1.1 PURPOSE OF THE MANUAL

1.2 PROJECT BACKGROUND

1.3 PROJECT COMPONENTS

1.4 OBJECTIVE OF THE EM&A

1.5 SCOPE OF THE EM&A PROGRAMME

1.6 WORKS PROGRAMME & WORKS LOCATIONS

1.7 ORGANISATION & STRUCTURE OF THE EM&A

1.8 STRUCTURE OF THE EM&A MANUAL

2.1 CONSTRUCTION PHASE

2.2 OPERATION PHASE

4 Noise

5.1 INTRODUCTION

5.2 SAMPLING & TESTING METHODOLOGY

5.3 SAMPLING FREQUENCY

5.4 SAMPLING DEPTHS & REPLICATION

5.5 WATER QUALITY COMPLIANCE

6.1 INTRODUCTION

6.2 WASTE MANAGEMENT PRACTICES

6.3 METHODOLOGY AND CRITERIA

7 Ecology

7.1 INTRODUCTION

7.2 MARINE MAMMAL MONITORING

7.3 MARINE MAMMAL EXCLUSION ZONE MONITORING

7.4 MARINE AND TERRESTRIAL ECOLOGY MITIGATION MEASURES

9 Visual

11 Environmental Site Inspection

11.1 SITE INSPECTIONS

11.2 COMPLIANCE WITH LEGAL & CONTRACTUAL REQUIREMENTS

11.3 ENVIRONMENTAL COMPLAINTS

11.4 LOG-BOOK

12 Reporting

12.1 GENERAL

12.2 BASELINE WATER QUALITY MONITORING REPORT

12.3 POST-CONSTRUCTION WATER QUALITY MONITORING REPORT

12.4 MONTHLY EM&A REPORTS

12.5 QUARTERLY EM&A SUMMARY REPORT

12.6 ANNUAL/ FINAL EM&A REVIEW REPORTS

12.7 WATER QUALITY MONITORING REPORT FOR THE FIRST YEAR OF OPERATION OF THE LNG TERMINAL

12.8 DATA KEEPING

12.9 INTERIM NOTIFICATIONS OF ENVIRONMENTAL QUALITY LIMIT EXCEEDANCES

Figure 1.1 Indicative Location of Key Project Components

Figure 1.2 Indicative Location of the Gas Receiving Station at Black Point Power Station

Figure 1.3 Indicative Location of the Gas Receiving Station at Lamma Power Station

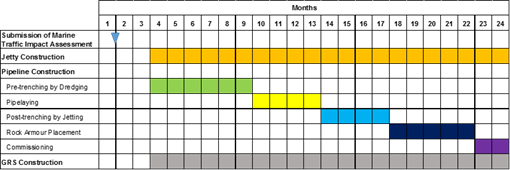

Figure 1.4 Preliminary Construction Programme of the Project

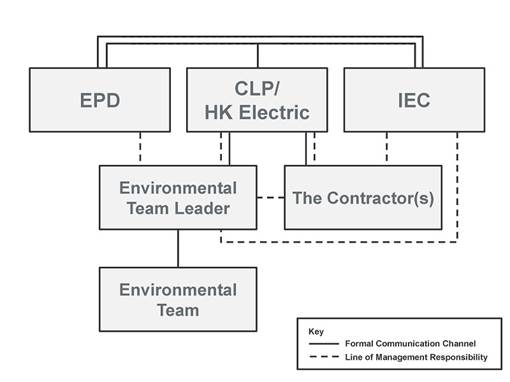

Figure 1.5 Indicative Project Organisation Chart

Figure 5.1 Water Quality Monitoring Stations

Figure 7.1 Proposed Vessel-Based Marine Mammal Survey Location

Figure 11.1 Flow Chart for Handling Environmental Complaints

LIST OF ANNEXES

Annex A Implementation Schedule

Annex B Proforma for Construction Phase EM&A Programme

1

Introduction

1.1 Purpose of the Manual

This Environmental Monitoring and Audit (EM&A) Manual (��the Manual��) has been prepared by ERM-Hong Kong, Limited (ERM) on behalf of CLP Power Hong Kong Limited (CLP) and The Hongkong Electric Company, Limited (HK Electric), the Project Proponent. The Manual is a supplementary document to the Environmental Impact Assessment (EIA) Report of the Hong Kong Offshore Liquefied Natural Gas (LNG) Terminal Project (hereafter referred to as the Project).

The Manual has been prepared in accordance with the EIA Study Brief (No. ESB-286/2015) and the Technical Memorandum of the Environmental Impact Assessment Process (EIAO-TM). The purpose of the Manual is to provide information, guidance and instruction to personnel charged with environmental duties and those responsible for undertaking EM&A work during Project construction and operation. It provides systematic procedures for monitoring and auditing the environmental performance of the Project.

This Manual contains the following information:

�P Responsibilities of the Contractor(s) for Project construction, Environmental Team (ET), and the Independent Environmental Checker (IEC) with respect to the EM&A requirements during the course of the Project;

�P Project organisation;

�P Requirements with respect to the construction and operational programme schedule and the necessary EM&A programme to track the environmental impact;

�P Details of the methodologies to be adopted including field, laboratory and analytical procedures, and details on quality assurance and quality control programme;

�P Preliminary definition of Action and Limit levels;

�P Establishment of Event and Action plans;

�P Requirements for reviewing pollution sources and working procedures required in the event of exceedances of applicable environmental criteria and/or receipt of complaints;

�P Requirements for presentation of EM&A data and appropriate reporting procedures; and

�P Requirements for review of EIA predictions and the effectiveness of the mitigation measures/environmental management systems and the EM&A programme.

CLP and HK Electric are both responsible for providing a safe, highly reliable and clean supply of electricity to Hong Kong��s population at reasonable cost.

CLP operates three power stations that supply electricity to the population in Kowloon, the New Territories and most of the outlying islands, namely the Castle Peak Power Station (CPPS), the Black Point Power Station (BPPS) and the Penny��s Bay Power Station (PBPS) which are owned by the Castle Peak Power Company Limited (CAPCO), a joint venture between CLP and China Southern Power Grid International (HK) Co., Limited, of which CLP holds a 70% interest.

HK Electric operates the Lamma Power Station (LPS) that supplies electricity to the population on Hong Kong and Lamma Island.

Hong Kong has no indigenous energy resources and all energy for Hong Kong needs to be imported. Dependable fuel sources are critical to maintaining reliable power supply for the Hong Kong population, while providing environmental benefits. The Hong Kong Special Administrative Region (HKSAR) Government plans to increase the percentage of natural gas used for power generation to around 50 per cent by 2020 to meet its pledged environmental targets.

The Hong Kong Climate Action Plan 2030+ Report states that the HKSAR Government will work closely with CLP and HK Electric; to ensure they can secure adequate supplies of natural gas and put the required infrastructure in place in the coming decade to handle the larger quantities of natural gas that will be required to be imported into Hong Kong in order to meet these HKSAR Government emissions targets.

To support the HKSAR Government in the increased use of natural gas in Hong Kong to reduce carbon intensity from 2020 onwards, CLP and HK Electric have identified that the development of an offshore LNG receiving terminal in Hong Kong based on Floating Storage and Regasification Unit (FSRU) technology presents an additional gas supply option that will provide long-term energy security for Hong Kong, as well as access to competitive gas supplies from world markets.

The purpose of CLP and HK Electric��s current proposal is to consider the development of an offshore LNG receiving terminal (LNG Terminal) in Hong Kong based on FSRU technology that is located in HKSAR waters to serve as a gas supply source to meet Hong Kong��s future power generation fuel supply needs (hereinafter referred to as the ��Hong Kong Offshore LNG Terminal�� or the ��Project��). The Project will increase CLP and HK Electric��s options regarding the sourcing of future gas supplies for Hong Kong, and provide the flexibility to directly access competitively priced gas from the global LNG market, including its associated spot market, therefore improving the Hong Kong LNG buyers�� future negotiating position, and diversity of gas supply sources. The Project is planned to be a ��shared-use�� import facility that has the capability to receive and store LNG and then deliver regasified LNG (natural gas) by subsea pipeline to the BPPS and the LPS.

The implementation of this Project is therefore a critical step for ensuring a gas supply source is made available to meet Hong Kong��s future power generation fuel supply needs and supporting air quality improvements and environmental performance in Hong Kong.

CLP is leading the development of the Project, acting for and on behalf of CAPCO and HK Electric.

The Project is comprised of the following key components which are discussed in detail in Section 3 of the EIA Report:

�P An offshore LNG receiving terminal (LNG Terminal) that comprises of the Jetty and the FSRU Vessel;

�P Two subsea gas pipelines, namely:

Ÿ The BPPS Pipeline, connecting the LNG Terminal with the GRS at the Black Point Power Station (BPPS); and

Ÿ The LPS Pipeline, connecting the LNG Terminal with the GRS at the Lamma Power Station (LPS)

�P The gas receiving station (GRS) facilities, namely:

Ÿ The GRS located within the BPPS; and

Ÿ The GRS located within the LPS.

The location of these components is shown in Figures 1.1 to 1.3.

The following elements of the Project are classified as Designated Projects under the Environmental Impact Assessment Ordinance (EIAO) (Cap. 499):

Ÿ Construction of a storage, transfer and trans-shipment facility of liquefied natural gas with a storage capacity of not less than 200 tonnes (Item L.2 of Part I of Schedule 2 of EIAO);

Ÿ Dredging operations for the construction and maintenance of the LNG Terminal Jetty, the construction of the BPPS Pipeline and the LPS Pipeline that exceeds 500,000m3 or are less than 500m from the nearest boundary of an existing or planned marine park (Item C.12 of Part I of Schedule 2 of EIAO); and

Ÿ Construction of the subsea gas BPPS Pipeline and LPS Pipeline connecting the LNG Terminal with the GRS at the BPPS and the GRS at the LPS (Item H.2 of Part I of Schedule 2 of EIAO).

1.4 Objective of the EM&A

The broad objective of this Manual is to define the procedures of the EM&A programme for monitoring the environmental performance of the Project during design, construction and operation. The construction and operational impacts arising from the implementation of the Project are specified in the EIA Report. The EIA Report also specifies mitigation measures and construction practices that may be needed to confirm compliance with the environmental criteria. These mitigation measures and their implementation requirements are presented in the Implementation Schedule of Mitigation Measures (Annex A).

The main objectives of the EM&A programme are to:

�P provide a database of environmental parameters against which to determine any short term or long term environmental impacts;

�P provide an early indication should any of the environmental control measures or practices fail to achieve the acceptable standards;

�P confirm that the mitigation recommendations of the EIA are included in the design of the Project;

�P clarify and identify potential sources of pollution, impact and nuisance arising from the works for the responsible parties;

�P confirm compliance with regulatory requirements, contract specifications and EIA study recommendations;

�P confirm compliance of environmental designs during the design phase of the Project with the specifications stated in the EIA Report and the Environmental Permit (EP);

�P monitor performance of the mitigation measures and to assess their effectiveness;

�P take remedial action if unexpected issues or unacceptable impacts arise;

�P verify the environmental impacts predicted in the EIA; and

�P audit environmental performance.

This EM&A Manual is a working document which will be reviewed periodically and updated if necessary during the course of implementing the project

1.5 Scope of the EM&A Programme

The scope of this EM&A programme is to:

�P establish baseline water quality levels at specified locations and implement monitoring requirements for water quality monitoring programme;

�P implement monitoring requirements for marine mammal monitoring programme;

�P implement inspection and audit requirements for waste management;

�P liaise with, and provide environmental advice (as requested or when otherwise necessary) to construction site staff on the significance and implications of the environmental monitoring data;

�P identify and resolve environmental issues and other functions as they may arise from the works;

�P check and quantify the Contractor(s)��s overall environmental performance, implementation of Event and Action Plans (EAPs), and remedial actions taken to mitigate adverse environmental effects as they may arise from the works;

�P conduct regular reviews of monitored impact data as the basis for assessing compliance with the defined criteria and to verify that necessary mitigation measures are identified and implemented, and to undertake additional ad hoc monitoring and auditing as required by special circumstances;

�P evaluate and interpret environmental monitoring data to provide an early indication should any of the environmental control measures or practices fail to achieve the acceptable standards, and to verify the environmental impacts predicted in the EIA;

�P manage and liaise with other individuals or parties concerning other environmental issues deemed to be relevant to the construction process;

�P conduct regular site inspections and audits of a formal or informal nature to assess:

(i) the level of the Contractor(s)��s general environmental awareness;

(ii) the Contractor(s)��s implementation of the recommendations in the EIA and their contractual obligations;

(iii) the Contractor(s)��s performance as measured by the EM&A;

(iv) the need for specific mitigation measures to be implemented or the continued usage of those previously agreed;

(v) to advise the site staff of any identified potential environmental issues; and

�P produce monthly EM&A reports which summarise project monitoring and auditing data, with full interpretation illustrating the acceptability or otherwise of any environmental impacts and identification or assessment of the implementation status of agreed mitigation measures.

1.6 Works Programme & Works Locations

The preliminary construction programme is given in Figure 1.4. The locations of works are shown in Figures 1.1 to 1.3.

Figure 1.4

Preliminary Construction Programme of the Project

|

|

1.7 Organisation & Structure of the EM&A

The EM&A will require the involvement of the Project Proponent, an Environmental Team (ET), an Independent Environmental Checker (IEC) and the Contractor(s). The roles and responsibilities of the various parties involved in the EM&A process are further expanded in the following sections and in Figure 1.5.

Figure 1.5

Indicative Project Organisation Chart

|

|

The Project Proponent will appoint an ET to conduct the site inspection and monitoring and, to provide specialist advice on the undertaking and implementation of environmental responsibilities. The ET will be led and managed by the ET Leader. The ET Leader will have relevant education, training, knowledge, experience and professional qualifications. Suitably qualified staff will be included in the ET, and the ET should not be in any way an associated body of the Contractor(s) for Project construction. For the purpose of this Manual, the ET Leader, who will be responsible for, and in charge of, the ET, is referred to as the person delegated the role of executing the EM&A requirements.

To maintain strict control of the EM&A process, the Project Proponent will appoint independent environmental consultants to act as an IEC to verify and validate/ audit the environmental performance of the Project Proponent��s Contractor(s) for Project construction and effectiveness of ET. The IEC will have previous relevant experience with checking and auditing similarly sized EM&A programmes and the IEC will be a recognised environmental professional. Sufficient and suitably qualified professional and technical staff will be employed by the IEC, as required under the EM&A programme for the duration of the Project.

The Project Proponent will:

�P employ an ET as described above;

�P employ an IEC as described above;

�P supervise the Contractor(s)�� activities and confirm that the requirements in the EM&A Manual are fully complied with;

�P inform the Contractor(s) when action is required to reduce impacts in accordance with the Event and Action Plans;

�P adhere to the procedures for carrying out complaint investigation; and

�P participate in joint site inspections undertaken by the ET and IEC.

The Contractor(s) for Project construction will:

�P implement the EIA recommendations and requirements where applicable;

�P provide assistance to the ET in carrying out monitoring and site inspections;

�P submit proposals on mitigation measures in case of exceedances of Action and Limit levels in accordance with the Event and Action Plans;

�P implement measures to reduce impact where Action and Limit levels are exceeded;

�P implement the corrective actions instructed by the Project Proponent/ET/IEC;

�P participate in the site inspections undertaken by the ET and the IEC, as required, and undertake any corrective actions instructed by the Project Proponent/ETL/IEC; and

�P adhere to the procedures for carrying out complaint investigation.

The ET will:

�P monitor various environmental parameters as required in this EM&A Manual;

�P assess the EM&A data and review the success of the EM&A programme determining the adequacy of the mitigation measures implemented and the validity of the EIA predictions as well as identify any adverse environmental impacts before they arise;

�P carry out regular site inspection to investigate the Contractor(s)��s site practice, equipment and work methodologies with respect to pollution control and environmental mitigation, and effect proactive action to pre-empt issues;

�P review the Contractor(s)��s working programme and methodology, and comment as necessary;

�P review and prepare reports on the environmental monitoring data and site environmental conditions;

�P report on the environmental monitoring results and conditions to the IEC, Contractor(s), EPD and the Project Proponent;

�P recommend suitable mitigation measures and/or review the proposals of mitigation measure from the Contractor(s) in the case of exceedance of Action and Limit levels in accordance with the Event and Action Plans; and

�P adhere to the procedures for carrying out complaint investigation.

The IEC will:

�P review and audit the implementation of the EM&A programme and the overall level of environmental performance being achieved;

�P arrange and conduct regular independent site audits of the works;

�P validate and confirm the accuracy of monitoring results, monitoring equipment, monitoring stations, monitoring procedures and locations of sensitive receivers;

�P audit the EIA recommendations and requirements against the status of implementation of environmental protection measures on site;

�P on an as needed basis, audit the Contractor(s)��s construction methodology and agree the appropriate, reduced impact alternative in consultation with the Project Proponent, the ET and the Contractor(s);

�P adhere to the procedures for carrying out complaint investigation;

�P review the effectiveness of environmental mitigation measures and project environmental performance including the proposed corrective measures;

�P review EM&A report submitted by the ET leader and feedback audit results to ET by signing off relevant EM&A proformas; and

�P report the findings of site audits and other environmental performance reviews to the Project Proponent, ET, EPD and the Contractor(s).

1.8 Structure of the EM&A Manual

The remainder of the Manual is set out as follows:

�P Section 2 sets out the EM&A requirements for air quality;

�P Section 3 sets out the EM&A requirements for hazard to human life;

�P Section 4 sets out the EM&A requirements for noise;

�P Section 5 details the EM&A requirements for water quality baseline and impact monitoring, and lists relevant monitoring equipment, compliance and Event and Action Plans (EAPs);

�P Section 6 details the EM&A requirements for waste management;

�P Section 7 details the EM&A requirements for ecology;

�P Section 8 details the EM&A requirements for fisheries;

�P Section 9 sets out the EM&A requirements for visual;

�P Section 10 sets out the EM&A requirements for cultural heritage;

�P Section 11 describes the scope and frequency of site environmental inspection;

�P Section 12 details the reporting requirements for the EM&A;

�P Annex A contains the implementation schedule summarising all mitigation measures proposed in the EIA Report;

�P Annex B contains the proforma for the EM&A programme, including monitoring and complaint log sheets.

2

Air Quality

2.1 Construction Phase

The EIA Study concluded that no adverse fugitive dust impact is anticipated during the construction phase, and dust monitoring is considered not necessary. However, it is recommended to conduct regular environmental site inspections, i.e. on a monthly basis, at the GRSs at the BPPS and the LPS to check the implementation of the dust control measures and good site practices as recommended in Section 4.10.1 of the EIA Report throughout the construction phase.

These measures are also summarised in the Implementation Schedule provided in Annex A.

2.2 Operation Phase

No adverse air quality impact is anticipated during the operation of the GRSs at the BPPS or the LPS. Environmental monitoring and audit during the operation phase is not considered necessary.

3

Hazard to Life

This EIA Study concluded that no unacceptable risks are foreseen as a result of the construction and operation of the proposed Project with safety management measures and safety systems outlined in Section 5.3.3 and Annex 5B of the EIA Report in place to further manage and minimise the external hazards from construction and operational activities.

For operation of the LNG Terminal, implementation of safety management measures and safety systems outlined in Section 5.3.3 and Annex 5B of the EIA Report is recommended, including conducting safety inspections and audits.

These safety measures are summarised in the Implementation Schedule provided in Annex A.

4

Noise

The EIA study of the Project concluded that no unacceptable impacts will be associated with the construction or operation of the Project. Based on this, no construction or operational noise monitoring is considered necessary. Nevertheless, regular site inspections and audits are recommended to be carried out during the construction phase in order to confirm that regulatory requirements are being met.

5

Water Quality

5.1 Introduction

A number of mitigation measures and standard site practice measures for marine and land-based construction activities have been recommended to reduce potential impacts to water quality sensitive receivers. These measures are summarised in the Implementation Schedule provided in Annex A.

In accordance with the recommendations of the EIA, water quality EM&A is required during construction phase and operation phase. The following sections provide details of the water quality monitoring to be undertaken by the ET to detect any deterioration of water quality and indirect impacts at water and ecological sensitive receivers. The water quality monitoring programme will be carried out to allow any deteriorating water quality to be readily detected and timely action taken to rectify the situation. The status and locations of water quality sensitive receivers and the marine works location may change after issuing this Manual. If required, the ET in consultation with the IEC will propose updated monitoring locations and seek approval from EPD.

Water quality monitoring for the Project can be divided into the following stages:

�P Marine water quality monitoring for dredging and jetting activities during construction phase of the BPPS Pipeline and the LPS Pipeline;

�P Verification of efficiency of silt curtain systems;

�P Marine water quality monitoring at selected nearby location during the first year of operation of the LNG Terminal ([1]); and

�P Marine water quality monitoring for maintenance dredging during operation phase of the LNG Terminal.

5.2 Sampling & Testing Methodology

5.2.1 Water Quality Parameters

The parameters that have been selected for measurement in situ and in the laboratory are those that were either determined in the EIA to be those with the highest potential to be affected by the construction works or are a standard check on water quality conditions. Parameters to be measured in the construction phase, operation phase are listed in Table 5.1.

Table 5.1 Parameters Measured in the Marine Water Quality Monitoring

|

Parameters |

Unit |

Abbr. |

Marine Water Quality Monitoring |

||

|

Baseline |

Construction Phase and Maintenance Dredging for Jetty |

First-year Operation |

|||

|

In situ measurements |

|

||||

|

Dissolved oxygen |

mg/L |

DO |

ü |

ü |

ü |

|

Dissolved oxygen saturation |

% |

DOS |

ü |

ü |

ü |

|

Temperature |

�XC |

- |

ü |

ü |

ü |

|

pH |

- |

- |

ü |

ü |

ü |

|

Turbidity |

NTU |

- |

ü |

ü |

|

|

Salinity |

‰ |

- |

ü |

ü |

ü |

|

Total Residual Chlorine

|

mg/L |

TRC |

ü |

|

ü |

|

Laboratory measurements |

|

||||

|

Suspended Solids (SS) |

mg/L |

SS |

ü |

ü |

ü |

|

Total Inorganic Nitrogen (TIN) |

mg/L |

TIN |

|

|

ü |

|

5-day Biochemical Oxygen Demand (BOD5) |

mg/L |

BOD5 |

|

|

ü |

In addition to the water quality parameters, other relevant data will also be measured and recorded in Water Quality Monitoring Logs, including the location of the sampling stations, water depth, time, weather conditions, sea conditions, tidal stage, current direction and velocity, special phenomena and work activities undertaken around the monitoring and works area that may influence the monitoring results. A sample data record sheet is shown in Annex B for reference.

5.2.2 Monitoring Equipment

For water quality monitoring, the following equipment will be used:

�P Dissolved Oxygen and Temperature Measuring Equipment - The instrument will be a portable, weatherproof dissolved oxygen measuring instrument complete with cable, sensor, comprehensive operation manuals, and will be operable from a DC power source. It will be capable of measuring: dissolved oxygen levels in the range of 0 - 20 mg L-1 and 0 - 200% saturation; and a temperature of 0 - 45 degrees Celsius. It shall have a membrane electrode with automatic temperature compensation complete with a cable of not less than 35m in length. Sufficient stocks of spare electrodes and cables shall be available for replacement where necessary (e.g. YSI model 59 DO meter, YSI 5739 probe, YSI 5795A submersible stirrer with reel and cable or an approved similar instrument).

�P Turbidity Measurement Equipment - The instrument will be a portable, weatherproof turbidity-measuring unit complete with cable, sensor and comprehensive operation manuals. The equipment will be operated from a DC power source, it will have a photoelectric sensor capable of measuring turbidity between 0 - 1000NTU and will be complete with a cable with at least 35m in length (for example Hach 2100P or an approved similar instrument).

�P pH Measurement Instrument - A portable pH meter capable of measuring a range between 0.0 and 14.0 will be provided for measuring pH.

�P Salinity Measurement Instrument - A portable salinometer capable of measuring salinity in the range of 0 - 40‰ will be provided for measuring salinity of the water at each monitoring location.

�P Water Depth Gauge �V A portable, battery-operated echo sounder (for example Seafarer 700 or a similar approved instrument) will be used for the determination of water depth at each designated monitoring station. This unit will preferably be affixed to the bottom of the work boat if the same vessel is to be used throughout the monitoring programme. The echo sounder should be suitably calibrated. The ET shall seek approval for their proposed equipment with the client prior to deployment.

�P Current Velocity and Direction �V No specific equipment is recommended for measuring the current velocity and direction. The environmental contractor shall seek approval of their proposed equipment with the client prior to deployment.

�P Positioning Device �V A Global Positioning System (GPS) shall be used during monitoring to allow accurate recording of the position of the monitoring vessel before taking measurements. The Differential GPS, or equivalent instrument, should be suitably calibrated at appropriate checkpoint (e.g. Quarry Bay Survey Nail) to verify that the monitoring station is at the correct position before the water quality monitoring commence.

�P Water Sampling Equipment - A water sampler, consisting of a PVC or glass cylinder of not less than two litres, which can be effectively sealed with cups at both ends, will be used (e.g. Kahlsico Water Sampler 13SWB203 or an approved similar instrument). The water sampler will have a positive latching system to keep it open and prevent premature closure until released by a messenger when the sampler is at the selected water depth.

�P Total Residual Chlorine - Total residual chlorine (TRC) shall be measured in-situ using approved test kit.

5.2.3 Sampling / Testing Protocols

All in situ monitoring instruments will be checked, calibrated and certified by a laboratory accredited under the Hong Kong Laboratory Accreditation Scheme (HOKLAS) or any other international accreditation scheme before use, and subsequently re-calibrated at monthly intervals throughout the stages of the water quality monitoring. Responses of sensors and electrodes will be checked with certified standard solutions before each use.

On-site calibration of field equipment shall follow the ��Guide to On-Site Test Methods for the Analysis of Waters��, BS 1427: 2009. Sufficient stocks of spare parts shall be maintained for replacements when necessary. Backup monitoring equipment shall also be made available so that monitoring can proceed uninterrupted even when equipment is under maintenance, calibration etc.

5.2.4 Laboratory Measurement and Analysis

All laboratory work shall be carried out in a HOKLAS accredited laboratory. Sufficient volume of each water sample shall be collected at the monitoring stations for carrying out the laboratory analyses. Using chain of custody forms, collected water samples will be transferred to an HOKLAS accredited laboratory for immediate processing. The determination work for SS, TIN and BOD5 shall start within 24 hours after collection of the water samples. The laboratory measurements shall be provided to the client as soon as the results are available. Analytical methodology and sample preservation of monitoring parameters will be based on the latest edition of Standard Methods for the Examination of Waste and Wastewater published by American Public Health Association (APHA), American Water Works Association (AWWA) and methods by USEPA, or suitable method in accordance with requirements of HOKLAS or another internationally accredited scheme. The submitted information should include pre-treatment procedures, instrument use, Quality Assurance/Quality Control (QA/QC) details (such as blank, spike recovery, number of duplicate samples per-batch etc.), detection limits and accuracy. The QA/QC details shall be in accordance with requirements of HOKLAS or another internationally accredited scheme.

Parameters for laboratory measurements, their standard methods and their detection limits are presented in Table 5.2.

Table 5.2 Standard Methods and Corresponding Detection Limits of Marine Water Quality Monitoring

|

Parameters |

Standard Methods |

Detection Limit |

Reporting Limit |

|

Baseline, Construction Phase and Maintenance Dredging |

|||

|

Dissolved oxygen (mg L-1) |

Instrumental, CTD |

0.1 |

‒ |

|

Temperature (�XC) |

Instrumental, CTD |

0.1 |

‒ |

|

pH |

Instrumental, CTD |

0.1 |

‒ |

|

Turbidity (NTU) |

Instrumental, CTD |

0.1 |

‒ |

|

Salinity (‰) |

Instrumental, CTD |

0.1 |

‒ |

|

SS (mg L-1) |

APHA 2540E |

1.0 |

‒ |

|

Operation Phase |

|||

|

Dissolved oxygen (mg L-1) |

Instrumental, CTD |

0.1 |

‒ |

|

Temperature (�XC) |

Instrumental, CTD |

0.1 |

‒ |

|

pH |

Instrumental, CTD |

0.1 |

‒ |

|

Turbidity (NTU) |

Instrumental, CTD |

0.1 |

‒ |

|

Salinity (‰) |

Instrumental, CTD |

0.1 |

‒ |

|

SS (mg L-1) |

APHA 2540E |

1.0 |

‒ |

|

TIN (mg L-1) |

By calculation (APHA 22ed 4500-NO2- B (FIA), APHA 22ed 4500-NO3- I(FIA), ASTM D3590-11 B (FIA)) |

0.02 |

‒ |

|

BOD5 (mg L-1) |

APHA 5210b |

0.1 |

‒ |

|

TRC (mg L-1) |

Test-kit * |

* |

* |

*Note: The testing methods, Quality Assurance/Quality Control (QA/QC) details, detection limits and accuracy shall be submitted by ET to IEC for agreement prior to the commencement of monitoring programme.

5.2.5 Monitoring Locations

The water quality monitoring locations for baseline, construction and first-year operation phases are shown in Figure 5.1 and detailed in Table 5.3 below. A schedule for water quality monitoring shall be prepared by the ET and approved by IEC and EPD prior to the commencement of the monitoring.

Table 5.3 Location of Water Quality Monitoring Stations for Construction Phase

|

Station |

Easting |

Northing |

Description |

Baseline |

Construction and Post-Construction |

|

|

During construction at the pipeline shore approach at LPS (KP18.2-17.4), West Lamma Channel (KP14.5-17.4) |

||||||

|

IM1 |

829453 |

806896 |

Impact Station for Coastline of South Lamma |

ü |

ü |

|

|

IM2 |

828235 |

810347 |

Impact Station for Coastline of North Lamma |

ü |

ü |

|

|

E1 |

827317 |

811510 |

Control Station for Ebb Tide |

ü |

ü |

|

|

F1 |

827892 |

804243 |

Control Station for Flood Tide |

ü |

ü |

|

|

During construction at the Double Berth Jetty to West Lamma Channel (KP0.0-14.5) |

||||||

|

IM3 |

820683 |

805931 |

Impact Station for Coastline of South Cheung Chau |

ü |

ü |

|

|

IM4 |

816997 |

805153 |

Impact Station for Coastline of South Shek Kwu Chau |

ü |

ü |

|

|

IM5 |

814068 |

804100 |

Boundary of Proposed South Lantau Marine Park (MP) |

ü |

ü |

|

|

IM6 |

814073 |

802029 |

Boundary of Proposed South Lantau MP |

ü |

ü |

|

|

E2 |

813367 |

808213 |

Control Station for Ebb Tide |

ü |

ü |

|

|

F2 |

822532 |

802161 |

Control Station for Flood Tide |

ü |

ü |

|

|

F3 |

815032 |

801161 |

Control Station for Flood Tide |

ü |

ü |

|

|

During construction at the Jetty Approach (KP0.0 �V 5.0), South of Soko Islands (KP5.0 �V 8.9), Southwest of Soko Islands (KP8.9 - 12.1) |

||||||

|

IM6 |

814073 |

802029 |

Boundary of Proposed South Lantau MP |

ü |

ü |

|

|

IM7 |

810833 |

801430 |

Boundary of Proposed South Lantau MP |

ü |

ü |

|

|

IM8 |

811652 |

802029 |

Boundary of Proposed South Lantau MP |

ü |

ü |

|

|

IM9 |

807101 |

801595 |

Boundary of Proposed South Lantau MP |

ü |

ü |

|

|

E3 |

802686 |

804123 |

Control Station for Ebb Tide |

ü |

ü |

|

|

F3 |

815032 |

801161 |

Control Station for Flood Tide |

ü |

ü |

|

|

During construction at the Adamasta Channel (KP12.1 - 15.6), Southwest Lantau (KP15.6 - 21.3) |

||||||

|

IM10 |

803145 |

806407 |

Boundary of Proposed Southwest Lantau MP |

ü |

ü |

|

|

IM11 |

802033 |

806487 |

Boundary of Proposed Southwest Lantau MP |

ü |

ü |

|

|

IM12 |

801041 |

807024 |

Boundary of Proposed Southwest Lantau MP |

ü |

ü |

|

|

IM13 |

800386 |

810750 |

Boundary of Proposed Southwest Lantau MP |

ü |

ü |

|

|

IM14 |

801376 |

810750 |

Boundary of Proposed Southwest Lantau MP |

ü |

ü |

|

|

E4 |

801571 |

811923 |

Control Station for Ebb Tide |

ü |

ü |

|

|

F4 |

809058 |

806567 |

Control Station for Flood Tide |

ü |

ü |

|

|

During construction at the West of Tai O to West of HKIA (KP21.3 �V 31.5) |

||||||

|

IM15 |

804820 |

821110 |

Boundary of Sha Chau and Lung Kwu Chau MP |

ü |

ü |

|

|

E5 |

804634 |

822606 |

Control Station for Ebb Tide |

ü |

ü |

|

|

F5 |

805185 |

816591 |

Control Station for Flood Tide |

ü |

ü |

|

|

During construction at the West of HKIA to Lung Kwu Chau (KP31.5 �V 37.5) |

||||||

|

IM15 |

804820 |

821110 |

Boundary of Sha Chau and Lung Kwu Chau MP |

ü |

ü |

|

|

IM17 |

804865 |

827855 |

Boundary of Sha Chau and Lung Kwu Chau MP |

ü |

ü |

|

|

IM16 |

805094 |

824250 |

Coral Colonies at Pak Chau |

ü |

ü |

|

|

E6 |

805418 |

832113 |

Control Station for Ebb Tide |

ü |

ü |

|

|

F5 |

805185 |

816591 |

Control Station for Flood Tide |

ü |

ü |

|

|

During construction at the Lung Kwu Chau to Urmston Anchorage (37.5 - 41.1), Urmston Road (KP41.1 �V 42.9) |

||||||

|

IM17 |

804865 |

827855 |

Boundary of Sha Chau and Lung Kwu Chau MP |

ü |

ü |

|

|

IM18 |

806220 |

827890 |

Boundary of Sha Chau and Lung Kwu Chau MP |

ü |

ü |

|

|

IM19 |

807274 |

829250 |

Impact Station for Coastline of Lung Kwu Tan |

ü |

ü |

|

|

E6 |

805418 |

832113 |

Control Station for Ebb Tide |

ü |

ü |

|

|

F6 |

808812 |

824266 |

Control Station for Flood Tide |

ü |

ü |

|

|

E5 |

804634 |

822606 |

Control Station for Flood Tide |

ü |

ü |

|

|

During construction at the West of BPPS (KP42.9 - 44.9), Pipeline shore approach at BPPS (KP44.9 - 45.0) |

||||||

|

IM19 |

807274 |

829250 |

Impact Station for Coastline of Lung Kwu Tan |

ü |

ü |

|

|

IM20 |

810252 |

832575 |

Impact Station for Coastline of Deep Bay |

ü |

ü |

|

|

IM21 |

808936 |

830867 |

Coral Colony at Artificial Seawall at BPPS |

ü |

ü |

|

|

IM22 |

808759 |

830684 |

Coral Colony at Artificial Seawall at BPPS |

ü |

ü |

|

|

E7 |

809784 |

834261 |

Control Station for Ebb Tide |

ü |

ü |

|

|

F6 |

808812 |

824266 |

Control Station for Flood Tide |

ü |

ü |

|

Table 5.4 Location of Water Quality Monitoring Station for Operation Phase

|

Station |

Easting |

Northing |

Description |

Operation |

|

|

Maintenance Dredging |

First Year of LNG Terminal |

||||

|

During operation phase |

|

||||

|

IM6 |

814073 |

802029 |

Boundary of Proposed South Lantau MP |

ü |

ü |

|

F3 |

815032 |

801161 |

Control Station for Flood Tide |

ü |

ü |

|

E2 |

813367 |

808213 |

Control Station for Ebb Tide |

ü |

ü |

The status and locations of water quality sensitive receivers and the monitoring sites may change after issuing this Manual. If such cases exist, the ET shall propose updated monitoring locations and seek approval from the IEC and EPD. The above exercise of reviewing the list of water quality monitoring stations should be conducted prior to each maintenance dredging.

When alternative monitoring locations are proposed, they shall be chosen based on the following criteria:

�P at locations close to and preferably at the boundary of the site activities as indicated in the EIA Report, which are likely to have water quality impacts;

�P close to the sensitive receptors which are directly or likely to be affected;

�P for monitoring locations located in the vicinity of the sensitive receptors, care should be taken to cause minimal disturbance during monitoring; and

�P control stations which are at locations representative of the project site in its undisturbed condition.

5.3 Sampling Frequency

5.3.1 Baseline Monitoring

Baseline conditions for water quality shall be established and agreed with the IEC and the EPD prior to the commencement of marine construction works for the BPPS Pipeline and the LPS Pipeline. The purpose of the baseline monitoring is to establish ambient conditions prior to the commencement of the marine construction works and to demonstrate the suitability of the proposed control monitoring stations. The baseline conditions shall normally be established by measuring the water quality parameters specified above.

The measurements shall be taken at all designated monitoring stations including control stations, at both mid-ebb and mid-flood tides on the same day for a minimum of three days per week for four weeks prior to the commencement of the marine construction works. Measurements shall be taken at each station at any time. The interval between two sets of monitoring shall not be less than 36 hours.

No construction activities shall be on-going in the vicinity of the stations during the baseline monitoring. The ET shall be responsible for undertaking the baseline monitoring and submitting the results within 10 working days from the completion of the baseline monitoring work.

The ET shall consider if baseline monitoring needs to be extended or repeated to take into account the seasonal variations in water quality, and seek agreement with the IEC and EPD. In exceptional cases when insufficient baseline monitoring data or questionable results are obtained, the ET shall seek approval from the IEC and the EPD on an appropriate set of data to be used as baseline reference.

The baseline monitoring schedule shall be issued to the IEC and EPD at least 2 weeks before the first day of the monitoring event for agreement. The baseline water quality conditions shall be established and agreed with EPD before commencement of marine construction works. EPD shall also be notified immediately for any changes in schedule.

5.3.2 Efficiency of Silt Curtain System

Different silt curtain arrangements have been recommended for marine dredging and jetting works under this Project, including (1) single silt curtain at grab dredger (with silt removal efficiency of 75%), (2) silt curtain at jetting machine (with silt removal efficiency of 85%) and (3) double layer of silt curtains at sensitive receivers (with silt removal efficiency of 80%). The ET shall conduct pilot tests to confirm that the efficiency of the silt curtain system to be adopted to satisfy the requirements in the EIA Report.

At the early stage of marine dredging and jetting works, the ET shall prepare the methodology for such pilot test for determination of silt removal efficiency of different silt curtain systems required, for agreement by IEC and EPD.

Regardless of the measured efficiency of the silt curtain system, the event and action plan shall only be based on the monitoring results at the proposed monitoring stations.

5.3.3 Construction Phase

During periods when there are pipeline dredging or jetting works, impact monitoring shall be undertaken at the monitoring stations as shown in Figure 5.1 and Table 5.3 three times a week. Monitoring at each station would be undertaken at both mid-ebb and mid-flood tides on the same day. The tidal range selected for the impact monitoring will be at least 0.5m for both flood and ebb tides as far as practicable. The interval between two sets of monitoring would not be less than 36 hours. The monitoring frequency would be increased in the case of exceedances of Action/Limit Levels if considered necessary by ET. Monitoring frequency would be maintained as far as practicable.

The monitoring location/position, time, water depth, water temperature, salinity, weather conditions, sea conditions, tidal stage, special phenomena and work underway at the marine works site will be recorded.

5.3.4 Post-Construction Monitoring

Upon completion of all marine construction activities, a post-construction water quality monitoring exercise would be carried out for four weeks, in the same manner as the impact monitoring.

5.3.5 First-year of LNG Terminal Operation

Upon commencement of the LNG Terminal��s operation, an operation phase water quality monitoring exercise shall be carried out for one year, in the same manner as the baseline monitoring except at a frequency of once per week. Monitoring shall be conducted at proposed locations stated in Table 5.4. In case of non-compliance, suitable actions shall be undertaken to notify the plant operator for the non-compliance and identify the cause for the non-compliance. Corrective and remedial actions shall be implemented to improve the effluent quality. The non-compliance events and preventive measures shall be documented. This discharge is subject to the control under WPCO. Thus, a licence under WPCO should be obtained in due course.

5.3.6 Maintenance Dredging

In case maintenance dredging at the LNG Terminal is required, the same water quality monitoring exercise, including baseline monitoring (Section 5.3.1), impact monitoring (Section 5.3.3) and post-construction monitoring (Section 5.3.4) shall be conducted to before, during and after the dredging works. Monitoring shall be conducted at proposed locations stated in Table 5.4.

5.4 Sampling Depths & Replication

For baseline, construction phase and operation phase monitoring, each applicable station will be sampled and measurements/ water samples will be taken at three depths, 1m below the sea surface, mid-depth and 1m above the seabed. For stations that are less than 3m in depth, only the mid-depth sample shall be taken. For stations that are less than 6m in depth, only the surface and seabed sample shall be taken. For in situ measurements, duplicate readings shall be made at each water depth at each station. Duplicate water samples shall be collected at each water depth at each station.

5.5 Water Quality Compliance

Water quality monitoring will be evaluated against Action and Limit Levels. The key assessment parameters are dissolved oxygen (DO), temperature, suspended solids (SS), total inorganic nitrogen (TIN) and biochemical oxygen demand (BOD5) and total residual chlorine (TRC), and thus Action and Limit Levels based on the assessment criteria are identified for these. However, turbidity can also provide valuable instantaneous information on water quality and thus Action and Limit Levels are also recommended for this parameter to facilitate quick responsive action in the event of any apparent unacceptable deterioration attributable to the works. The proposed Action and Limit Levels are shown in Table 5.5.

Action and Limit levels are used to determine whether operational modifications are necessary to mitigate impacts to water quality. In the event that the levels are exceeded, appropriate actions in Event and Action Plan (Table 5.6) should be undertaken and a review of works will be carried out by the Contractor(s).

Any noticeable change to water quality will be recorded in the monitoring reports and will be investigated and remedial actions will be undertaken to reduce impacts. Particular attention will be paid to the Contractor(s)��s implementation of the recommended mitigation measures.

Site audit will be conducted throughout the construction phase of the land and marine-based works to confirm the implementation of the water pollution control measures and good site practices as recommended in Annex A.

Table 5.5 Action and Limit Level for Water Quality

|

Parameter |

Action Level |

Limit Level |

|

Construction Phase and Maintenance Dredging Marine Water Monitoring |

||

|

DO in mg L-1 a |

Surface and Middle 5th%-ile of baseline data for surface and middle layers Bottom 5th%-ile of baseline data for bottom layer

|

Surface and Middle 4 mg L-1 or 1%ile of baseline for surface and middle layers Bottom 2 mg L-1 or 1%ile of baseline for bottom layer

|

|

Turbidity in NTU (Depth-averaged b) c |

95th%-ile of baseline data, and 120% of the relevant control station's turbidity at the same tide of the same day

|

99th%-ile of baseline data, and 130% of the relevant control station's turbidity at the same tide of the same day |

|

SS in mg L-1 (Depth-averaged b) c |

95th%-ile of baseline data, and 120% of the relevant control station's SS at the same tide of the same day

|

99th%-ile of baseline data, and 130% of the relevant control station's SS at the same tide of the same day |

|

First-year Operation Phase Marine Water Monitoring |

||

|

DO in mg L-1 a |

Surface and Middle 5th%-ile of baseline data for surface and middle layers Bottom 5th%-ile of baseline data for bottom layer

|

Surface and Middle 4 mg L-1 or 1%ile of baseline for surface and middle layers Bottom 2 mg L-1 or 1%ile of baseline for bottom layer

|

|

Water temperature in �XC (Depth-averaged b) c |

��1.5 �XC of baseline data, and ��1.5 �XC of the relevant control station's water temperature at the same tide of the same day |

��2.0 �XC of baseline data, and ��2.0 �XC of the relevant control station's water temperature at the same tide of the same day |

|

Turbidity in NTU (Depth-averaged b) c |

95th%-ile of baseline data d, and 120% of the relevant control station's turbidity at the same tide of the same day |

99th%-ile of baseline data d, and 130% of the relevant control station's turbidity at the same tide of the same day |

|

SS in mg L-1 (Depth-averaged b) c |

95th%-ile of baseline data d, and 120% of the relevant control station's SS at the same tide of the same day |

99th%-ile of baseline data d, and 130% of the relevant control station's SS at the same tide of the same day |

|

TIN in mg L-1 (Depth-averaged b) c |

95th%-ile of baseline data d, and 120% of the relevant control station's TIN at the same tide of the same day |

99th%-ile of baseline data d, and 130% of the relevant control station's TIN at the same tide of the same day |

|

BOD5 in mg L-1 (Depth-averaged b) c |

95th%-ile of baseline data d, and 120% of the relevant control station's BOD5 at the same tide of the same day |

99th%-ile of baseline data d, and 130% of the relevant control station's BOD5 at the same tide of the same day |

|

TRC in mg L-1 (Depth-averaged b) c |

0.02 mg L-1 |

0.02 mg L-1 |

|

Notes: a. For DO, non-compliance of the water quality limits occurs when monitoring result is lower than the limits. b. ��Depth-averaged�� is calculated by taking the arithmetic means of reading of all three depths. c. For water temperature, salinity, SS, turbidity, BOD5, TIN and TRC, non-compliance of the water quality limits occurs when monitoring result is higher than the limits. d. Baseline data from EPD Marine Water Quality Monitoring Station SM17 should be referred. The proposed monitoring data shall be submitted to EPD for approval prior to the commencement of monitoring programme. |

||

Table 5.6 Event and Action Plan for Water Quality Monitoring

|

Event |

Action |

|||

|

ET |

IEC |

Contractor(s) |

Project Proponent |

|

|

Action Level being exceeded by one sampling day |

1. Repeat in-situ measurement to confirm findings; 2. Check monitoring data, plant, equipment and Contractor(s)��s working methods; 3. Identify source(s) of impact and record in notification of exceedance; 4. Inform IEC, Contractor(s) and Project Proponent.

|

1. Check monitoring data submitted by ET and Contractor(s)��s working methods. |

1. Confirm receipt of notification of exceedance in writing; 2. Check plant and equipment and rectify unacceptable practice. |

1. Confirm receipt of notification of exceedance in writing. |

|

Action Level being exceeded by two or more consecutive sampling days |

1. Repeat in-situ measurement to confirm findings; 2. Check monitoring data, plant, equipment and Contractor(s)��s working methods; 3. Identify source(s) of impact and record in notification of exceedance; 4. Inform IEC, Contractor(s) and Project Proponent; 5. Discuss with IEC and Contractor(s) on additional mitigation measures and ensure that they are implemented

|

1. Check monitoring data submitted by ET and Contractor(s)��s working methods; 2. Discuss with ET and Contractor(s) on additional mitigation measures and advise Project Proponent accordingly; 3. Assess the effectiveness of the implemented mitigation measures.

|

1. Confirm receipt of notification of exceedance in writing; 2. Check plant and equipment and rectify unacceptable practice; 3. Consider changes of working methods; 4. Discuss with ET and IEC on additional mitigation measures and propose them to Project Proponent within 3 working days; 5. Implement the agreed mitigation measures. |

1. Confirm receipt of notification of exceedance in writing; 2. Discuss with the IEC on the proposed additional mitigation measures and agree on the mitigation measures to be implemented. 3. Ensure additional mitigation measures are properly implemented. |

|

Limit Level being exceeded by one sampling day |

1. Repeat in situ measurement to confirm findings; 2. Check monitoring data, plant, equipment and Contractor(s)��s working methods; 3. Identify source(s) of impact and record in notification of exceedance; 4. Inform IEC, Contractor(s), Project Proponent and EPD; 5. Discuss with IEC and Contractor(s) on additional mitigation measures and ensure that they are implemented

|

1. Check monitoring data submitted by ET and Contractor(s)��s working methods; 2. Discuss with ET and Contractor(s) on additional mitigation measures and advise Project Proponent accordingly; 3. Assess the effectiveness of the implemented mitigation measures.

|

1. Confirm receipt of notification of exceedance in writing; 2. Check plant and equipment and rectify unacceptable practice; 3. Critically review the need to change working methods; 4. Discuss with ET and IEC on additional mitigation measures and propose them to Project Proponent within 3 working days; 5. Implement the agreed mitigation measures. |

1. Confirm receipt of notification of exceedance in writing; 2. Discuss with the IEC on the proposed additional mitigation measures and agree on the mitigation measures to be implemented. 3. Ensure additional mitigation measures are properly implemented. 4. Request Contractor(s) to critically review the working methods. |

|

Limit Level being exceeded by two or more consecutive sampling days |

1. Repeat in situ measurement to confirm findings; 2. Check monitoring data, plant, equipment and Contractor(s)��s working methods; 3. Identify source(s) of impact and record in notification of exceedance; 4. Inform IEC, Contractor(s), Project Proponent and EPD; 5. Discuss with IEC and Contractor(s) on additional mitigation measures and ensure that they are implemented

|

1. Check monitoring data submitted by ET and Contractor(s)��s working methods; 2. Discuss with ET and Contractor(s) on additional mitigation measures and advise Project Proponent accordingly; 3. Assess the effectiveness of the implemented mitigation measures. |

1. Confirm receipt of notification of exceedance in writing; 2. Check plant and equipment and rectify unacceptable practice; 3. Critically review the need to change working methods; 4. Discuss with ET and IEC on additional mitigation measures and propose them to Project Proponent within 3 working days; 5. Implement the agreed mitigation measures. 6. As directed by Project Proponent, slow down or stop all or part of the marine construction works until no exceedance of Limit Level. |

1. Confirm receipt of notification of exceedance in writing; 2. Discuss with the IEC on the proposed additional mitigation measures and agree on the mitigation measures to be implemented. 3. Ensure additional mitigation measures are properly implemented. 4. Request Contractor(s) to critically review the working methods; 5. Consider and instruct, if necessary, the Contractor(s) to slow down or to stop all or part of the marine construction works until no exceedance of Limit Level |

6

Waste Management

6.1 Introduction

The construction of the Project is expected to generate the following types of waste during the construction phase:

�P Dredged marine sediment;

�P Construction & demolition (C&D) materials;

�P Chemical waste; and

�P General refuse.

Mitigation measures, where appropriate, have been recommended as part of the EIA to avoid or reduce potential adverse environmental impacts associated with handling, collection, transport and disposal of waste arising from the construction of the proposed Project.

Waste management will be the Contractor(s)��s responsibility and wastes produced during the construction phase will be managed in accordance with appropriate waste management practices and EPD��s regulations and requirements.

Auditing of waste management practices during regular site inspections on land-based work sites (at the GRSs at the BPPS and the LPS), and at marine-based work sites (on marine vessels and at the Jetty) will be conducted to determine if wastes are being managed in accordance with the approved procedures and the site Waste Management Plans. The construction Contractor(s) will be responsible for the implementation of any mitigation measures to reduce waste or redress issues arising from the waste materials.

6.2 Waste Management Practices

The waste management practices and recommended mitigation measures will be incorporated into a Waste Management Plan (WMP) as stated in the Practice Notes for Authorised Persons, Registered Structural Engineers and Registered Geotechnical Engineers (PNAP) ADV-19 Construction and Demolition waste for the Project for managing the different types of wastes by the Contractors on site. The WMP will become a part of the Environmental Management Plan (EMP). The contractor is required to prepare the EMP and submit it to the Project Proponent for approval and then implement the EMP accordingly.

The WMP shall describe the arrangements for avoidance, reuse, recovery and recycling, handling, collection, transport, the estimated rate of C&D materials generation and disposal, and the recommended mitigation measures on waste management as set out in Section 8.5 of the EIA Report. The WMP shall indicate the disposal arrangements and locations of C&D materials and other wastes.

A Trip Ticket system will be included in the WMP. Surplus excavated spoil and other wastes will not be disposed at any other designated disposal locations unless otherwise approved in writing by EPD, Secretary of Public Fill Committee and/or other authorities as appropriate.

The Implementation Schedule (Annex A) provides details on the appropriate mitigation measures for avoiding and preventing adverse environmental impacts associated with dredged marine sediment, C&D materials, chemical wastes, general refuse and sewage from the workforce; as well as industrial wastes from maintenance activities and material from maintenance dredging. The WMP will be refined and updated as more detailed information is generated on the volume of dredged marine sediment and the agreed disposal arrangements. Similarly, it will be regularly reviewed, and updated as appropriate, throughout the course of the construction works to confirm that it remains current with the latest detailed information and works practices.

The WMP will also outline the requirements for a waste audit program to verify that the measures outlined in the plan are effectively implemented and adhered too.

6.3 Methodology and Criteria

The construction Contractor(s) must confirm that the necessary disposal permits or licences are obtained from appropriate authorities in accordance with the various Ordinances. In addition to the monthly joint inspections/ audits, each construction Contractor(s) will designate a member of staff as being responsible for routine inspections and audits of on-site waste management practices, with reference to the relevant legislation and guidelines as well as the recommendations given in the Implementation Schedule contained in Annex A of this Manual, and defined below:

(1) General Legislation

�P Waste Disposal Ordinance (WDO) (Cap 354);

�P Waste Disposal (Chemical Waste) (General) Regulation (Cap 354C);

�P Buildings Ordinance (Cap 123);

�P Land (Miscellaneous Provisions) Ordinance (Cap 28);

�P Public Health and Municipal Services Ordinance (Cap 132) �V Public Cleansing and Prevention of Nuisances Regulations;

�P Dumping at Sea Ordinance (DASO) (Cap. 466); and

�P Merchant Shipping (Prevention and Control of Pollution) Ordinance (Cap 413).

(2) Other Relevant Guidelines

�P Waste Disposal Plan for Hong Kong (December 1989), Planning, Environment and Lands Branch Government Secretariat, HKSAR Government;

�P Code of Practice on the Packaging, Labelling and Storage of Chemical Wastes (1992), EPD, HKSAR Government;

�P Hong Kong Planning Standards and Guidelines Planning (2014), Planning Department, HKSAR Government;

�P WBTC No. 2/93 - Public Dumps, Works Branch, HKSAR Government;

�P WBTC No. 2/93B - Public Filling Facilities, Works Branch, HKSAR Government;

�P WBTC No. 16/96 - Wet Soil in Public Dumps, Works Branch, HKSAR Government;

�P Waste Reduction Framework Plan, 1998 to 2007, Planning, Environment and Lands Bureau, Government Secretariat, 5 November 1998;

�P WBTC No. 4/98 and 4/98A - Use of Public Fill in Reclamation and Earth Filling Projects, Works Bureau, HK SAR Government;

�P Project Administration Handbook for Civil Engineering Works, Section 3.3(i) of Chapter 2 and Section 4.13 of Chapter 4 - Incorporation of Information on Construction and Demolition Material Management in Public Works Subcommittee Papers, Hong Kong SAR Government;

�P WBTC No. 12/2000 - Fill Management, Works Bureau, HKSAR Government;

�P WBTC No. 19/2001 - Metallic Site Hoardings and Signboards; Works Bureau, HKSAR Government;

�P Project Administration Handbook for Civil Engineering Works, Section 21.25 of Chapter 7 and Section 9.12 of Chapter 5 - Control of Site Crushers, HKSAR Government;

�P WBTC No. 12/2002 - Specifications Facilitating the Use of Recycled Aggregates, Works Bureau, HKSAR Government;

�P Project Administration Handbook for Civil Engineering Works, Section 4.1.3 of Chapter 4 - Management of Construction and Demolition Material Including Rock, HKSAR Government;

�P ETWB TC(W) No. 19/2005 - Environmental Management on Construction Sites, Environment, Transport and Works Bureau, HKSAR Government;

�P DevB TC(W) No. 6/2010 - Trip Ticket System for Disposal of Construction & Demolition Materials, Development Bureau, HKSAR Government;

�P Practice Notes for Authorised Persons, Registered Structural Engineers and Registered Geotechnical Engineers (PNAP) ADV-19 Construction and Demolition Waste; and

�P PNAP ADV-21 Management Framework for Disposal of Dredged/ Excavated Sediment.

The Contractor(s)��s waste management practices will be audited with reference to the checklist detailed in Table 6.1 below.

Details of the required mitigation measures are included in the Implementation Schedule of Annex A of this EM&A Manual.

Table 6.1 Waste Management Checklist

|

Activities |

Timing |

Checking Frequency |

If non-compliance noted, Action Required |

|

Necessary waste disposal permits or licences have been obtained |

Before the commencement of works |

Once |

The ET will inform the Contractor(s), IEC and Project Proponent. The Contractor(s) will apply for the necessary permits/ licences prior to disposal of the waste. The ET will verify that corrective action has been taken.

|

|

Dredged sediments are managed and disposed in accordance with PNAP ADV-21: Management Framework for Disposal of Dredged/ Excavated Sediment and Dumping at Sea Ordinance (DASO). |

Throughout the dredging works |

Each Month

|

The ET will inform the Contractor(s), IEC and Project Proponent. Project Proponent will instruct the Contractor(s) to manage and dispose the dredged materials properly. The Contractor(s) will immediately suspend dredging until the dredging materials are properly managed and disposed.

|

|

Waste are collected by licensed waste hauliers and disposed of at licensed sites. |

Throughout the works |

Each Week |

The ET will inform the Contractor(s), IEC and Project Proponent. Project Proponent will instruct the Contractor(s) to comply. The Contractor(s) will temporarily suspend waste collection of that particular waste until a licensed waste haulier is used. Corrective action will be undertaken within 48 hours.

|

|

Records of quantities of wastes generated, recycled and disposed of and the disposal sites are properly kept.

|

Throughout the works |

Each Month |

The ET will inform the Contractor(s), IEC and Project Proponent. The Contractor(s) will estimate the missing data based on previous records and the activities carried out. The ET will review the results and forward to Project Proponent for approval.

|

|

Sufficient waste disposal points are provided. Wastes are collected and removed from site in a timely manner. General refuse is collected on a regular basis.

|

Throughout the works |

Each Week |

The ET will inform the Contractor(s), IEC and Project Proponent. Project Proponent will instruct the Contractor(s) to remove waste accordingly. |

|

Waste storage areas are properly cleaned and do not cause windblown litter and dust nuisance. Appropriate measures to reduce windblown litter and dust nuisance of waste will be adopted, e.g. by either covering trucks or by transporting wastes in enclosed containers.

|

Throughout the works |

Each Week |

The ET will inform the Contractor(s), IEC and Project Proponent. Project Proponent will instruct the Contractor(s) to clean the storage area and/or cover the waste. |

|

Different types of waste are segregated in different containers or skip to enhance reuse and recycling of material and proper disposal of waste. |

Throughout the works |

Each Week |

The ET will inform the Contractor(s), IEC and Project Proponent. Project Proponent will instruct the Contractor(s) to provide separate skips/ containers. The Contractor(s) will verify that the workers place the waste in the appropriate containers.

|

|

Chemical wastes are stored, handled and disposed of in accordance with the Code of Practice on the Packaging, Handling and Storage of Chemical Wastes, published by the EPD. Chemical wastes are separated for special handling and appropriate treatment at the Chemical Waste Treatment Centre at Tsing Yi. |

Throughout the works |

Each Week |

The ET will inform the Contractor(s), IEC and Project Proponent. Project Proponent will instruct the Contractor(s) to rectify the issues immediately. Warning will be given to the Contractor(s) if corrective actions are not taken within 24 hrs. |

|

|

|

|

|

Note: ET �V Environmental Team, IEC �V Independent Environmental Checker

7

Ecology

7.1 Introduction

The EIA indicates that construction phase impacts with recommended mitigation, and operation phase impacts are not expected to be unacceptable to terrestrial and marine ecological resources. Appropriate mitigation measures are proposed in the EIA to control the environmental impacts to marine and terrestrial ecology to within acceptable levels.

The following sections provide details of the measures to be undertaken by the ET to ensure that the measures recommended in the EIA are carried out.

7.2 Marine Mammal Monitoring

In order to determine the efficacy of the recommended mitigation measures and provide verification of impact prediction/ evaluation results, monitoring of marine mammal is recommended. Monitoring shall cover a baseline period, the construction and post-construction monitoring. The monitoring will be conducted using vessel-based line transect survey and passive acoustic monitoring (PAM) method. All monitoring should be led by suitably qualified persons (degree in biology or equivalent).

Details on the vessel-based line transect survey and PAM survey are presented below. The ET shall finalise the marine mammal monitoring programme with Agriculture, Fisheries and Conservation Department (AFCD) prior to the monitoring being undertaken.

7.2.1 Vessel-based Line Transect Survey

General Approach, Schedule and Survey Area

Vessel-based marine mammal survey by means of systematic line-transect boat survey will be undertaken to examine the distribution and encounter rate of Finless Porpoise in southern Lantau where a majority of Project construction works would take place. Survey transects are proposed to cover three survey areas for line-transect boat surveys, namely Southwest Lantau, Southeast Lantau and Lamma are presented in Figure 7.1. The methodology of the survey will be consistent and compatible with that adopted in the EIA baseline surveys as well as the long-term marine mammal monitoring programme conducted by AFCD since 1995 to allow potential comparisons and pooling data for analysis.

The transect boat survey will be conducted from a 15m inboard vessels (with an open upper deck above the pilothouse, providing a mostly unobstructed 180�X view of the area ahead of the vessel), weather permitting (Beaufort 0-5, no heavy rain, and visibility > 1,200m). The marine mammal observer (MMO) team will conduct searches and observations from the flying bridge area, 4-5m eye height above the water surface. In order to ensure the quality of the data and allow consistency with the long-term AFCD database, and take consideration of the sea conditions of the monitoring site, a team of three qualified and trained MMOs will make up the survey team.

As the vessel transits the transect lines at a relatively constant speed of 13-15km hr-1, the primary MMO searches for marine mammals continuously through 7 X 50 marine binoculars. A second MMO searches with unaided eye and fills out data sheets. Both MMOs search ahead of the vessel, between 270�X and 90�X (in relation to the bow, which is defined as 0�X). MMOs rotate positions approximately every 30 minutes. There will be an additional MMO on the boat, who rotate into position to give observers a rest after each hour of search effort, thereby minimizing fatigue.

Effort data collected during on-effort monitoring periods includes time and position for the start and end of search effort, vessel speed, sea state (Beaufort scale), visibility, and distance travelled in each series (a continuous period of search effort). When marine mammals are sighted, the MMO fills out a sighting sheet (Annex B), and generally the team is taken off-effort and the vessel is diverted from its course to approach the marine mammal group for group size estimation, behavioural observations, and collection of identification photos. The sighting sheet includes information on initial sighting angle and distance, position of initial sighting, sea state, group size and composition, and behaviour, such as response to the survey vessel and associations with vessels. Position, distance travelled, and vessel speed are obtained from a hand-held Global Positioning System (GPS) unit.

All records of marine mammal sightings will be collated, compiled and integrated with Geographic Information System (GIS). Positions of sightings together with group sizes, activities and calf occurrence will be plotted on figures for illustration of spatial and temporal patterns of porpoise distribution, if any. The method for line transect analysis of porpoise encounter rate will follow the established approach for AFCD long-term marine mammal monitoring ([2]). It should be noted that as Finless Porpoises are cryptic and difficult to identify as unique individuals with no useful natural markings, the potential of double counting cannot be eliminated and hence rendering any abundance or density estimation confounded with serious violation of assumption under the line-transect survey method; therefore such analysis is not proposed to be completed for Finless Porpoise, which is the same approach for the AFCD long-term marine mammal monitoring.

Vessel-based line transect marine mammal surveys are proposed to be conducted during the 6-month baseline monitoring, construction of the LNG Terminal and for a period of one year post-construction following the start of operation of the LNG Terminal. Each transect line is proposed to be surveyed twice per month.

The final survey method, survey areas and duration of the survey shall be agreed in consultation with a marine mammal expert with experience in vessel-based line transect surveys and the AFCD.

Determination of Action and Limit Levels

The EIA predicts that marine mammals would avoid the vicinity of the works areas during the construction period and would return to the areas upon cessation of the disturbance. Consequently, there may be a decline of Finless Porpoise usage of some waters of the Southeast Lantau survey area where the LNG Terminal is located, while the animals are expected to move to the broader southern Lantau waters including the Southwest Lantau and Lamma survey areas and continue to use the broader areas to a similar degree.

To detect unacceptable/ unforeseen changes in Finless Porpoise distribution as construction work progresses, it is proposed to establish the Action Level and Limit Level for marine mammal monitoring using encounter rate calculated from the vessel-based line transect surveys from the three survey areas as a whole. For each monthly reporting period, encounter rate from construction phase monitoring will be calculated using the last three months�� monitoring data, i.e. a running quarterly value, and compared with the encounter rate from baseline monitoring to check if the threshold values are triggered for remedial actions to be undertaken. This approach would allow natural seasonal fluctuations in Finless Porpoise encounter rate to be accounted for, and allow porpoise data to be reviewed every month such as appropriate actions could be taken timely.

Details on the calculation of encounter rate and appropriate Action and Limit Levels will be agreed with the AFCD, subsequently to the completion of baseline monitoring. An Event and Action Plan for marine mammal monitoring (Table 7.1) will also be developed and agreed with the AFCD to describe the appropriate actions that need to be undertaken in the event that the Action and Limit Levels are exceeded, with a view to mitigating unacceptable/ unforeseen changes in Finless Porpoise distribution as a result of Project construction works.

Table 7.1 Event and Action Plan for Marine Mammal Monitoring

|

Event |

Action |

|||

|

ET |

IEC |

Contractor(s) |

Project Proponent |

|

|

Action Level exceeded |

1. Check monitoring data and repeat data analysis to confirm findings; 2. Review available AFCD data and relevant EM&A data to check if the exceedance is due to natural variation or works related; 3. Identify potential source(s) of impact; 4. Inform the IEC, Project Proponent and Contractor; 5. Increase site inspection and audit frequency to ensure all the marine mammal protective and/or precautionary measures are properly implemented.

|

1. Check monitoring data and analysis and investigation by ET; 2. Conduct additional site inspection and audit with ET to ensure all the marine mammal protective and/or precautionary measures are properly implemented and advise Project Proponent the audit results and findings accordingly

|

1. Inform the Project Proponent and confirm notification of the non-compliance in writing; 2. Conduct site inspection and audit with the ETL and IEC; 3. Ensure all the marine mammal protective and/or precautionary measures are properly implemented. |