1.4 Scope

of the EM&A Programme

1.5 Works

Programme & Works Locations

1.6 Organisation

& Structure of the EM&A

1.7 Structure

of the EM&A Manual

2.1 Introduction

3.2 Operation

Phase

5 Noise

6.1 Introduction

6.2 Sampling

& Testing Methodology

6.4 Sampling

Depths & Replication

7.1 Introduction

7.2 Waste

Management Practices

9 Ecology

10 Fisheries

13 Health

14 Environmental

Site Inspection

14.1 Site

Inspections

14.2 Compliance

with Legal & Contractual Requirements

14.4 Log-Book

15 Reporting

15.1 General

15.2 Baseline

Water Quality Monitoring Report

15.3 Post-Construction

Water Quality Monitoring Report

15.4 Monthly

EM&A Reports

15.5 Quarterly

EM&A Summary Report

15.6 Annual/

Final EM&A Review Reports

15.7 Water

Quality Monitoring Report for the First Year of Additional CCGT Commissioning

15.8 Data

Keeping

15.9 Electronic

Reporting of EM&A Information

15.10 Interim

Notifications of Environmental Quality Limit Exceedances

Annex A Implementation Schedule

Annex B Proforma

for Construction Phase EM&A Programme

1

Introduction

1.1

Purpose

of the Manual

This

Environmental Monitoring and Audit

(EM&A) Manual (��the Manual��) has been prepared by ERM-Hong Kong,

Limited (ERM) on behalf of The Castle Peak Power Company Limited (CAPCO). The Manual is a supplementary document

to the Environmental Impact Assessment (EIA) Report of the Additional Gas-fired

Generation Units Project at the Black Point Power Station (BPPS) (hereafter

referred to as the Project).

The

Manual has been prepared in accordance with the EIA Study Brief (No. ESB-286/2015) and the Technical Memorandum of the Environmental Impact Assessment Process

(EIAO-TM). The purpose of the

Manual is to provide information, guidance and instruction to personnel charged

with environmental duties and those responsible for undertaking EM&A work

during Project construction and operation.

It provides systematic procedures for monitoring and auditing the

environmental performance of the Project.

This

Manual contains the following information:

�P

Responsibilities

of the Contractor(s) for Project construction, Environmental Team (ET), and the

Independent Environmental Checker (IEC) with respect to the EM&A

requirements during the course of the Project;

�P

Project

organisation;

�P

Requirements

with respect to the construction and operational programme schedule and the

necessary EM&A programme to track the environmental impact;

�P

Details

of the methodologies to be adopted including field, laboratory and analytical

procedures, and details on quality assurance and quality control programme;

�P

Preliminary

definition of Action and Limit levels;

�P

Establishment

of Event and Action plans;

�P

Requirements

for reviewing pollution sources and working procedures required in the event of

exceedances of applicable environmental criteria and/or receipt of complaints;

�P

Requirements

for presentation of EM&A data and appropriate reporting procedures; and

�P

Requirements

for review of EIA predictions and the effectiveness of the mitigation

measures/environmental management systems and the EM&A programme.

1.2

Project

Description

1.2.1

Site Location

Black Point, where the BPPS

is situated, is located in the western-most part of the New Territories. It comprises a headland extending from

the east (land) to the west (sea) with granitic soil underneath, typical of the

Tuen Mun and Castle Peak

areas. The major development at

Black Point is the BPPS, which is the first natural gas-fired power plant in

Hong Kong. The BPPS is located to

the north of the headland on reclaimed land. Reclamation in Black Point was completed

in 1993 followed by construction of the BPPS and commencement of operation in

1996. BPPS is surrounded by

mountain to the east and south while to the immediate north and west is the

mouth of Deep Bay.

The proposed location for

the Project is within the existing boundaries of the BPPS site and the location

for each of the additional gas-fired generation units is illustrated in Figure 1.1.

The size of the land reserved for the additional generation units and

the associated facilities (the Project Site) is about 40,000 m2. The reserved land has been used for

material storage in warehouses and temporary structures. The northern half of the reserved land

is not occupied by any buildings or facilities, whereas the southern half is

occupied by a single storey warehouse.

There are no other facilities or utilities within the reserved land

except the surrounding chain link fence.

1.2.2

Project Scope

The scope of the Project

involves the phased construction and operation of up to two additional CCGT

units (with an installed capacity of up to 600 MW each) at the BPPS. The additional generation units will be

of combined

cycle gas turbine (CCGT) configuration using natural gas as the primary fuel,

thereby providing a cleaner source of electricity for Hong Kong. The Project is comprised of the

following key components:

�P

Up

to two CCGT units;

�P

Cooling

water intake facility and discharge facility;

�P

Alternation

of temporary warehouse;

�P

Civil

works and electrical / mechanical installation works for the CCGT units; and

�P

Infrastructure

for making connections (fuel gas, fuel oil, electricity supply, water supplies,

auxiliary gas supplies, etc.) from existing plant equipment in BPPS and their

associated engineering works for enhancement / additions of equipment.

The location of these

components is shown in Figures 1.2a and 1.2b.

The

following elements of the Project addressed in this EIA Report are classified

as Designated Projects under the Environmental

Impact Assessment Ordinance (Cap. 499) (EIAO):

�P

Installation

of additional gas-fired generation unit(s) in phases at the BPPS (Schedule 2,

Part I, Item D.1 - Public utility electricity power plant); and

�P

If

a second unit is to be installed, a dredging operation less than 100 m from the

BPPS seawater intake location would be required (Schedule 2, Part I, Item

C.12(b) - A dredging operation which is less than 100 m from a seawater intake

point).

1.3

Objective

of the EM&A

The

broad objective of this Manual is to define the procedures of the EM&A

programme for monitoring the environmental performance of the Project during

design, construction and operation.

The construction and operational impacts arising from the implementation

of the Project are specified in the EIA Report. The EIA Report also specifies mitigation

measures and construction practices that may be needed to confirm compliance

with the environmental criteria.

These mitigation measures and their implementation requirements are

presented in the Implementation Schedule of Mitigation Measures (Annex A).

The

main objectives of the EM&A programme are to:

�P

provide

a database of environmental parameters against which to determine any short

term or long term environmental impacts;

�P

provide

an early indication should any of the environmental control measures or

practices fail to achieve the acceptable standards;

�P

confirm

that the mitigation recommendations of the EIA are included in the design of

the Project;

�P

clarify

and identify potential sources of pollution, impact and nuisance arising from

the works for the responsible parties;

�P

confirm

compliance with regulatory requirements, contract specifications and EIA study

recommendations;

�P

confirm

compliance of environmental designs during the design phase of the Project with

the specifications stated in the EIA Report and the Environmental Permit (EP);

�P

monitor

performance of the mitigation measures and to assess their effectiveness;

�P

take

remedial action if unexpected issues or unacceptable impacts arise;

�P

verify

the environmental impacts predicted in the EIA; and

�P

audit

environmental performance.

1.4

Scope of the

EM&A Programme

The

scope of this EM&A programme is to:

For

both CCGT Unit No.1 and No.2:

�P

implement

inspection and audit requirements for waste management;

�P

liaise

with, and provide environmental advice (as requested or when otherwise

necessary) to construction site staff on the significance and implications of

the environmental monitoring data;

�P

identify

and resolve environmental issues and other functions as they may arise from the

works;

�P

check

and quantify the Contractor(s)��s overall environmental performance,

implementation of Event and Action Plans (EAPs), and remedial actions taken to

mitigate adverse environmental effects as they may arise from the works;

�P

conduct

monthly reviews of monitored impact data as the basis for assessing compliance

with the defined criteria and to verify that necessary mitigation measures are

identified and implemented, and to undertake additional ad hoc monitoring and

auditing as required by special circumstances;

�P

evaluate

and interpret environmental monitoring data to provide an early indication

should any of the environmental control measures or practices fail to achieve

the acceptable standards, and to verify the environmental impacts predicted in

the EIA;

�P

manage

and liaise with other individuals or parties concerning other environmental

issues deemed to be relevant to the construction process;

�P

conduct

regular site inspections and audits of a formal or informal nature to assess:

(i) the

level of the Contractor(s)��s general environmental awareness;

(ii) the

Contractor(s)��s implementation of the recommendations in the EIA and their

contractual obligations;

(iii) the

Contractor(s)��s performance as measured by the EM&A;

(iv) the

need for specific mitigation measures to be implemented or the continued usage

of those previously agreed;

(v) to

advise the site staff of any identified potential environmental issues; and

�P

produce

monthly EM&A reports which summarise project monitoring and auditing data,

with full interpretation illustrating the acceptability or otherwise of any

environmental impacts and identification or assessment of the implementation

status of agreed mitigation measures.

�P

establish

baseline water quality levels at specified locations and implement monitoring

requirements for water quality monitoring programme; and

�P

implement

monitoring requirements for marine mammal monitoring programme.

1.5

Works

Programme & Works Locations

The

preliminary construction programme is given in Figure 1.3. The locations of works are shown in Figure 1.1.

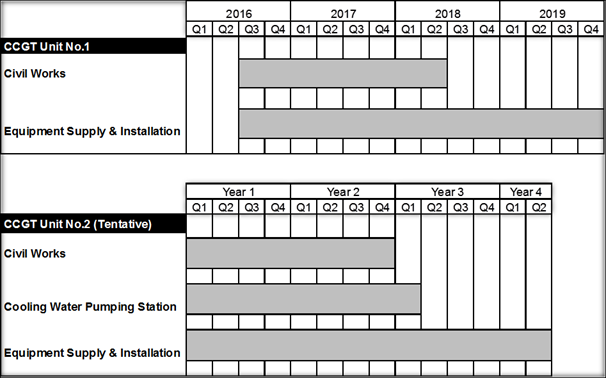

Figure 1.3 Preliminary

Construction Programme of the Project

1.6

Organisation

& Structure of the EM&A

The

EM&A will require the involvement of CAPCO, an ET, an IEC and the

Contractor(s). The roles and

responsibilities of the various parties involved in the EM&A process are

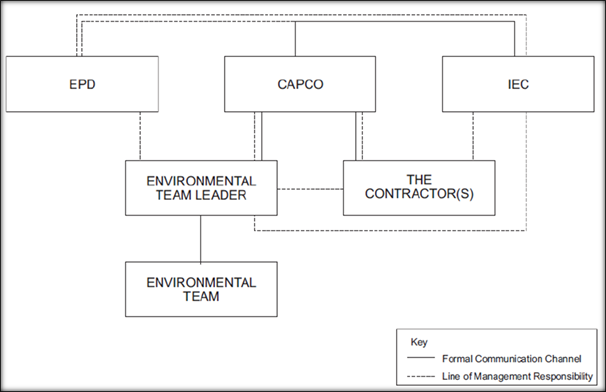

further expanded in the following sections and in Figure 1.4.

Figure 1.4 Indicative Project

Organisation Chart

CAPCO

will appoint an ET to conduct the site inspection and monitoring and, to

provide specialist advice on the undertaking and implementation of

environmental responsibilities. The

ET will be led and managed by the ET Leader. The ET Leader will have relevant

education, training, knowledge, experience and professional qualifications and

the appointment will be subject to the approval of the Director of

Environmental Protection. Suitably

qualified staff will be included in the ET, and the ET should not be in any way

an associated body of the Contractor(s) for Project construction. For the purpose of this Manual, the ET

Leader, who will be responsible for, and in charge of, the ET, is referred to

as the person delegated the role of executing the EM&A requirements.

To

maintain strict control of the EM&A process, CAPCO will appoint independent

environmental consultants to act as an IEC to verify and validate/ audit the

environmental performance of CAPCO��s Contractor(s) for Project construction and

effectiveness of ET. The IEC will

have previous relevant experience with checking and auditing similarly sized

EM&A programmes and the IEC will be a recognised environmental

professional. Sufficient and

suitably qualified professional and technical staff will be employed by the

IEC, as required under the EM&A programme for the duration of the Project.

CAPCO

will:

�P

employ

an ET as described above;

�P

employ

an IEC as described above;

�P

supervise

the Contractor(s)�� activities and confirm that the requirements in the EM&A

Manual and the Contract Document are fully complied with;

�P

develop

appropriate contract clauses to confirm that the Contractor(s) will have

qualified professionals to interface with the ETL/CAPCO/IEC to fulfil the

EIA/EP requirements;

�P

inform

the Contractor(s) when action is required to reduce impacts in accordance with

the Event and Action Plans;

�P

adhere

to the procedures for carrying out complaint investigation; and

�P

participate

in joint site inspections undertaken by the ET and IEC.

The

Contractor(s) for Project construction will:

�P

work

within the scope of the construction contract and other tender conditions;

�P

provide

assistance to the ET in carrying out monitoring and site inspections;

�P

submit

proposals on mitigation measures in case of exceedances of Action and Limit

levels in accordance with the Event and Action Plans;

�P

implement

measures to reduce impact where Action and Limit levels are exceeded;

�P

implement

the corrective actions instructed by CAPCO/ET/IEC;

�P

participate

in the site inspections undertaken by the ET and the IEC, as required, and

undertake any corrective actions instructed by CAPCO/ETL/IEC; and

�P

adhere

to the procedures for carrying out complaint investigation.

The

ET will:

�P

monitor

various environmental parameters as required in this EM&A Manual;

�P

assess

the EM&A data and review the success of the EM&A programme determining

the adequacy of the mitigation measures implemented and the validity of the EIA

predictions as well as identify any adverse environmental impacts before they

arise;

�P

carry

out regular site inspection to investigate the Contractor(s)��s site practice,

equipment and work methodologies with respect to pollution control and

environmental mitigation, and effect proactive action to pre-empt issues;

�P

review

the Contractor(s)��s working programme and methodology, and comment as

necessary;

�P

provide

advice (if required) to CAPCO for the development of environmental contract

clauses for contractor contract;

�P

review

and prepare reports on the environmental monitoring data and site environmental

conditions;

�P

report

on the environmental monitoring results and conditions to the IEC,

Contractor(s), EPD and CAPCO;

�P

�Precommend

suitable mitigation measures to the Contractor(s) in the case of exceedance of

Action and Limit levels in accordance with the Event and Action Plans; and

�P

adhere

to the procedures for carrying out complaint investigation.

The

IEC will:

�P

review

and audit the implementation of the EM&A programme and the overall level of

environmental performance being achieved;

�P

arrange

and conduct monthly independent site audits of the works;

�P

validate

and confirm the accuracy of monitoring results, monitoring equipment,

monitoring stations, monitoring procedures and locations of sensitive

receivers;

�P

audit

the EIA recommendations and requirements against the status of implementation

of environmental protection measures on site;

�P

on

an as needed basis, audit the Contractor(s)��s construction methodology and

agree the appropriate, reduced impact alternative in consultation with CAPCO,

the ET and the Contractor(s);

�P

adhere

to the procedures for carrying out complaint investigation;

�P

review

the effectiveness of environmental mitigation measures and project

environmental performance including the proposed corrective measures;

�P

review

EM&A report submitted by the ET leader and feedback audit results to ET by

signing off relevant EM&A proformas; and

�P

report

the findings of site audits and other environmental performance reviews to

CAPCO, ET, EPD and the Contractor(s).

1.7

Structure

of the EM&A Manual

The

remainder of the Manual is set out as follows:

�P

Section

2 sets out the EM&A general requirements;

�P

Section

3 sets out the EM&A requirements for air quality;

�P

Section

4 sets out the EM&A requirements for hazard to human life;

�P

Section

5 sets out the EM&A requirements for noise;

�P

Section

6 details the requirements for water quality baseline and impact monitoring,

and lists relevant monitoring equipment, compliance and Event and Action Plans

(EAPs);

�P

Section

7 details the requirements for waste management;

�P

Section

8 details the requirements for land contamination;

�P

Section

9 details the requirements for ecology;

�P

Section

10 details the requirements for fisheries;

�P

Section

11 sets out the EM&A requirements for landscape and visual;

�P

Section

12 sets out the EM&A requirements for cultural heritage;

�P

Section

13 sets out the EM&A requirements for health;

�P

Section

14 describes the scope and frequency of site environmental inspection;

�P

Section

15 details the reporting requirements for the EM&A;

�P

Annex A contains the implementation schedule summarising

all mitigation measures proposed in the EIA Report; and

�P

Annex B contains

the monitoring and complaint log sheets.

2

EM&A

General Requirement

2.1

Introduction

In this section, the

general requirements of the EM&A programme for the Project are

presented. The scope of the

programme is developed with reference to the findings and recommendations of

the EIA Report.

It

should be noted that the construction and operation of the two proposed

additional CCGT units, namely CCGT Units No.1 and No.2, are phased. The required EM&A exercises

stipulated in this Manual are applicable to the construction and operation of

both units unless otherwise specified in the corresponding sections. A summary of the requirements for each

of the environmental parameters in each stage of the Project is detailed in Table 2.1.

Table 2.1 Summary of EM&A Requirements

for the Project

|

Parameters |

EM&A Requirement |

||||

|

Design

Phase (1) |

CCGT Unit No.1 |

CCGT Unit No.2 |

|||

|

Construction

Phase |

Operation

Phase |

Construction

Phase |

Operation

Phase |

||

|

Air

Quality |

- |

ü

(SI) |

ü |

ü

(SI) |

ü |

|

Hazard

to Human Life |

ü |

ü

(SI) |

- |

ü

(SI) |

- |

|

Noise |

- |

ü

(SI) |

- |

ü

(SI) |

- |

|

Water

Quality |

- |

ü

(SI) (2) |

ü |

ü

(2) |

ü |

|

Waste |

- |

ü

(SI) |

- |

ü

(SI) |

- |

|

Land

Contamination |

- |

ü

(SI) |

- |

ü

(SI) |

- |

|

Ecology |

- |

ü

(SI) |

- |

ü

(SI) |

- |

|

Fisheries |

- |

- |

- |

- |

- |

|

Landscape

& Visual |

ü |

ü

(SI) |

- |

ü

(SI) |

- |

|

Cultural

Heritage |

- |

- |

- |

- |

- |

|

Health |

- |

- |

- |

- |

- |

|

Notes: ��

(SI) ��= Site Inspection forms the main checking method; ��- �� = no EM&A required |

|||||

|

(1) EM&A

requirements in the design phase shall include confirmation on the compliance

for environmental designs which were specified in the EIA Report and the EP

for all parameters. (2) For

the construction phase of the CCGT Unit No.1, no marine construction works

would be required. Therefore

construction phase marine water quality monitoring exercise is only required

for the construction phase of the CCGT Unit No.2. |

|||||

2.2

Construction Phase EM&A

2.2.1

General

Potential environmental

impacts, which were identified during the EIA study and are associated with the

construction phase of the Project, will be addressed through the monitoring and

controls specified in this EM&A Manual and in the construction contracts.

During the construction

phases of the Project (for both CCGT Units No.1 and

No.2), air

quality, hazard to human life, noise, water quality, waste management, land

contamination, ecology, and landscape and visual will be subject to EM&A,

with environmental monitoring being undertaken for water quality for the

construction phase of the CCGT Units No.2 as determined in the

EIA. Monitoring of the

effectiveness of the mitigation measures will be achieved through the

environmental monitoring programme as well as through site inspections. The inspections will include within

their scope, mechanisms to review and assess the Contractor(s)��s environmental

performance, ensuring that the recommended mitigation measures have been

properly implemented, and that the timely resolution of received complaints are

managed and controlled in a manner consistent with the recommendations of the

EIA Report.

2.2.2

Environmental Monitoring

The environmental

monitoring work throughout the Project will be carried out in accordance with

this Manual and reported by the ET.

Monitoring works is only required during the construction phase of CCGT

Unit No.2 and will cover water quality and marine mammal monitoring.

2.2.3

Action and Limit Levels

Action and Limit (A/L)

Levels are defined levels of impact recorded by the environmental monitoring

activities which represent levels at which a prescribed response is

required. Since environmental

monitoring is only required for the construction phase of CCGT Unit No.2,

details on these Levels are provided in the Water Quality Section (Section 6).

2.2.4

Event and Action Plans

The purpose of the Event

and Action Plans (EAPs) is to provide, in association with the monitoring and

audit activities, procedures for ensuring that if any significant environmental

incident occurs, the cause will be quickly identified and remediated. This also applies to the exceedances of

A/L criteria identified in the EM&A programme.

2.2.5

Site Inspections

In addition to monitoring,

as a means of assessing the ongoing performance of the Contractor(s) for

Project construction, the ET will undertake site inspections of the compliance

with stipulated procedures and on-site practices. The primary objective of the inspection

and audit programme will be to assess the effectiveness of the environmental

controls established by the Contractor(s) and the implementation of the

environmental mitigation measures recommended in the EIA Report. The IEC will undertake site audits on as

need basis to assess the performance of the Contractor(s).

Whilst the audit and

inspection programme will complement the monitoring activity, the criteria

against which the audits will be undertaken will be derived from the Clauses

within the Contract Documents which seek to enforce the recommendations of the

EIA Report and the EM&A Manual.

The findings of site

inspections and audits will be made known to the Contractor(s) at the time of

the inspection to enable the rapid resolution of identified

non-conformities. Non-conformities,

and the corrective actions undertaken, will also be reported in the monthly

EM&A Reports.

Section

14 of this Manual presents details of

the scope and frequency of on-site inspections and defines the range of issues

that the audit protocols will be designed to address.

2.2.6

Enquiries, Complaints and

Requests for Information

Enquiries, complaints and

requests for information may occur from a wide range of individuals and

organisations including members of the public, Government departments, the

press and community groups.

All enquiries concerning

the environmental impacts of the Project, irrespective of how they are

received, will be reported to CAPCO and IEC and directed to the ET who should

set up procedures for handling, investigation and storage of such

information. The following steps

should be followed:

(1) The

ET Leader should notify the IEC and CAPCO of the nature of the enquiry.

(2) An

investigation should be initiated to determine the validity of the complaint

and to identify the source(s) of the problem.

(3) The

ET Leader should undertake the following steps, as necessary:

�P

investigate

and identify source(s) of the problem, with assistance from CAPCO and relevant

Contractor(s);

�P

if

considered necessary by CAPCO following consultation with the IEC, undertake

additional monitoring to verify the existence and severity of the alleged

complaint;

�P

identify

necessary remedial measures and implement as soon as possible;

�P

if

the complaint is transferred from EPD, submit interim report to EPD on status

of the complaint investigation and follow-up action within the time frame

assigned by EPD;

�P

repeat

the monitoring to verify effectiveness of mitigation measures; and,

�P

repeat

review procedures to identify further possible areas of improvement if the

repeat monitoring results continue to substantiate the complaint.

(4) The

outcome of the investigation and the action taken will be documented on a

complaint log (Annex B). A formal response to each complaint

received will be prepared by the Contractor(s) within five working days and

submitted to CAPCO, in order to notify the concerned person(s) that action has

been taken.

(5) All

enquiries/complaints that trigger this process should be reported in the

monthly EM&A reports, which should include results of investigations

undertaken by the ET Leader, and details of the measures taken, and additional

monitoring results (if deemed necessary).

It should be noted that the receipt of complaint or enquiry should not

be, in itself, a sufficient reason to introduce additional mitigation

measures.

The complainant will be

notified of the findings, and audit procedures will be put in place to verify

that the issue does not recur.

2.2.7

Reporting

Baseline, construction

phase and post-construction phase monitoring, monthly, and annual/final reports

will be prepared and certified by the ET Leader and verified by the IEC. The reports will be submitted to CAPCO

and EPD. The monthly reports will

be prepared and submitted within two weeks of the end of each calendar month.

2.2.8

Cessation of EM&A

The cessation of EM&A

programme is subject to the satisfactory completion of the EM&A Final

Report, agreement with the IEC and approval from EPD.

2.3

Operation Phase EM&A

Based on the findings of

the EIA, air and water quality monitoring during operation phase of both CCGT

Units is considered necessary.

Monitoring of any planting works should also continue over their

establishment period, which may extend into the operation phase, and will be

covered by regular site inspections.

Other operational licences will require specific monitoring or audit

conditions or practices, and a non EIA EM&A practice will need to be put in

place.

3

Air

Quality

3.1

Construction

Phase

The EIA study concluded

that no adverse fugitive dust impact is anticipated during the construction of

CCGT Units No.1 and No.2, and dust monitoring is considered not necessary. However, it is recommended to conduct

regular environmental site audit, i.e. on weekly basis, to confirm the

implementation of the dust control measures and good site practices as

recommended in Section 4.10.1 of the

EIA Report throughout the construction of these two units. These measures are also summarised in the

Implementation Schedule provided in Annex A.

3.2

Operation

Phase

Based on the prediction of

the air quality modelling exercise conducted under this EIA study, no adverse

air quality impact is anticipated during the operation of the additional CCGT

units. Air pollutants of the

exhaust gas streams emitted from the stacks of the CCGT units will be

continuously monitored and recorded by means of Continuous Emission Monitoring

System (CEMS) per the licence requirements.

Existing continuous

monitoring of ambient concentrations of SO2, NO and NO2

will be continued at the current CLP��s air quality monitoring stations, as

required by specific emissions licences.

4

Hazard

to Human Life

The

EIA study concluded that the individual risk and societal risks posed by the

proposed Project and the existing BPPS facilities for both construction and

operation phases are acceptable and in compliance with risk criteria in Section 2 of Annex 4 of EIAO-TM. No unacceptable risks are foreseen as a

result of the operation of the proposed Project. No mitigation measures are thus deemed

necessary and no monitoring will be required for the construction and operation

phases. Safety management measures

are recommended to further manage and minimise the external hazards from

constructions activities risk during the construction phase of the two

units. They are summarised in the

Implementation Schedule provided in Annex A.

CAPCO

is a registered gas supply company and will periodically review and update the

risk assessment associated with the operations of the natural gas facilities

under the Gas Safety Ordinance to

demonstrate that the members of the public are not exposed to undue risks.

5

Noise

Noise monitoring is considered not necessary during both construction and

operation phases of the proposed Project.

Monthly site inspections and audits are recommended to be carried out

during the construction phase of the two units in order to confirm that

regulatory requirements are being met.

6

Water Quality

6.1

Introduction

In accordance with the

recommendations of the EIA, water quality EM&A is required during dredging

at the cooling water intake and discharge outfall for construction of CCGT Unit

No.2 and operation phase maintenance dredging. In addition, baseline water quality

monitoring will be required prior to the commencement of marine construction

activities of CCGT Unit No.2. The following sections provide details of the

water quality monitoring to be undertaken by the ET to verify the distance of

sediment and thermal plume dispersion and to identify whether the potential

exists for any indirect impacts to occur to ecological sensitive receivers. The water quality monitoring programme

will be carried out to allow any deteriorating water quality to be readily

detected and timely action taken to rectify the situation. The status and locations of water

quality sensitive receivers and the marine works location may change after

issuing this Manual. If required,

the ET in consultation with IEC will propose updated monitoring locations and

seek approval from EPD.

Water quality monitoring

for the Project can be divided into the following stages:

�P

Marine

water quality monitoring for dredging activities during construction phase of

the CCGT Unit No.2;

�P

Marine

water quality monitoring on first year of commissioning of the CCGT Unit No.1;

�P

Marine

water quality monitoring on first year of commissioning of the CCGT Unit No.2;

�P

Marine

water quality monitoring for maintenance dredging during operation phase of the

CCGT Unit No.2 and

�P

Regular

monitoring of effluent quality.

6.2

Sampling

& Testing Methodology

6.2.1

Water Quality Parameters

The parameters that have

been selected for measurement in situ and in the laboratory are those that were

either determined in the EIA to be those with the most potential to be affected

by the construction works or are a standard check on water quality

conditions. Parameters to be

measured in the construction phase, operation phase and effluent quality

monitoring are listed in Table 6.1.

Table

6.1 Parameters Measured

in the Marine Water Quality Monitoring

|

Parameters |

Unit |

Abbr. |

Marine Water Quality Monitoring |

Effluent Monitoring |

|||

|

Baseline |

Construction

and Maintenance Dredging of CCGT Unit No.2 |

First-year

Operation |

|||||

|

CCGT Unit No.1 |

CCGT Unit No.2 |

||||||

|

In situ

measurements |

|||||||

|

Dissolved

oxygen |

mg/L |

DO |

ü |

ü |

ü |

ü |

|

|

Temperature |

�XC |

- |

ü |

ü |

ü |

ü |

ü |

|

pH |

- |

- |

ü |

ü |

ü |

ü |

ü |

|

Turbidity |

NTU |

- |

ü |

ü |

|

|

|

|

Salinity |

‰ |

- |

ü |

ü |

ü |

ü |

|

|

Total

Residual Chlorine |

mg/L |

TRC |

ü |

|

ü |

ü |

ü |

|

Laboratory

measurements |

|||||||

|

Suspended

Solids |

mg/L |

SS |

ü |

ü |

|

|

|

In addition to the water quality

parameters, other relevant data will also be measured and recorded in Water

Quality Monitoring Logs, including the location of the sampling stations, water

depth, time, weather conditions, sea conditions, tidal stage, current direction

and velocity, special phenomena and work activities undertaken around the

monitoring and works area that may influence the monitoring results. A sample data record sheet is shown in Annex B for reference.

6.2.2

Monitoring Equipment

For water quality

monitoring, the following equipment will be used:

�P

Dissolved

Oxygen and Temperature Measuring Equipment - The instrument will be a portable,

weatherproof dissolved oxygen measuring instrument complete with cable, sensor,

comprehensive operation manuals, and will be operable from a DC power

source. It will be capable of

measuring: dissolved oxygen levels in the range of 0 - 20 mg L-1 and 0 - 200%

saturation; and a temperature of 0 - 45 degrees Celsius. It shall have a membrane electrode with

automatic temperature compensation complete with a cable of not less than 35 m

in length. Sufficient stocks of

spare electrodes and cables shall be available for replacement where necessary

(e.g. YSI model 59 DO meter, YSI 5739 probe, YSI 5795A submersible stirrer with

reel and cable or an approved similar instrument).

�P

Turbidity

Measurement Equipment

- The instrument will be a portable, weatherproof turbidity-measuring unit

complete with cable, sensor and comprehensive operation manuals. The equipment will be operated from a DC

power source, it will have a photoelectric sensor capable of measuring

turbidity between 0 - 1000 NTU and will be complete with a cable with at least

35 m in length (for example Hach 2100P or an approved

similar instrument).

�P

Salinity

Measurement Instrument

- A portable salinometer capable of measuring

salinity in the range of 0 - 40 ppt will be provided for measuring salinity of

the water at each monitoring location.

�P

Water

Depth Gauge

�V A portable, battery-operated echo sounder (for example Seafarer 700 or a

similar approved instrument) will be used for the determination of water depth

at each designated monitoring station.

This unit will preferably be affixed to the bottom of the work boat if

the same vessel is to be used throughout the monitoring programme. The echo sounder should be suitably

calibrated. The ET shall seek

approval for their proposed equipment with the client prior to deployment.

�P

Current

Velocity and Direction

�V No specific equipment is recommended for measuring the current velocity and

direction. The environmental

contractor shall seek approval of their proposed equipment with the client

prior to deployment.

�P

Positioning

Device

�V A Global Positioning System (GPS) shall be used during monitoring to allow

accurate recording of the position of the monitoring vessel before taking

measurements. The Differential GPS,

or equivalent instrument, should be suitably calibrated at appropriate

checkpoint (e.g. Quarry Bay Survey Nail) to verify that the monitoring station

is at the correct position before the water quality monitoring commence.

�P

Water

Sampling Equipment

- A water sampler, consisting of a PVC or glass cylinder of not less than two

litres, which can be effectively sealed with cups at both ends, will be used

(e.g. Kahlsico Water Sampler 13SWB203 or an approved

similar instrument). The water

sampler will have a positive latching system to keep it open and prevent

premature closure until released by a messenger when the sampler is at the

selected water depth.

�P

Total

Residual Chlorine

- Total residual chlorine (TRC) shall be measured in-situ using approved test

kit.

6.2.3

Sampling / Testing

Protocols

All in situ monitoring instruments will be checked, calibrated and

certified by a laboratory accredited under the Hong Kong Laboratory

Accreditation Scheme (HOKLAS) ([1])

or any other international accreditation scheme before use, and subsequently re-calibrated

at monthly intervals throughout the stages of the water quality

monitoring. Responses of sensors

and electrodes will be checked with certified standard solutions before each

use.

On-site calibration of

field equipment shall follow the ��Guide

to On-Site Test Methods for the Analysis of Waters��, BS 1427: 2009. Sufficient stocks of spare parts shall

be maintained for replacements when necessary. Backup monitoring equipment shall also

be made available so that monitoring can proceed uninterrupted even when

equipment is under maintenance, calibration etc.

6.2.4

Laboratory Measurement and

Analysis

All laboratory work shall

be carried out in a HOKLAS accredited laboratory. Sufficient volume of each water sample

shall be collected at the monitoring stations for carrying out the laboratory

analyses. Using chain of custody

forms, collected water samples will be transferred to an HOKLAS accredited

laboratory for immediate processing.

The determination work shall start within the next working day after collection

of the water samples. The

laboratory measurements shall be provided to the client within 5 working days

of the sampling event. Analytical

methodology and sample preservation of other parameters will be based on the

latest edition of Standard Methods for the Examination of Waste and Wastewater

published by American Public Health Association (APHA), American Water Works

Association (AWWA) and methods by USEPA, or suitable method in accordance with

requirements of HOKLAS or another internationally accredited scheme. The submitted information should include

pre-treatment procedures, instrument use, Quality Assurance/Quality Control

(QA/QC) details (such as blank, spike recovery, number of duplicate samples per-batch

etc.), detection limits and accuracy.

The QA/QC details shall be in accordance with requirements of HOKLAS or

another internationally accredited scheme.

Parameters for laboratory

measurements, their standard methods and their detection limits are presented

in Table 6.2.

Table

6.2 Laboratory

measurements, standard methods and corresponding detection limits of marine

water quality monitoring

|

Parameters |

Standard

Methods |

Detection Limit |

Reporting Limit |

|

Construction Phase |

|||

|

Dissolved

oxygen (mg/L) |

Instrumental,

CTD |

0.1 |

‒ |

|

Temperature

(�XC) |

Instrumental,

CTD |

0.1 |

‒ |

|

pH |

Instrumental,

CTD |

0.1 |

‒ |

|

Turbidity

(NTU) |

Instrumental,

CTD |

0.1 |

‒ |

|

Salinity

(‰) |

Instrumental,

CTD |

0.1 |

‒ |

|

Suspended

Solids (mg/L) |

APHA

2540E |

1.0 |

‒ |

|

Operation Phase |

|||

|

Dissolved

oxygen (mg/L) |

Instrumental,

CTD |

0.1 |

‒ |

|

Temperature

(�XC) |

Instrumental,

CTD |

0.1 |

‒ |

|

pH |

Instrumental,

CTD |

0.1 |

‒ |

|

Salinity

(‰) |

Instrumental,

CTD |

0.1 |

‒ |

|

Suspended

Solids (mg/L) |

APHA

2540E |

1.0 |

‒ |

|

Total

Residual Chlorine (mg/L) |

Test-kit

* |

* |

* |

*Note: The testing methods,

Quality Assurance/Quality Control (QA/QC) details, detection limits and

accuracy shall be submitted to EPD for approval prior to the commencement of

monitoring programme.

6.2.5

Monitoring Locations

The water quality

monitoring locations for baseline, construction and first-year operation phases

are shown in Figure 6.1

and detailed in Table 6.3 below. A schedule for water quality monitoring

shall be prepared by the ET and approved by IEC and EPD prior to the

commencement of the monitoring.

Table

6.3 Location of

Water Quality Monitoring Stations

|

Station |

Easting |

Northing |

Description |

Baseline |

Construction and

Maintenance Dredging |

First-year

Operation |

|

|

CCGT Unit No.1 |

CCGT Unit No.2 |

||||||

|

SR3 |

812234 |

832326 |

Ha

Pak Nai |

ü |

ü |

ü |

ü |

|

SR5 |

809170 |

829218 |

Lung

Kwu Sheung Tan |

ü |

ü |

ü |

ü |

|

SR6 |

804834 |

827940 |

Northwestern

corner of the Sha Chau and Lung Kwu Chau Marine

Park |

ü |

ü |

ü |

ü |

|

SR7 |

806218 |

827940 |

Northeastern

corner of the Sha Chau and Lung Kwu Chau Marine

Park |

ü |

ü |

ü |

ü |

|

SR14 |

812168 |

833209 |

Oyster

production area |

ü |

ü |

ü |

ü |

|

SR16 |

810349 |

831706 |

Seawater

intake of the Sludge Treatment Facilities |

ü |

ü |

|

|

|

SR18 |

808759 |

830684 |

Coral

colonies at the existing seawall of BPPS |

ü |

ü |

|

|

|

CE |

811708 |

834740 |

Control

station for ebb tide |

ü |

ü |

ü |

ü |

|

CF |

806912 |

826205 |

Control

station for flood tide |

ü |

ü |

ü |

ü |

Cooling water effluent from

BPPS shall be collected at a suitable location before discharge. The sampling location should be agreed

with CAPCO and EPD, and should fulfil the following requirements:

�P

Effluent

collected at the sampling location is representative to the effluent discharged

at the outfall diffuser;

�P

Sampling

works at the sampling location would not interfere with the normal operation of

the BPPS; and

�P

Sampling

works at the sampling location would not induce safety hazard.

The status and locations of

water quality sensitive receivers and the monitoring sites may change after

issuing this Manual. If such cases

exist, the ET shall propose updated monitoring locations and seek approval from

the IEC and EPD.

When alternative monitoring

locations are proposed, they shall be chosen based on the following criteria:

�P

at

locations close to and preferably at the boundary of the site activities as

indicated in the EIA Report, which are likely to have water quality impacts;

�P

close

to the sensitive receptors which are directly or likely to be affected;

�P

for

monitoring locations located in the vicinity of the sensitive receptors, care

should be taken to cause minimal disturbance during monitoring; and

�P

control stations which are at locations

representative of the project site in its undisturbed condition.

6.3

Sampling

Frequency

6.3.1

Baseline Monitoring

Baseline conditions for

water quality shall be established and agreed with the IEC and the EPD prior to

the commencement of marine dredging works for CCGT Unit No.2. The purpose of the baseline monitoring

is to establish ambient conditions prior to the commencement of the dredging

works and to demonstrate the suitability of the proposed control monitoring

stations. The baseline conditions shall normally be established by measuring

the water quality parameters specified above.

The measurements shall be

taken at all designated monitoring stations including control stations, at both

mid-ebb and mid-flood tides on the same day for a minimum of 3 days per week

for 4 weeks prior to the commencement of the construction works. Measurements shall be taken at each station

at any time. The interval between

two sets of monitoring shall not be less than 36 hours.

No construction activities

shall be on-going in the vicinity of the stations during the baseline

monitoring. The ET shall be

responsible for undertaking the baseline monitoring and submitting the results

within 10 working days from the completion of the baseline monitoring work.

In exceptional cases when

insufficient baseline monitoring data or questionable results are obtained, the

ET shall seek approval from the IEC and the EPD on an appropriate set of data

to be used as baseline reference.

The baseline monitoring

schedule shall be issued to the IEC and EPD at least 1 week prior to the

commencement of baseline monitoring.

6.3.2

Construction Phase

During periods when there

are dredging works, impact monitoring shall be undertaken at the monitoring

stations as shown in Figure 6.1 and Table 6.3 three times a week. Monitoring at each station would be

undertaken at both mid-ebb and mid-flood tides on the same day. The tidal range selected for the

baseline monitoring will be at least 0.5 m for both flood and ebb tides as far

as practicable. The interval

between two sets of monitoring would not be less than 36 hours. The monitoring frequency would be

increased in the case of exceedances of Action/Limit Levels if considered

necessary by ET. Monitoring

frequency would be maintained as far as practicable.

The monitoring

location/position, time, water depth, water temperature, salinity, weather

conditions, sea conditions, tidal stage, special phenomena and work underway at

the marine works site will be recorded.

6.3.3

Post-Construction Phase

Upon completion of all

marine construction activities, a post-construction water quality monitoring

exercise would be carried out for four weeks, in the same manner as the

baseline monitoring.

6.3.4

First-year of Additional

CCGT Commissioning

Upon commencement of CCGT

Unit No.1 and No.2, an operation phase water quality monitoring exercise shall

be carried out for one year, in the same manner as the baseline monitoring

except at a frequency of once per week.

Monitoring of cooling water

effluent quality shall be conducted daily for one year at specific location

agreed by IEC prior to the commissioning of the CCGT Unit No.1 or No.2. The monitoring exercise shall be conducted

in accordance with the effluent parameters and standards stipulated by the WPCO

Discharge Licence conditions and therefore would not be further detailed in

this Manual. The monitoring

requirement for the monitoring of cooling water effluent quality shall be

approved by EPD. The effluent results

reflect whether the effluent quality is in compliance with the Discharge

Licence requirements. In case of

non-compliance, suitable actions shall be undertaken to notify the plant

operator for the non-compliance and identify the cause for the non-compliance. Corrective and remedial actions shall be

implemented to improve the effluent quality. The non-compliance events and preventive

measures shall be documented.

6.3.5

Maintenance Dredging

In case maintenance

dredging at the seawater intake and / or discharge outfall of CCGT Unit No.2 is

required, the same water quality monitoring exercise, including baseline

monitoring (Section 6.3.1), impact monitoring (Section 6.3.2) and post-construction monitoring (Section 6.3.3) shall be conducted to before, during

and after the dredging works.

6.4

Sampling

Depths & Replication

For baseline, construction

phase and operation phase monitoring, each station will be sampled and

measurements/ water samples will be taken at three depths, 1 m below the sea

surface, mid-depth and 1 m above the seabed. For stations that are less than 3 m in

depth, only the mid-depth sample shall be taken. For stations that are less than 6 m in

depth, only the surface and seabed sample shall be taken. For in

situ measurements, duplicate readings shall be made at each water depth at

each station. Duplicate water

samples shall be collected at each water depth at each station.

The effluent sampling

should be planned carefully to ensure appropriate volume of effluent

sub-samples is collected to prepare sufficient amount of flow-weighted

composite effluent sample for carrying out subsequent chemical analysis and

testing.

6.5

Water Quality

Compliance

Water quality monitoring will

be evaluated against Action and Limit Levels. The key assessment parameters are

dissolved oxygen, temperature, suspended solids and TRC and thus Action and

Limit Levels based on the assessment criteria are identified for these. However turbidity can also provide

valuable instantaneous information on water quality and thus Action and Limit

Levels are also recommended for this parameter to facilitate quick responsive

action in the event of any apparent unacceptable deterioration attributable to

the works. The proposed Action and

Limit Levels are shown in Table 6.4.

Action and Limit levels are

used to determine whether operational modifications are necessary to mitigate

impacts to water quality. In the

event that the levels are exceeded, appropriate actions in Event and Action

Plan (Table

6.5) should be undertaken and a review of

works will be carried out by the Contractor(s).

Any noticeable change to

water quality will be recorded in the monitoring reports and will be

investigated and remedial actions will be undertaken to reduce impacts. Particular attention will be paid to the

Contractor(s)��s implementation of the recommended mitigation measures.

Site audit will be

conducted throughout the construction phase of CCGT Units No.1 and No.2 to

confirm the implementation of the water pollution control measures and good

site practices as recommended in Annex A.

Table 6.4 Action and Limit Level for Water

Quality

|

Parameter |

Action Level |

Limit Level |

|

Construction

Phase and Maintenance Dredging Marine Water Monitoring |

||

|

DO in mgL-1 a |

Surface and Middle 5th%-ile

of baseline data for surface and middle layer Bottom 5th%-ile of baseline data for bottom layers |

Surface and Middle 4

mg L-1

or 1%ile of baseline for surface and middle layers Bottom 2 mg L-1

or 1%ile of baseline for surface and middle layers |

|

Turbidity in NTU (Depth-averaged b) c |

95th%-ile

of baseline data, or 20% exceedance of value at any

impact station compared with corresponding data from control station |

99th%-ile

of baseline data, or 30% exceedance of value at any impact

station compared with corresponding data from control station |

|

SS in mgL-1 (Depth-averaged b) c |

95th%-ile

of baseline data, or 20% exceedance of value at any

impact station compared with corresponding data from control station |

99th%-ile

of baseline data, or 30% exceedance of value at any impact station compared

with corresponding data from

control station |

|

First-year

Operation Phase Marine Water Monitoring |

||

|

DO in mgL-1 a |

Surface and Middle 5th%-ile

of baseline data for surface and middle layer Bottom 5th%-ile of baseline data for bottom layers |

Surface and Middle 4

mg L-1

or 1%ile of baseline for surface and middle layers Bottom 2 mg L-1

or 1%ile of baseline for surface and middle layers |

|

Water temperature in �XC (Depth-averaged b) c |

��1.5 �XC

of baseline data |

��2.0 �XC

of baseline data |

|

Turbidity in NTU (Depth-averaged b) c |

95th%-ile

of baseline data, or 20% exceedance of value at any

impact station compared with corresponding data from control station |

99th%-ile

of baseline data, or 30% exceedance of value at any

impact station compared with corresponding data from control station |

|

TRC in mgL-1 (Depth-averaged b) c |

0.02 mg L-1 |

0.02 mg L-1 |

|

Notes: a.

For

DO, non-compliance of the water quality limits occurs when monitoring result

is lower than the limits. b.

��Depth-averaged��

is calculated by taking the arithmetic means of reading of all three depths. c.

For

water temperature, SS, turbidity and TRC, salinity, non-compliance of the

water quality limits occurs when monitoring result is higher than the limits. |

||