2 Objectives and Benefits for the Project and Consideration of Alternatives

In accordance with Clause 3.2.1 (i) and Clause 5.2 (iii) of the EIA Study Brief, the purpose of Section 2 of the EIA Report is to provide information on the objective, purpose and benefits of the Project, environmental benefits and dis-benefits of different development options for the Project, including the siting of the Jetty, the subsea pipeline alignments (also referred to as ‘routes’), the overall system design, construction methods, and operational modes of the Project with a view to deriving the preferred option for the siting, alignment, construction and operations of the Project’s facilities that will avoid or minimize adverse environmental impact; and to describe the scenarios with and without the Project.

2.1 Objectives, Purpose and Benefits of the Hong Kong Offshore LNG Terminal Project

2.1.1 Introduction

Since 1996, with the commissioning of the BPPS, natural gas has been an important component of CLP's fuel supply mix.

Similarly, natural gas has been an important component of HK Electric’s fuel supply since 2006 following the commissioning of its first gas-fired power generation unit at the LPS.

Currently, both energy providers are in the process of augmenting their generation capacity with further gas-fired power generation units. The use of natural gas has delivered significant environmental benefits, as well as adding diversity to the fuel mix used for power generation, thereby enhancing the security of electricity supply in Hong Kong.

2.1.2 Background

Over the past decades, the fuel used for power generation in Hong Kong has evolved from being primarily coal to a diverse mix of coal, nuclear and natural gas. As referenced in Section 1, the HKSAR Government plans to increase the percentage of natural gas used for power generation to around 50% by 2020 onwards to meet the HKSAR Government’s pledged environmental targets ([1]).

Due partly to the introduction of nuclear power and natural gas into the fuel mix, CLP’s air emissions from power generation have significantly improved, with nitrogen oxides (NOx), sulphur dioxides (SO2) and particulates (PM10) reduced by more than 85% over the period between 1990 and 2016 ([2]).

Similarly, HK Electric’s emissions from power generation have also significantly improved, with NOx, SO2 and PM10 cut by 50-90% over the period between 2005 and 2016 by adopting natural gas in its fuel mix and the introduction of other emissions mitigation measures ([3]).

Fuel diversity has enabled these improvements to be achieved while maintaining competitive tariffs and world-class electricity supply reliability.

Often taken for granted, a reliable electricity supply is a key contributor to Hong Kong’s quality of life, competitiveness in the global market, and ability to attract inward investment. Businesses in Hong Kong, ranging from large multi-national companies to small local shops are all dependent on a cost-competitive and uninterrupted supply of electricity.

The following Section sets out the main objectives, purpose and benefits of the Project, namely:

Ÿ Reducing carbon emissions;

Ÿ Improving air quality;

Ÿ Securing competitive gas supply options; and

Ÿ Ensuring electricity reliability.

2.1.3 Contributing to Hong Kong’s Climate Change Commitments to Reducing Carbon Emissions

The Paris Agreement

Hong Kong has acceded to the Paris Agreement with China’s ratification. The Paris Agreement is an ambitious multilateral treaty agreed in December 2015 that succeeds the Kyoto Protocol. The Paris Agreement came into force on 4 November 2016.

The key provisions of the Paris Agreement call for global actions to:

Ÿ Achieve ‘peak’ greenhouse gas (GHG) emissions (referred to as carbon emissions hereinafter) as soon as possible and achieve a balance between carbon sources and sinks in the second half of the 21st century (i.e. to reach ‘carbon neutrality’ between 2051 and 2100); and

Ÿ Keep global average temperature increase well below 2°C relative to pre-industrial levels, and to pursue efforts to limit it to 1.5°C.

As part of the Paris Agreement process, China has devised its 2030 nationally determined contributions (NDCs) and included the following goals:

Ÿ To peak carbon dioxide emissions in around 2030 while making best efforts to achieve this peak earlier;

Ÿ To lower carbon dioxide emissions per unit of GDP by 60% to 65% from the 2005 level;

Ÿ To increase the share of non-fossil fuels in primary energy consumption to around 20%; and

Ÿ To increase the forest stock volume by around 4.5 billion m3 compared to the 2005 level.

Hong Kong’s Actions

Hong Kong contributes to China’s fulfillment of its obligations under the Paris Agreement. As such, and following on from its fuel mix policy (see Section 2.1.4 for further information), the HKSAR Government published Hong Kong's Climate Action Plan 2030+ Report in January 2017 ([4]), which sets the following targets :

Ÿ To reduce absolute carbon emissions by 20% by 2020, and by 26% - 36% by 2030, using 2005 as the base year; and

Ÿ To reduce carbon intensity by 50% - 60% by 2020, and by 65% - 70% by 2030, using 2005 as the base year.

Local power generation is the biggest contributor to Hong Kong’s carbon emissions making up about 70% of the total. Hong Kong’s emission levels have remained at around 40-45 million tonnes of CO2-e in recent years, despite increased population and steady economic growth. In keeping with Hong Kong’s contribution towards the 2°C target, Hong Kong would need to continue to substantially reduce its carbon emissions beyond 2030.

The Climate Action Plan 2030+ Report includes phasing down the use of coal for power generation and replacing it with natural gas by 2030, with an increase in the local gas-fired power generation to around 50% by 2020, to enable Hong Kong to reduce carbon emissions significantly in the medium term. The HKSAR Government estimates that Hong Kong’s carbon emissions will peak by 2020. To contribute to Hong Kong’s climate change commitments to reduce carbon emissions, the HKSAR Government supports CLP and HK Electric’s plans to increase Hong Kong’s natural gas-fired power generation capacity.

2.1.4 Supporting HKSAR Government’s Objective of Improving Air Quality

The HKSAR Government’s environmental policy includes the control of emissions from the existing power stations in Hong Kong. The recognition of the role of natural gas in emissions control was affirmed by the HKSAR Government in the 2005-06 Policy Address ([5]):

“61. To fully achieve the emissions reduction targets in 2010, we have asked the power companies to … use natural gas for power generation as much as possible.

Subsequent Policy Addresses have continued to encourage an enhanced fuel mix. As a consequence, CLP and HK Electric are well positioned to continue to enable the increased utilisation of natural gas and make it play an increasingly important role in power generation in Hong Kong.

Hong Kong’s Emissions Caps

The Air Pollution Control Ordinance (Cap.311) (APCO) empowers the HKSAR Government to cap the emissions of power plants to improve air quality. APCO section 26G provides for the Secretary for the Environment to allocate emission allowances for three specified pollutants, i.e. SO2, NOx and respirable suspended particulates (RSP), for power plants by way of a Technical Memorandum (TM). Six TMs have been issued in 2008, 2010, 2012, 2014, 2015 and 2016, setting the emission allowances for the years 2010 to 2021.

The Advisory Council on Environment (ACE) Paper 11/2017([6]) and the Legislative Council Paper No. CB(1)1286/16-17(03)([7]) stated that the power companies should continue to use low emission coal and uphold the performance of their emission control devices while maximising the use of gas-fired power generation units (gas-fired units) and prioritise the use of coal-fired power generation units (coal-fired units) equipped with advanced emission control devices so as to meet the emission allowances set for 2022 and beyond. The proposal to further reduce the emissions from 2022 was tabled at the Legislative Council on 18 October 2017. The new set of emission allowances will come into effect on 1 January 2022, in accordance with the APCO requirements.

Local Power Generation Assets: the Shift from Coal to Gas

The HKSAR Government has not allowed power companies to build new coal-fired units since 1997. Most of the coal-fired units at the CPPS have been in operation for over 30 years, and the coal-fired units at the LPS have been in operation for over 35 years. Subject to the actual operating conditions, the coal-fired units could be extended beyond their design lives but they will have to be phased down over time. Furthermore, the extensive retrofits that the power companies have undertaken to reduce their emissions have made further retrofits impracticable.

Natural gas has the lowest carbon content of the fossil fuels ([8]) and produces virtually no particulates and less NOx and carbon dioxide (CO2) than other fossil fuels when it is combusted to produce energy. Since sulphur is almost entirely removed as part of the liquefaction process, combustion of natural gas emits negligible amounts of SO2. Natural gas has been employed around the world for power generation for over 40 years ([9]) and is used in the Combined Cycle Gas Turbines (CCGT) installed at the BPPS and the LPS. The natural gas process used in Hong Kong is a proven technology. Both the BPPS and the LPS use advanced technology in terms of equipment and operating systems. Moreover, CCGTs have higher thermal efficiency than conventional fossil fuel fired power stations with the same generating capacity ([10]).

The gradual replacement of coal-fired units with gas-fired units is helping to further lower emissions from power generation activities in the long-term. Consequently, in order to ensure an efficient, secure and stable electricity supply and meet the long-term demand growth in the electricity market, sufficient local gas-fired power generation capacity and natural gas supplies are required to replace the reducing coal-fired power generation capacity at the CPPS and the LPS.

Hong Kong’s Fuel Mix Policies

A public consultation was conducted in the first half of 2014 on two fuel mix options to meet the environmental targets in 2020. Based on the public views and comments received, the HKSAR Government set out its plan to implement the future fuel mix policy in March 2015. The future fuel mix policy includes a policy direction to increase the proportion of natural gas-fired power generation for Hong Kong as a whole by 2020. As such, the HKSAR Government has set out a fuel mix target of around 50% natural gas-fired power generation by 2020 to support meeting the pledged environmental targets for 2020. CLP and HK Electric support the HKSAR Government’s objective of improving air quality and reducing carbon intensity of local power generation.

In the 2015 fuel mix, the gas-fired electricity generation shares about 27% ([11]). To support the increased use of natural gas in Hong Kong from 2020 onwards, the HKSAR Government has envisaged that a small number of additional gas-fired units would need to be built by CLP and HK Electric in order to increase the installed capacity for gas-fired power generation. As a consequence, CLP and HK Electric have identified the need for a viable additional gas supply option that will provide long-term energy security for Hong Kong through access to competitive gas supplies from world markets.

2.1.5 Securing Competitive Gas Supply Options

Natural gas is currently imported into Hong Kong via three subsea gas pipelines:

Ÿ From the Yacheng gas fields via the Yacheng Pipeline and from Turkmenistan via the Second West-to-East Pipeline / Hong Kong Branch Line to the BPPS; and

Ÿ From the Guangdong Dapeng LNG receiving terminal in Shenzhen via the Dapeng Pipeline to the LPS.

The increasingly wider use of LNG enables more of the world’s gas reserves to be available to consumers in locations remote from existing gas supply sources. According to the International Energy Agency (IEA), natural gas production in 2016 is approximately 3,613bcm (billion cubic metres) worldwide ([12]). The LNG process enables a greater range and reach of the transportation of natural gas beyond pipelines.

In 2016 there were 18 countries producing and exporting LNG and 35 countries importing LNG, with a total consumption of about 258Mtpa (million tonnes per annum), with additional countries having the potential to become LNG importers by 2025 ([13]).

Maintaining a cost-effective, diverse, reliable and adequate supply of fuel remains a priority for CLP and HK Electric. The Project would increase CLP and HK Electric’s optionality regarding the sourcing of future gas supplies for Hong Kong and provide the flexibility to directly access competitively priced gas from the global LNG market, including its associated spot market. This would assert the Hong Kong LNG buyers’ future negotiating position, diversity of gas supply sources, and provide options to ensure security of supply.

LNG suppliers tend to focus on buyers with strong markets for gas demand. The Project would demonstrate the intent of CLP and HK Electric as buyers able to undertake long term LNG supply contractual commitments and prove Hong Kong to be a sustainable energy market in the long term. CLP and HK Electric would then be able to attract reliable LNG suppliers and achieve the best possible combination of pricing and terms for the benefit of electricity consumers.

2.1.6 Ensuring Electricity Reliability

Hong Kong has no indigenous energy resources and most of the fuel for Hong Kong needs to be imported. Based on the 2016 peak local electricity demand for CLP at 6,841 megawatts (MW) and HK Electric at 2,428MW and the future electricity demand, CLP’s and HK Electric’s supply capacity may not be able to satisfy electricity demand in the event of any interruption of the existing pipeline gas supplies to the gas-fired units at the BPPS and the LPS. Under such a scenario, CLP and HK Electric might need to meet electricity demand by a higher reliance on their coal-fired units which would result in increased air emissions beyond existing levels and beyond the HKSAR Government targets at the time. In parallel, Hong Kong electricity users would be exposed to possible power cuts or rationing. Such a disruption to Hong Kong’s electricity supply reliability could compromise Hong Kong’s competitiveness and quality of life.

The future gas supply for Hong Kong is challenged by the following three fundamental requirements:

1. Certainty of Timely Availability: The Yacheng 13-1 gas field, which partially supplies the BPPS, is expected to deplete early next decade. CLP must have absolute certainty that an additional gas supply will be available at the time it is required but it typically takes 4 – 6 years to put the required gas exploration and production infrastructure, as well as the associated connecting pipeline infrastructure, in place to provide additional gas supply. As such, only potential gas supply sources that have the required gas reserves base, have already achieved significant engineering and approval milestones and have an established operating track record can provide certainty on the timing of gas supply availability to substitute the Yacheng 13-1 gas field.

Similarly, with regard to any future LNG supply, this must be from an identifiable source or an established LNG supply portfolio such that this can be seen to provide the required certainty of gas supply and timely availability. Use of LNG enables access to additional gas supplies from both existing gas fields and gas fields in development, and avoids relying wholly on the need to develop new gas supplies with connecting infrastructure such as pipelines and LNG export / import terminals.

2. Supply Security for Hong Kong: Gas is expected to represent up to around 50% of Hong Kong’s fuel mix for power generation by 2020, therefore the security of gas supply is essential for the power companies to maintain the existing high levels of electricity supply reliability in Hong Kong. The global gas supply market is however subject to ongoing risks of disruption, for instance:

a. Disruptions to fuel supply can occur, as evidenced by past gas supply disruptions in Ukraine ([14]) (which left Ukraine short of gas for a period during winter, and supplies in Europe disrupted) and Singapore ([15]) (which resulted in blackouts in many parts of the island state in summer months);

b. In December 2015 ([16]) CLP’s supply of natural gas via the Second West-to-East Pipeline was disrupted due to a landslide in Shenzhen. This required CLP to implement a number of contingency measures to ensure supply reliability, including increasing generation capacity of coal-fired units at CPPS and drawing on generation capacity from Guangzhou Pumped Storage Power Station; and

c. Following Japan’s Fukushima nuclear accident, gas-fired power generation replaced one-third of the nuclear power generation loss between 2011 and 2013 ([17]).

The BPPS currently relies entirely on just these two pipelines which are not inter-connected. In the event of a disruption to one of them, there could be insufficient gas supply from the remaining pipeline to support the required gas-fired power generation leading to a loss of power supply. This risk is likely to be exacerbated by the required increase in gas-fired power generation by 2020 for the BPPS.

The above risk in securing gas supply is even more critical for HK Electric as it is entirely reliant on supply from the Dapeng Pipeline. Therefore, in the event of a disruption to this pipeline, there would be a complete loss of gas supply for gas-fired power generation.

In this context and to cater for the increased share of gas in the fuel mix, it is prudent to ensure a number of gas supply sources to provide energy security for Hong Kong. This can be achieved by:

a. Prioritising CLP and HK Electric’s gas supply requirements and diversifying the current gas supply arrangements from the three pipeline gas sources; and

b. Ensuring that the gas supply chain is managed by companies with proven operating track records which are aligned with industry best practices.

3. Adequate Volume and Flexibility: The Project would augment the existing contracted pipeline gas supplies so as to achieve the following objectives:

a. Meet gas demand growth in future years as a result of the HKSAR Government’s environmental initiatives and Hong Kong’s electricity demand growth; and

b. Provide the flexibility for CLP and HK Electric to meet seasonal demand patterns and the power plants’ operational requirements.

CLP and HK Electric have identified the Project as the critical enabling infrastructure that will make a significant contribution to achieving Hong Kong’s commitment to improving air quality and reducing carbon emissions.

2.2 Consideration of an Onshore versus Offshore LNG Terminal

In 2006 to 2007, when planning the earlier HKLNG Terminal, the EIA Report included a FSRU-based LNG terminal as one of the technology options for receiving imported LNG. However, at that time, the FSRU technology was considered nascent and was not progressed. Since then, FSRU technology has advanced quickly and the use of an LNG import facility based on an FSRU vessel moored at a jetty is now considered a mature technology, with many worldwide applications.

The requirements of the onshore, land-based HKLNG Terminal meant that it occupied a footprint of approximately 37 hectares (ha) of land which was needed to locate the necessary infrastructure including the inter-connections with the marine jetty, the three (3) LNG storage tanks, the compression, vaporization, seawater intake and gas send-out process areas, including flare and utilities areas, the control room, and the maintenance workshop, administration building and guard house. In addition, a marine jetty area of 4ha was also required, increasing the total footprint and permanent land and marine habitat loss from the land-based HKLNG Terminal to 41ha.

By comparison, the offshore LNG Terminal for the Project occupies a footprint of approximately 2.5ha, a much smaller permanent marine habitat loss, yet it is comprised of similar facilities and provides the same LNG import operations, albeit on a slightly smaller scale. All of the LNG unloading, storage, regasification and send out facilities are located on the FSRU Vessel and the Jetty topsides, both of which are located offshore, with no land footprint or habitat loss. Significant amount of reclamation which may be required for onshore LNG terminal can be avoided for offshore LNG terminal.

The FSRU Vessel for the Project is proposed to be an existing or a ‘new build’ and together with the Jetty will form the FSRU-based LNG Terminal. Consequently, both key components of the offshore LNG Terminal can be constructed in a significantly shorter period and at a lower capital cost, compared to an onshore land-based LNG import terminal of similar capacity ([18]).

An onshore LNG terminal can be constructed in 36 to 39 months which is driven by the time required to build the double-containment LNG storage tanks. Whereas, an offshore LNG terminal of the type planned for the Project can be constructed in approximately 21 months.

2.2.1 Floating Storage Regasification Unit Technology

Introduction to the LNG Supply Chain with an FSRU based LNG Terminal

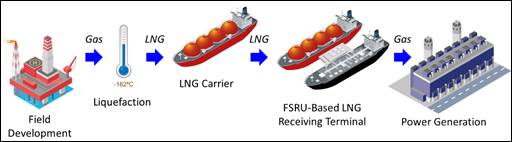

To bring natural gas produced from the major gas supply sources around the world to the major gas markets, which are usually located a long distance away, natural gas is either transported to market by a long distance pipeline or converted into LNG and then transported to market by a special purpose LNGC. The LNGC receives its LNG cargo at an LNG liquefaction plant in an exporting country and then delivers this LNG to an importing country, where the LNG is unloaded at an onshore or offshore LNG receiving terminal.

FSRU technology has developed and matured over the recent years since the start-up of the first project in 2007, and has been chosen by many governments / companies as a viable and cost effective design for an LNG receiving terminal where constraints exist concerning a large, onshore, land-based LNG receiving terminal.

An illustration of the full LNG Supply Chain with a FSRU-based LNG receiving terminal used for LNG importation is shown in Figure 2.1. At the gas producing country, the process of LNG production involves the transport of the natural gas from the production fields via pipeline to a liquefaction plant. Prior to liquefaction, the gas is treated to remove contaminants, such as carbon dioxide, water and sulphur to avoid them freezing and damaging equipment when the gas is cooled to -162°C where it enters its liquid state.

The LNG produced from the liquefaction process is piped into LNG storage tanks. The piping and equipment and the LNG storage tanks are thermally insulated to maintain the low cryogenic temperature. LNG storage tanks are designed and constructed using special materials to contain the cryogenic liquid LNG.

When required for send-out from the liquefaction plant, LNG is pumped from the LNG storage tanks, and loaded onto a specially equipped LNGC and then transported to the LNG importing country.

When the LNGC arrives at the place of import, LNG is unloaded from the LNGC onto the FSRU Vessel moored at the LNG receiving terminal where it is stored on board in the LNG storage tanks. Then, when required to meet local gas demand, the LNG is re-gasified into natural gas and sent out to end-users, such as power plants and major industries, by high pressure pipelines.

Figure 2.1 LNG Supply Chain including Offshore LNG Receiving Terminal

Offshore LNG Receiving Terminal Key Components and Process

An offshore LNG receiving terminal is located towards the end of the gas supply chain and operates in the same manner as a conventional onshore, land-based LNG receiving terminal.

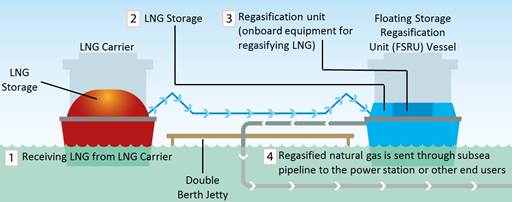

Typical key features of the FSRU based LNG Terminal for the Project are as follows:

Ÿ FSRU Vessel permanently moored at the Jetty (except under adverse weather conditions) which has the following on-board facilities;

- LNG storage tanks – either Membrane (the LNG storage tank matches the configuration of the hull of the FSRU Vessel) or MOSS (the LNG storage tank is spherical);

- LNG regasification units – e.g. LNG booster pumps, LNG vaporizers, etc.

Ÿ Jetty which has a double berth for mooring both the FSRU Vessel and the LNGCs that deliver the LNG; together with LNG unloading arms and transfer piping and high pressure gas send-out arms, metering equipment and piping ; and

Ÿ Subsea pipelines connecting the Jetty to the end-users i.e. the BPPS and the LPS.

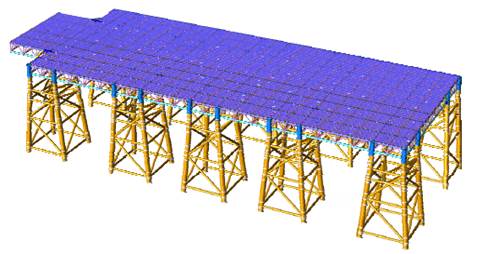

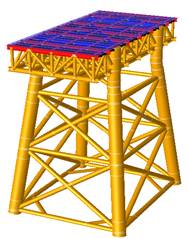

The key components and process overview of an FSRU Vessel and the Jetty are depicted in Figure 2.2.

Figure 2.2 Offshore LNG Receiving Terminal Key Components and Process Overview

The FSRU Vessel design and operations will be under internationally accepted merchant shipping standards such as the International Maritime Organization (IMO) International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) and ship classification society regulations. The FSRU Vessel is required to comply with the same strict international regulations and industry guidelines as LNGCs that have been in place since the start of the LNG industry over 50 years ago, an industry that has since grown substantially worldwide and has an outstanding safety record.

International FSRU Based LNG Import Projects

Over recent years, offshore LNG import projects using FSRU technology have been chosen over onshore, land-based projects, and this trend is set to continue as FSRU based LNG import projects are proving to be a viable and cost-effective solution overcoming many of the permitting and environmental constraints that are typically faced by large, onshore, land-based infrastructure developments. As of April 2018, there are 22 FSRU based LNG import projects in operation; and many projects are in various stages of development around the world.

In the history of LNG shipping (1964-2017), LNGCs have demonstrated an outstanding industry safety record and have rarely been involved in collisions and groundings; none of these leading to a breach of an on-board LNG storage tank.

Since the first FSRU based LNG import project was commissioned in 2009, up to the present time (2017), there have been no accidents ([19]). This excellent operational safety record has been maintained through the application of rigorous safety policies, stringent design codes and operational practices implemented by the LNG industry.

With Hong Kong’s rising demand for land availability being a significant development constraint, coupled with the advantages of a remote offshore location in HKSAR waters, this leads to the conclusion that the Hong Kong Offshore LNG Terminal based on FSRU technology, together with its quicker construction time, lower capital cost and reduced environmental impact is, therefore, the preferred choice over an onshore, land-based LNG import terminal.

2.3 Consideration of the Site and Layout Options for the LNG Terminal

2.3.1 Introduction

In early 2015 CLP commenced work on the identification of potential locations within Hong Kong that could accommodate the LNG Terminal and its associated infrastructure required for the Project. The following section details the processes by which a suitable location (‘Study Area’) was identified, selected and recommended for more detailed analysis as part of this EIA Study in order to determine the actual Site for the LNG Terminal.

2.3.2 Selection of the Preferred LNG Terminal Location

The approach to selecting suitable locations for the LNG Terminal Site has been based on other site search studies conducted in Hong Kong ([20]) ([21]) ([22]) ([23]) ([24]). The approach was organised into two main phases, the first focussed mainly on excluding incompatible areas and the second in narrowing down to a most preferred /suitable location. In order to guide the site selection procedure, the key engineering requirements were referred to, in particular, marine access and berthing requirements and met-ocean conditions.

Absolute Constraints

These factors are seen to pose an ‘absolute’ obstacle to the development of the Project justified by the presence of highly significant issues. These are used for the preliminary elimination of all unsuitable locations to facilitate the establishment of ‘No Go Areas’, including statutory protected locations at which the LNG Terminal would not be allowed to be constructed and are, therefore, avoided from the outset. These Absolute Constraints, which were grouped into Marine Safety and Environmental categories, were applied as the first screen to eliminate unsuitable locations so as to identify potential locations for the LNG Terminal Site that were available within Hong Kong waters.

Marine Safety Constraints

The LNG Terminal when operating will involve the transfer and storage of LNG, as well as the regasification of the LNG and send out of natural gas at high pressure in subsea pipelines. Consequently, it is critical from a safety perspective that the LNG Terminal is away from areas of heavy marine traffic and nearby populations, and is not overly exposed to adverse weather or met-ocean conditions. Therefore, areas of Hong Kong waters that are designed for marine traffic purposes were excluded from further consideration and these included:

· Marine Vessel Fairways;

· Access Channels and Traffic Separation Schemes;

· Restricted Areas (high/low/unrestricted traffic volume);

· Existing Anchorages (dangerous goods, immigration and others); and

· Gazetted Typhoon Shelters and Marina.

The siting of the LNG Terminal also gave consideration to operational limits for navigation, berthing, loading/unloading, gas export, and mooring. For safe transit and approach, a water depth of approximately -15 metres Chart Datum (mCD) is required. Certain depth limitations can be overcome by engineering solutions, for instance, the lack of water depth can be compensated for by dredging. However, a balance should be struck between the extent of engineering solutions which have the potential to introduce additional environmental impacts and minimum met-ocean thresholds required. Therefore a water depth of shallower than -10mCD was applied as an absolute constraint.

Stability of the moored FSRU vessel and the LNGC is important during LNG unloading and transfer and gas send out to avoid accidental spills of the cryogenic liquid. Consequently, areas in Hong Kong waters that experience extreme wave heights or high current speeds were excluded from further consideration.

The limiting extreme wave height for navigation is assumed to be at 3.5m. Given the interactive nature of wind, wave and current (see operational limits for FSRU vessel and LNGC operations in Table 2.2), wind speed alone is not necessary a limiting factor to FSRU vessel and LNGC operations, but its compound effect on wave height could affect their operations. Peak current speed tolerances for berthing during wet and dry seasons in ebb and flow were modelled and applied. The limiting current speed for berthing, LNG unloading and regasification and send-out operations was assumed to be 0.6ms-1.

Environmental & Conservation Constraints

Areas that have been designated for environmental conservation were also excluded from further consideration and these included:

· Designated Marine Parks and Marine Reserves;

· Sites of Special Scientific Interest (SSSI);

· Coastal Protection Areas;

· Country Parks and Special Areas;

· Mai Po Nature Reserve Area;

· Restricted Areas gazetted under Wild Animals Protection Ordinance;

· Fish Culture Zones;

· Gazetted Artificial Reefs; and

· Gazetted Beaches.

All of the above constraints have some form of development control which would either render the development of the LNG Terminal in these areas unsuitable or involve significant permitting challenges that would add prohibitive costs and time to gain all necessary approvals required to develop the LNG Terminal.

The above Absolute Constraint layers were collated to create a map of “No Go Areas”, as shown in Figure 2.3.

It is apparent from this process that the majority of marine areas in western and north-western waters were excluded as part of the constraint mapping exercise. This includes the area around the BPPS, an end-user of natural gas from the LNG Terminal. The rationale for this is that the majority of these areas have relatively high current speeds and are very shallow and, therefore, would require substantial dredging to be able to accommodate the LNG Terminal. The areas of deeper water that have the required depth of -15mCD are typically shipping lanes or fairways and hence are not suitable for siting the LNG Terminal. In addition the transit routes for the LNGCs in these areas are not considered suitable due to the presence of heavy marine traffic.

The constraint mapping exercise also excluded the majority of marine areas in central waters north of Lamma Island. This is because these areas have a number of maritime and port operations that represent safety constraints to the LNG Terminal as well as LNGC transit. The majority of these areas also have relatively high current speeds and are shallow and, therefore, would require substantial dredging to be able to accommodate the LNG Terminal. The areas to the southwest of Lamma Island also experience extreme wave heights (> 3.5m) and hence are not suitable for siting the LNG Terminal.

Following the identification of less constrained areas (i.e. those areas outside the Absolute Constraint areas), a further review was conducted considering the availability of space to accommodate the proposed LNG Terminal, which for the site selection exercise was assumed to be about 29ha ([25]). Areas that were considered inadequate to accommodate the LNG Terminal were, therefore, eliminated (see Figure 2.4). Therefore, a total of nine (9) potential locations were identified as shown in Figure 2.4.

Potential Constraints

Further to the Absolute Constraints, potential locations were mapped against ‘Potential Constraint’ factors. These factors may render potential locations undesirable due to an established or proposed use, environmental value and / or technical challenges amongst other reasons. Although considered not to prevent locating the LNG Terminal, these constraints pose significant issues or implications that may potentially present an obstacle to the development of the Project, and risk its safe and timely delivery. The potential constraints covered four main categories:

1. Marine: (a) ease of navigation of LNGCs transit route; (b) dredging requirements for LNG Terminal and LNGCs transit route; (c) presence of subsea utilities; and, (d) presence of designated mud disposal/sand dredging areas.

2. Environmental: (a) proposed and potential areas of conservation interest, including marine parks and geoparks; (b) marine mammal habitats; (c) fisheries resources, spawning and nursery areas; and (d) coastal ecological resources such as corals, mangroves etc.

3. Planning: (a) proposed and potential land developments; (b) proximity to the BPPS; and, (c) proximity to the LPS.

4. Social: (a) marine recreation areas including secondary contact zone; and, (b) size and distance of nearest population.

The areas excluded by the Absolute Constraints were mapped out and the remaining areas examined with reference to the Potential Constraints, see Figure 2.5. This process helped identify locations that could be considered as suitable for siting the LNG Terminal.

The nine potential locations were considered for their practicality for siting an LNG Terminal, access by LNGCs, and their surrounding environment. Potential locations that face multiple constraints and/or are likely to pose challenges to the practicality of the FSRU facility were eliminated.

A number of factors that were considered to make some potential locations in the eastern and southern part of Hong Kong not practical included: near high marine traffic on marine fairways (posing constraints to LNGC transit) and recreational marine usage; within secondary contact recreational zones; limited space for LNGCs transit and manoeuvring; adjacent to anchorage sites; long distance to major users (GRSs at the BPPS and the LPS); within or in close proximity to Geoparks, SSSIs or adjacent to numerous areas of conservation interest or high ecological value; and proximity to large populations.

As a result of these constraints, of the nine potential locations, considering the less constrained areas that were considered to be of sufficient size for the LNG Terminal Site and broadly accessible by an LNGC, six potential locations were not taken forward and three shortlisted potential locations (West Lamma, South of Cheung Chau & Shek Kwu Chau, and Southwest Hong Kong Water Boundary) were identified and examined further.

Review of the Three Shortlisted Potential Locations

West Lamma

This potential location is west of Lamma Island, adjacent to the Lamma Power Station Access Channel. The total size of the potential location is approximately 150ha. It covers marine waters in the West Lamma Channel, and is south of the confluence of Adamasta Channel, East Lamma Channel in central Hong Kong waters. The nearest population can be found near the ferry pier at Yung Shue Wan about 2km away.

• Marine: this potential location experiences marine traffic along the West Lamma Channel. LNGCs will likely approach the potential location via the southern Hong Kong waters, passing the three anchorages sites south of Lamma, and up north along the Lamma Power Station Access Channel. Depending on the frequency of use of the Access Channel, the LNGCs transit may be able to share this existing channel. However, the potential area for siting the LNG Terminal is not considered to be large and therefore may constrain LNGCs movements and any collision would potentially affect both coal and gas power supplies. This potential location also covers an existing subsea pipeline from Dapeng supplying gas to Lamma Power Station. The water depth is about -10mCD therefore moderate dredging is required for the LNG Terminal.

• Environmental: the potential location is generally away from areas of conservation interest or important ecological habitats. Hard coral communities have been recorded along the western Lamma coasts in patchy distribution, but generally of low coverage ([26]). However, the potential location is considered to be within the habitat of Finless Porpoises in southern Hong Kong waters, as southwestern part of Lamma Island has been identified as a calving area for Finless Porpoises typically most abundant during winter and spring seasons ([27]) ([28]).

• Planning: the potential location is closest to the GRS at the LPS, and is relatively further to the BPPS compared to the other shortlisted potential locations. At present, this potential location is not within areas of known proposed or potential development; however it falls within the study area of the proposed artificial islands in the central waters.

• Social: the potential location is located near secondary contact recreation zones around Lamma Island, as well as gazetted bathing beaches on the west coast of Lamma Island. The nearest population can be found in Yung Shue Wan within 2km of approximately 1,200 people (and Lamma Island has a total population of about 6,000) which is considered to be medium sized.

In summary, the major advantages of locating the LNG Terminal at the potential location at West Lamma are that it is away from proposed and potential development, area of conservation interest and important coastal ecological resources. However, this potential location is in a busy marine traffic area within the West Lamma Channel, its area is restricted by Lamma Power Station Access Channel to the right, which are potential concerns for LNGCs transit routing and the siting of the LNG Terminal, and moderate dredging would be required.

South of Cheung Chau & Shek Kwu Chau

This potential location refers to the southern waters surrounding Cheung Chau and Shek Kwu Chau in the south of Lantau Island. The total size of the potential location is approximately 950ha and is constrained by a typhoon shelter at the west of Cheung Chau. The nearest population can be found on Cheung Chau and relatively few populations on Shek Kwu Chau. The potential location is situated within two major marine vessel fairways with constricted directions and, therefore, LNGC transit would have to approach the potential location following set marine traffic schemes.

• Marine: the potential location experiences significant amounts of marine traffic as the Adamasta Channel to the north and the channel to the south of the location are main fairways for vessels arriving and departing Hong Kong, including regular high speed ferry services to Macau, river trade vessels and several outlying island ferry services ([29]). The Adamasta Channel is a constricted passage between Cheung Chau Island and Chi Ma Wan Peninsula on Lantau Island, with a water depth that ranges from -10 to -15mCD. Any construction obstructing this channel would pose significant complications and delays to marine traffic ([30]). Furthermore, Cheung Chau piers experience traffic from small crafts and fishing boats. All these factors render access to the potential location challenging for LNGCs transit. One option for LNGCs approach would be by making a left turn from the West Lamma Channel, and entering and exiting the marine vessel fairway south of the potential location following its set direction. The water depth at this potential location is about -10mCD therefore moderate dredging is required for the LNG Terminal. Several subsea cables and pipelines run from Cheung Chau and Shek Kwu Chau to the south of Lantau Island.

• Environmental: South of Cheung Chau and Shek Kwu Chau waters is known habitat for Finless Porpoise. Chinese White Dolphins have been recorded in south Lantau waters ([31]). The entire potential location falls within the study area of the proposed artificial islands in the central waters. Shek Kwu Chau is a designated conservation area. Their coastlines, together with the eastern coast of Cheung Chau, are coastal protection areas. Nevertheless, the potential location does not cover known habitats of other important ecological resources.

• Planning: the potential location is located relatively closer to the GRS at the LPS and the GRS at the BPPS. The west of Shek Kwu Chau has been earmarked for the location of the IWMF project.

• Social: Cheung Chau has a population of about 23,000 people and is bounded by the potential location. The population is considered to be large. Both Cheung Chau and Shek Kwu Chau are encircled by secondary contact recreation zones.

In summary, the major advantages of locating the LNG Terminal at the potential location at South of Cheung Chau & Shek Kwu Chau are its relatively closer distance to the GRS at the LPS and the BPPS, and away from important coastal ecological resources. However, the potential location is inconveniently located within two busy marine vessel fairways with set directions, which means that LNGCs would likely need to approach the potential location by making a sharp left turn into West Lamma Channel, which pose significant challenges to LNGCs transit.

Southwest Hong Kong Water Boundary

This potential location refers to the area in the south of Lantau Island in the southwest of Hong Kong water boundary. The total size of the potential location is approximately 3,100ha. It covers marine waters east of Tau Lo Chau, Soko Islands, south of Shek Kwu Chau and Cheung Chau. The nearest population is at Sha Tsui on Lantau Island of about 1,200 people and 5.4km from the nearest boundary of the potential location. The north of the potential location is the high speed craft channel used for many ferry services to Macau and outlying islands.

• Marine: the potential location experiences some traffic from the high speed craft channel south of Adamasta Channel which can be utilized for LNGCs transit. Since the potential location is located close to the southern HKSAR waters boundary, it is considered relatively accessible by LNGCs. LNGCs transit can approach the potential location by travelling outside the HKSAR waters boundary through the Danggan Channel from the east or Zhujiang Traffic Separation Schemes from the west. It is noted that many (11) subsea cables run through the potential location from Lantau Island to Hong Kong; however the potential location is considered to be able to locate the LNG Terminal between cables, or outside the subsea cable corridor, subject to detailed evaluation to confirm that the LNG Terminal Jetty can be safely constructed in a suitable location in the vicinity of the subsea cables (see Section 2.3.3). The water depth at the potential location is about -10 to -15mCD therefore moderate to minimum \ no dredging may be required for the LNG Terminal.

• Environmental: Similar to the potential location at South of Cheung Chau & Shek Kwu Chau, this potential location is a known habitat for Finless Porpoises and Chinese White Dolphins have been recorded in south Lantau waters. It is partially covered the proposed South Lantau Marine Park.

• Planning: this potential location is comparatively relatively close to the GRS at the LPS, and is the closest to the GRS at the BPPS. The potential location is also located away from proposed and potential development, and the majority of the potential location falls within the study area of the proposed artificial islands in the central waters.

• Social: this potential location is the most distant away from population with the smallest nearby population of 1,200 people in Sha Tsui on Lantau Island. Due to its remote location, it is also not within secondary contact recreation zones or areas with high recreational marine traffic, and is therefore considered compatible with existing recreational uses.

In summary, the major advantages of locating the LNG Terminal at the potential location at South-West Hong Kong Water Boundary are its location away from densely populated areas, heavy marine traffic areas, and recreational use while being relatively closer to the GRS at the LPS and the BPPS. However, the potential location is within known habitats of the Finless Porpoises and close to the habitats of the Chinese White Dolphins, as well as partially covered by the proposed South Lantau Marine Park.

Summary of Key Advantages and Disadvantages of the Three Shortlisted Potential Locations

The key advantages and disadvantages of the three shortlisted potential locations are presented in Table 2.1.

Table 2.1 Summary of Key Advantages and Disadvantages of Three Shortlisted Potential Locations

|

Location |

Pros |

Cons |

|

West Lamma (southern Hong Kong)

|

Ÿ Away from areas of conservation interest and important coastal ecological resources Ÿ Deep waters with less dredging requirement

|

Ÿ Proximity to moderately populated areas Ÿ Within the Finless Porpoise habitats, including calving area Ÿ Close to Lamma Power Station Access Channel and West Lamma Channel, which are busy marine traffic areas Ÿ Covered by Dapeng LNG pipeline supplying Lamma Power Station but with sufficient space between pipeline routes for LNG Terminal Ÿ Relatively small potential area Ÿ Covered by the study area of the proposed artificial islands in the central waters Ÿ Water depth is about -10mCD with moderate dredging requirements Ÿ Near recreational zones and gazetted beaches |

|

South of Cheung Chau & Shek Kwu Chau |

Ÿ Away from areas of known habitats of other important ecological resources Ÿ Relatively sheltered met-ocean conditions |

Ÿ Proximity to densely populated areas Ÿ Between two high traffic marine vessel fairways posing constraints to LNGCs transit Ÿ Close to area of recreational uses Ÿ Within the Finless Porpoise habitats, and in proximity to the Chines White Dolphins habitats Ÿ In vicinity of IWMF Project Ÿ Water depth is about -10mCD with moderate dredging requirements Ÿ Partially covered by subsea cable utilities and pipelines

|

|

Southwest Hong Kong Water Boundary |

Ÿ Away from densely populated areas Ÿ Away from recreational zones Ÿ Relatively close to the pipeline connections to GRS at the LPS, and is the closest to the GRS at the BPPS. Ÿ Water depth is between -10 to -15mCD with moderate to minimum \no dredging requirements Ÿ Away from dense marine traffic areas Ÿ LNGCs transit is relatively simple as located close to southern HKSAR water boundary Ÿ LNGC transit is relatively short in HKSAR waters Ÿ Relatively large potential area |

Ÿ Within Finless Porpoise habitats, and in proximity to the Chines White Dolphins habitats Ÿ Partially covered by subsea cable utilities, but is considered to be able to safely locate LNG Terminal Jetty between cables, or outside the subsea cable corridor Ÿ Partially covered by the proposed SLMP and South Cheung Chau mud disposal site (Sediment Disposal Area) Ÿ Covered by the study area of the proposed artificial islands in the central waters

|

Identification of the Preferred Location (“Study Area”)

Of the three shortlisted potential locations, “Southwest Hong Kong Water Boundary” located east of the Soko Islands was selected for further analysis as the preferred location for the LNG Terminal Site for the following reasons:

· The preferred location is remote from populated areas and secondary recreational zones, with the closest populations located in southern Lantau Island and Cheung Chau at a distance of more than 5km;

· The preferred location is also located well away from designated marine vessel fairways and high-speed passenger ferry routes between Hong Kong and the Pearl River Delta;

· The preferred location has sufficient water depth of -10 to -15mCD with no or minimum dredging requirements for the LNG Terminal or the LNGC transit route, compared to other potential locations; and,

· The preferred location has relatively shorter LNGC transit route and is in relatively calm waters, sheltered from typhoon conditions, thereby considered as favourable to LNG Terminal operations.

The relative shortcomings of the preferred location for the LNG Terminal include its location within known habitats of species of conservation interest i.e. Finless Porpoise and Chinese White Dolphin, to the west, and the South Cheung Chau mud disposal site to the east. It is also in the vicinity of the proposed South Lantau Marine Park and submarine telecommunication cable corridor.

Further analysis has been carried out and is detailed in the following Sections in order to confirm the optimal Site for the LNG Terminal within the Southwest Hong Kong Water Boundary Study Area. The analysis considered the comments and feedback that were received from the relevant government departments and other environmental, marine, engineering, construction and operational considerations, as well as engaging with relevant stakeholders e.g. subsea cable owners, etc.

Section 2.3.3 below presents the outcomes from the detailed analysis of the Study Area, which includes environmental, marine, engineering, construction and operational considerations in order to ensure that the most suitable Site was selected for the LNG Terminal considering the future safe and reliable operation of the Project.

2.3.3 Selection of the Preferred LNG Terminal Site

Consideration of Environmental, Social and Marine Aspects Near to / within the Southwest Hong Kong Water Boundary (herein ‘the Study Area’)

The Study Area has been identified as the preferred location for the LNG Terminal. It is noted, however that, there remain some other uses related to the Study Area that need to be taken into consideration when selecting the most preferred location for the LNG Terminal.

South of Cheung Chau Open Sea Sediment Disposal Area (Sediment Disposal Area)

Close to the east side of the Study Area is the uncontaminated Sediment Disposal Area designated by the Civil Engineering and Development Department (CEDD). This Sediment Disposal Area is the only one in Hong Kong that can receive sediments all year round and consequently, it is of strategic importance to the Fill Management Division of CEDD. Southwest of the Study Area there is relatively deep water and is considered dispersive as seabed currents and waves gradually disperse the marine sediments into the surrounding marine areas.

Given the use of the Sediment Disposal Area to the east of the Study Area, this is considered to be relatively less environmentally sensitive.

CEDD has indicated that due to the importance of their Sediment Disposal Area for receiving dredged sediment on a year round basis; this should not be compromised by the future operations at the LNG Terminal. CLP and HK Electric recognise the need to maintain the all year operation of the Sediment Disposal Area and supports close coordination and management with CEDD to ensure that both operations can co-exist in an otherwise unoccupied offshore area of the HKSAR waters.

Consequently, locating the LNG Terminal adjacent to the Sediment Disposal Area would be beneficial as it is a relatively less environmentally sensitive. Although there are potential future operational interface to be considered, these can be overcome by design solutions and close planning and establishing an operational interface with the CEDD who is responsible for the management of the Sediment Disposal Area operations.

Marine Traffic Fairways

Locating the LNG Terminal in the Study Area will avoid all existing navigation channels, vessel fairways and other shipping lanes which will help reduce potential collision from passing marine traffic.

It is also considered prudent, from a safe operations perspective, for the LNG Terminal to be located at a Site that is a suitable distance from areas of busy marine traffic. To the north of the Study Area is the Adamasta Channel traffic separation scheme which is a recommended route for high speed craft. To the south of the Study Area is the Zhujiang / Pearl River Estuary TSS which is used by ocean going vessels transiting to and from the ports in the Pearl River Delta. It is desirable to maintain a large a distance as possible between the LNG Terminal Jetty and the busy shipping lane frequently used by large vessels just outside of the HKSAR maritime boundary to decrease the collision risk potential, and also to maintain the maneuvering water space available and to avoid restricting the ability of the FSRU Vessel to berth at the LNG Terminal Jetty from the southern approach, if needed.

The Jetty Marine Traffic Impact Assessment (MTIA) that was carried out for the Study Area has demonstrated a low level of marine traffic activities, and these are mainly from fishing vessels and small crafts, which gives a lower risk of collision damage around the Site of the LNG Terminal.

Consequently, the Study Area is an area of low marine traffic, and a suitable separation distance from the boundary of the various marine vessel fairways and the Site of the LNG Terminal can be achieved.

Subsea Telecommunications Cables

To the west of the Study Area, there are ten (10) existing subsea telecommunications cables that run in a north / south direction under the seabed in what is termed the SW Lantau cable corridor. It is preferred that the location of the LNG Terminal is in an area free of existing subsea cables in order to reduce the risk of disruption and reduce Jetty construction risk, although the BPPS Pipeline will have to cross these subsea cables.

Consequently a Site for the LNG Terminal within the Study Area that avoids disturbance to these important subsea telecommunications cables is preferred.

As stated above, it is noted that the BPPS Pipeline connecting the LNG Terminal to the GRS at the BPPS will need to cross these cables (and in two (2) other locations along the LPS Pipeline route to the GRS at the LPS it also is required to cross subsea cables), therefore the input from and an agreement with the Subsea Cable Owners on the design and construction of the subsea pipeline / cable crossings will be required.

Consequently, interference between the location of the LNG Terminal and the existing subsea telecommunications cables is required to be minimised, and suitable engineering and construction special crossing arrangements are required where the subsea BPPS Pipeline and LPS Pipeline will cross any subsea cables. Appropriate design will be carefully studied and reviewed by the Project Proponent. Design will consider provisions to allow future new or replacement subsea cables to cross the BPPS Pipeline and the LPS Pipeline without impacting the integrity of the new cables, and the safety concern of installation across the Pipelines.

Proposed South Lantau Marine Park (SLMP)

A marine park area of at least 700ha is to be established as a mitigation measure for the Integrated Waste Management Facility (IWMF) under the project’s Environmental Permit (EP-429/2012). This proposed marine park will be located between Shek Kwu Chau and the Soko Islands as indicated in the approved EIA Report; the exact boundary of this marine park is yet to be finalised by EPD, whilst this proposed marine park will be administered by the AFCD. The timing of its designation is to be confirmed, with the project’s Environmental Permit (EP-429/2012/A) requiring designation immediately following the completion of construction works of the IWMF ([32]).

The detailed design and progress on the development of the proposed compensatory marine park of the IWMF Project and the proposed Soko Islands Marine Park were briefed to the Country and Marine Parks Board on 24 Nov 2017 ([33]). To achieve better synergy in the future management of these two Marine Parks, it is proposed by AFCD to combine them into one single marine park of approximately 2,067ha, to be named as the South Lantau Marine Park (SLMP). This approach will facilitate the future management and operation of the SLMP in terms of maintenance of facilities, enforcement and patrolling, implementation of fisheries enhancement measures, etc.

The location for the LNG Terminal has avoided the proposed SLMP and buffer distance to the proposed SLMP (approximately 100m) has been maintained considering other environmental and operational constraints in the vicinity. The buffer distance is demonstrated to be adequate based on no indirect water quality and marine ecological impacts on the proposed SLMP during the construction and operation phases of this Project.

There are no unacceptable impacts on the proposed SLMP from monitoring and management of third parties during operations of the LNG Terminal.

Consequently, the location of the Site of the LNG Terminal has taken into consideration the establishment of the boundary of the SLMP and a buffer distance has been maintained where practicable considering other environmental and operational constraints in the vicinity, and with no unacceptable impacts on the proposed SLMP from monitoring and management of third parties during operations of the LNG Terminal.

Distance to Land / Residential Areas

The nearest land masses to the Study Area are the unoccupied Soko Islands at approximately 2.5km (including Tau Lo Chau, at approximately 1.6km) to the west, whose potential users may include recreational users, and future users (e.g. of a potential spa and resort); and Shek Kwu Chau at approximately 4.5km to the north, whose potential users may include staff and inmates at a drug rehabilitation center and also future users around Shek Kwu Chau (e.g. proposed Integrated Waste Management Facilities).

The closest residential area to the Study Area are further north on Cheung Chau at approximately 7km away, however the views to the Study Area from the ferry pier and harbour town area are largely obscured by the seawalls protecting the Cheung Chau Typhoon shelter, as well as vessels in the bay.

The nearest recreational zones and residential areas on Lantau include the southern coastline of Lantau (approximately 7km away) and hiking trails on Lantau (at least 6km away).

Consequently, to minimise the potential impacts on recreational zones and potential existing and future users of the nearest land masses, the distance to the Site of the LNG Terminal has been maximized, i.e. located to the southeast of the Study Area.

Marine Mammal Population Density

Long-term monitoring studies carried out by AFCD and baseline surveys conducted for this EIA Study have mapped the population densities of both Chinese White Dolphin (CWD) and Finless Porpoise (FP) throughout the Study Area. The results indicate that relatively few CWD frequent the Study Area. In terms of FP population densities, the results indicate that FP densities are relatively lower to the east of the Study Area.

Consequently, to minimise the potential impacts on CWD and FP the Site of the LNG Terminal has been located to the east of the Study Area.

Operational Considerations

A number of marine and engineering studies have been undertaken focused on the Study Area, in parallel with the mapping of environmental, social, marine and planning constraints to develop the Site and layout arrangements of the LNG Terminal. Met-ocean studies were carried out considering the water depth, wave movement, wave heights, current speeds, winds impact etc. to refine the proposed Site for the LNG Terminal within the Study Area. In addition, a Mooring System Design Study was carried out to ensure that the FSRU Vessel (and an LNGC) can safely berth, and could remain on berth throughout the prevailing met-ocean conditions; the exception being the onset of a typhoon when the FSRU Vessel and an LNGC (if on berth at the time) would be required to deberth from the Jetty and sail to a safe location to avoid the typhoon.

As part of the studies referenced above, navigation simulations were carried out to confirm that the FSRU Vessel and an LNGC could transit to the Jetty, safely berth, and depart under normal operating and emergency conditions, and this does not impact the marine traffic passing to the south, or any adjacent marine facilities.

Ÿ FSRU Vessel and LNGC Operational Limits: Typical FSRU Vessel / LNGC operational limits for the Project based on other FSRU based LNG import projects and available met-ocean data on wind, waves and currents for the navigation approach, berthing and mooring of the FSRU Vessel and LNGCs alongside the Jetty, followed by the safe, simultaneous LNG unloading operations and send-out of natural gas have been assessed. These operational limits are based on LNG industry practice and information available during the preparation of this EIA Study and have been used to refine the selection of the preferred Site for the LNG Terminal and are presented in Table 2.2.

Table 2.2 Typical Operational Limits for FSRU Vessel and LNGC Operations

|

|

Limiting Wind Speed (m s-1)* |

Limiting Wave Height (m) |

Limiting Current Speed (m s-1) |

|

Navigation |

26.0 |

3.5 |

1.54

|

|

Berthing |

12.0 |

2.0 |

0.6

|

|

LNG Unloading Operations |

19.0 |

2.0 |

0.6

|

|

Jetty Mooring |

26.0 |

2.25 |

0.8

|

* Note that the table shows assumed sets of limits for wind, waves and currents which in reality are interactive, i.e. lowering the wind speed could potentially increase the tolerance of wave height and current speed. Specific met-ocean limits will be further determined during the implementation of the Project.

Ÿ FSRU Vessel / LNGC Transit in Hong Kong Waters: In general, the shorter the distance travelled, and less complex the manoeuvres required to be carried out in HKSAR waters by the FSRU Vessel and a visiting LNGC is preferred. As such, siting the LNG Terminal to the south of the Study Area is preferable.

Ÿ Met-ocean Conditions: An assessment of the met-ocean criteria (covering water depth, winds, waves, currents) coupled with a review of physical constraints (proximity to the BPPS and the LPS, Marine Parks, marine navigation and Sediment Disposal Area exclusions) has confirmed that the Study Area is the preferred location for the Site of the LNG Terminal. Siting an LNG Terminal outside the Study Area places it in areas where there are strong currents or shallow water (requiring significant dredging), or in the vicinity of busy shipping lanes, or a combination of the above.

n Bathymetry: The Met-ocean Study has shown that the eastern half of the Study Area has a water depth exceeding 15m which is suitable for safe LNG Terminal operations including FSRU Vessel and LNGC arrivals and departures. It has also been shown that the western half of the Study Area has water depths between 10 to 15m, therefore for this area to be suitable for safe LNG Terminal operations including FSRU Vessel and the more frequent LNGC arrivals and departures, capital and maintenance dredging to create a berthing pocket and potentially a navigation access channel, is likely to be required.

n Winds: It is considered that the wind speed / directionality is not significantly different across the Study Area therefore this is not considered a key determining factor in locating the LNG Terminal within the Study Area.

n Waves: The frequency of wave activities across the Study Area illustrates an essentially uniform distribution. The Study Area is considered suitable for LNG Terminal operations almost all year round, including FSRU Vessel and the more frequent LNGC arrivals and departures; therefore this is not considered a key determining factor in locating the LNG Terminal within the Study Area.

n Currents: Flood and Ebb tides, and related local currents, have a relatively uniform intensity across the Study Area, at a similar orientation to the peak wave energy. Current levels within the Study Area fall well below those required to inhibit safe LNG Terminal operations, including FSRU Vessel and the more frequent LNGC arrivals and departures, therefore this is not considered a key determining factor in locating the LNG Terminal within the Study Area.

Taken together, from the point of view of considering all of the above factors including marine traffic densities, FSRU Vessel and LNGC transits, and met-ocean conditions (including bathymetry, wind, waves, currents), the Study Area is found to be a suitable location for safe LNG Terminal operations – provided that the alignment of the LNG Terminal Jetty is arranged such that the dominant directions of waves and currents are respected, and that the most suitable side of the Jetty is selected for the permanent mooring of the FSRU Vessel.

Therefore, the Study Area was further assessed in order to determine the optimum location and orientation of the LNG Terminal.

2.3.4 Preferred Site and Orientation of LNG Terminal

Siting

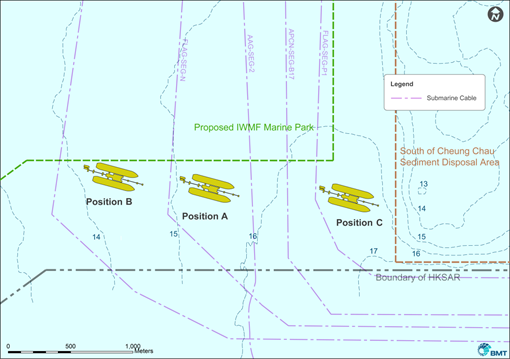

The environmental and physical constraints in the vicinity of the LNG Terminal are illustrated in Figure 2.6. It was identified that the eastern corner of the Study Area is best suited for siting the LNG Terminal. However, it is noted that three existing subsea cables (which are buried within the seabed) cross this area, therefore it is not be possible to locate the LNG Terminal directly within the subsea cable area. As such, other potential location options were considered for the Site of the LNG Terminal as shown in Figure 2.7, and their relative merits / demerits are discussed below.

1. Position A: Located in an available water space in close proximity to two existing subsea cables; where FSRU Vessel and LNGC access could be achieved with the minimum of dredging (if any); or

2. Position B: Located in an available water space west of the Study Area; with a greater separation distance between two existing subsea cables than Position A. However, the water depth is less at this location, and this would require dredging to provide a berthing pocket and a navigation channel to the LNG Terminal.

3. Position C: Located in an available water space at the eastern boundary of the Study Area, with a constraint being its proximity to the Sediment Disposal Area. However, the deeper water depth means that the FSRU Vessel and LNGC access could be achieved with the minimum of dredging (if any), and a shorter distance to travel to the LNG Terminal.

Figure 2.7 Potential Sites for the LNG Terminal

As discussed above, Position A and Position B were considered as other potential options for the Site of the LNG Terminal, however, it was identified that the water depths at these locations are shallower than at Position C, and access north of the LNG Terminal with a fully laden LNGC may not be viable at some states of the tide.

Therefore, Position C was identified as the preferred Site for the LNG Terminal as it is in deeper water and is a little closer to the HKSAR’s boundary (i.e. relatively less distance to travel by the LNGC); the constraint being the orientation required to achieve an adequate clearance from the existing subsea cables, and the proximity to the Sediment Disposal Area.

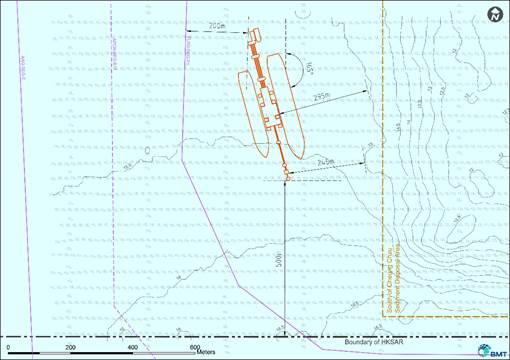

Orientation

The boundary conditions related to the Site for the LNG Terminal at Position C are (i) the nominal offset of 500m from the HKSAR southern waters boundary and the boundary of the Sediment Disposal Area stipulated by the Civil Engineering and Development Department and (ii) a predefined 200m separation from the nearest subsea cable to the west.

The preferred orientation of the Jetty, was selected on the basis of:

Ÿ Accessibility: The ease of access arrangements to the LNG Terminal under normal weather conditions for arrival and extreme weather conditions for departure; also considering if potential dredging may be required; and

Ÿ Operability: Loss of availability - as the orientation turns and the Jetty is positioned perpendicular to the dominant incident waves, increasing motions of the vessels and tolerances of lines and couplings.

In view of setting a balance between accessibility and operability, and recognizing the proximity to the Sediment Disposal Area and the proposed SLMP to Position C, the preferred orientation of the LNG Terminal is at 165° North, as illustrated below in Figure 2.8.

Figure 2.8 Preferred Orientation of the LNG Terminal

Conclusion

In the selection of the preferred Site for the LNG Terminal, full consideration has been given to the environmental, social, and marine constraints, and related benefits including suitable water depth to minimize the need for dredging; avoiding the nearby proposed SLMP; and the Site being in an area of relatively lower FP density (as identified by AFCD’s long-term monitoring and baseline surveys conducted for the EIA Study).

A benefit from the selection of Position C is that it maximizes the relative distance of the Site from the Soko Islands (including Tau Lo Chau), Shek Kwu Chau and the closest residential areas approximately 7km away on Cheung Chau and southern Lantau. The proposed Site for the LNG Terminal is to the west of the Sediment Disposal Area, which is considered to be a relatively less environmentally sensitive location.

Further, the proposed Site of the LNG Terminal and its navigation approach and manoeuvring / turning area) has also been determined on the basis of a number of operational considerations, i.e. the required water depth of >15m, the relatively low wave heights (minimizing exposure to swells and consequent disruption to LNG unloading operations), relatively lower peak current speeds of 1-1.5 knots (minimizing navigational impacts) and low marine traffic densities (minimizing impacts to/from other passing marine vessels), in addition to direct, close access to/from open HKSAR waters (benefitting navigation and access by the FSRU Vessel and the LNGCs to the LNG Terminal).

The environmental benefits and dis-benefits for the proposed Site of the LNG Terminal are presented below:

Benefits

1. Adjacent to the relatively less environmentally sensitive Sediment Disposal Area, but a manageable distance away;

2. Maintains a suitable separation distance from the boundary of the various vessel fairways;

3. Minimizes the proximity to and interference with the existing subsea cables;

4. Outside the boundary limits for the proposed SLMP;

5. Maximises the distance from potential existing and future users of the nearest land masses including the closest population on Cheung Chau and South Lantau, as well as potential existing or future users of Soko Islands (including Tau Lo Chau) and Shek Kwu Chau;

6. Maximises the distance from recreational zones;

7. In an area with few CWD, and relatively less FP;

8. Maximum water depth and thus minimizes requirements for capital and maintenance dredging and related marine sediment disposal;

9. Not in proximity to dense marine traffic areas; and

10. The transit of the FSRU Vessel and the LNGCs through HKSAR waters to the Site is relatively short.

Dis-benefits

1. Close planning and future operations interface with relevant Government departments, such as CEDD related to the proximity of the Site to the Sediment Disposal Area;

2. Close planning and future operations interface with relevant Government departments, such as AFCD related to the proximity to the proposed SLMP.

3. The LNG Terminal Jetty is in the vicinity of a subsea cable to the eastern boundary of the South West Lantau cable corridor.

Consequently, considering all of the above factors including access arrangements and operability, and with no unacceptable impacts on the proposed SLMP from monitoring and management of third parties during operations of the LNG Terminal, Position C with an orientation of 165° North is found to be the preferred Site for the LNG Terminal.

2.4 Consideration of Alignment options for BPPS Pipeline

2.4.1 Marine Only vs Marine-Land-Marine Approach

Based on the preferred Site for the LNG Terminal, a number of alternative alignment (herein also referred to as ‘route’) options were considered by CLP for the BPPS Pipeline that runs from the LNG Terminal to the GRS at the BPPS.

Three ‘marine only’ route options were considered for the pipeline route to BPPS, namely (i) Option B1: a subsea route running west from the LNG Terminal to the south of the SLMP, then passing to the southwest of Lantau Island, then running north to the landfall at the BPPS; (ii) Option B2: a subsea route running north from the LNG Terminal, then to the north of the proposed SLMP; and (iii) Option B3: a subsea route running west from the LNG Terminal through the proposed SLMP towards the Soko Islands, then turning south and running to the south of the Soko Islands (see Figures 2.9a-c).

A ‘marine – land – marine’ route option was also considered namely Option B4: a route running subsea west from the LNG Terminal, then turning to the north to a landfall on Lantau Island, then traversing Lantau Island (either buried below ground, or in a tunnel), then departing Lantau Island to join the subsea route running north to the landfall at the BPPS (see Figures 2.9a-c).

The BPPS Pipeline route options have been broadly defined, to enable their review and further refinement. As part of the pipeline route selection exercise, environmental, physical, risk and constructability constraints were reviewed to determine the most appropriate pipeline route where environmental impacts can be managed and mitigated.

Environmental Issues

Areas of known environmental importance in the marine and terrestrial environment (i.e. in western HKSAR waters, and on Lantau Island) through which the BPPS Pipeline may pass have been identified. The environmentally important areas and issues for the BPPS Pipeline route are illustrated in Figure 2.9a and discussed in Table 2.3.

Table 2.3 Environmental Issues for BPPS Pipeline Options

|

Issues |

Notes |

Marine Based (1) |

|

|

· Designated Marine Parks |

There is one designated Marine Park at Sha Chau and Lung Kwu Chau. Marine Parks are gazetted for conservation, recreation and educational purposes and are under the control of the Country and Marine Parks Authority (CMPA).

|

|

· Proposed Marine Parks |

There are several proposed Marine Park at South Lantau, Southwest Lantau, and the Marine Park related to the Airport’s Third Runway System in western Hong Kong waters.

|

|

· Fish Culture Zones |

There is a Fish Culture Zone (FCZ) within the South Lantau waters, which is located at Cheung Sha Wan. Impacts to FCZs are controlled by the Water Pollution Control Ordinance and the Marine Fish Culture Ordinance. FCZs can be regarded as water quality sensitive receivers.

|

|

· Seawater Intake Points |

Seawater intake points are located at Tuen Mun (WSD Intake), Airport, the Black Point Power Station and the Castle Peak Power Station. Intakes have their own water quality standards that have to be met during construction.

|

|

· Gazetted Bathing Beaches |

There are several gazetted bathing beaches in South Lantau and near Tuen Mun.

|

|

· Sites of Special Scientific Interest (SSSIs) |

There are two marine SSSIs located within along the northern Lantau coast which have been designated for ecological reasons. The SSSI at San Tau Beach (No. 58) was established because of the seagrass bed, whereas Tai Ho stream (No. 63) was established because of the natural stream, seagrass and mangrove stands at the southern end of Tai Ho Wan.

|

|

· Gazetted Artificial Reef Deployment Sites |

Artificial reefs (ARs) have been deployed in the Sha Chau and Lung Kwu Chau Marine Park and is planned to be deployed in waters around the Airport. ARs are deployed to enhance fisheries and marine ecological resources.

|

|

· Spawning Ground of Commercial Fisheries Resources |

Spawning ground of commercial fisheries resources is located in the North Lantau Waters.

|

|