3. project description

3.1. Description of the Site Area

3.1.1.

The proposed Project is planned to be constructed on a piece

of land which is currently allocated as a works and staging area by the Drainage

Services Department (DSD). It is surrounded by Sheung Tat Street to the

northwest, Sheung Mau Street to the southwest and Sheung On Street to the

southeast. According to the approved Chai Wan Outline Zoning Plan (OZP) No.

S/H20/21, the Project site is zoned ��Government, Institution or Community (2)��

(��G/IC(2)��). The proposed Project is subject to a building height restriction

of 70mPD (including roof-top structures).

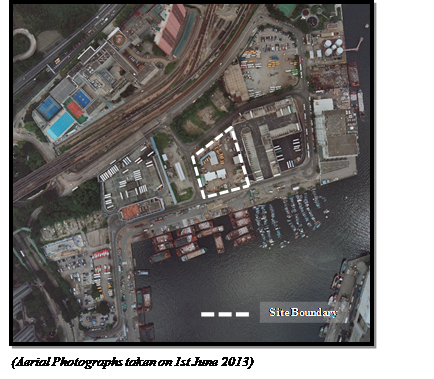

3.1.2. As shown in Figure 1.1, the Project site is located near the promenade of Chai Wan Public Cargo Working Area. The adjacent developments are identified and summarised as follows:

|

To the South: |

Tsui Wan Estate, Citybus Depot |

|

To the East: |

Chai Wan Public Cargo Working

Area |

|

To the North: |

NWFB Depot, Heng Fa Chuen |

|

To the West: |

Knight Court, Hong Kong

Institute of Vocational Education (Chai Wan), Pamela Youde Nethersole Eastern

Hospital |

3.1.3. The historical land use activities in chronological order are summarised as follows:

|

Before 1984: |

Marine environment |

|

1984 �V 1985: |

Reclamation |

|

1988 �V 1997: |

Sheung On Temporary Housing Area |

|

2001 �V 2002: |

Temporary works area for road construction project in Chai Wan

Reclamation Area |

|

2003 �V 2004: |

A fee-paying public carpark |

|

2005 �V Present: |

Temporary works area for Drainage Term Contract for Drainage

Maintenance and Construction in Hong Kong Islands and Islands Districts |

3.2. Design of the Proposed Project

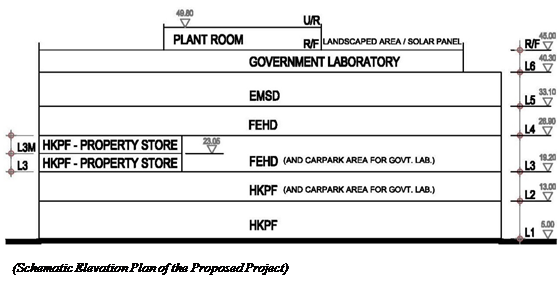

3.2.1. Based on the preferred option as discussed in Section 2.3, the proposed Project will be constructed in the form of a six-storey building (with a mezzanine floor above Level 3), with a proposed height of +49.8 mPD. The area of the Project site is approximately 7,000 m2. The floor plans that show the preliminary design of the proposed Project are set out in Figure 3.1. The proposed Project involves the following facilities:

(a) Construction of the HKPF PVP&EC of 5,200 m2 on Level 1 and 2, which includes:

- Vehicle examination area accommodates an inspection pit (100 m2), a roller brake tester and load simulator (100 m2), a vehicle lift (100 m2), and a level floor examination area (150 m2);

- Area of staff including offices, discussion room, lecture room, guard room and locker/ changing room (75 m2);

- A brake test strip (660 m2) and a brake test ramp (180 m2);

- Store (39 m2) and workshop (16 m2);

- Parking spaces for detention of a minimum of 81 vehicles of various sizes including covered parking for 25 saloon car spaces and 20 motorcycles; and

- Parking spaces for 5 police operational vehicles.

(b) Construction of a vehicle depot under the FEHD of 4,600 m2 or as appropriate on Level 3 and 4, which includes:

- Parking spaces with minimum headroom of 4 m for 70 vehicles of various sizes with a total required area of 3,755 m2 or as appropriate with inclusion of circulation space;

- Vehicle washing bay for 1 vehicle with high pressure water jet guns and drainage facilities (72 m2 or as appropriate);

- Water refilling bay for 2 vehicles (84 m2 or as appropriate);

- Office area (49 m2 ) (22.9m2 for the open plan office for staff and F/E), ancillary area (233 m2 or as appropriate), including meeting room, driver stand-by-briefing room, locker and changing rooms, toilet and shower facilities, storeroom and pantry;

- Fire services pump room, compressor room and switch room (100m2 or as appropriate); and

- Security guard booth (2.5 m2).

(c) Construction of the HKPF Centralised Case Property Store for the storage of case property for Crime Formations on Level 3 and 3M (about 1,942 m2).

(d) Construction of a permanent depot under the EMSD of 2,200 m2 on Level 5, which includes:

- Vehicle repair area and parking area (1,784 m2);

- Battery charging room (9 m2);

- Vehicle washing bay for two vehicles with petrol interceptor;

- Lubricant storage/lubricant dosing equipment/ chemical waste storage (37 m2);

- Air compressor room (7 m2);

- Tyre charger and tyre balancer area (8 m2);

- Waste oil tank (200 Litre);

- Waste water sedimentation tanks;

- Office area (total 120 m2 ) ; and

- Ancillary area with toilet, shower facilities, pantry, locker, changing rooms and storage.

(e) Construction of a specialist laboratory under the GL of about 2,160 m2 on Level 6, which includes:

- Testing laboratory area;

- Storage rooms;

- Offices, changing rooms and meeting room;

- Dangerous good stores for Categories 2, 3 and 5 dangerous goods; and

- Parking spaces.

3.3.

Operation of the Proposed Project

Operation Hours in Proposed Project

3.3.1. The vehicles move in and out of the proposed Project only when operation needs, and the movement of vehicles within the proposed Project will be limited. The average daily in and out traffic volumes would be about 365. The total estimated daily numbers of vehicles detained in the proposed Project was determined to be of around 260 in maximum (which equals to the parking spaces for vehicles) and types of vehicles comprise RCVs, street washing vehicles, lorries, saloon cars, motorcycles, police operational vehicles, ambulances and vans.

3.3.2. Major vehicle repair / testing activities at the EMSD Depot will be taken from 0800 to 1800 hours on weekdays, whilst the HKPF examination works will be taken on irregular basis due to operation needs. The PVP & EC will be in operation 24 hours on 7-day per week basis. FEHD depot will operate daily from 0600 to 2330 hours. General offices of EMSD and GL, etc. will operate mainly during normal office hours (0800 to 1800 hours). The summary is shown in Table 3.1 below:

Table 3.1 Operation Hours of the Project

|

Facilities |

Operation Hours |

|

HKPF PVP&EC |

Mon �V Sun, 24 hrs |

|

HKPF Centralised Case Property Store |

Irregular operation hours due to

operational needs |

|

FEHD Depot |

Mon �V Sun, 0600 �V 2330 hrs |

|

GL Specialist Laboratory |

Mon �V Fri, 0800 �V 1800 hrs |

|

EMSD Depot |

Mon �V Fri, 0800 �V 1800 hrs |

3.3.3. The number of staff working in the proposed Project is estimated to be about 180 and 55 during daytime (0800 to 1800 hours) and evening time (1800 to 2330 hours) respectively, which is shown in Table 3.2 below.

Table 3.2 Total Number of Staff Working in the Proposed Project

|

Facilities |

Total Number of Staff Working at Chai Wan Government Complex and

Vehicle Depot |

||

|

Day (0800 - 1800 hrs) |

Evening (1800 �V 0200 hrs) |

Night (0200 �V 0800 hrs) |

|

|

HKPF

PVP&EC |

7 |

1 |

1 |

|

HKPF Centralised

Case Property Store |

21 |

0 |

0 |

|

FEHD Depot |

80 + 3 (station in

office during each shift) |

41 + 3 (station in

office during each shift) |

0 |

|

GL Specialist

Laboratory |

36 |

0 |

0 |

|

EMSD Depot |

33 |

10 |

0 |

Proposed Activities in Proposed Project

3.3.4. The activities to be carried out in the proposed Project are summarised in Table 3.3 and further depicted below. Photos of the proposed activities are shown in Appendix 3.2.

Table 3.3 Summary of Vehicle Repair / Testing Equipment and Activities

|

HKPF

PVP&EC |

EMSD Depot |

FEHD Depot |

GL Specialist

Laboratory |

|

Braking test (on grade) |

Braking test (for vehicles other than motorcycle) |

Vehicle washing |

Vehicle parking |

|

Braking test (on slope) |

Braking test (for motorcycle) |

Water refilling in vehicle |

Chemical testing |

|

Braking test (for vehicles other than motorcycle) |

Speedometer test (for motorcycle) |

Vehicle parking |

|

|

Use of compressed air, e.g. screw driving |

Tyre balancing |

|

|

|

Hammering |

Tyre changing |

|

|

|

Vehicle parking |

Hammering |

|

|

|

Vehicle lifting |

Use of compressed air, e.g. screw driving |

|

|

|

Vehicle examination (in pit) |

Vehicle washing |

|

|

|

Vehicle examination (at ground) |

Vehicle lifting |

|

|

|

|

Engine testing |

|

|

|

|

Vehicle parking |

|

|

|

|

Chemical mixing, e.g. lubricant mixing |

|

|

|

|

Battery charging |

|

|

|

|

Chemical refilling, e.g. lubricant refilling |

|

|

HKPF PVP&EC

�P Braking test (on grade) �V The brake test strip is used to test the brake system on a vehicle that is operated on grade. During the test at the brake test strip, the vehicle runs at a maximum speed of 30 km/hr. As confirmed by the HKPF, the maximum number of use is assumed to be 5 times per day and it takes around 30 seconds for each operation.

�P Braking test (on slope) �V The brake test ramp is used to test the brake system on a vehicle that is operated on slope. During the test at the brake test ramp, the engine is either set at idle or off. During the test, minimal noise is generated. As confirmed by the HKPF, the maximum number of use is assumed to be 5 times per day and it takes 30 seconds for each operation.

�P Braking test (for vehicles other than motorcycle) �V A roller brake tester will be equipped at the HKPF PVP&EC. During the test, the roller brake tester runs the vehicle��s front wheel or rear wheel at a low speed, while the vehicle has its engine switched off. The operator then applies the brake of the vehicle under testing and eventually the respective wheel is locked. The maximum torque is then recorded by the brake tester and the vehicle is pushed away from the brake tester indicating the end of the testing. It also consists of a load simulator which is a device with hydraulic cylinder to test the efficiency of the brake using difference braking forces when loaded or unloaded simulation. During the brake testing and loading test, minimal noise is generated. It takes a maximum of 2 minutes for each operation and the maximum number of use is estimated to be 5 times per day.

�P Use of compressed air, e.g. for screw driving �V An air compressor will be employed for providing power to the pneumatic tools for vehicle repair / testing activities. The air compressors will be housed in a dedicated compressor room. It also involves small wheel wrenches, small jacks, tyres inflators and pumps for pumping of used lube oil.

�P Hammering �V Hammer, a hand-held tool consisting a handle with a head of metal, is used for striking or pounding. It will be used by the vehicle examiner to test if the screw is loosen or to assist dismantling parts of the detained vehicles for testing only. No maintenance or repair services for the detained vehicles will be involved.

�P Vehicle parking �V Vehicle parking spaces will be assigned in the HKPF PVP&EC for various types of vehicles. Vehicle parking activity will be most likely found in day and evening time, whilst car parking at night-time will only be occasional.

�P Vehicle lifting �V A total of 1 vehicle lifting hoist for vehicles would be provided in the HKPF PVP&EC. The hoist is electrically powered with small output motors.

�P Vehicle examination (in pit) �V Vehicle examination pit is a narrow pit or trench over which a vehicle can be parked and conveniently worked on from beneath. The testing at the vehicle examination pit is performed with the engine set at idle.

�P Vehicle examination (at ground) �V There will be a designated area for parking a vehicle for inspection and examination in the HKPF PVP&EC. The testing at the vehicle examination ground is performed with the engine set at idle.

EMSD Depot

�P Braking test (for vehicles other than motorcycle) �V A roller brake tester will be equipped at the EMSD Depot at Level 5. During the test, the roller brake tester runs the vehicle��s front wheel or rear wheel at a low speed, while the vehicle has its engine switched on. The operator then applies the brake of the vehicle under testing and eventually the respective wheel is locked. The maximum torque is then recorded by the brake tester and the vehicle is pushed away from the brake tester indicating the end of the testing. It takes around 30 seconds for each operation and the maximum number of use is estimated to be 6 times per day.

�P Braking test (for motorcycle) �V This activity consists of a motorcycle brake tester, and the necessary fixtures. The motorcycle tester operating in a principle similar to the roller brake tester which measures the torque of the wheel when brake is applied. The motorcycle engine running is, however, not required during operation and it takes around 2 minutes per operation and the frequency of use is estimated to be 3 times per day.

�P Speedometer calibration (for motorcycle) �V The motorcycle speedometer calibration involves the motor turning the back wheel of the motorcycle and increasing the speed gradually from 0 km/hr to 150 km/hr, which generates some noise during testing. The speedometer calibrator to be used in the EMSD Depot will be the same or similar to the one utilised at existing EMSD Workshop at Sheung On Street, Chai Wan.

�P Tyre balancing �V A tyre balancer is a piece of motorised measurement equipment which is used to identify the shift of centre of mass of a wheel. During operation, the tyre balancer spins the wheel under testing and suggests the location of calibration weight to be installed. The spinning is conducted at a low speed.

�P Tyre changing �V A tyre changer is an equipment to help the operator to remove and install the tyre from and onto the rim. It basically consists of a fixture and a hook that are placed between the tyre and the rim to pull the tyre from the rim in a rotation. The motor required for the tyre changer is small in scale. It takes around 2 minutes for each operation and the maximum number of use is estimated to be 10 times per day.

�P Hammering �V Hammer, a hand-held tool consisting a handle with a head of metal, is used for striking or pounding.

�P Use of compressed air, e.g. for screw driving �V An air compressor will be employed for providing power to the pneumatic tools for vehicle repair / testing activities. The air compressors will be housed in a dedicated compressor room. It also involves small wheel wrenches, small jacks, tyres inflators and pumps for pumping used lube oil.

�P Vehicle washing �V Water point will be provided for vehicle washing bay in the EMSD Depot. Each operation lasts for around 1 minute and the maximum number of use is estimated to be 10 times per day. As no automatic vehicle washing machine will be provided and thus operational noise generated from cleaning is not considered.

�P Vehicle lifting �V A total of 9 vehicle lifting hoists for vehicles will be provided in the EMSD Depot. The hoists are electrically powered with small output motors.

�P Engine testing �V The testing is performed with the engine set at idle.

�P Vehicle parking �V Vehicle parking spaces will be assigned at Level 5 for various types of vehicles. Vehicle parking activity will be found at day-time and evening time only. No cars will be entering and leaving the EMSD Depot at night-time.

�P Chemical mixing, e.g. lubricant mixing �V The lubricant dosing equipment is used to move a precise volume of liquid in a specified time period providing an accurate flow rate.

�P Battery charging �V An automatic battery charger is used for providing low current charging to vehicle sealed lead-acid battery. No gases/ electrolyte are discharged during the charging operation.

�P Chemical refilling, e.g. lubricant refilling �V Lubricant is filled to vehicles during operation, whilst fresh and waste lubricants are stored at the designated area in the EMSD Depot with spilling control system.

FEHD Depot

�P Vehicle washing �V 1 water point for manual vehicle washing and 1 automatic vehicle washing machine will be provided in the FEHD Depot. When passing the vehicle washing machine, vehicle keeps the engine running. It normally takes about 2 minutes to complete a washing cycle. It is expected that a maximum of about 33 vehicles (including RCVs) would use the automatic vehicle washing machine every day. More details in relation to the operation of RCVs are given in Sections 3.3.5 to 3.3.8.

�P Water refilling in vehicles �V 1 water refilling machine will be provided for street washing vehicles and the provision will be the same or similar to the one at existing FEHD Depot in Quarry Bay. Engine of street washing vehicle is switched off when refilling.

�P Vehicle parking �V 70 vehicle parking spaces will be assigned at Level 3 and 4 of the FEHD Depot for storage of various types of vehicles. Vehicle parking activity will be found in day-time, evening time and night-time.

GL Specialist Laboratory

�P Vehicle parking �V Vehicle parking spaces will be assigned at Level 2 and 3 for various types of vehicles for the GL. Vehicle parking activity will be found in day-time and evening time only.

�P Chemical testing �V Chemical testing will be carried out during normal office hours at Level 6 of the proposed Project. Samples to be analysed in the Government laboratory include sediment, soil, wastewater, marine water, river water, biota, consumer products, air canister, etc. Proper devices such as fumehood will be installed to minimise the exhaust of volatile compound and acidic gases.

Refuse Collection Vehicles (RCVs) in Proposed Project

3.3.5. A total of 17 parking spaces in the FEHD Depot will be designated for parking of RCVs. The fleet of 16 RCVs are expected to enter the proposed Project from 0600 to 2300 hours every day. The maximum hourly flow will happen between 1200 and 1300 hours, during which 8 RCVs will move in the proposed Project.

3.3.6. No vehicle repair / testing activities for RCVs will be conducted within the entire depot areas, including the EMSD Depot.

3.3.7. All the RCVs that visit the proposed Project are of enclosed-type and equipped with deodourising system with an odour removal efficiency of 85% or above. The design of the RCVs complies with the Code of Practice on the Operation of RCVs jointly published by the EPD, Transport Department and Environmental Contractors Management Association.

3.3.8. To avoid the spreading of odour, all RCVs will be fully off-loaded in designated refuse disposal sites and washed thoroughly in the Island East Transfer Station or disposal site before returning to the FEHD Depot. Extensive cleansing and clearance of refuse residual inside the compactor of the RCVs would not be carried out within the proposed Project. The body shell of RCVs may be rinsed again in the FEHD Depot to ensure the removal of any waste residue. All RCVs will be wiped dry before leaving proposed Project.

3.3.9. The metal tailgate cover and compactors of RCVs will not be opened while passing through the vehicle washing bay or automatic vehicle washing machine. It normally takes about 2 minutes to complete a washing cycle. Moreover, wastewater from the washing of RCVs will not be recovered for other uses. No potential odour, noise and waste water runoff nuisance is therefore anticipated.

3.4. Construction Methodology

3.4.1. Based on the preferred option of the proposed Project, at the commencement of construction, site formation works will be carried out and these will comprise the fencing off of the site boundary, cutting and removal of unwanted rocks, shrubs, trees and building debris, levelling of soil surface, excavation of soil to the required level with shoring if necessary. These tasks will involve the use of hand-held breakers and tracked excavators etc.

3.4.2. Conventional steel H-pile has been proposed. It is estimated that 325 nos. of 50 m steel H-pile may be required, subject to future design. Conventional bottom-up reinforced concrete construction will be adopted for the superstructure construction with beam-slab. The floor consists of suspended beam and slabs which are supported by columns and structural walls. Formwork and temporary support for the beam and slab construction will be installed.

3.5. Project Implementation Programme

3.5.1. The construction of the proposed Project will tentatively be commenced in period from Mid 2016 to Mid 2017 depending on the design process and will last for about 29 months. For the purpose of this EIA study, a conservative approach for the construction period is assumed to start in Mid 2016, where more concurrent projects are in place. The preliminary construction programme of the proposed Project is shown in Appendix 3.1.

3.6. Concurrent Projects

3.6.1. There are several concurrent projects in the vicinity of the Project site, as also depicted in Figure 1.1 and summarised in Table 3.4. At this stage, consideration of concurrent projects for cumulative environmental impacts will only take into account those with the available implementation programmes. Cumulative impacts from existing, committed and planned major concurrent projects, if any, have been assessed in the individual sections of this EIA study.

Table 3.4 List of Potential Concurrent Projects

|

Concurrent

Projects |

Potential

Cumulative Impacts |

|

|

Construction

Phase |

Operation

Phase |

|

|

Planned

THEi New Campus (construction tentatively between the third quarter of 2013

and the third quarter of 2016; operation phase from the third quarter of

2016) |

P |

P |

|

Existing

EMSD Hong Kong Workshop at Chai Wan (EP-442/2012) |

O |

O |

|

Existing

New World First Bus Permanent Depot at Chai Wan (EP-052/2000) |

O |

P |

|

Existing Headquarter and Bus Maintenance Depot in Chai Wan

(EP-107/2001) |

O |

P |

3.7. Identification of Key Environmental Issues

3.7.1. The identified key environmental issues during the construction and operation phases include the following:

During Construction Phase

�P Potential dust impacts arising from the construction works activities of the proposed Project;

�P Potential noise impacts arising from the construction works activities of the proposed Project;

�P Potential water quality and sewerage impacts arising from the construction works activities and workforce;

�P Potential waste management implication and land contamination issues arising from the construction works activities;

�P Potential landscape and visual impacts arising from the construction works activities;

�P Potential hazard to life arising from the neighbouring dangerous goods (DGs) processing and storage facilities; and

�P Potential cumulative environmental impacts through interaction or in combination with other existing, committed and planned concurrent projects.

During Operation Phase

�P Potential fixed noise impacts arising from operation plant and vehicle repair / testing activities in the proposed Project and road carriageways in the vicinity of the proposed Project;

�P Potential vehicular emission and pollutant emission impacts arising from the vehicle repair / testing activities in the proposed Project and road carriageways in the vicinity of the proposed Project;

�P Potential sewerage impacts arising from the workforce in the proposed Project;

�P Potential waste management implications arising from the vehicle repair / testing activities of the proposed Project;

�P Potential hazard to life arising from the neighbouring dangerous goods (DGs) processing and storage facilities as well as the proposed Project;

�P Potential landscape and visual impacts arising from the operation of the proposed Project; and

�P Potential cumulative environmental impacts of the proposed Project, through interaction or in combination with other existing, committed and planned projects in the vicinity of the proposed Project, and that those impacts may have a bearing on the environmental acceptability of the proposed Project.

3.8. Public Engagement

3.8.1. Public comment, including potential odour issues from the activities, road vehicular noise and air emissions, as well as the selection of traffic routing of the future vehicle fleets, were received from different stakeholders during the course of planning and development of the proposed Project in the meetings of District Facilities Management Committee (DFMC) of the Eastern District Council.

3.8.2. The project design team has been exploring possible design enhancement in response to the public comment received. For example, the current design of the proposed Project has already incorporated the provision of odour removal equipment and ventilation system in order to minimise nuisance to the neighbourhood. The proposed Project would also maximises the building footprint and be built with building height of 49.8mPD (or 45.0mPD excluding roof-top structures), in respond to the comments from DFMC that the site area shall be maximised and building height of the proposed Project should be comparable to that of the adjoining NWFB Depot, which is approximately 45.0mPD.

3.8.3. Furthermore, the associated environmental nuisances have been adequately assessed in the following sections of the report to address public concerns.