3

Project Description

and Construction Methodologies

3.1

Key

Elements of Works

3.1.1.1

Section 2 has described the approaches

adopted to avoid and minimise various environmental impacts throughout the

design process. As mentioned in Section

2.1, the site formation of the original design is about 10ha as stated in EIA

Study Brief (ESB-271/2014), however, during the design process, environmental

impacts are considered, and the site formation of the final design has reduced

to about 8ha. The final design has therefore been taken forward

as the basis for this EIA to demonstrate that all statutory requirements under EIA

Study Brief (ESB-271/2014) and the Environmental Impact Assessment Ordinance

(EIAO) are complied with. A brief summary

of key elements of the project is given below:

|

Area

|

Proposed

Works

|

|

Works Within Study Area

|

·

Site formation of about 8ha of land for

proposed C&C Facilities (including the proposed pick-up and drop-off area

for shuttle buses).

|

|

|

·

Widening of the existing Sha Ling Road

(about 900m) - from existing 3m wide to a 7.3m wide single two-lane

carriageway, including its associated noise barriers.

|

|

|

·

Construction of internal roads for

C&C Facilities.

|

|

|

·

Widening of the existing Lin Ma Hang

Road (about 1.4km long) – from existing 6m wide to a 7.3m wide single two-lane

carriageway, including its associated noise barriers.

|

|

|

·

Construction of a new road (about 600m)

including a section of viaduct connecting platform for Crematorium and Man

Kam To Road.

|

|

|

·

Construction of the pick-up and drop-off

point at Man Kam To Road.

|

|

Outside the Columbarium / Crematorium Site

|

·

Temporary pick-up

and drop-off points of shuttle buses for grave-sweepers

during festive periods at MTR Kwu Tung Station,

Sheung Shui Landmark North Public Transport Interchange, MTR Fanling Station,

and layby at Pak Wo Road near Flora Plaza.

·

Necessary landscaping, sewerage,

waterworks and utility works for the proposed development along Man Kam To

Road.

·

Barging point in Siu Lam.

|

3.1.1.2

The construction of the proposed works elements within the Study Area

would involve relatively more construction activities, especially those for the

site formation work and associated infrastructure. In comparison, the works for

the temporary pick-up and drop-off points of shuttle buses for the MTR stations

would be very minor and only involve some retrofitting of existing facilities

such as rearrangement of planter and street furniture (i.e. street lighting and

railing) and bus routes. Major excavation works etc. would not be required. For MTR Kwu Tung Station (including the PTI and shuttle bus services

area), it will be constructed under the Planning and Development

Study on North East New Territories (NENT) Contract and will be

available by 2026. In addition, a barging point currently used by the Express

Rail Link project at Siu Lam is added.

3.1.1.3

The barging point is located off-site along Tsing Fat Street, Tuen Mun.

In order to reduce the impact on road traffic, surplus inert construction and

demolition (C&D) materials from the construction of the C&C facilities

at Sandy Ridge Cemetery and Lin Ma Hang Road will be stored at a temporary

stockpile area on-site. The surplus inert C&D materials will be transported

to designated barging point facility by lorries, and then transported by barges

for the reuse of other concurrent projects. The maximum

number of barge

movement is 2 round trips per day. The current location is an existing barging

point used by the Express Rail Link project. Minor construction works for the

tipping halls and new ramps are required. No maintenance dredging is required

and no night-time operation is anticipated.

3.1.1.4

As improvement works at the barging point will be land-based on

existing hard standing / developed area and levels of marine traffic will be

very low and following route to avoid areas of high dolphin density (Section 9 for details), it is

considered that the use of this site is unlikely to change, the evaluation of

habitat quality and potential impacts on the coastal environment is considered

not necessary.

3.1.1.5

The comparison of the scope

of works and designated projects of the original design and the current design

is given in Table 2.1 below:

Table 3.1 The comparison of

the scope of works and designated projects of the original design and the

current design

|

|

Description (Study Brief ESB 271/2014)

|

Original Design

|

Current Design

|

|

Scope of works

|

Site formation and associated works of about 10

hectares of land including landscaping, geotechnical, drainage and sewerage

works, waterworks, and other utilities services for development of C&C

faculties at Sandy Ridge Cemetery;

|

P (10 ha)

|

P (8 ha)

|

|

Road works including access road, tunnel and

viaducts within Sandy Ridge Cemetery;

|

P (1 tunnel and

6 viaducts)

|

P (Tunnel

removed and only 1 viaduct required)

|

|

Pedestrian walkway between MTR Lo Wu Station and

proposed columbarium;

|

P

|

O

|

|

Widening the eastbound of Choi Yuen Road near MTR

Sheung Shui Station from 1-lane to 2-lane carriageway (widening by about 3m)

for about 400 length

|

P

|

O

|

|

Widening a section of Lin Ma Hang Road (about 1km

in length) from 6.5 to 7.3m

|

P

|

P

|

|

Designated projects

|

Item A.1 – A road which is an expressway, trunk

roads, primary distributor road or district distributor road including new

roads, and major extension or improvement to existing roads;

|

P

|

O

|

|

Item A.8 – A road or railway bridge more than 100

m in length between abutments;

|

P

|

P

|

|

Item I.1

(b)(vii) – A drainage channel or

river training and diversion works which discharges or discharge into an area

which is less than 300 m from the nearest boundary of an existing or planned

conservation area.

|

P

|

P

|

3.2

Tentative Implementation Programme

3.2.1.1

It is anticipated that the site formation and associated

infrastructural works for the development of columbarium, crematorium and

related facilities will be commenced in the 3rd quarter of 2017 and

is targeted for completion by 2022. The tentative construction programme is

given in Appendix

3.1.

3.2.1.2

A summary of the key dates for construction phase is given below. All

these key dates are tentative and would be subject to amendment as the design

evolves.

Table 3.2 Summary of key construction dates

|

Key

Construction Elements

|

Tentative Dates

|

|

Commencement

|

Completion

|

|

Columbarium (site formation, retaining

walls, slopes, internal roads, etc.)

|

Q3 2017

|

Q4 2020

|

|

Crematorium (site formation, retaining

walls, slopes, internal roads, etc.)

|

Q3 2018

|

Q4 2021

|

|

New road with viaduct

|

Q3 2019

|

Q4 2022

|

|

Widening of Sha Ling access road

|

Q3 2017

|

Q4 2020

|

|

Utilities laying

|

Q1 2020

|

Q2 2022

|

|

Lin Ma Hang Road Widening and associated

slopes, etc.

|

Q2 2019

|

Q2 2022

|

3.3

Consideration of Alternative Construction

Methodologies

3.3.1.1

Section

3.1 has

described the keys elements of works required from the proposed development at

Sandy Ridge. In order to develop these elements in an environmentally friendly

manner, a number of alternative construction methods and sequences including

the following have been considered:

·

Avoid using blasting for site formation to

reduce impulsive noise;

·

Avoid using percussive piling for site

formation to reduce impulsive noise;

·

Use of temporary stockpile area to maximise

on-site reuse of C&D materials and reduce number of trucks to barging point;

·

Use of bored pile foundation for retaining

walls to minimise impacts on underground water flow;

·

Avoid disposal by barges at Shenzhen River

or Deep Bay to minimise impacts on Shenzhen River and Deep Bay; and

·

Avoid disposal to landfill.

3.3.2

Avoid Using Blasting for Site Formation

3.3.2.1

Given the extent of site formation and the local geological

conditions, there are two possible ways for the excavation for the main

platforms for both the columbarium and crematorium, including using blasting or

mechanical excavation.

3.3.2.2

The benefit of using blasting for the site formation is that the site

formation work could be completed within a shorter period of time. Although the impulsive noise and the dust

generated by the blasting process could be readily mitigated by good site

practices, the transportation and use of explosives may cause concern for some

of the residents in the vicinity, especially the explosives would need to be

transported to the site via a number of heavily trafficked roads including Man

Kam To Road, and other roads along which residential premises are located in

close proximity (e.g. Sha Ling Road). In

fact, using blasting would still inevitably require mechanical equipment to

break up the boulders into manageable sizes.

3.3.2.3

In comparison, the use of mechanical excavation for the site

formation would generally require more equipment such as excavator, piling rig

and drilling rig, dump truck, etc. to be operating on site. However, it could

be seen that the site formation work for the main platforms for both the

columbarium and crematorium are located at a distance from the nearest Noise

and Air Sensitive Receivers, in the range of 250m. Quantitative analysis in Sections 4 and 5 have illustrated that, with the use

of good site practices, the construction noise caused by the site formation

work would not be the dominate noise sources, and the cumulative dust impacts would comply with the

statutory requirements.

3.3.2.4

Hence, on the basis of the above discussion, the use of mechanical

excavation for the site formation has been selected as the preferred construction

methodology.

3.3.3

Avoid Using Percussive Piling

for Site Formation

3.3.3.1

As far as the foundation of retaining walls and bridge sections are concerned,

the use of percussive piling against bored pile has been considered. The

benefit of using percussive piling is to achieve a shorter construction

programme and hence a lower construction cost. However, the use of percussive

piling would inevitably generate a much higher impulsive noise.

3.3.3.2

For example, using one pneumatic driving steel pile at a distance of 250m

from the Noise Sensitive Receiver would generate a maximum noise level as high

as 77dB(A). In comparison, using a vibratory piling rig will cause a sound

pressure level of 62dB(A) at the same distance. Hence, the use of percussive

piling would cause more nuisances to the sensitive receivers.

3.3.3.3

Given the environmental setting of the Noise Sensitive Receivers in

the vicinity, such high and impulsive noise lasting for months would cause significant

nuisance on the neighbouring community.

3.3.3.4

Hence, on the basis of the above discussion, the use of percussive

piling for the foundation of retaining wall and the bridges has not be further

considered.

3.3.4

Use of Temporary Stockpile Area

3.3.4.1

Given the extent of site formation, a stockpile area will be located at the proposed columbarium site during construction phase for

temporary storage of inert soft construction and demolition (C&D)

materials. The temporary stockpile area will be located

with an approximate capacity of 9,000m3. The benefit of using stockpile area is

to provide backfill material within the site formation and thus will reduce

noise and dust generation from transportation of inert soft C&D materials

from external site.

3.3.4.2

Hence, on the basis of the above discussion, the use of temporary

stockpile area for the site formation has been selected as the preferred construction

methodology.

3.3.5

Use of Bored Pile Foundation for Retaining Walls

3.3.5.1

A wet woodland is located at the western side of the site formation

of columbarium. In order to allow groundwater to pass through, the foundation design would compose of bore piles of about 0.6m in

diameter and the spacing between each pile would be approximately 3.5 – 5m. As

compared to other foundation designs such as (Diaphragm wall) D-wall or pipepiles,

the proposed small diameter bored pile system would allow a notional free area

of about 87– 91% for groundwater to pass through.

3.3.5.2

Hence, based on the above

arguments, it is considered that the use of bored pile foundation for retaining

walls facing the wet woodland would not cause a significant change in the

groundwater flow to the wet woodland and it has been selected as the preferred construction

methodology.

3.3.6

Avoid Disposal by Barges at

Deep Bay / Shenzhen River

3.3.6.1

Other than using lorries,

the use of barges at Deep Bay / Shenzhen River to transport C&D materials away

from the construction site has also been considered. However, the water

level of Shenzhen River is shallow and there is not enough draft for the barges

to navigate through. Hence, large amount of dredging work would be

required and these dredging works would inevitably generate a large amount of sediment

of uncertain quality.

3.3.6.2

Due to the nature of this

project, the dredged sediment cannot be reused on–site and hence has to be

disposed of at designated marine disposal sites. Since the sediment marine

disposal sites have limited capacity, it is preferred to minimise their utilisation. Besides,

Deep Bay and certain sections of Shenzhen River are famous in their biodiversity

and extensive dredging would inevitably generate certain direct ecological

impacts as well. Other than the large amount of sediment dredged and the

direct ecological impacts, the large number of barges navigating through

Shenzhen River and subsequently through Deep Bay would increase the possibility

of indirect impacts on the sensitive ecological habitats in the vicinity.

3.3.6.3

Hence, on the basis of the above discussion,

the use of trucks for disposal of C&D materials during site formation has

been selected as the preferred construction methodology.

3.3.7

Avoid Disposal to Landfill

3.3.7.1

As discussed above, the surplus inert C&D materials from the construction of the

C&C facilities at Sandy Ridge Cemetery and Lin Ma Hang Road will be stored

at a temporary stockpile area on-site. In order to minimise the disposal to

landfill, the use of trucks for transport of inert surplus C&D materials to

designated barging point at Siu Lam for the reuse of other concurrent projects

has been selected as the preferred construction methodology.

3.4

Preferred Construction

Methodology – Works Within Study Area

3.4.1.1

The preferred construction methods are presented in the following

sections.

3.4.2

Site Formation

3.4.2.1

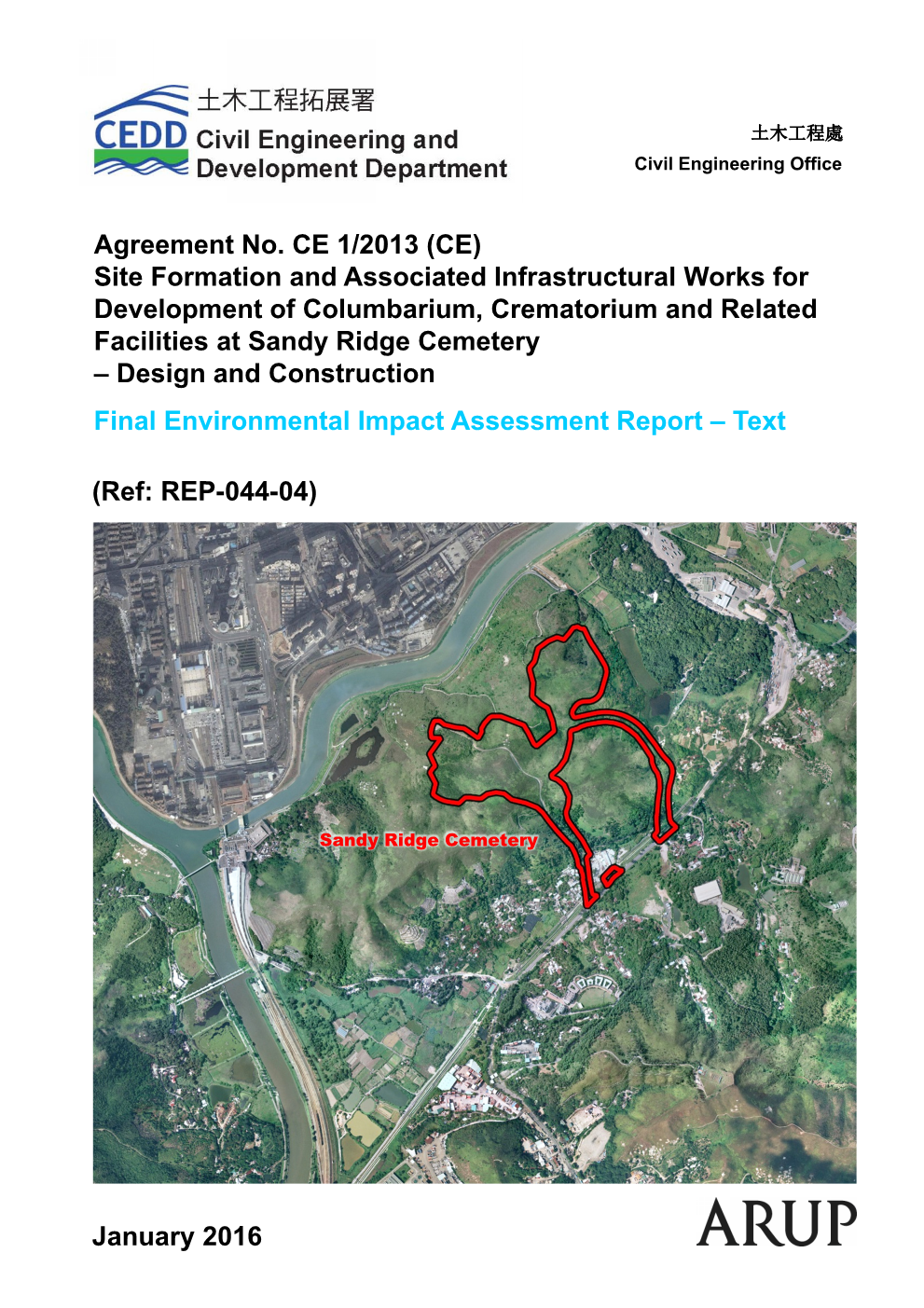

The total area for the site formation work is about 8ha. As shown in Figure 1.1. The

eastern portion of the development will comprise a total of 2 platforms. The two platforms with formation levels at +37mPD and +40mPD, will accommodate building blocks of Crematorium, Funeral Parlour,

Visitor Service Centre and associated facilities which are to be separately

implemented.

3.4.2.2

The western portion of the development

comprise of one platform with a formation level at +50mpD. It will serve as the pick-up / drop-off area for shuttle buses,

and accommodate the

building blocks for the Columbarium

and associated facilities such as joss paper burner and refuse collection point

respectively.

3.4.2.3

For the columbarium site, the site formation works for the platform is

mainly for the provision of pick-up / drop-off area to cater for visitors

during festive days. Meanwhile, cut/fill slopes will be more preferable than

retaining walls for the design of geotechnical engineering features, where more

landscaping works can be provided to mitigate the visual impacts. Most of the

columbaria buildings will be constructed along the slope to minimise the visual

impacts and the extent of site formation works.

3.4.2.4

In considering of the placing the pick-up / drop-off area decked or at

an open area, according to the current design, the future columbarium building

blocks are recommended to be sited separate from the pick-up/ drop-off area for

the following considerations:

·

An integrated complex housing the pick-up / drop-off area and the

columbarium buildings with 200,000 niches will inevitably become a

mega-structure towering over the +50mPD platform, which would introduce adverse

visual impacts to the surrounding due to its massive building bulk.

·

In view of its location, an open-air pick-up / drop-off area arrangement

will have no adverse environmental impact and will result in less energy

consumption in future operation than a covered pick-up / drop-off area, for

which mechanical ventilation system would be unavoidable.

·

The development of the columbarium at Sandy Ridge Cemetery is expected

to span over 10 years in different phases to meet the demands. If an integrated

design for columbarium and pick-up / drop-off area is used, when Phase 1 (i.e.

the completion of pick-up/ drop-off area and one of the columbarium buildings)

is completed and in operation, construction works for the following phases will

inevitably cause safety risks and nuisances to the users / visitors especially

during the festive days, which would be undesirable.

3.4.2.5

Given the size of the site formation work, the construction

methodologies have been duly reviewed to ensure that the associated

environmental impacts are optimised during this design stage. A description of the key construction stages

is given below:

|

Key

Stages

|

Construction

Methodology

|

|

Site Clearance

|

Firstly,

trees will be cleared by backhoes and transported out of the site by crane

lorries. After that, the top soil, rock and inert debris will be cleared by

backhoes and transported to the stockpiling area for

temporary storage. The top soil will be considered to be

used for grassland reinstatement. The remaining top soil, rock and inert

debris will be transferred to or public filling area by trucks.

|

|

|

The

surplus inert C&D materials will be transferred to the barging point at

Siu Lam for the reuse of other concurrent projects.

|

|

Construction of haul road

|

Construction

of access route mainly involves temporary

cut and fill works. Therefore, excavators and bulldozers

will be deployed to excavate and place the fill material to the desired slope

angle of the proposed access road. After placing the fill material on the

haul road, vibratory rollers will be used for compaction.

|

|

Earth filling and excavation

|

The

existing soil will be excavated by excavators while the general fill will be

placed by backhoes. After finishing the excavation and filling

works, the surface of soil will be further compacted by vibratory rollers.

|

|

Construction of Bored Pile Foundation and Soldier

Pile Foundation for the Retaining Walls

|

For the construction of retaining

walls with bored pile foundation, piling rigs will be mobilized to drill the

holes. The steel case will be inserted and the piles will be tremie concreted

by concrete pump. For the construction of retaining walls with soldier pile foundation,

piling rigs will be mobilized to drill the holes. The H piles will be

inserted and tremie grouting will be carried out. This

method is mainly used in site formation to allow minimise the change in the

groundwater hydrology connecting to the wet woodland.

|

|

Construction of Reinforced Concrete (RC) L-shape

retaining walls for roads

|

For

the construction of L-shape retaining wall, backhoes will be deployed for the

excavation of soil and then excavation lateral support will be installed for

temporary support against the pressure of soil. These two steps will be

repeated until reaching the formation level. After that, construction of the

L-shape retaining wall will be started and follow by the backfilling of soil

to the finish level. This retaining structure will be mainly used in road

widening work.

|

|

Construction of soil nailing

|

For the soil nailing

works, metal scaffolding will be erected and nail locations will be set out

on site. Drilling rigs will be

mobilized to form the holes and the steel reinforcement will be inserted.

Tremie grouting will be carried out and the sprayed concrete will be applied

on the nail heads. Where applicable, the construction method of soil nail is faster

and causes less environmental impact compared to other retaining

structures.

|

3.4.2.6

For the construction of retaining walls for site platform in

particular, the foundation design has considered the use of D-wall or pipepiles.

However, the use of D-wall or pipepiles may affect the groundwater hydrology to

the wet woodland. Therefore, the use of bored piles for the retaining wall has

been selected to allow passage of groundwater to the wet woodland. More details

have been discussed in Section 6.5.

3.4.3

Widening of Sha Ling Road & Internal Roads

Sha Ling Road

3.4.3.1

In order to fully utilize the existing Sha Ling Road, about 900m of the

existing Sha Ling Road (approximately 3m wide) would need to

be widened. That section will be widened to a single

two-lane carriageway with a width of 7.3m and with a 3m footpath

on both sides as the main access to the Columbarium site (except the portion

beside the pick-up / drop-off area which is single two-lane carriageway with 4m

footpath on both sides).

3.4.3.2

Vehicular traffic can then access the

Columbarium site via the internal road, which is also designed as single

two-lane carriageway with 2m to 4m footpath on both sides.

3.4.3.3

Both the widening of Sha Ling Road and the internal roads would

require site formation, cut-&-fill and slope retaining structures. The

construction methodology would be similar to those for the site formation work

for the platform although the scale of work involved would be less extensive.

3.4.3.4

For the at-grade section of Sha Ling Road in particular, the existing ground level will

be excavated to the soffit level of proposed manhole. The manhole will be constructed and the pipe

will be laid after the completion of excavation. Subsequently, backfilling with

granular sub base and bituminous material will be carried out by excavator and

road grinder.

3.4.3.5

It should be noted that part of Sha Ling Road would require the

installation of noise barrier as a noise mitigation measures to abate road

traffic noise (see Section 5). The total length of the proposed noise

barrier is approximately 185m. These noise barriers would involve using concrete

footings or mini-piles for the foundation and light weight panels installed to achieve

the designated height. According to the

requirements in Guidelines on Design of Noise Barrier by Environmental

Protection Department and Highways Department in 2003, the lower portion of the

noise barriers would be installed with sound absorptive panels.

3.4.3.6

For the foundation of using mini-piles, piling rigs

will be mobilized to drill the holes first. After that, the existing ground level will be excavated to

the formation level of footing by backhoes. If there are proposed underground

utilities, they will be installed before backfilling soil. After laying underground

utilities, soil compaction by vibratory rollers would be carried out after soil

backfilling. Finally the noise barrier will be installed by mobile cranes.

Internal Roads

3.4.3.7

The upgrading of an

existing short section of Sha Ling Road to MacIntosh Fort and the proposed

roundabout as turnaround facility for vehicles is considered necessary. The internal roads with dead end

aligned on the slope near the proposed open car park are emergency vehicular

access (EVA) for the columbarium buildings, and EVA is required according to Architectural

Services Department’s (ArchSD) design standard to comply with the Code of

Practice for Fire Safety in Buildings.

3.4.4

New Road connecting Crematorium Site and Man Kam To Road

3.4.4.1

A new road junction at Man Kam To Road will

be formed to allow the vehicular access to the Crematorium site via the at-grade road and a

new viaduct, which will link to the internal loop surrounding crematorium and

funeral parlour. This new road is designed as single two-lane carriageway with

7.3m in width and 2m footpath on both sides.

3.4.4.2

For the at-grade section, the existing ground level will be excavated

to the soffit level of proposed manhole.

The manhole will be constructed and the pipe will be laid after the

completion of excavation. Subsequently, backfilling with granular sub base and

bituminous material will be carried out by excavators and road grinders.

3.4.4.3

For the viaduct section which is

approximately 300m long, the existing ground level will be excavated to the

soffit level of footing by excavator. Drilling will be carried out by piling

rig or earth auger. The mini piles or bored piles would be adopted. The pad

footing will be constructed and concreted by concrete pumps. Steel

reinforcement of column will be fixed with concrete casted in-situ by concrete

pumps. The falseworks and formworks will be installed and the decking will be

constructed afterwards by in-situ concreting.

3.4.5

Pick-up and Drop-off Point at Man Kam To Road

3.4.5.1

A pick-up

and drop-off point for the mini-buses, taxis and private cars is proposed at

Man Kam To Road as these vehicles are not allowed to go uphill during the

festive periods.

3.4.5.2

Site clearance will be carried out to remove

the obstruction.

After that, the existing concrete paving will be broken and then soil

excavation to the formation level will be carried out. The proposed underground

utilities and sewage will be installed and finally, backfilling

with granular sub base and bituminous material will be carried out by excavators

and road grinders.

3.4.6

Widening of Lin Ma Hang Road

3.4.6.1

The existing Lin Ma Hang Road is approximately 6m wide and will need

to be widened to single two-lane carriageway with 7.3m in width and a 2m footpath on

both sides. However, Lin Ma Hang Road does not involve

site formation instead it only involves minor slope works.

3.4.6.2

The existing ground level will be excavated

to the soffit level of proposed manhole.

The manhole will be constructed and the pipe will be laid after the

completion of excavation. Subsequently, backfilling with granular sub base and

bituminous material will be carried out by excavator and road grinder.

3.4.6.3

Apart from the roadwork, the construction of Lin Ma Hang Road may involve some

construction of retaining structures. The size of retaining structure is

relatively small compared to that of site formation at Sandy Ridge. Soil nail

will be mainly adopted as its construction method cause less disruption to traffic

and less environmental impact compared to other retaining

structure.

3.4.6.4

Similar to Sha Ling Road, some section of Lin Ma Hang Road will require

noise barrier to abate road traffic noise impacts on sensitive receivers in the

vicinity. The total length of the proposed noise barrier is approximately 400m.

These noise barriers would involve using concrete footings or minipiles for the

foundation and light weight panels installed to achieve the designated

height. According to the requirements in

Guidelines on Design of Noise Barrier by Environmental Protection Department

and Highways Department in 2003, the lower portion of the noise barriers would

be installed with sound absorptive panels.

3.5

Preferred Construction

Methodology – Works Outside Columbarium / Crematorium Site

3.5.1.1

There is a total of 4 pick-up / drop-off points outside the columbarium

/ crematorium site as mentioned in Section

3.1.1.2. Most of these pick-up / drop-off points would only require

temporary and minor modification to the current existing facilities. There

are permanent works proposed only at MTR Fanling Station and existing Sheung Shui Landmark North. For MTR Kwu Tung Station (including the PTI and shuttle bus services

area), it will be constructed under the Planning and Development

Study on North East New Territories (NENT) Contract and will be

available by 2026. The description and construction methods are presented in the sections below.

3.5.2

MTR Fanling Station

3.5.2.1

In order to provide adequate bus lay-bys for pick-up

and drop-off, some of the existing planters

on Fanling Station Road and San Wan Road need

to be removed to provide sufficient area for shuttle bus boarding /alighting. In addition, to avoid blockage of lane due to any broken

down bus, the physical barriers at the

Fanling Station Road pickup point will be demolished to provide ample room for

bypassing.

3.5.2.2

Besides, some of the existing planters on Fanling Station Road and

San Wan Road will be removed. The trees in the planters will be affected and

subject to the tree removal application to be submitted later. One backhoe and one hand-held

breaker will then be deployed to break the planter and the debris will be disposed

of by truck. Finally, the concerned area will be constructed as the pedestrian

footpath.

3.5.3

Sheung Shui Landmark North

3.5.3.1

It is noted that there is

an existing KMB bus route 73K serving grave sweepers between Sheung Shui and

existing Sandy Ridge Cemetery. It is proposed to provide a vehicular

opening connecting the Sheung Shui Landmark North PTI and Lung Sum Avenue to avoid the detour of bus

heading towards Man Kam To Road direction.

3.5.3.2

In order to achieve this, a portion of the

existing traffic island would need to be retrofit to allow for a new vehicular

opening. The road surface will then be reinstated by concreting.

3.5.4

Drainage, Sewerage, Waterworks and Utility Works

3.5.4.1

All the site formation works, road widening works, new road construction

etc. would inevitably require re-routing of existing drainage, sewerage, waterworks and utility

works.

3.5.4.2

The construction method of laying drainage, sewage, waterworks and

underground utility is similar. The

first stage will be to have trial pits to identify underground drainage and

underground utility. After that, the existing ground level will be excavated to

the formation level of proposed drainage and underground utility. If the depth of trench is large (typically

deeper than 1.2m), necessary excavation lateral support (ELS) will be against

the pressure of soil. Installation of drainage will then be carried out after

flattening and clearing the formation level. Soil will then be backfilled by

backhoes and compacted by vibratory rollers. Finally, the concrete paving will

be reinstated

by concreting

3.5.5

Temporary Works Sites / Areas

3.5.5.1

In order to

minimise the potential disturbance and impact to the public and environment,

the major works sites / areas are typically located at the site of the

permanent works. To support the construction of the Project, additional

temporary works areas would be required within project boundary for the

provision of site office, storage of materials, utility, temporary traffic

management scheme, temporary accesses / bridges, silos and ground treatment.

The locations of works areas have been selected with consideration of their accessibility

and suitability for construction works and future permanent facilities. The EIA

report has included locations of the works sites / areas for the Project and

indicated the project boundary (as indicated in Figures 1.1

and 1.2) within

which minor activities / works for supporting the construction of the Project

may occur based on the latest information at the time of writing.

3.5.5.2

As mentioned in Section 1.3 and shown in

Figure 1.3, a barging point is added and is

located off-site along Tsing Fat Street in Tuen Mun. The site is being utilised

as an existing barging point, no maintenance dredging and no night time

operation are anticipated. Minor construction works for the tipping halls and

new ramps are required.

3.5.5.3

Subject to actual site conditions and

constraints, minor preparatory works could also be required to be conducted in

and around the project boundary indicated in the EIA report. However,

these would only be short-term without inducing major environmental

implications to nearby sensitive receivers. With the implementation of

appropriate standard control measures and good site practices for construction

works, no adverse environmental impact would be anticipated.