|

SCL Tai Wai Station

|

500

|

500

|

1250

|

20%

|

100%

|

100%

|

50%

|

50%

|

100%

|

1

|

1

|

Based on MTRCL

data. SCL is under construction under Year 2014 and will operate at Year 2018

(1).

|

|

02D

|

Development atop Tai Wai

Station

|

0

|

0

|

6752

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

39

|

Value from

Planning Department. The residential and commercial development is now

pending for approval.

Population

intake in Year 2019 tentatively.

No. of

building = 8 and no. of floor = 39 - 49 (conservatively assumed 39)

|

|

03

|

T.W.G.Hs. Mok Wong Fung Yee Home for

the Elderly, G/F floor Sun Chui Estate

|

68

|

121

|

121

|

100%

|

100%

|

100%

|

100%

|

100%

|

95%

|

3.3

|

1

|

Base value

from: http://www.swd.gov.hk/ (1).

75 bed space

and 46 staff were considered in 2016 & 2031.

|

|

04A

|

Cheong Wong Wai Primary School

|

315

|

418

|

418

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

5

|

School

capacity from: http://www.edb.gov.hk/ was taken as base value. (1) Assume

30 students per class. 13 classes, 28 staff. Numbers of class and staff

numbers from http://www.chsc.hk/ were considered in 2016 & 2031.Time

factor of 0.67 applied in modelling.

|

|

04B

|

Free Methodist Bradbury Chun Lei

Primary School

|

1087

|

829

|

829

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

5

|

School

capacity from: http://www.edb.gov.hk/ was taken as base value. (1).

Assume 30 students per class. 26 classes, 49 staff. Numbers of class and

staff numbers from http://www.chsc.hk/ were considered in 2016 & 2031. Time factor of 0.67 applied in modelling.

|

|

04C

|

KCBC Hay Nien (Yan Ping) Primary

School

|

780

|

385

|

385

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

5

|

Base school capacity

value was referenced: from 2001 QRA. (1)

Assume 30 students per class. 12 classes, 25 staff. Numbers of class and

staff numbers from http://www.chsc.hk/ were considered in 2016 & 2031. Time

factor of 0.67 applied in the modelling.

|

|

05

|

Ng Yuk Secondary School and TWGHs

Wong Fut Nam College

|

2386

|

2515

|

2515

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

1

|

5

|

Base school

capacity value was referenced: http://www.edb.gov.hk/. (1)

Shatin Tsung

Tsin Secondary School moved to ref. 17B, TWGHs Wong Fut Nam College

temporarily using the site as a decanting site. Information from

http://www.chsc.hk/. Assume 45 students per class for Form 1-5 and 30

students per class for Form 6. 46 classes of Form 1-5, 10 classes of Form 6

and 145 staff. Numbers of class and staff numbers from http://www.chsc.hk/.

Numbers are combined for the 2 schools were considered in 2016 & 2031. Time

factor of 0.67 applied in modelling.

|

|

06

|

Lung Hang Estate

|

14020

|

18288

|

18288

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

12

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

07

|

King Tin Court

|

3836

|

5004

|

5004

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

35

|

Value from

Centamap (updated based on 2011 Population Census Street Block data)., scaled

according to 2011 based TPEDM projection.

|

|

08

|

Tin Sam Village

|

1537

|

2005

|

2005

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

3

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

09

|

Salvation Army - Hong Kong and Macau

Command Lung Hang Residence for Senior Citizens (The) G/F Lung Hang Estate

|

134

|

134

|

134

|

100%

|

100%

|

100%

|

100%

|

100%

|

95%

|

3.3

|

1

|

Value from ERM

(2001) report (1).

|

|

10.1

|

PLK C. H. Wong Primary School

|

1215

|

860

|

860

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

6

|

Base school

capacity value was referenced: http://www.edb.gov.hk/ (1). Assume

30 students per class. 27 classes, 50 staff. Numbers of class and staff

numbers from http://www.chsc.hk/ were considered in 2016 & 2031. Time

factor of 0.67 applied in modelling.

|

|

10.2

|

PLK C W Chu College

|

1035

|

1114

|

1114

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

1

|

5

|

Base school

capacity value was referenced: http://www.edb.gov.hk/ (1).. Assume

45 students per class for Form 1-5 and 30 students per class for Form 6. 20

classes of Form 1-5, 5 classes of Form 6 and 64 staff. Numbers of class and

staff numbers from http://www.chsc.hk/ were considered in 2016 & 2031. Time

factor of 0.67 applied in modelling.

|

|

11

|

Lok Sin Tong Young Ko Hsiao Lin

Secondary School and Pok Oi Hospital Chan Kai Memorial College

|

2428

|

2413

|

2413

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

1

|

5

|

Base school

capacity value was referenced: http://www.edb.gov.hk/ (1). Assume

45 students per class for Form 1-5 and 30 students per class for Form 6. 44

classes of Form 1-5, 10 classes of Form 6 and 133 staff. Numbers of class and

staff numbers from http://www.chsc.hk/ were considered in 2016 & 2031.

Numbers are combined for the 2 schools. Time factor of 0.67 applied in modelling

|

|

12

|

Carado Garden

|

6252

|

8155

|

8155

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

20

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

13

|

Misc. residential buildings

|

7786

|

7786

|

7786

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

10

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

14

|

Holford Garden

|

2184

|

2184

|

2184

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

25

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

15

|

Christian Alliance Cheng Wing Gee

College and GCC&ITKD Lau Pak Lok Secondary School

|

2324

|

2277

|

2277

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

1

|

5

|

Base school

capacity value was referenced: http://www.edb.gov.hk/ (1). Assume

45 students per class for Form 1-5 and 30 students per class for Form 6. 42

classes of Form 1-5, 9 classes of Form 6 and 117 staff. Numbers of class and

staff numbers from http://www.chsc.hk/ were considered in 2016 & 2031.

Numbers are combined for the 2 schools. Time factor of 0.67 applied in modelling.

|

|

16

|

Shatin Public School

|

220

|

523

|

523

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

1

|

Base school

capacity value was referenced: http://www.edb.gov.hk/ (1). Special School for slightly mentally

challenged students. Both primary and secondary students. Assume 30 students

per primary class. Assume 45 students per class for Form 1-5 and 30 students

per class for Form 6. 7 classes of primary, 5 classes of Form 1-5, 1 class of

Form 6 and 58 staff. Numbers of class and staff numbers from

http://www.chsc.hk/ were considered in 2016 & 2031. Time factor of 0.67

applied in modelling.

|

|

17

|

Tai Wai MTR Depot

|

47

|

47

|

47

|

44%

|

50%

|

50%

|

55%

|

100%

|

80%

|

1

|

1

|

Following to

information provided by MTRCL (QRA 2011). (1).

|

|

17A

|

Festival City Development being constructed in Tai Wai Depot area

|

6107

|

11932

|

11932

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

40

|

Values from

Planning Department.

|

|

17B

|

Shatin Tsung Tsin Secondary School

|

1343

|

1343

|

1343

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

1

|

8

|

Assume 45

students per class for Form 1-5 and 30 students per class for Form 6. 25

classes of Form 1-5, 5 classes of Form 6 and 68 staff. Numbers of class and

staff numbers from http://www.chsc.hk/. Time factor of 0.67 applied in

modelling. Confirmed by site survey Jan 2014.

|

|

17C

|

Immaculate Heart of Mary School

|

860

|

860

|

860

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

8

|

Assume 30

students per class. 27 classes, 50 staff. Numbers of class and staff numbers

from http://www.chsc.hk/. Time factor of 0.67 applied in modelling. Confirmed

by site survey Jan 2014.

|

|

17D

|

Caltex Petrol Station

|

10

|

10

|

10

|

50%

|

100%

|

100%

|

100%

|

100%

|

0%

|

1

|

-

|

Confirmed by

site survey Jan 2014.

Assume no. of

population is 10 conservatively.

|

|

18

|

Golden Lion Garden –

Phase II

|

3664

|

3664

|

4000

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

35

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

19

|

Kak Tin Village

|

1013

|

1013

|

1106

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

1

|

Number of

houses extracted from Centamap, scaled according to PDZ projection. Note that

in the 2001 Report, unit 21 populations was listed together with unit 19,

scaled according to 2011 TPEDM based projection.

|

|

20

|

Worldwide Garden

|

1268

|

1654

|

1654

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

35

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

21

|

Tai Wai

Village

|

1350

|

1350

|

1350

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

3

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

22

|

Sha Tin Heights

|

279

|

290

|

290

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

5

|

Based on number of units

extracted from Centamap and PDZ household size (3.46), scaled according to

2011-based TPEDM projection.

|

|

23

|

Tai Po Road (1 km from WTW to Mei Tin

Rd)

|

724

|

724

|

724

|

2%

|

100%

|

33%

|

16%

|

18%

|

0%

|

1

|

-

|

Traffic data

from 2013 Annual Traffic Census were considered in 2016 & 2031; length

0.8 km. Assume one direction jammed and the other free-flow at Jammed Peak.

|

|

24

|

Tai Po Road (Mei Tin Rd to 3 km from

WTW)

|

836

|

836

|

836

|

1%

|

100%

|

16%

|

8%

|

9%

|

0%

|

1

|

-

|

Traffic data

from 2013 Annual Traffic Census were considered in 2016 & 2031; length

1.4 km. Assume one direction jammed and the other free-flow at Jammed Peak.

|

|

25

|

Che Kung Miu Road (Lion Rock Tunnel

Rd to 1 km from WTW)

|

322

|

322

|

322

|

5%

|

100%

|

100%

|

50%

|

55%

|

0%

|

1

|

-

|

Traffic data

from 2013 Annual Traffic Census were considered in 2016 & 2031; length

1.8 km.

|

|

26

|

Tin Sam Street

|

107

|

107

|

107

|

5%

|

100%

|

100%

|

50%

|

55%

|

0%

|

1

|

-

|

Traffic data

from 2013 Annual Traffic Census were considered in 2016 & 2031; length

0.7 km.

|

|

27

|

Hung Mui Kuk Road

|

208

|

208

|

208

|

5%

|

100%

|

100%

|

50%

|

55%

|

0%

|

1

|

-

|

Traffic data

from 2013 Annual Traffic Census were considered in 2016 & 2031; length

0.8 km.

|

|

28

|

Mei Tin Road

|

203

|

203

|

203

|

5%

|

100%

|

100%

|

50%

|

55%

|

0%

|

1

|

-

|

Traffic data

from 2013 Annual Traffic Census were considered in 2016 & 2031; length

0.7 km.

|

|

29

|

Lion Rock Tunnel Road – Sha

Tin Rd to Lion Rock Tunnel

|

2471

|

2471

|

2471

|

4%

|

100%

|

84%

|

42%

|

46%

|

0%

|

1

|

-

|

Traffic data

from 2013 Annual Traffic Census were considered in 2016 & 2031. Road

length ~2.6 km; Assumed one direction jammed and the other free-flow at

Jammed Peak.

|

|

30

|

Lion Rock Tunnel Road – Che

Kung Miu Rd to Sha Tin Rd

|

39

|

39

|

39

|

5%

|

100%

|

100%

|

50%

|

55%

|

0%

|

1

|

-

|

Traffic data

from 2013 Annual Traffic Census were considered in 2016 & 2031; length

0.4 km.

|

|

31

|

Lion Rock Tunnel Road – Tai

Po Rd to Che Kung Miu Rd

|

112

|

112

|

112

|

5%

|

100%

|

100%

|

50%

|

55%

|

0%

|

1

|

-

|

Traffic data

from 2013 Annual Traffic Census were considered in 2016 & 2031; length

0.6 km.

|

|

32

|

Populated area 2–3km

northeast of Sha Tin WTW

|

78044

|

84436

|

84436

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

20

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

33

|

East Rail

Train near Shatin WTW (Outside 1-km CZ)

|

718

|

718

|

806

|

20%

|

100%

|

100%

|

50%

|

50%

|

100%

|

1

|

1

|

Following to

the information provided by MTRCL (QRA 2011). Length = 1.5 km

SCL is under construction under Year 2014 and will operate at Year 2018.

|

|

34

|

Sha Tin Rural

Commetee Road

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

Outside of

consideration 2-km Zone

|

|

35

|

Shatin Wai

Road to Sha Tin Road

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

Outside of

consideration 2-km Zone

|

|

36

|

Chik Wan

Street

|

217

|

217

|

217

|

2%

|

100%

|

33%

|

16%

|

18%

|

0%

|

1

|

0

|

Assume

population 30% of Tai Po Rd (Ref. 23)

|

|

37

|

Lower Shing

Mun Road

|

217

|

217

|

217

|

2%

|

100%

|

33%

|

16%

|

18%

|

0%

|

1

|

0

|

Assume

population 30% of Tai Po Rd (Ref. 23)

|

|

A

|

Hin Tin

Swimming Pool

|

300

|

300

|

300

|

0%

|

50%

|

50%

|

100%

|

50%

|

30%

|

1

|

-

|

Based on the

average daily usage data provided by LCSD and an interview with the pool

staff, assuming each user would spend about 1.5 hours at the pool. 50% of

maximum occupancy assumed. *Population for summer is 300. Population for rest

of the year is 123. 30% of population is indoors in summer. 50% is indoors

for rest of the year (1). The population data is verified in 2014 .

|

|

A1

|

Auxiliary

Medical Service NTE Regional Office

|

10

|

10

|

10

|

0%

|

100%

|

100%

|

0%

|

100%

|

95%

|

1

|

2

|

2 storeys

office, confirmed with observation during site survey Jan 2014. Assume no. of

staff: 10 conservatively.

|

|

B1

|

Hin Tin Playground

|

133

|

0

|

128

|

0%

|

50%

|

50%

|

100%

|

50%

|

0%

|

1

|

-

|

Based on the

average daily usage data provided by LCSD, assuming each user would spend

about 1.5 hours at the playground. To be converted to the SCL Project works

areas (unit Z9) during the SCL construction phases. Part of the Playground to

be permanently used by the planned SCL Hin Keng Station (1).

|

|

B2

|

Hin Tin tennis court and Football

field

|

87

|

87

|

87

|

0%

|

50%

|

50%

|

100%

|

50%

|

0%

|

1

|

-

|

Based on the

average daily usage data provided by LCSD, assuming each user would spend

about 1.5 hours at the playground(1).

The population

data is verified in 2014.

|

|

C

|

Carmel Alison Lam Primary School

|

1042

|

764

|

764

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

6

|

Base school

capacity value was referenced: http://www.edb.gov.hk/ (1). Assume

30 students per class. 24 classes, 44 staff. Numbers of class and staff

numbers from http://www.chsc.hk/ were considered in 2016 & 2031. Time

factor of 0.67 applied in modelling.

|

|

D

|

Wong Wah San Hostel for the Elderly

|

140

|

0

|

0

|

100%

|

100%

|

100%

|

100%

|

100%

|

95%

|

3.3

|

1

|

Name changed

(from Wong Wah San Hostel for the Elderly to SAGE Mrs. Wong Yee Jar Jat

Memorial Home for the Elderly) and moved to Hin Yeung House (Ref. AK).

This location is

changed purpose of use and moved to Ref. AL (SAGE Mrs. Wong Yee Jar Jat

Memorial Neighbourhood Elderly Centre).

|

|

E

|

Hin Keng Estate North

|

10229

|

10277

|

10277

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

35

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

F

|

Ka Keng Court

|

1083

|

1089

|

1089

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

41

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

G

|

Sheung/Ha Keng Hau Village

|

2045

|

2055

|

2055

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

3

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

H

|

Parc Royale

|

2570

|

2582

|

2582

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

20

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

H1

|

Julimount Garden

|

693

|

904

|

904

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

22

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

H2

|

Hill Paramount

|

443

|

578

|

578

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

27

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

I

|

Hin Tin Village Housing

|

1176

|

1181

|

1181

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

3

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

J

|

Market Place/Bazaar/Restaurant

|

400

|

400

|

400

|

0%

|

50%

|

50%

|

100%

|

50%

|

90%

|

1

|

4

|

2001 QRA

population numbers increased, portion outdoors and time distribution slightly

modified following the 2009 survey. Shops and sports centre across the street

taken into account. (1) Confirmed to be still existing and

applicable during site survey Jan 2014.

|

|

K

|

Bus Station

|

50

|

50

|

50

|

10%

|

100%

|

100%

|

50%

|

50%

|

0%

|

1

|

1

|

Value from

2001 QRA reduced following the 2009 survey (1). Confirmed to be

still existing and applicable during site survey Jan 2014.

|

|

L

|

Union Hospital and Staff Quarters

|

473

|

473

|

473

|

100%

|

100%

|

100%

|

100%

|

100%

|

99%

|

3.3

|

13

|

Based on ERM

(2001) (1).

|

|

L1

|

Proposed residential HOS development

at Hin Tin St. (construction)

|

200

|

200

|

0

|

0%

|

50%

|

50%

|

0%

|

100%

|

0%

|

1

|

0

|

Based on information from Housing

Authority

|

|

|

HOS development at Hin Tin St.

occupied

|

0

|

0

|

810

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

40

|

Based on information from Housing

Authority

|

|

M

|

Helen Liang Memorial School

|

1040

|

1070

|

1070

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

1

|

6

|

Base school

capacity value was referenced: http://www.edb.gov.hk/ (1). Assume

45 students per class for Form 1-5 and 30 students per class for Form 6. 20

classes of Form 1-5, 4 classes of Form 6 and 50 staff. Numbers of class and

staff numbers from http://www.chsc.hk/ were considered in 2016 & 2031. Time

factor of 0.67 applied in modelling.

|

|

N

|

CUHK FAA Thomas Cheung Primary School

|

1116

|

606

|

606

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

6

|

Base school

capacity value was referenced: http://www.edb.gov.hk/ (1). Assume

30 students per class. 19 classes, 36 staff. Numbers of class and staff

numbers from http://www.chsc.hk/ were considered in 2016 & 2031. Time

factor of 0.67 applied in modelling.

|

|

O

|

Hin Keng Estate South

|

8985

|

9027

|

9027

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

35

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

P

|

Residential Area (Keng Hau Road)

|

122

|

129

|

129

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

3

|

Based on number of units

and PDZ household size (3.3).

|

|

Q

|

K. K. Terrace, Woodcrest Hills

|

171

|

178

|

178

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

1

|

Based on number of units

extracted from Centamap and PDZ household size (3.46), scaled according to

2011-based TPEDM projection.

|

|

R1

|

East Rail Train near Sha Tin WTW

|

718

|

718

|

806

|

16%

|

100%

|

100%

|

41%

|

41%

|

100%

|

1

|

1

|

Based on MTRCL data.

SCL is under construction in

Year 2014 and will operate at Year 2018. (1).

|

|

S1

|

Tsing Sha Hwy (formerly Route 16:

Northern Section)

|

540

|

559

|

559

|

1%

|

100%

|

17%

|

8%

|

9%

|

0%

|

1

|

-

|

Based on the

traffic data provided by TD. Traffic in stationary on one direction during

Jammed Peak was considered.

|

|

S2

|

Sha Tin Heights Tunnel (formerly

Route 16: Sha Tin Tunnel)

|

1620

|

1676

|

1676

|

1%

|

100%

|

17%

|

8%

|

9%

|

100%

|

1

|

-

|

Based on the

traffic data provided by TD. Traffic in stationary on one direction during

Jammed Peak was considered. Shatin Heights Tunnel is 100% indoor.

|

|

S3

|

Route 8 (formerly Route 16): Toll

Plaza

|

693

|

731

|

731

|

3%

|

100%

|

55%

|

27%

|

34%

|

0%

|

1

|

-

|

Based on the

traffic data provided by TD. Traffic in stationary on one direction during

Jammed Peak was considered. Population in Toll Plaza is separated from Ref.

S3 to S31

|

|

S3A

|

Tsing Sha Highway Toll Plaza

|

10

|

10

|

10

|

50%

|

90%

|

100%

|

100%

|

100%

|

0%

|

1

|

-

|

10 Booths was

observed on site survey Jan 2014 and based on data provided by TD.

|

|

T

|

Staff Quarters of Sha Tin WTW

|

10

|

10

|

10

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

1

|

Based on WSD data

(1).

|

|

T1

|

WTW reprovisioning workers, South

Works

|

0

|

93

|

0

|

0%

|

50%

|

50%

|

0%

|

100%

|

33%

|

1

|

-

|

Based on WSD

data (1).

|

|

T2

|

WTW reprovisioning workers, Chemical

House

|

0

|

70

|

0

|

0%

|

50%

|

50%

|

0%

|

100%

|

33%

|

1

|

-

|

Based on WSD

data (1).

|

|

T5

|

WTW reprovisioning workers, Washwater

Recovery Tank

|

0

|

35

|

0

|

0%

|

50%

|

50%

|

0%

|

100%

|

33%

|

1

|

-

|

Based on WSD

data (1).

|

|

U

|

Ka Tin Court

|

4707

|

4729

|

4729

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

35

|

Value from

Centamap (updated based on 2011 Population Census Street Block data), scaled

according to 2011 based TPEDM projection.

|

|

V

|

Assemblies of God Wa Wai Church Hin

Keng Anglo-Chinese Kindergarten G/F of Hin Kwai House

|

90

|

0

|

0

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

1

|

Base value

from: http://www.edb.gov.hk (1). Confirmed to be shut down during

site survey Jan 2014.

|

|

W

|

Po Leung Kuk District Support Centre

(Shatin) G/F of Hin Fu House

|

0

|

50

|

50

|

0%

|

100%

|

100%

|

100%

|

100%

|

95%

|

3.3

|

1

|

Based on site

survey Jan 2014 and telephone interview, there is approximately 50 people

including a dental care centre of 1 dental bed.

|

|

W1

|

Beacon Hill North Gas Offtake Station

|

3

|

3

|

3

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

1

|

1

|

Based on the

site surveys and Towngas information (2).

|

|

X

|

Kindergarten G/F of Hing Tak Lau

|

240

|

118

|

118

|

0%

|

50%

|

50%

|

0%

|

100%

|

95%

|

3.3

|

1

|

Base value

from: http://www.edb.gov.hk (1). confirmed with observation during

site survey Jan 2014. 98 students in total with 20 staff, data from

http://www.chsc.hk/ were considered in 2016 & 2031.

|

|

Y

|

Tai Po Road

|

1574

|

1574

|

1574

|

2%

|

100%

|

32%

|

16%

|

18%

|

0%

|

1

|

-

|

Traffic data

from the 2013 annual traffic census. Length 1.5 km. Traffic in stationary on

one direction during Jammed Peak was considered.

|

|

Z1

|

Che Kung Miu Road

|

300

|

300

|

300

|

5%

|

100%

|

100%

|

50%

|

55%

|

0%

|

1

|

-

|

Value from 2001 QRA,

partially verified during 2009 ERM survey, population was updated from Site

survey Jan 2014. 86 vehicles per 5

minutes in average.

More conservative data

(2011) were adopted (1).

|

|

Z2

|

Hin Keng Street

|

270

|

270

|

270

|

5%

|

100%

|

100%

|

50%

|

55%

|

0%

|

1

|

-

|

Value from 2001 QRA,

partially verified during 2009 ERM survey, population was updated from Site

survey Jan 2014. 30 vehicles per 5 minutes in average.

More conservative data

(2011) were adopted (1).

|

|

Z5

|

SCL train (moving)

|

0

|

0

|

501

|

16%

|

100%

|

100%

|

41%

|

41%

|

100%

|

1

|

-

|

Based on MTRCL

data (1).

|

|

Z6

|

Hin Keng Station

|

0

|

0

|

372

|

16%

|

100%

|

100%

|

41%

|

41%

|

0%

|

1

|

4

|

Based on MTRCL

data. SCL is under construction in Year 2014 and will operate at Year 2018 (1).

|

|

|

Stationary train at HIK Station

|

0

|

0

|

607

|

16%

|

100%

|

100%

|

41%

|

41%

|

100%

|

1

|

-

|

Based on MTRCL

data. SCL is under construction in Year 2014 and will operate at Year 2018 (1).

|

|

|

HIK Station construction workers

|

0

|

140

|

0

|

0%

|

50%

|

50%

|

10%

|

100%

|

0%

|

1

|

-

|

Based on MTRCL

data. SCL is under construction in Year 2014 and will operate at Year 2018 (1).

SCL construction workers are conservatively included in 2016 scenario.

|

|

Z7

|

SCL Tunnel portal construction

workers

|

0

|

120

|

0

|

0%

|

50%

|

50%

|

10%

|

100%

|

0%

|

1

|

-

|

Based on MTRCL

data. SCL is under construction in Year 2014 and will operate at Year 2018 (1).

SCL construction workers are conservatively included in 2016 scenario.

|

|

Z8

|

SCL Alignment construction workers

|

0

|

20

|

0

|

0%

|

50%

|

50%

|

10%

|

100%

|

0%

|

1

|

-

|

Based on MTRCL

data. SCL is under construction in Year 2014 and will operate at Year 2018 (1).

SCL construction workers are conservatively included in 2016 scenario.

|

|

Z9

|

SCL Construction Offices/yard

|

0

|

80

|

0

|

0%

|

50%

|

50%

|

10%

|

100%

|

50%

|

1

|

1

|

Based on MTRCL

data. SCL is under construction in Year 2014 and will operate at Year 2018

(1).

|

|

Z10

|

Keng Hau Rd underpass below the SCL

alignment

|

6

|

11

|

11

|

5%

|

100%

|

100%

|

50%

|

55%

|

0%

|

1

|

-

|

Based on ERM 2011 site survey (1), population taken from Site survey Jan

2014. 8 vehicles per 5 minutes in average were

considered in 2016 & 2031.

|

|

AA1

|

Lion Rock Tunnel Toll Plaza

|

12

|

12

|

12

|

50%

|

100%

|

100%

|

100%

|

100%

|

0%

|

1

|

-

|

12 Booths as observed on site survey

Jan 2014. Information provided by Transport Department. Assume no. of staff :

1 staff per booth

|

|

AA2

|

Lion Rock Tunnel Office (Transport

Department)

|

63

|

63

|

63

|

50%

|

100%

|

100%

|

100%

|

100%

|

95%

|

1

|

2

|

2 storey, confirmed with observation

during site survey Jan 2014.

Information provided by Transport Department. No. of staff at LRT =

75; Assume no. of staff at toll plaza = 12

|

|

AA3

|

Lion Rock Tunnel (Inside the tunnel)

|

190

|

190

|

190

|

4%

|

100%

|

84%

|

42%

|

46%

|

100%

|

1

|

-

|

Traffic data from 2013 Annual Traffic

Census. Road length ~200m; Traffic in stationary on one

direction during Jammed Peak was considered.

Lion Rock Tunnel is 100% indoor.

|

|

AD

|

Ascot Villas, Golden Time Villas,

Chase Villa and Albert Villas

|

135

|

135

|

135

|

100%

|

50%

|

50%

|

70%

|

50%

|

99%

|

1

|

3

|

Confirmed with observation during

site survey Jan 2014. Ascot Villas: 3 3-storey blocks, 15 units in total,

data from https://bmis.buildingmgt.gov.hk/,