Air Treatment

We have kept close monitoring on the air condition of the transfer stations. Routine odour patrol is being carried out inside the station and along the station boundary. We also liaise with FEHD closely for the odour nuisances caused by refuse collection vehicles (RCV) such as leachate dripping and Vehicle exhaust emissions.

Our daily monitoring programme includes the following parameters : -

- Vehicle Exhaust Emission - including carbon monoxide (CO) and nitrogen dioxde(NO2)

- Dust Control - including Total Suspended Particulates (TSP) and Respirable Suspended Particulates (RSP)

- Odour - we perform odour monitoring frequently to keep track the odour level inside and outside the station.

- Temperature - The tipping hall is adequately ventilated and / or heat insulated such that the temperature inside the tipping hall does not significantly exceed the ambient temperature.

The following are being carried out to control the air condition :

- A wet scrubbing system for odour removal

- All refuse transfer operation are carried out in enclosed area as far as possible

- The plant includes the facility for washing down all surfaces with which refuse comes in contact

- Waste must only be stored in sealed containers except for any necessary venting

- Air extracted from the plant is treated by the odour scrubbing systems prior to discharging

- Access roads, ramp, tipping apron and vehicle maneuvering areas are mechanically washed and swept frequently to prevent odour accumulation

- All RCVs are washed externally before leaving the transfer station

1. Air Collection

| In tipping hall, dust and odours are generated during unloading of refuse. |  |

|

Water spraying system located at the top of live-floor is used to minimise the dust and odours. |

| Air is extracted by the air extraction system. |  |

|

Exhaust emission from RCVs accumulated in the tipping hall is extracted by the ventilation duct located at the top of tipping hall, and treated by the Air Scrubbing System. |

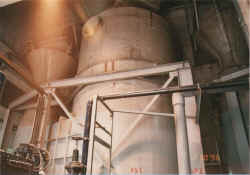

2. Air Scrubbing

A typical Air Scrubbing System installed at Sha Tin Transfer Station consists of two parts, they are Venturi Scrubbers and Final Scrubbers. The air extracted from Tipping Hall will be flown to the Venturi Scrubbers first.

|

Air is flushed with high flow of waste water in the two venturi scrubbers for dust and primary odour removal. [click here to view the schematic diagram of Venturi Scrubber] |

| Treated air is flown to the two final scrubbers for further dust and odour removal. [click here to view the schematic diagram of the final scrubber] |  |

|

Finally, treated air will be discharged. |