2.1 Project

Location and Site History

2.4 Need and Benefit of the Project

2.5 Consideration of Alternatives

2.6 Interfacing and Concurrent Projects

2.7 Documentation of Public Concerns

List of tables

Table 2.1..... Existing Effluent Standards of TPSTW to be Maintained for this Project

Table 2.2..... Sewage Sludge and

Pre-treated Food Waste Co-digested under this Project

Table 2.3..... Reclaimed Water Requirements

– WSD Water Quality Objectives

Table 2.4..... Reuse of Treated Sewage

Effluent

Table 2.5..... Environmental Benefits and Dis-benefits

of Alternative Sewage Treatment Schemes

Table 2.6 .... Consideration of Treatment

Technologies for the Project

Table 2.7..... Environmental Benefits and

Dis-benefits of Emergency Outfall Options

Table 2.8..... Environmental Benefits and

Dis-benefits of Alternative Construction Sequences

Table 2.9..... Environmental Benefits and

Dis-benefits of Alternative Demolition Methods

Table 2.10... Environmental Benefits and

Dis-benefits of Alternative Piling Methods

List of EXHIBITS

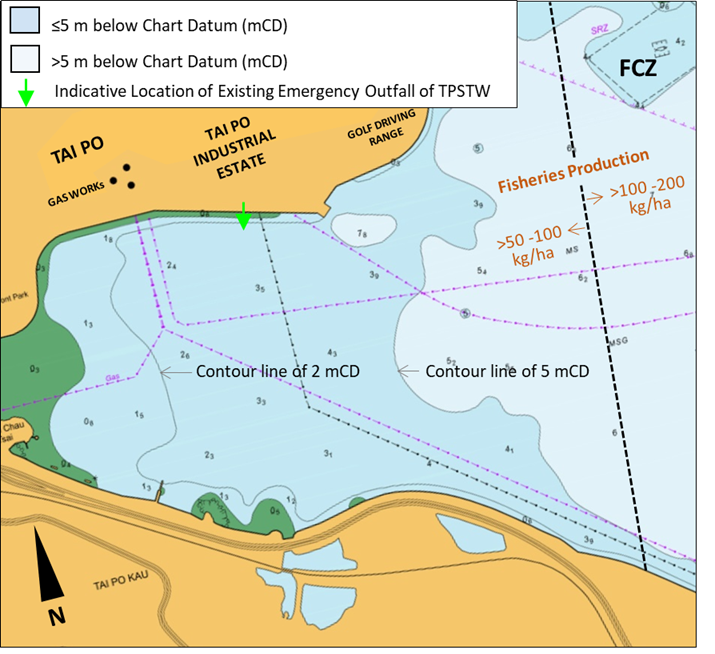

Exhibit

2.1 Water Depth and Fisheries Production

Figure

2.1... General Layout of TPSTW

Upgrading

Figure

2.2... Concurrent Projects

List of Appendices

Appendix 2.1 Existing Layout of Project Site

Appendix 2.2 Responses to Public Comments

2 Project Description

2.1

Project Location and Site History

2.1.1 The Project site, covering the existing Tai Po Sewage Treatment Works (TPSTW) and the proposed expansion site, is located in Tai Po Industrial Estate (TPIE). TPIE is situated on a flat reclaimed land and is surrounded by gentle hills to the North and marine water to the South. The existing Project site is bounded by industrial premises to the North, South and West and Shuen Wan Restored Landfill (SWRL) to the East. The TPIE (including the Project site) was once part of the Tolo Harbour (i.e. the sea), and was formed via land reclamation during the 1970s.

2.1.2 The existing TPSTW comprises two independent plants, namely West Plant (Stage I/II) commissioned in 1979/1983 and East Plant (Stage IV) commissioned in 1996. In order to cope with the rapid development in the district, Stage V works were carried out to further increase treatment capacity of TPSTW. The Stage V works were completed in 2013. According to the information from DSD, there is no TPSTW Stage III. The existing design capacity of the West Plant and the East Plant is 44,000 m3 per day and 76,000 m3 per day respectively. The overall design capacity of the existing TPSTW is therefore 120,000 m3 per day.

2.1.3 Currently, the proposed expansion site (located on government land) comprises three Short Term Tenancies (STTs) , a Temporary Government Land Allocation (TGLA) lot and a vacant land. The three STT lots have been utilizing by a number of existing and past waste recyclers since lands were formed via reclamation. The existing or past land uses in the TGLA lot and the vacant land solely involve government’s and contractors’ offices.

2.1.4 The general layout of the existing facilities within the Project site is shown in Appendix 2.1.

2.2

Project

Scope and Scale

Sewage Treatment Scheme

Design Capacity

2.2.1 This Project will upgrade the design capacity of TPSTW from 120,000 m3 per day to 160,000 m3 per day to meet the projected sewage treatment demand.

Treatment Level and Effluent Standards

2.2.2 The existing TPSTW provides secondary level treatment of sewage with disinfection. The existing treatment level and treated effluent standards of TPSTW will be maintained for this Project as summarized in Table 2.1.

Table 2.1 Existing

Effluent Standards of TPSTW to be Maintained for this Project

|

Parameter |

Unit |

95th

percentile |

Maximum |

Annual

Average |

Monthly

Geometric Mean |

|

5-day Biological Oxygen

Demand (BOD5) |

mg/L |

20 |

40 |

- |

- |

|

Total Suspended Solids

(TSS) |

mg/L |

30 |

60 |

- |

- |

|

Total Nitrogen (TN) |

mg/L |

- |

35 |

20 |

- |

|

Ammonia Nitrogen (NH3-N) |

mg/L |

- |

10 |

5 |

- |

|

E. coli |

counts/ 100mL |

15,000 |

- |

- |

1,000 |

Effluent Disposal Scheme

2.2.3 Currently, the ultraviolet (UV) disinfected secondary effluent from the existing TPSTW is discharged to Tolo Harbour Effluent Export Scheme (THEES) for disposal in Victoria Harbour. During the THEES maintenance period or under emergency situation, the TPSTW effluent will be discharged via the existing emergency outfall of TPSTW at the seawall of TPIE waterfront. This Project will follow the same effluent disposal arrangement of the existing TPSTW during both construction and operational phases.

Co-digestion of Sewage Sludge and Pre-treated

Food Waste

2.2.4 Sludge treatment facilities at the existing TPSTW includes primary sludge gravity thickeners, surplus activated sewage sludge thickening house, anaerobic digesters, sludge dewatering works, and combined heat and power (CHP) units. The CHP units are used to recover energy from the biogas generated in anaerobic digestion process for on-site electricity supply.

2.2.5

The Environmental Protection

Department (EPD) will be responsible for the construction and operation of a

full-scale Organic Waste Pre-treatment Centre (OWPC) (New Territories East)

located adjoining to the northern boundary of TPSTW. The proposed OWPC will be designed to receive

and pre-treat organic waste or source-separated food waste of up to about 500

wet tonnes per day (wt/d), which is equivalent to about 75 dry tonnes per day

(dt/d).

2.2.6

The proposed anaerobic

co-digestion system of this Project will utilize sewage sludge from TPSTW,

other STWs in New Territories, and pre-treated food waste from the adjoining

OWPC. The pre-treated food waste will be

delivered from the OWPC to the adjacent TPSTW through enclosed pipelines. The sewage sludge from other STWs will be

dewatered before importing into the Project site by trucks. Total quantities of

sludge and food waste feedstocks to be managed under this Project are summarized in Table 2.2.

Table 2.2 Sewage Sludge and Pre-treated Food Waste

Co-digested under this Project

|

Type of Feedstock |

Source of Feedstock |

Quantity (dt/d) |

|

Wastewater Derived Sewage

Sludge |

TPSTW |

35 |

|

Other existing and proposed STWs in New Territories

|

150 |

|

|

Pre-treated Food Waste |

Proposed OWPC |

75 |

|

Total |

260 |

|

2.2.7 The energy generated from the proposed co-digestion of sewage sludge and pre-treated food waste of the Project will be utilized for electricity supply onsite. Any surplus electricity and / or gas generated under this Project may be supplied to other government facilities such as the adjoining OWPC as well as private companies such as the CLP Power Hong Kong Limited and Hong Kong China Gas Company Limited.

Treated Sewage Effluent Reuse for Non-potable

Use

2.2.8

Effluent reuse facility

including additional treatment processes will be provided under this Project to

polish some of the TSE to produce reclaimed water. The reclaimed

water produced from the reuse facility will meet the water quality standards provided by Water Supplies Department (WSD) as shown in Table 2.3.

2.2.9 The reclaimed water will be applied within the Project site for non-potable use such as toilet flushing and landscape irrigation.

Table 2.3 Reclaimed

Water Requirements – WSD Water Quality Objectives

|

Parameter |

Unit |

Reclaimed Water Quality |

|

E. coli |

cfu/100mL |

Non

detectable |

|

Total Residual Chlorine |

mg/L |

≥1 (existing

treatment system) |

|

Dissolved Oxygen (DO) |

mg/L |

≥2 |

|

TSS |

mg/L |

≤5 |

|

Colour |

Hazen Unit (HU) |

≤20 |

|

Turbidity |

NTU |

≤5 |

|

pH |

- |

6 to 9 |

|

Odour |

Threshold odour no. |

≤100 |

|

BOD5 |

mg/L |

≤10 |

|

NH3-N |

mg/L as N |

≤1 |

|

Synthetic Detergents |

mg/L |

≤5 |

2.2.10

Some of the TSE (secondary effluent)

will be directly reused in the sewage treatment process (e.g.

for polymer preparation) within the Project site. Partially treated sewage,

including but not limited to surplus activated sludge (SAS), supernatant from

thickened SAS, primary effluent from the Project, may also be explored for

directly reuse in the treatment process (e.g. for

imported sludge dilution) within the Project site.

2.2.11

Some of the TSE of the Project

will be transferred to the proposed OWPC directly for use in the food waste pre-treatment

process or dilution of food waste. The reuse of effluent generated from the

sewage treatment process proposed in OWPC is covered in this EIA.

2.2.12

All the TSE or partially

treated sewage to be reused in the treatment process of this Project and the proposed

OWPC will be conveyed and handled within an automatic close-loop system without

direct human contact. The spent reclaimed water (e.g.

from toilet flushing) will be transferred back to the treatment units of this

Project by fully enclosed pipelines for further treatment. No human health

concern will arise. A summary of the proposed

effluent reuse is given in the table below.

Table 2.4 Reuse

of Treated Sewage Effluent

|

Effluent Type |

Effluent Source |

Effluent Reuse Location |

Effluent Usage |

|

Reclaimed

water |

Effluent reuse facility

within the Project site (Sections 2.2.8 and 2.2.9) |

Project site |

Non-potable

use (e.g. toilet flushing, irrigation) |

|

Effluent generated from the

sewage treatment process |

Secondary treatment

facility of this Project (Section 2.2.10) |

Project site |

Reuse in sewage treatment (e.g. polymer preparation) |

|

Secondary treatment

facility of this Project (Section 2.2.11) |

OWPC |

Reuse in food waste

pre-treatment process or dilution of food waste |

|

|

Primary treatment facility,

SAS, supernatant from thickened SAS of this Project (Section 2.2.10) |

Project site |

Reuse in co-digestion (e.g. imported sludge dilution) |

Construction Arrangement

2.2.13

In order to maintain normal sewage

treatment services of the existing TPSTW during the construction phase, a New

West Plant will be built in the proposed expansion site outside the existing

TPSTW boundary. The New West Plant will

be a relatively compact sewage treatment works (STW) and able to provide

adequate sewage treatment capacity to meet the projected sewage flow buildup

before the normal treatment services of the existing West Plant is

decommissioned.

2.2.14

After the New West Plant is fully

commissioned, the existing West Plant will be partially demolished to make room

for the construction of new facilities including the sludge treatment and

co-digestion works. The reconstruction works in the existing TPSTW will be

split into stages to maintain adequate sludge treatment capacity throughout the

construction phase. For example, after the New West Plant is commissioned, the

existing sewage treatment facilities (e.g. primary sedimentation tanks

and aeration tanks) can be demolished and redeveloped into new sludge treatment

works before the existing sludge treatment facilities are decommissioned. This approach will enable continuous plant operation with

minimal service interruption. The need of temporary bypass of untreated or partially treated

sewage effluent into the marine water will be avoided.

2.2.15

Decommissioning and demolition

of the existing facilities in the proposed expansion site will be carried out

separately by the occupants or tenants of the site, and therefore outside the

scope of this Project. Only land-based

construction in TPIE will be involved in this Project. No marine construction

works will be carried out under the Project.

Project Facilities and General Layout

2.2.16 The New West Plant of this Project in the proposed expansion site will comprise inlet works, primary and secondary treatment facilities and other ancillary works.

2.2.17 New sludge treatment and co-digestion facilities will be located in the existing TPSTW site. These facilities will include the import sludge reception facilities, anaerobic digesters, sludge dewatering facilities, sludge thickening facilities, biogas recovery and storage facilities, CHP units, sidestream treatment facilities and other ancillary works. Expansion of the existing Tai Po Effluent Pumping Station (TPEPS) will also be carried out within the existing TPSTW site.

2.2.18 This Project will not involve building higher than three storeys above ground level. All new facilities of this Project are low-rise with building height similar to the nearby existing industrial development in TPIE. The general Project layout developed with reference to the preliminary design of this Project is shown in Figure 2.1.

2.3

Implementation

Programme

2.3.1 The construction works of this Project are tentatively scheduled to commence in 2025 for completion in 2036. Majority of the demolition works in the existing West Plant of TPSTW will be carried out from 2029 to 2033 after the New West Plant in the proposed expansion site is in operation.

2.4

Need and

Benefit of the Project

Sewage Flow Projection

2.4.1 The flow projection for TPSTW was evaluated with reference to the 2019-based Territorial Population and Employment Data Matrix (TPEDM) data published in December2021, the latest information of the proposed development projects within the sewerage catchment area of TPSTW, historical TPSTW flow data, and EPD’s “Guideline for Estimating Sewage Flows for Sewage Infrastructure Planning” (GESF, 2005).

2.4.2 The projected Average Dry Weather Flow (ADWF) for the TPSTW catchment will nearly reach the existing design capacity by 2031. Taking into account the latest planning data, housing development programme, industrial flow, the wastewater flows from sludge thickening, sludge dewatering, and co-digestion of imported sewage sludge and pre-treated food waste, the required design ADWF for the TPSTW may reach 160,000 m3 per day by 2041. Thus, there is a need to upgrade the capacity of TPSTW to meet the required sewage treatment demand.

Aging of West Plant

2.4.3 The existing West Plant was commissioned in 1979/1983 and has been in operation for nearly 40 years. Continuous aging of the existing West Plant is expected, and this may result in increasing maintenance needs and demand for substantial rehabilitation and modernization of the plant. This Project will provide an opportunity to develop a New West Plant with improved sewage treatment technologies and efficiency, minimizing the possibility of emergency sewage discharge, and release of odour due to equipment failure.

Synergy of Sewage Sludge and Organic Waste

Co-digestion

2.4.4 The upgrading of TPSTW provides opportunity to co-digest indigenous sewage sludge from TPSTW, imported sewage sludge from multiple STWs in New Territories and imported pre-treated food waste from the proposed OWPC adjacent to TPSTW. There will be a synergy effect in co-location and co-treatment of different waste types in TPSTW.

2.4.5 The anaerobic co-digestion of sewage sludge and pre-treated food waste will improve nutrient balance and biogas yield, and thus increase energy recovery from the anaerobic digestion process.

Preservation of Landfill Space

2.4.6 The Project will facilitate the recycling of up to 260 dt/d of sewage sludge and pre-treated food waste, contributing to the preservation of precious landfill space and reduction of landfill gas including methane generated at landfills.

Minimization of Environmental Impact

2.4.7 Provision of adequate STW capacity to cope with new development and population growth will be essential for protection of coastal water quality. This Project is thus beneficial to the environment by reducing the pollution loading and avoiding the release of untreated sewage from other new developments. This Project will also reuse the TSE for non-potable use, resulting a further positive environmental effect by minimizing the TSE discharge and pollution loading to the water environment.

Comparison between With and Without

Co-digestion

2.4.8 Previous studies concluded that provision of dedicated organic (food) waste treatment facilities (i.e. organic resources recovery centre (ORRC)) and implementation of sewage and food waste co-digestion at STW are both economically viable and comparable.

2.4.9 Further to the commissioning of ORRC at Siu Ho Wan (O·Park1) and the ongoing construction of O·Park2 at Sha Ling, the Government extend the spectrum of resource recovery and divert food waste from landfill through the implementation of co-digestion at STW.

2.4.10 Based on the findings of “Agreement No. CE 55/2015 (EP) A Review of the Management and Disposal Arrangement for Sewage Sludge – Feasibility Study”, it is viable and beneficial to implement co-digestion facilities within TPSTW for the treatment of indigenous sewage sludge, imported sewage sludge, and 500 wt/d of food waste from the OWPC, which would bring forth the synergy in biogas production and utilisation at the TPSTW, at the same time, converting food waste into renewable energy.

2.4.11 Without co-digestion, the Project contribution to the sustainability and circularity for waste management in Hong Kong will be lost.

Scenario without the Project

2.4.12 The capacity of the existing TPSTW will be inadequate to cope with the increase in sewage flow within its catchment in the coming years. The possible consequences of not implementing this Project will include the discharge of untreated sewage into the Tolo Harbour or the need for an alternative sewage treatment scheme to handle the excess flow. The benefits associated with co-digestion as described in Section 2.4.9 to 2.4.11 will be lost. In particular, more landfill space will be occupied and additional land will be required for construction of new ORRC.

Scenario with the Project

2.4.13 With the Project, the treatment capacity of TPSTW will be upgraded to meet the projected sewage treatment demand in its sewage catchment areas. Thus, the coastal water quality can be protected by avoiding the release of untreated sewage into the Tolo Harbour from other new developments.

2.4.14 Implementation of this Project will provide opportunity to improve odour management in the TPSTW by replacing the existing open surface sewage treatment units, which are major odourous sources, in the West Plant, with new treatment units equipped with odour covers and deodourisation systems. With implementation of this Project, an improvement of the existing odour environment in TPSTW is anticipated.

2.5

Consideration

of Alternatives

Alternative Project Sites

2.5.1

Due

to the space constraints, upgrading within the existing TPSTW site will require

demolition of existing treatment units before construction of new Project

facilities. As the existing TPSTW is already operating close to its design

capacity, terminating part of the existing facilities within TPSTW for expansion

will likely induce bypass of untreated sewage or partially treated effluent

failing to meet the discharge standards.

Upgrading within the existing TPSTW site only is not a feasible option.

2.5.2

Utilizing

the proposed expansion site adjoining the existing TPSTW is recommended for the

Project. It is a government land where

the existing land uses (STTs and TGLAs) are temporary. The land can be utilized

for construction of new Project facilities prior to decommissioning of the

existing facilities in TPSTW. This

option is selected for the Project as it will cause minimal interruption to the

normal treatment services during both construction and operational phases (see

Sections 2.2.13 to 2.2.14 above).

2.5.3

By

virtue of its upgrading and co-locating natures, except the adjoining expansion site,

no other alternative site location is applicable to this Project.

Alternative Sewage Treatment Schemes

2.5.4

The

existing TPSTW provides a secondary level treatment. Tolo Harbour is rich in

fisheries resources including four existing Fish Culture Zones (FCZs) and an important nursery area of commercial fisheries resources. To resolve the

red-tide problem in Tolo Harbour, which may cause fish kills and adverse impact

on marine life, the disinfected secondary effluent from TPSTW has been

transferring to Victoria Harbour for discharge since the THEES implementation

in the 80s. The water quality in Tolo

Harbour has shown marked improvement in the past three decades.

2.5.5

Kai

Tak River is the receiving water of the THEES effluent. It is a man-made concrete nullah in highly

developed urban land for drainage purpose. It is designed to receive treated

sewage effluent from THEES and stormwater from a large catchment of old

urbanized areas. There has been no

report of any particular environmental concern in

Victoria Harbour due to the treated effluent discharge from the THEES. Based on the past records and the water

quality impact assessment in Section 4, the THEES effluent will not affect the

open channel of Victoria Harbour with high flushing capacity. It is concluded that the secondary level

treatment will be the most effective treatment level for the Project in

minimizing the water quality impacts in Victoria Harbour.

2.5.6

Two

sewage treatment schemes have been considered for the Project as follows.

Existing Treatment Level for Discharging to the Victoria Harbour (Recommended Option)

2.5.7

This

option will require the THEES system to accommodate the additional flow of 40,000 m3 per day (i.e. increase from 120,000 m3 per day to 160,000 m3 per day). The Project may remain as a

secondary treatment works without any change to the water quality discharge

standards.

Tertiary Treatment for Discharging to the Tolo Harbour

2.5.8

This

will require construction and operation of a new tertiary treatment plant for

discharging the additional flow of 40,000 m3 per day to Tolo Harbour. The remaining

TPSTW secondary effluent will be discharged to the THEES for disposal. Despite

the reduced contaminant concentration in the tertiary effluent, this option

will permanently increase the pollution load to the sensitive Tolo Harbour,

which is not preferred.

2.5.9

The

environmental benefits and dis-benefits of the alternative treatment schemes

are summarized as follows.

Table 2.5 Environmental

Benefits and Dis-benefits of Alternative Sewage Treatment Schemes

|

Options |

Environmental Benefits |

Environmental Dis-benefits |

|

Existing Treatment Level for Discharging to the

Victoria Harbour (Recommended Option) |

n No additional

discharge to Tolo Harbour n Protection of

water quality, fisheries and ecological resources in

Tolo Harbour |

n Additional

discharge and potential water quality impact in Victoria Harbour, which has

been assessed under this EIA to be acceptable (see Section 4). |

|

Tertiary

Treatment for Discharging to the Tolo Harbour |

n No additional

discharge and no water quality impact in Victoria Harbour |

n Permanent discharge

and potential water quality impact in the sensitive Tolo Harbour |

Alternative Treatment Technologies

2.5.10 Consideration of alternative sewage treatment technologies for the Project is summarized below.

Table 2.6 Consideration

of Treatment Technologies for the Project

|

Category |

Technology |

To

Be Considered In Design Stage |

Comments/Notes |

|

Primary Treatment |

Conventional Sedimentation/

Clarification |

X |

Eliminated as the Project site does not

have sufficient space to accommodate the facilities |

|

Ballasted Flocculation |

X |

Eliminated as the Project site does not

have sufficient space to accommodate the facilities |

|

|

High Rate

Filtration (HRF) |

√ |

|

|

|

Mechanical Mesh Filter (MMF) |

X |

Eliminated because it was shown to be

less space efficient than HRF |

|

|

Biological Active Filter (BAF) |

X |

Eliminated because high TSS in raw

sewage may lead to frequent clogging of the filters |

|

|

High Rate

Lamella Clarification |

X |

Eliminated due to high chemical

consumption (ferric, polymer, carbon source) and release of residual

chemicals, which may affect the downstream biological treatment |

|

|

Lamella Plates Sedimentation (LPS) |

√ |

|

|

|

Secondary Treatment |

Aerobic Granular Sludge (AGS) |

√ |

|

|

Membrane Bioreactor (MBR) |

√ |

|

|

|

Moving Bed Biofilm Reactor – Dissolved

Air Flotation (MBBR-DAF) |

√ |

|

|

|

Membrane Aerated Biofilm Reactor (MABR) |

X |

Eliminated as the Project site does not

have sufficient space to accommodate the facilities |

|

|

Biological Active Filter (BAF) |

X |

Eliminated as the Project site does not

have sufficient space to accommodate the facilities |

|

|

Integrated Fixed-Film Activated Sludge

(IFAS)-Secondary Clarifier |

X |

Eliminated as the Project site does not

have sufficient space to accommodate the facilities |

|

|

Sludge Treatment

Technologies |

Conventional Mesophilic Anaerobic

Digestion (MAD) |

√ |

|

|

Thermal Hydrolysis Process (THP) with

Anaerobic Digestion |

√ |

|

|

|

Dewatering

Process Side-stream Nutrient Removal Technologies |

Deammonification |

√ |

|

|

Post Aerobic Digestion (PAD) |

X |

Eliminated due to the possible foaming

and production of malodorous air |

2.5.11

The

available space at the proposed expansion site is limited. The results of treatment option evaluation

suggest that it is feasible and beneficial to implement the new West Plant in

the proposed expansion site using the HRF or LPS technology (for primary

treatment) as well as the AGS or MBR or MBBR technology (for secondary

treatment). These compact-type technologies (coupled with UV disinfection) will

provide secondary level treatment capable of achieving the proposed effluent

standards presented in Table 2.1.

2.5.12

The

treatment option evaluation also suggests that it is feasible to accommodate

the new co-digestion facilities within the existing TPSTW, which conventional

MAD with or without THP is recommended.

2.5.13

Deammonification

has been evaluated to be the preferred technology for removing the nutrient in

the liquid side stream from the sludge dewatering process (before the side

stream is returned to the main liquid treatment process).

2.5.14

Change

of the sludge treatment technologies may affect the biogas production rate. The

preliminary arrangement of biogas related facilities and storage volume assumed

in the hazard to life assessment of this EIA have been reviewed to be

applicable to the conventional MDA with or without THP. Other key environmental

impacts during the Project operation will be the air quality (odour) and

noise. Contemporary good practice is for

all odourous treatment units to be enclosed, and

having the exhaust air treated to remove odour emissions to an acceptable

level. The enclosed nature of the new

West Plant and the new co-digestion facilities will also help mitigating the

noise impact.

2.5.15

In

summary, the acceptability of environmental impacts arising from the Project is

not sensitive to the choice of treatment technology to be considered in the

design stage. The environmental benefits

and dis-benefits of different treatment technologies are not further

considered.

Alternative Emergency Outfall Options

2.5.16

Under normal operation, treated sewage effluent from the Project will be

conveyed by the THEES effluent tunnel for discharge into Victoria Harbour. An emergency outfall is needed for bypass of treated or partially treated effluent to Tolo Harbour during the THEES maintenance period or emergency situations. Two options

of an emergency outfall for the Project have been considered as discussed

below.

Utilization of the Existing Emergency Outfall (Recommended Option)

2.5.17 The existing emergency outfall of TPSTW is in the form of underground sewage pipeline for diverting the effluent from TPEPS for discharge at the seawall to the south of Tai Po Industrial Estate (TPIE). The existing sewage pipeline has been reviewed to have sufficient capacity to handle the design flow of this Project. The marine water depth to the south of the existing emergency outfall or close to the waterfront of TPIE is > 2 - 5 m below the Chart Datum (mCD). Although the water depth near the outfall is relatively shallow, which may not be favorable to effluent dispersion, it is located in an area with the lowest fisheries production yield amongst all other waters in Tolo Harbour. The fisheries production yield recorded near the outfall is >50 -100 kg/ha.

Exhibit 2.1 Water Depth and Fisheries Production

Source

of Information:

Water

depth - Marine Department.

Fisheries

production – 2016 / 2017 Port Survey, Agriculture, Fisheries and Conservation

Department.

2.5.18 Using the existing emergency outfall for this Project is predicted to cause no unacceptable water quality, ecological and fisheries impacts with the implementation of the recommended mitigation measures (see Sections 4, 5 and 6). In order to minimize the scale and scope of construction and the associated environmental impacts, construction of new emergency outfall is not proposed.

Construction of a New Submarine Outfall

2.5.19 Diverting the effluent discharge to a deeper water away from the coastline may enhance the effluent dispersion and dilution effect. In view that the waters to the further south of the existing seawall outfall are also relatively shallow with similar depths and in order to achieve a better or noticeable dilution effect, the outfall should be extended to a location beyond the contour line of 5 mCD in the east (as shown in Exhibit 2.1 above). However, such location could be closer to the existing FCZ or area with higher fisheries production yield. This option will also require the laying of new outfall diffuser in the deeper water. Installation of the new outfall diffuser may disturb the seabed sediments and cause a release of sediment and sediment-bounded contaminants during the construction phase. The new outfall diffuser will also induce a permanent loss of fishing ground in Tolo Harbour. This option is not further considered.

2.5.20

The

environmental benefits and dis-benefits of the alternative emergency outfall

options are summarized as follows.

Table 2.7

Environmental Benefits and Dis-benefits of Emergency Outfall Options

|

Options |

Environmental Benefits |

Environmental Dis-benefits |

|

Utilization of the Existing Emergency Outfall

(Recommended Option) |

n No loss of fishing

ground nor marine habitat during construction and operational phases. n No disturbance to

seabed sediment and no release of sediment-bound contaminants in Tolo

Harbour. |

n Relatively poorer

effluent dispersion capacity in shallower water during operational phase. n The water quality

impact, however, has been assessed to be acceptable with proper

implementation of the recommended mitigation measures (see Section 4). |

|

Construction of a New Submarine Outfall |

n Potentially better

effluent dispersion and dilution capacity in deeper water during operational

phase. |

n Release of

sediments and sediment-bounded contaminants (e.g.

metals) during construction of new outfall diffuser and inducing additional

marine water quality, fisheries and marine ecological impacts. n Temporary loss of

fishing ground in Tolo Harbour during the construction of the new outfall

diffuser. n Permanent loss of

fishing ground and marine habitat due to operation of the new outfall

diffuser. |

Alternative Construction Sequences

2.5.21

Two construction sequences have been considered for the Project as

follows.

Phased Construction (Recommended Option)

2.5.22 Phased construction as described in Sections 2.2.13 and 2.2.14 will allow construction and commissioning of new treatment units before the demolition of existing similar facilities such that adequate treatment capacity can be provided through the construction phase.

Concurrent Construction in Existing TPSTW and Proposed Expansion Site

2.5.23 Due to the limited space available, construction of new facilities in TPSTW will require prior decommissioning and demolition of existing facilities in TPSTW. Under this option. construction in existing TPSTW will be carried out prior to the completion and commissioning of the new West Plant in the proposed expansion site.

2.5.24

The

environmental benefits and dis-benefits of the alternative construction

sequences are summarized as follows.

Table 2.8 Environmental Benefits and Dis-benefits of

Alternative Construction Sequences

|

Options |

Environmental Benefits |

Environmental Dis-benefits |

|

Phased

Construction (Recommended Option) |

n This option will

maintain continuous sewage treatment services throughout the construction

phase and eliminate the chance of temporary sewage bypass into the

environment. n Phased

construction will reduce the total construction emissions (dust and noise) at

one time and minimize the environmental impacts. |

n This option may imply

a relative longer construction period. The overall duration of construction

phase impact on the environment may be lengthened. |

|

Concurrent

Construction in Existing TPSTW and Proposed Expansion Site |

n This option may

imply a relatively shorter construction period. The overall duration of

construction phase impact on the environment may be shortened. |

n There will be a

higher chance to release untreated sewage effluent into the environment and

induce additional marine water quality, ecology and fisheries impacts in Tolo

Harbour. n The cumulative or

total pollution emissions (dust and noise) at a time will be higher during

the construction phase. |

Alternative

Demolition Methods

2.5.25

This Project will involve partial demolition of the existing treatment

units in TPSTW for construction of new facilities. Different demolition methods

have been considered and are discussed as follows.

Breakers Mounted on Excavator (Recommended Option)

2.5.26 Using breakers mounted on excavator is a conventional method for demolition of all types of structures. Concrete breaking using this method will induce a relatively higher noise emission as compared to other quieter methods.

2.5.27 Based on the construction programme and due to the urgency to upgrade the TPSTW to cater for the projected sewage flow buildup, the time allowing for the demolition works of this Project will be limited. Demolition of key facilities in the existing TPSTW cannot be carried out until the completion and commissioning of the new West Plant of this Project to ensure normal sewage treatment services throughout the construction phase. The demolition of the existing TPSTW will also need to be undertaken by stages in order to maintain adequate sludge treatment capacity throughout the construction phase (see Sections 2.2.13 and 2.2.14 above). Using breakers mounted on excavator will be the most efficient scheme and a faster demolition method to meet the tight construction programme.

2.5.28 There is no Noise Sensitive Receivers (NSRs) identified within 300 m from the Project site. The planned NSRs (staff quarters, overnight accommodations, etc.) of the proposed Shuen Wan Golf Course (SWGC) as identified in the approved EIA for SWGC are all located outside the noise impact assessment area of this EIA. According to the ecological impact assessment in Section 5, the key pre-roosting/roosting sites of Collared Crow and roosting sites of Black Kites in Shuen Wan Restored Landfill (which may be sensitive to noise) are separated from the construction site of this Project. Most of them are blocked by the existing topography with no direct line of sight to the Project construction activities. It is recommended that movable and non-reflective temporary noise barriers with sound absorptive materials can be deployed close to noisy plant and be moved concurrently with the plant along a worksite for effective noise screening from the pre-roosting sites located to the east of the Project site. Quality Powered Mechanical Equipment (QPME) listed in the QPME system in the EPD web pages will also be used as far as possible.

2.5.29 An existing tree group located within the proposed works area of this Project is identified as an occasional night roosting habitat for the non-breeding ardeids. The concerned tree group will be transplanted or compensated within the Project layout. To minimize the disturbance (e.g. construction noise) to any roosting ardeids, all noisy construction works within 100m of the concerned tree group should cease at least 1 hour before sunset before the removal/transplantation of the tree group. All noisy construction works within 100m of the relevant transplantation/compensation planting area should also cease at least 1 hour before sunset after transplantation/compensatory planting.

2.5.30 No unacceptable noise impact would be expected with implementation of the recommended mitigation measures.

Quieter Demolition Methods

2.5.31

Concrete breaking using quieter equipment such as

crushers and saw cutting can reduce the noise emissions as compared to the

breakers mounted on excavator. The

demolition rates of using these methods are generally longer. Using these

slower demolition methods will be infeasible to meet the construction programme

and are therefore not selected.

2.5.32

The

environmental benefits and dis-benefits of the alternative construction

sequences are summarized as follows.

Table 2.9

Environmental Benefits and Dis-benefits of Alternative Demolition Methods

|

Options |

Environmental

Benefits |

Environmental

Dis-benefits |

|

Breaker Mounted on Excavator (Recommended Option) |

n Shorter

demolition duration and shorter demolition noise emission period. |

n This option will

induce a higher noise level in TPIE but no NSRs are identified in TPIE |

|

Quieter Demolition Methods (such as using crushers

or saw cutting) |

n These quieter

demolition methods may reduce the construction noise level in TPIE. |

n Longer demolition

duration and longer demolition noise emission period. |

Alternative Piling Methods

2.5.33 Piling will be required for construction of the foundation for new facilities at the Project site. Selection of the piling methods will be subject to the site-specific ground conditions. Alternative piling methods have been considered as follows.

Quieter Piling Methods (Recommended Option)

2.5.34 Quieter piling method, namely pre-bored steel H piles, will involve a hole (formed by rotary dill into the ground and to the rock where the upper section in soil is supported by a steel casing. The steel H piles are then inserted and grout is pumped into the hole while the steel casing is removed. No percussive action is required for forming the holes.

2.5.35 This method is not applicable for all types of ground conditions. For example, it will require a longer construction time in areas with a very deep bed rock.

2.5.36 Based on the preliminary Ground Investigation (GI) data available at the Project site, this quiet piling method is considered suitable. It is therefore proposed to use this method as far as practicable to minimize the noise impact.

Percussive Piling (Alternative Option)

2.5.37 Construction of percussive piles will induce a relatively high disturbance in term of noise level during the construction stage. With this consideration, application of percussive piling should be avoided as far as practicable.

2.5.38 This method is applicable to all ground conditions with less construction time required.

2.5.39 If any updated GI data (to be collected at the design stage of this Project) reveal that the pre-bored steel H piles are not practical, this conventional percussive pilling should be used as an alternative method and should be undertaken within non-sensitive hours (e.g. close to noon) as far as practicable.

2.5.40

The

environmental benefits and dis-benefits of the alternative piling method are

summarized as follows.

Table 2.10

Environmental Benefits and Dis-benefits of Alternative Piling Methods

|

Options |

Environmental Benefits |

Environmental

Dis-benefits |

|

Quieter Piling Methods (e.g.

pre-bored steel H piles) (Recommended Option) |

This option will induce a lower level of noise

disturbance in TPIE. |

|

|

Percussive Piling (Alternative Option) |

|

This option will

induce a higher level of noise disturbance in TPIE |

Other Construction Activities

2.5.41 Other Civil & Structural works including the excavation and concrete construction works will be adopted for the Project. Control of the total active construction works area at a time or phasing of construction have been considered in the air quality impact assessment in Section 3 to minimize the construction dust impact. For Electrical and Mechanical (E&M) works, general fixing and installation of treatment plants and facilities such as pumps and conveyors are required. For Building Services works, small-scale utilities installations such as pipe-laying, ducting and cabling will be conducted. The E&M and Building Services works are considered to create less environmental impact (dust and noise emissions). It is recommended that construction by precast or prefabrication units should be adopted as far as practicable to minimize the environmental impacts during construction phase.

2.6

Interfacing

and Concurrent Projects

2.6.1 This section describes the interfacing and concurrent projects based on the best available information at the time of preparing this EIA Report. Locations of concurrent projects in the vicinity of the Project site are presented in Figure 2.2. The description and layout of these concurrent projects as presented below will be subject to changes and further updates by the respective project proponents.

Proposed Sha Tin Cavern Sewage Treatment

Works

2.6.2 This is a DSD project, which mainly include relocation of the existing Sha Tin Sewage Treatment works (STSTW) to caverns. During normal plant operation, the effluent of the proposed Sha Tin Cavern Sewage Treatment Works (CSTW) will be discharged to Kai Tak River in Victoria Harbour via the Tolo Harbour Effluent Export Scheme (THEES). The discharge of CSTW effluent into the Tolo Harbour will occur during the THEES maintenance period or under emergency condition. The cumulative environmental impact due to the concurrent discharge from the CSTW operation have been considered in this EIA. The project is currently under construction phase and is anticipated to commission before 2030. The construction activities of the CSTW project is outside the assessment area of this EIA.

Proposed THEES Upgrading

2.6.3 This is a separate interfacing project proposed by EPD under “Agreement No. CE 13/2015 (DS)”. It involves upgrading of the effluent conveyance capacity of THEES in order to cater for the projected effluent flow of this Project.

2.6.4 The proposed THEES upgrading works involve expansion of the Tai Po Effluent Pumping Station (TPEPS) within the Project site, as well as construction of a new effluent rising mains in TPIE and a new submarine pipeline (across inner Tolo Harbour) to handle the Project flow.

2.6.5 The new submarine pipeline will be installed by the Horizontal Directional Drilling (HDD) method, which is a trenchless method with no disturbance to the seabed and marine habitat. All the remaining THEES upgrading works are land-based.

2.6.6 The proposed TPEPS expansion located within the Project site will be constructed and operated under this Project and incorporated into the construction programme and design of this Project. Construction of the new effluent rising mains and submarine pipeline will be undertaken separately and is tentatively scheduled to commence in 2025 for completion 2031. All the proposed THEES upgrading works are committed to match the implementation programme of this Project. Cumulative environmental effects of the THEES upgrading works have been considered in this EIA.

Proposed Shuen Wan Golf Course

2.6.7 The proposed Shuen Wan Golf Course (SWGC) is located to the east of the Project site. It mainly involves the development of a new golf course within the existing Shuen Wan Restored Landfill (SWRL) site. According to the SWGC EIA Report, the construction of the proposed SWGC would be completed in end 2023 prior to the construction of this Project. Cumulative effects of the SWGC in particular on the terrestrial ecology have been considered in this EIA.

Proposed Organic Waste Pre-treatment Centre

2.6.8 Development of Organic Waste Pre-treatment Centre (New Territories East) is an interfacing project proposed by EPD under “Agreement No. CE 5/2021 (EP)”. The proposed Organic Waste Pre-treatment Centre (OWPC) is planned to receive and pre-treat the source-separated food waste for transferring to the TPSTW and / or off-site anaerobic digesters in other STWs for co-digestion with sewage sludge. It is tentatively scheduled to commence construction in 2025 for completion by 2029. This interfacing project will contribute cumulative environmental impact during construction (e.g. on dust) and operation (e.g. on odour).

Planned Residential Development at Ting Kok

2.6.9 Construction and operation of this land-based project will be located over 500m from the Project site. No cumulative environmental impact will be expected from this residential development project.

Kai Tak

Development – Interception and Pumping Scheme