2.

Project Description

2.1

Need

of the Project

The

existing OCGTs (i.e. GT2, GT3, GT4 and GT6) and CCGT (i.e. GT57) within the GT

Compound have been in operation for more than 30 years since 1989. The aging units, which are approaching the

end of their service life, are becoming less efficient in their operation and

requiring more frequent inspections and maintenance. The control system of the existing units is

also obsolete and the equipment suppliers do not have the necessary spare parts

or provide technical support that enable the continuous operation of these

existing units. Hence, there is a need

to decommission and demolish these existing units, and to construct and

commission new units progressively in the effort to replace the function of the

existing units in maintaining the peak-lopping and emergency operation

requirements, so as to ensure the continuous operation of the LPS and its

provision of stable and reliable electricity supply in Hong Kong.

2.2

Purpose

and Objectives of the Project

The

Project aims to decommission and demolish the existing GT2, GT3, GT4, GT57 and

GT6 which are approaching the end of their service life, and subsequently

construct and operate up to four new OCGTs (i.e. GT8, GT9, GT10 and GT11) as a

replacement to the abovementioned existing units. Upon the progressive retirement of the

existing units, the new OCGTs serve to take over the function of these existing

units in providing additional power generation during peak-lopping and

maintaining back-up power supply in case of emergency situations for the

continuous operation of the LPS. The

four new OCGTs would have a capacity of up to 130MW each, with a total power

generation capacity of up to 520MW.

The

Project is classified as a Designated Project under the EIAO (Cap. 499) as a

result of the following elements:

§ Demolition of

four existing OCGTs and one existing CCGT at LPS (Schedule 2, Part II, Item 4 A

public utility --- electricity power plant); and

§ Installation

of up to four new OCGTs at LPS (Schedule 2, Part I, Item D.1 Public utility

electricity power plant).

2.2.1

Environmental

Benefits of the Project

The

operation of the aging units is increasingly less efficient and could

potentially lead to higher air emissions.

New OCGTs are much more efficient and capable of attaining a more

stringent emission standards and thus producing lower air emissions during

operation, in particular nitrogen oxides (NOx), when generating the

same amount of power as the existing OCGTs.

Therefore, the Project is beneficial from an environmental perspective

and can be considered as part of the ongoing effort of HK Electric to further

reduce the overall air emissions from the operation of LPS and contribute to

the long-term air quality improvement in Hong Kong.

2.2.2

Scenarios

with and without the Project

If

the Project does not proceed, HK Electric will slowly lose the capacity of

additional power generation to cope with the electricity demand during

peak-lopping and maintaining power supply in case of emergencies upon the

progressive retirement of the existing units from 2022 onwards. Such capacity will be completely lost upon

complete retirement and decommissioning of these existing units. This would hamper the normal operation of LPS

significantly and put HK Electric’s stable and reliable supply of electricity

at risk.

With

the Project in place, HK Electric would enable the decommissioning of the

existing units and construction of the new OCGTs progressively (i.e.

decommissioning of at least one existing unit before commissioning of one new

OCGT), allowing a smooth transition of the OCGT reprovision programme and at

the same time maintaining the necessary capacity for coping with the additional

power demand during peak-lopping and emergency operation. Upon putting into operation, the new OCGTs

can be in service for years to come and are integral to the future LPS

operation in supplying stable and reliable electricity in Hong Kong.

2.3

Background

and History of the Project

The

existing GT2, GT3, GT4, GT57 and GT6 have been in operation since 1989 and are

situated in the GT Compound of the LPS at the western edge of Lamma Island (see

Figure 2.1a). The GT Compound has been occupied by these

existing units and their associated buildings and facilities ever since the

commencement of LPS operation. GT57 was

originally two separate OCGTs (i.e. GT5 and GT7) that were converted into a

CCGT with power generation capacity of 345MW in 2002. GT57 was subsequently converted to a gas-fired

unit in 2008. Having a power generation

capacity of 125MW each, GT2, GT3, GT4 and GT6, together with GT57, have a total

power generation capacity of 845MW. The

new OCGTs will be constructed within the GT Compound where the existing GT2,

GT3, GT4, GT57 and GT6 are located. This

has been identified as the preferred development option which is further

discussed in Section 2.4 below.

2.4

Consideration

of Different Development Options

A

number of different development options have been considered having regard to

the upcoming retirement and decommissioning of the existing OCGTs and CCGT

within the GT Compound. Options of power

generation for peak-lopping and emergency operations, and site selection for

the new OCGTs have been considered.

2.4.1

Power

Generation

A

number of options have been explored to cope with the electricity demand during

peak-lopping and emergency operations upon progressive retirement and

decommissioning of the aforementioned existing units. The options considered include:

§ Construction

of new CCGTs;

§ Construction

of new OCGTs;

§ Extending

services of existing OCGTs;

§ Importing

power supply from Mainland China; and

§ Use

of renewable energy.

The

considerations of the above options are discussed in the following

sub-sections.

2.4.1.1 Construction of New CCGTs

CCGT

is equipped with a steam generator to recover heat from exhaust gas of the gas

turbine and is thus more efficient than an OCGT in power generation. Due to CCGT’s higher efficiency, fuel

consumption and associated air emissions arising from the operation of a CCGT

would be lower than that from the operation of an OCGT. However, CCGT does not have fast start-up

capability which is the key to providing swift electricity supply during

peak-lopping and emergency situations.

Therefore, construction and operation of new CCGTs is considered not

suitable and thus is not preferred.

2.4.1.2 Construction of New OCGTs

OCGT

consists of a single compressor/ gas turbine assembly that is connected to an

electricity generator via a shaft. OCGT

has the major advantage of fast start-up capability and can generate

electricity within a relatively short time.

It is less efficient than a CCGT in power generation as it does not have

a steam generator to recover heat from the exhaust gas of the gas turbine. Due to OCGT’s relatively low efficiency, fuel

consumption and associated air emissions during the operation of an OCGT would

be higher as compared with that of a CCGT.

However,

given their fast start-up capability, OCGTs are capable of serving the

objective of providing swift electricity supply during peak-lopping and

emergency situations. As the OCGTs will

only be needed during peak-lopping and emergency situations and not used as

base load for electricity generation, the operation of the OCGTs is only

intermittent and the associated emissions are only short-term. New OCGTs can also achieve more stringent

emission standards as compared with the existing OCGTs. Hence, construction and operation of new

OCGTs is considered more favourable from an operational and fit-for-purpose

perspective.

2.4.1.3 Extending Services of Existing OCGTs

The

existing units have been in operation since 1989. Most of the critical components of the power

block facilities including the gas turbine casings, hot gas path components and

generators would require replacement in order to extend the services of these

existing units. Besides the need of

replacement of different components of the existing units, substantial

refurbishment works will also be required for the steel structures, gas turbine

inlet air and exhaust gas ductworks. The

control system of the existing units is also obsolete and the equipment

suppliers do not have the necessary spare parts or provide technical support

that enable the continuous operation of the existing units. Therefore, replacement of components and

refurbishment works to extend services of the existing units are considered not

technically viable or cost-effective and hence not the long-term solution for

the operation of LPS. Hence, such option

is considered less favourable.

2.4.1.4 Importing Power Supply from Mainland China

In

addition to generating power locally, importing power from the Mainland China

for the purpose of peak-lopping and emergency operations has also been explored

with the following considerations:

§ Infrastructure

– there is currently lack of infrastructure for connecting to the power grid in

Mainland China. There is a long lead

time to build the necessary infrastructure and will not meet the retirement

schedule of the existing units (to be retired and decommissioned tentatively

starting from 2022);

§ Reliability and control issue

– the HKSAR government do not have direct control and regulation of the

electricity imported from Mainland China.

Reliable electricity supply during peak-lopping or emergency operations

cannot be guaranteed if HK Electric rely on power supply import from Mainland

China;

§ Displacement of pollutants

– local pollutants from power generation will be displaced to Mainland China,

where the HKSAR government or HK Electric have no control over the emission

performance.

In

view of the above, it is considered that local generation would provide more

certainty in terms of maintaining electricity supply reliability, especially

during peak-lopping and emergency operations, as well as improving

environmental performance. Hence,

importing power from Mainland China is not preferred.

2.4.1.5 Use of Renewable Energy

HK

Electric has made continual effort to explore the use of renewable energy for

electricity generation. For example, HK

Electric is planning to build an offshore wind farm in Hong Kong waters to be

located around 4km southwest of Lamma Island.

However, renewable energy cannot supply electricity on demand in order

to serve the purpose of peak-lopping or emergency operations due to its

intermittent nature and is thus not a viable option.

2.4.1.6 Preferred Option of Power Generation

Based

on the above discussion, the construction and operation of new OCGTs is

considered the most practicable and preferred option to pursue as this involves

essentially like-to-like replacement, is fit for purpose, environmentally

beneficial and technically the most practicable. Other options would present impracticality

and uncertainties, or may not tie in with the retirement schedule of the

existing units.

2.4.2

Siting

The

existing GT Compound, L13 area and L3 Main Station Building within the LPS and

Lamma Extension (LMX) have been identified as potential sites for accommodating

the new OCGTs. The locations of the

existing GT Compound, L13 area and L3 Main Station Building are shown in Figure 2.2. These three potential sites have been

carefully compared based on a number of factors. Consideration of these factors for site

selection are detailed in Table 2.1.

Table 2.1 Comparison of the Identified Potential Sites for New OCGTs

|

Considering Factors |

GT Compound |

L13 Area |

L3 Main Station Building (a) |

|

Site Condition |

The GT

Compound area can be made available after demolition of the existing OCGTs

and CCGT. The existing foundation

piles and reinforced concrete structures could be reused for the construction

of the new OCGTs. |

The L13

Area is currently vacated for the future development of the proposed

L13. The layout of the proposed L13

will be affected and needs to be redesigned to accommodate the new OCGTs

within the L13 Area. The construction

of the new OCGTs could interface with that of the proposed L13 and

potentially pose constraints on the design and construction of the proposed L13. Foundations

and concrete structures for the new OCGTs need to be constructed. |

Part of

the L3 Main Station Building structures could be reused for the installation

of the new OCGTs. The

entire coal-fired boiler and power train and associated auxiliary equipment

inside the L3 Main Station Building need to be demolished to create space for

installation of the new OCGTs, which is a costly construction option and

requires much longer construction period.

The

proximity of the L3 Main Station Building to the existing coal conveyor and

electrostatic precipitators would restrict the layout of the new OCGTs. |

|

Space Adequacy |

With the removal of the existing OCGTs

and CCGT, there would be sufficient space for constructing the new OCGTs,

cable trenches and associated facilities. |

L13 Area is currently vacated and have

sufficient space for the Project.

However, the installation of the new OCGTs and associated facilities

would take up part of the L13 Area that would otherwise be available for the

proposed L13 and thus will hinder the development of the proposed L13 in the

future. |

The L3 Main Station Building is

congested with a number of existing equipment, some of which may need to be

demolished and removed to make space for the installation of the new OCGTs

and associated facilities. This would

pose challenges from a technical and engineering perspective and would also

prolong the construction period of the Project. |

|

Chimneys |

With minor repair and refurbishment

works, existing chimneys serving the existing OCGTs and CCGT can be reused

for the new OCGTs. |

The

chimney to be constructed for the proposed L13 could be used to serve the new

OCGTs. However, the chimney will need

to be re-designed to accommodate the new flues within the chimney. With the

use of the same chimney, there could be interfacing issue between the

development of the proposed L13 and the new OCGTs. |

Existing

chimney used to serve L3 cannot be reused for the new OCGTs and needs to be

removed which involve significant demolition works. Construction of a new chimney is required

for the new OCGTs. |

|

Foundation and Civil Works |

The

construction of the Project only involves minor civil works as the existing

foundation piles and reinforced concrete structures could be reused. Foundation works for the new OCGTs are not required. |

No

existing foundation piles or reinforced concrete structures are present. The construction of the Project requires

foundation works which involve considerable excavation and piling works. Major aboveground civil works are also

required. |

Existing

foundation piles and reinforced concrete structures cannot be reused. Significant demolition works followed by

excavation, piling and civil works are required for the construction of the

Project. |

|

Environmental Consideration |

No

foundation works and only minor civil works are required, resulting in low

generation of waste materials. Other

potential environmental impacts (e.g. air quality and noise) can also be

minimised. |

Significant

foundation works and civil works are required, resulting in high generation

of waste materials. The associated

excavation and piling works may also pose implications on other environmental

aspects (e.g. air quality and noise) |

Significant

demolition, foundation and civil works are required, resulting in higher

generation of waste materials. The

associated demolition, excavation and piling works may also pose implications

on other environmental aspects (e.g. air quality and noise). Detailed land contamination assessment

within the area may also be required. |

|

Notes: (a) Unit L3

was decommissioned in 2018. |

|||

The

site comparison assessment as shown in Table 2.1 revealed that it is more

desirable to develop the new OCGTs within the GT Compound where the existing

OCGTs and CCGT to be removed are located, having considered various factors

including site condition, space adequacy, construction feasibility and

complexity, and environmental impacts.

The development and construction of the new OCGTs in L13 Area and L3

Main Station Building would increase the scale and scope of the Project, are

technically more challenging and complex in construction, require a longer

programme and incur higher costs. In

terms of environmental impact, development of the new OCGTs in L13 Area and L3

Main Station Building would require considerable excavation and piling works

which have the potential to generate significant amount of construction waste

and also cause other environmental impacts such as impacts on air quality and

noise. Development of the new OCGTs in

L3 Main Station Building may even require extensive demolition works to create

space, resulting in additional environmental impacts. On the other hand, development of the new

OCGTs within the existing GT Compound can minimise waste generation and other

environmental impacts as the foundation and reinforced concrete structures

after the removal of the existing units can be reused for the installation of

the new OCGTs. Therefore, it is

considered preferable to develop the new OCGTs within the GT Compound.

2.5

Details

of the Project

The

Project involves the decommissioning and demolition of the existing GT2, GT3,

GT4, GT57 and GT6 within the GT Compound of LPS, and the construction and

operation of four new OCGTs (i.e. GT8, GT9, GT10 and GT11) within the GT

Compound, in order to maintain the peak-lopping and emergency operation

requirements essential for the continuous operation of LPS in the future. The Project site includes the GT Compound as

shown in Figure 2.1a / Figure 2.1b. The existing units will be decommissioned and

demolished sequentially, with one new OCGT to be constructed upon the removal

of at least one existing unit. The locations

of the existing units and the proposed new units within the Project site are

shown in Figure 2.1a and Figure 2.1b,

respectively. As part of the Project,

some modifications to the existing buildings and facilities and construction of

new cable trenches within the GT Compound will be carried out to support the

future operation of the new OCGTs.

2.5.1

Overview

of Project Components

2.5.1.1 New OCGTs

Each

of the four new OCGTs essentially consists of a gas turbine and a generator,

and will be operated by firing ultra-low sulphur diesel (ULSD) to produce

electricity under peak loads and emergency situations. Fresh air is drawn into the compressor where

it is compressed for mixing with the fuel (i.e. ULSD) and burning in the

combustion chamber. The high temperature

gas generated in the combustion chamber is then passed through the turbine

blades, which in turn rotate the generator rotor to generate electricity. The generation capacity of each new OCGT is

up to 130MW, with a total generation capacity of up to 520MW from four new

OCGTs. The exhaust gas from GT8, GT9,

GT10 and GT11 will be discharged via the existing chimneys currently serving

GT2, GT5, GT6 and GT7. The existing

chimneys for GT3 and GT4 will be retained but not utilised under this

Project. The new OCGTs will be

air-cooled with no requirement for cooling water intake or discharge during

operation.

2.5.1.2 Black Start Gas Turbine (BSGT)

A

BSGT with capacity of 2.2MW is currently installed near the west boundary of

the GT Compound and serves to provide start up power for the OCGTs in case of

rare black out situations. The existing

BSGT is also nearing the end of its service life and will be replaced by a new

BSGT of similar capacity as the existing BSGT as part of this Project.

2.5.1.3 Battery Energy Storage System (BESS)

A

new BESS with an estimated output of around 3MW will be erected to the south of

the BSGT. The BESS is of modular type

and will be accommodated in a container in which all equipment including

inverter, transformer, air conditioner, fire services, lighting etc. are

equipped. Similar to the BSGT, the BESS

also serves to provide start up power for the OCGTs in case of rare black out

situations. During black out situations,

the BESS will be put into operation first, while BSGT acts as the back up to

the BESS.

2.5.1.4 132kV Switching Station

The

existing GT57 Auxiliary Building (GTAB) will be converted to a new 132kV

Switching Station for the operation of the new OCGTs. All existing equipment inside the GTAB,

including the GT57 steam turbine, generator, condenser and other auxiliary

equipment as well as the existing Turbo Block structure will be removed and

demolished to make space for converting the GTAB into a new 132kV Switching

Station. The new 132kV Switching Station

will accommodate the gas insulated switchgear, associated electrical,

instrumentation and control equipment, as well as a battery charger system. A new staircase and lift for the new 132kV

Switching Station and new cable trenches for 132kV cables connecting the new

OCGTs, BSGT and BESS to the new 132kV Switching Station will also be

constructed.

2.5.2

Decommissioning,

Demolition and Construction Activities

2.5.2.1 Removal of Existing Units and Installation of New Units

The

existing GT2, GT3, GT4, GT57 and GT6 as well as their auxiliaries (e.g.

generator coolers, transformers) will be decommissioned and demolished to make

space for the construction of the new OCGTs.

The existing BSGT will also be demolished and replaced with a new

BSGT. The new BESS will also be

installed south of the BSGT. Typical

construction equipment such as electric breakers, flame cutting and powered

mechanical hand tools will be used during demolition works. All major equipment and piping associated

with the new OCGTs and BSGT will be fully assembled off-site as far as

practicable and then installed on site such that construction works on site can

be minimised. Mobile cranes will be

deployed for the removal and installation of heavy equipment such as

generators, gas turbines and tube bundles.

The new OCGTs and BSGT will have similar footprint as the existing ones

and as such, the existing foundation piles and reinforced concrete structure

will be reused to support the new OCGTs and BSGT as far as practicable. It is expected that foundation works for the

new OCGTs and BSGT are not required and the civil works associated with the

construction of the new OCGTs and BSGT are minimal. The existing chimneys to be retained for use

by the new OCGTs will undergo necessary refurbishment works.

2.5.2.2 Reconstruction Works within GTAB

The

existing GTAB will be converted to a new 132kV Switching Station. All equipment inside the existing GTAB, including

the lube oil tank, chemical dosing pit, steam turbine, generator, condenser,

cooling water pump, etc., will be removed and demolished using typical

equipment such as grinder, flame cutting and powered mechanical hand tools. The demolition and removal of the existing

Turbo Block Structure inside the GTAB will require minor excavation down to

about 2.6m below ground over an area of about 200m2, and such

demolition and removal works will use typical equipment such as excavators,

mobile cranes, electric breakers and other powered mechanical hand tools. The installation of gas insulated switchgear,

electrical and control panels and other associated equipment inside the new

132kV Switching Station will involve general lifting operation and manual installation,

which will be carried out by typical equipment such as overhead crane and

powered mechanical hand tools.

2.5.2.3 Construction of New Staircase and Lift and Cable Trenches

A

new staircase and lift will be constructed at the immediate east of the GTAB,

which is currently occupied by the circulating water pipe room to be demolished

under this Project. The construction of

the new lift pit will require excavation down to 5m below ground. In addition, new cable trenches will be

constructed to house the new 132kV cables connecting the new OCGTs, BSGT and

BESS to the new 132kV Switching Station.

Minor excavation down to about 1.8m below ground will be required for

the construction of new cable trenches, where the excavated materials will be

used for backfilling as far as practicable after cable laying. Typical equipment such as excavators, mobile

cranes, welding machines and other powered mechanical hand tools will be used

during excavation and backfilling works, cable laying and construction of the

new staircase and lift.

2.5.2.4 Removal of Other Existing Structures

As

part of the Project, the existing lube oil storage tank near GT5 and the

miscellaneous storage shed south of the existing BSGT will be demolished. Typical equipment used for removal of these

other structures include grinder, flame cutting and other powered mechanical

hand tools.

2.5.3

Operation

Activities

The

new OCGTs will commence operation in phases upon completion of construction and

testing and commissioning. The OCGTs

will be operated under peak-lopping and emergency situations. The new BESS and BSGT will also be put into

service upon completion of construction and testing and commissioning, but they

will only be operated to supply the required power to start up the new OCGTs in

case of rare black-out situation. Under

such rare black-out situation, the new BESS, which does not involve air

emissions during its operation, will be used first instead of the BSGT. Therefore, the operation of the new BSGT is

considered extremely rare.

Both

the new OCGTs and BSGT will be fuelled by ULSD and stack emissions during their

operation will comply with the requirements recommended in the Guidance Note on the Best Practicable Means

for Electricity Works (BPM7/1(2018)), and those to be stipulated in the SP

licence issued under the Air Pollution

Control Ordinance (APCO). The power

generated by the new OCGTs, BSGT and BESS will be transmitted via the new 132kV

cables to the 132kV Switching Station, and eventually to HK Electric’s power

grid.

2.6

Tentative

Implementation Programme

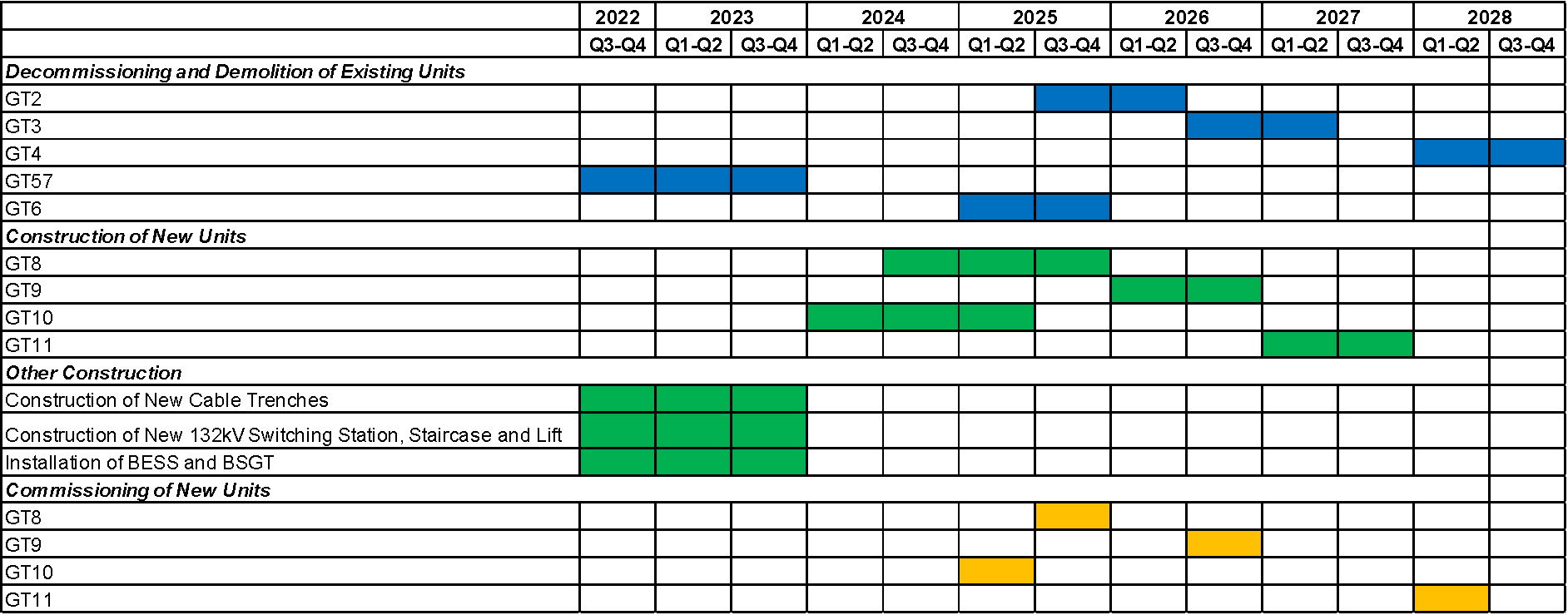

HK

Electric proposes to decommission and demolish the existing GT2, GT3, GT4, GT57

and GT6, and to construct and commission the new GT8, GT9, GT10 and GT11 within

the GT Compound successively between 2022 and 2028. The tentative implementation programme is

provided in Table 2.2.

Table 2.2 Tentative Implementation Programme of the Project

2.7

Concurrent

Projects

The

Project is located within the existing LPS site. The following existing, committed or planned

projects in the vicinity of the Project site may potentially interface with the

demolition, construction and operation of this Project:

§ 1,800MW Gas-fired Power Station at

Lamma Extension (AEIAR-010/1999): This project includes the

construction and operation of six new gas-fired CCGT units at the Lamma

Extension. L9 and L10 have been

constructed and are currently under operation.

L11 and L12 are currently under construction and are scheduled for

commercial operation in 2022 and 2023 respectively. L13 is scheduled for commercial operation

after 2023.

§ Hong Kong Offshore LNG Terminal

(AEIAR-218/2018):

This project involves the construction and operation of an offshore

liquefied natural gas (LNG) terminal that is to be located in the southern

waters of Hong Kong, to the east of the Soko Islands. The offshore LNG terminal will supply natural

gas to the gas receiving stations at the Black Point Power Station (BPPS) and

the LPS via two subsea pipelines. The

construction of the project commenced in the third quarter of 2020 and is

expected to last for about 2 years.

§ Improvement Dredging for Lamma

Power Station Navigation Channel (AEIAR-212/2017): This project involves

improvement dredging of the Channel to the west of LPS during construction

phase, and subsequent recurrent improvement dredging every 4 to 10 years during

operation phase. The construction of the

Project commenced in February 2020 for completion tentatively by end of 2021.

§ Development of a 100MW Offshore

Wind Farm in Hong Kong (AEIAR-152/2010): The project involves the development of an

offshore wind farm located in the waters between Lamma Island and Cheung

Chau. The offshore wind farm will

produce around 100MW of electricity, which will be supplied directly to the HK

Electric grid network. The

implementation programme of this project is under review and not yet available

at this stage.

§ Lamma Power Station – Unit L2 Flue Gas Desulphurization Plant Retrofit Project (DIR-153/2007): The project involves retrofit of Flue Gas Desulphuization (FGD) plant to the existing unit L2 for reducing sulphur dioxide emissions. The project is anticipated to retire along the tentative retirement of unit L2 in late 2022.

§ Lamma Power Station Units

L4 & L5 Flue Gas Desulphurization Plant Retrofit Project (AEIAR-098/2006): The project involves retrofit of FGD plant to

the existing units L4 and L5 for reducing sulphur dioxide emissions and is

currently under operation phase. The

project is anticipated to retire along the tentative retirement of units L4 and

L5 in 2022-2023.

§ Renewable Energy by a Wind Turbine

System on Lamma Island (AEIAR-080/2004): The project

involves the construction and operation of a 800kW wind turbine at Tai Ling

Tsuen on Lamma Island. The construction

of the project commenced in February 2005 and lasted for 12 months. The project has been put into operation since

February 2006

The

above concurrent projects may pose cumulative impact with the demolition,

construction and/or operation of the Project.

The cumulative impacts from the above concurrent projects are addressed

in the relevant technical assessments in this EIA as appropriate.

In

addition, Conversion of Two Existing Gas

Turbines (GT5 & GT7) into a Combined Cycle Unit (DIR-037/2000) is

currently active and in operation phase.

With GT57 to be decommissioned and demolished as part of this Project,

DIR-037/2000 will not interface with the demolition, construction or operation

of this Project and thus would not pose any cumulative impact.

2.8

Public

Engagement

As

part of the EIA study, ERM, on behalf of HK Electric has reached out to the

local communities in Lamma Island via three community leaders in Lamma, namely

Mr Chan Lin-wai, MH, Chairman of the Lamma Island (North) Rural Committee, Mr

Chow Yuk-tong, SBS, MH, Chairman of the Lamma Island (South) Rural Committee,

and Ms Lau Shun-ting, Islands District Council Member, by providing

them briefing notes of the Project by registered mail on 21 July 2021 in order

to seek their views and opinions on the Project and the associated

environmental impact. Face-to-face

meetings were avoided due to the current COVID-19 pandemic. No feedback or opinions have been obtained

from the stakeholders concerned during the course of the EIA study.