Environmental Impact Assessment Ordinance

(Cap. 499), Technical Memorandum on Environmental Impact Assessment

Process (TM-EIAO)

5.1.1.4

The TM-EIAO specifies the

assessment methods and criteria for impact assessment. This Study follows the TM-EIAO

to assess the potential water quality impact that may arise during both the

construction and operational phases of the Project. Sections in the TM-EIAO relevant

to the water quality impact assessment are:

·

Annex 6 -

Criteria for Evaluating Water Pollution; and

·

Annex 14 -

Guidelines for Assessment of Water Pollution.

Hong Kong Planning Standards and Guidelines

(HKPSG)

5.1.1.5

Chapter 9 of the HKPSG outlines

environmental requirements that need to be considered in land use planning. The

recommended guidelines, standards and

guidance cover the selection of suitable locations for the developments and

sensitive uses, provision of environmental facilities, and design, layout,

phasing and operational controls to minimise

adverse environmental impacts. It also

lists out environmental factors that influence land use planning and recommends

buffer distances for land uses.

Practice Note for Professional Persons on Construction

Site Drainage (ProPECC PN 1/94) “Construction Site Drainage”

5.1.1.6

The ProPECC PN1/94 provides

guidelines for the handling and disposal of construction discharges. It is applicable to this study for the

control of site runoff and wastewater generated during the construction

phase. The types of discharges from

construction sites outlined in the ProPECC PN1/94 include:

·

Surface runoff;

·

Groundwater;

·

Boring and drilling water;

·

Wastewater from concrete

batching plant;

·

Wheel washing water;

·

Bentonite slurries;

·

Water for testing and

sterilization of water retaining structures and water pipes;

·

Wastewater from building

construction and site facilities; and

·

Acid cleaning, etching and

pickling wastewater.

5.2.1.1 The Project falls within the Mirs Bay WCZ according to the WPCO. The Project site is located within Tung Ping Chau Marine Park, but outside the core areas of the marine park at Tai Tong Wan (i.e. about 240m to the north of the Project) and A Ma Tsui (i.e. about 510m to the south of the Project). Coral colonies and algae are commonly found within Tung Ping Chau Marine Park. Coral colonies are readily discovered around the Project site while algae mostly grow in the west coast of Tung Ping Chau where the water quality is not anticipated to be affected by the Project.

5.2.1.2 Furthermore, several land-based WSRs have been identified including Plover Cove (Extension) Country Park, which is 100m away from the Project, and the two watercourses at Tung Ping Chau, which are 200m and 350m away from the Project respectively.

5.2.1.3 A greater extend of Mirs Bay WCZ is also reviewed with respect to the potential water quality impact from the Project.

5.2.2 Baseline Water and Sediment Quality Conditions

Environmental Protection Department (EPD)’s

Marine Monitoring Stations

5.2.2.1 The latest marine water quality monitoring data in 2018 and sediment quality monitoring data in 2014-2018 were adopted to determine the ambient marine water and sediment quality, which are presented in Table 5.3 and Table 5.4 respectively. The locations of the monitoring stations are presented in Figure 5.1. According to the Marine Water Quality in Hong Kong 2018, the Mirs Bay WCZ attained full compliance of WQOs in 2018.

Table 5.3 Summary of EPD’s Routine Marine Water Quality Data for Mirs Bay WCZ in 2018

|

Parameters |

Mirs Bay WCZ [1]

[2] [3] [4] |

||

|

MM4 |

MM5 |

||

|

Temperature (°C) |

23.3 |

23.2 |

|

|

Salinity (‰) |

32.4 |

32.4 |

|

|

Dissolved Oxygen (mg/L) |

Depth Average |

6.5 |

6.4 |

|

Bottom |

6.0 |

5.7 |

|

|

Dissolved Oxygen (% saturation) |

Depth Average |

91 |

89 |

|

Bottom |

83 |

79 |

|

|

pH |

7.8 |

7.8 |

|

|

Secchi Disc Depth (m) |

3.8 |

4.3 |

|

|

Turbidity

(NTU) |

2.0 |

2.7 |

|

|

Suspended Solids (mg/L) |

6.2 |

6.1 |

|

|

5-day Biochemical Oxygen Demand (mg/L) |

0.6 |

0.6 |

|

|

Ammonia Nitrogen (mg/L) |

0.020 |

0.019 |

|

|

Unionised Ammonia (mg/L) |

<0.001 |

<0.001 |

|

|

Nitrite Nitrogen (mg/L) |

0.006 |

0.007 |

|

|

Nitrate Nitrogen (mg/L) |

0.013 |

0.014 |

|

|

Total Inorganic Nitrogen (mg/L) |

0.04 |

0.04 |

|

|

Total Kjeldahl Nitrogen

(mg/L) |

0.36 |

0.34 |

|

|

Total Nitrogen (mg/L) |

0.38 |

0.36 |

|

|

Orthophosphate Phosphorus (mg/L) |

0.006 |

0.006 |

|

|

Total Phosphorus (mg/L) |

0.02 |

0.02 |

|

|

Silica (as SiO2) (mg/L) |

0.47 |

0.50 |

|

|

Chlorophy ll-a (µg/L) |

1.8 |

1.8 |

|

|

E.coli (cfu/100mL) |

1 |

<1 |

|

|

Faecal Coliforms (cfu/100mL) |

1 |

1 |

|

Notes:

[1] The table above is extracted from the Annual Report of Marine Water Quality in Hong Kong in 2018.

[2] Unless otherwise specified, data presented are depth-averaged (A) values calculated by taking the means of three depths: Surface (S), Mid-depth (M), Bottom (B).

[3] Data presented are annual arithmetic means of the depth-averaged results except for E. coli and faecal coliforms which are annual geometric means.

[4] Data in brackets indicate the ranges.

Table 5.4 Summary of EPD’s Routine Marine Sediment Quality Data for Mirs Bay WCZ in 2014-2018

|

Parameters |

Mirs Bay WCZ [1] [2]

[3] |

|

|

MS4 |

MS5 |

|

|

Particle Size Fractionation <63μm (%w/w) |

85 |

92 |

|

Electrochemical Potential (mV) |

-286 |

-268 |

|

Total Solids (%w/w) |

41 |

39 |

|

Total Volatile Soilds

(%TS) |

8.3 |

8.9 |

|

Chemical Oxygen Demand (mg/kg) |

13300 |

13350 |

|

Total Carbon (%w /w ) |

0.8 |

0.7 |

|

Ammonical Nitrogen (mg/kg) |

8 |

5.28 |

|

Total Kjeldahl Nitrogen

(mg/kg) |

650 |

630 |

|

Total Phosphorus (mg/kg) |

220 |

210 |

|

Total Sulphide (mg/kg) |

33.3 |

21 |

|

Total Cyanide (mg/kg) |

0.1 |

0.1 |

|

Arsenic (mg/kg) |

7.1 |

7.4 |

|

Cadmium (mg/kg) |

0.1 |

<0.1 |

|

Chromium (mg/kg) |

32 |

31 |

|

Copper (mg/kg) |

15 |

15 |

|

Lead (mg/kg) |

36 |

39 |

|

Mercury (mg/kg) |

0.05 |

0.05 |

|

Nickel (mg/kg) |

22 |

22 |

|

Silver (mg/kg) |

<0.2 |

<0.2 |

|

Zinc (mg/kg) |

87 |

94 |

|

Total Polychlorinated Biphenyls (PCBs) (µg/kg) |

18 |

18 |

|

Low Molecular Weight Polycylic

Aromatic Hydrocarbons (PAHs) (µg/kg) [5] [7] |

140 |

130 |

|

High Molecular Weight Polycylic

Aromatic Hydrocarbons (PAHs) (µg/kg) [6] [7] |

63 |

51 |

Notes:

[1] The table above is extracted from the Annual

Report of Marine Water Quality in Hong Kong in 2018.

[2] Data presented are arithmetic means;

data in brackets indicate ranges.

[3] All data are based on the analyses

of bulk (unsieved) sediment and are reported on a dry

weight basis unless stated otherwise.

[4] Total PCBs results are derived from

the summation of 18 congeners. If the concentration of a congener is below

report limit (RL), the result will be taken as 0.5xRL in the calculation

[5] Low molecular weight poly aromatic

hydrocarbons (PAHs) include 6 congeners of molecular weight below 200, namely:

Acenaphthene, Acenaphthylene, Anthracene, Flourene,

Naphthalene and Phenanthrene.

[6] High molecular weight poly aromatic

hydrocarbons (PAHs) include 10 congeners of molecular weight above 200, namely:

Fluoranthene, Pyrene, Benzo(a)anthracene, Chrysene, Benzo(b)f luoranthene, Benzo(k)fluoranthene, Benzo(a)pyrene, Dibenzo(a,h)anthracene, Benzo(g,h,i)perylene

and Indeno(1,2,3-cd)pyrene.

[7] Low and high molecular weight PAHs

results are derived from the summation of the corresponding congeners. If the

concentration of a congener is below report limit (RL), the result will be

taken as 0.5xRL in the calculation.

5.2.3 Marine Park Water Quality Monitoring

5.2.3.1

In

addition, water quality monitoring in Tung Ping Chau Marine Park is carried out

quarterly by AFCD. The water quality monitoring at Tung Ping Chau Marine Park

is taken at two sites at Ma Kok Tsui and Cheung Sha Wan within the marine park.

This data will be adopted in establishing the water quality baseline conditions

for the Project. The monitoring results in 2019 are shown in Table 5.4.

Table 5.5 Water Quality of Tung Ping Chau Marine Park in Year 2019

|

Parameters |

Ma

Kok Tsui |

Cheung

Sha Wan |

||

|

Water

Depth Surface |

Surface |

Bottom |

Surface |

Bottom |

|

Air

Temperature (°C) |

25.68 |

25.83 |

||

|

Temperature

(°C) |

25.48 |

24.96 |

25.56 |

24.78 |

|

Salinity

(‰) |

32.34 |

32.50 |

32.34 |

32.82 |

|

Dissolved

Oxygen (mg/L) |

7.19 |

7.04 |

7.18 |

6.27 |

|

pH |

8.11 |

8.14 |

8.06 |

8.14 |

|

Secchi

Disc Depth (m) |

1.9 |

3.1 |

||

|

Turbidity

(NTU) |

<1 |

<1 |

1.13 |

<1 |

|

Suspended

Solids (mg/L) |

2.75 |

3.13 |

3.13 |

3.38 |

|

5-Day

Biochemical Oxygen Demand (mg/L) |

2.38 |

2.50 |

2.13 |

3.38 |

|

Ammoniacal

Nitrogen (mg/L) |

0.02 |

0.02 |

0.02 |

0.02 |

|

Unionized

Ammonia (mg/L) |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

|

Nitrite

Nitrogen (mg/L) |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

|

Nitrate

Nitrogen (mg/L) |

0.06 |

0.06 |

0.06 |

0.06 |

|

Total

Inorganic Nitrogen (mg/L) |

0.08 |

0.07 |

0.07 |

0.07 |

|

Total

Kjeldahl Nitrogen (mg/L) |

0.48 |

0.45 |

0.44 |

0.59 |

|

Total

Nitrogen (mg/L) |

0.54 |

0.50 |

0.49 |

0.65 |

|

Orthophosphate

Phosphorus (mg/L) |

0.01 |

0.01 |

0.01 |

0.01 |

|

Total

Phosphorus (mg/L) |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

|

Chlorophyll-a

(μg/L) |

0.66 |

0.59 |

0.84 |

0.86 |

|

E. coli

(cfu/100 mL) |

1 |

0 |

0 |

0 |

|

Faecal

Coliforms (cfu/100 mL) |

21 |

34 |

7 |

3 |

5.3 Assessment Area and Water Sensitive Receivers

5.3.1 Assessment Area

5.3.1.1

The

assessment area for the water quality impact assessment is stated in Clause

3.4.6.2 of EIA Study Brief (ESB-306/2017). It includes areas within 500m from

the boundary of the Project and the works of the Project, and covers the Mirs Bay Water Control Zone as designated under the Water

Pollution Control Ordinance (Cap. 358), and the water sensitive receivers

outside the 500m boundary but in the vicinity of the Project. The assessment

area for this Project includes Tung Ping Chau Marine Park. Figure 5.1 shows the water quality assessment area for this

Project.

5.3.2 Water Sensitive Receivers

5.3.2.1 Representative Water Sensitive Receivers (WSRs) are identified within the assessment area and are indicated in Figure 5.1. They include Marine Park, SSSI, Country Park, coral colonies and watercourses as summarised in Table 5.4.

Table 5.6 WSRs within the assessment area

|

WSR |

Description |

Type |

Nearest distance from the Project (m) |

|

TPC-W1 |

Tung Ping Chau Marine Park |

Marine Park and Coral

Colonies |

Project within the marine park |

|

TPC-W2 |

Plover Cove (Extension) Country Park |

Country Park |

100 |

|

TPC-W3 |

Ping Chau SSSI |

SSSI |

Project adjacent to SSSI |

|

TPC-W4 |

Watercourse near Chan Uk |

Inland Natural

Watercourse |

200 |

|

TPC-W5 |

Watercourse near Sha Tau |

Inland Natural

Watercourse |

350 |

5.4 Construction Phase Assessment

5.4.1 Identification of Environmental Impacts

5.4.1.1

The

Project comprises the following works which may

potentially give rise to minor water quality impacts during the

construction phase. No specific activity during the operational phase is

anticipated to bear water quality impacts. Detailed description of the works

and tentative construction programme are presented in Section

2.

· Carrying out site investigation works for detailed design;

· Provision of plants, equipment and materials on working barge(s) for implementation of the Project;

· Provision of temporary berthing and mooring facilities (temporary pier) using working barge and/or steel structures supported by piles to maintain access to Tung Ping Chau until a new berth of the pier is available for use;

· Removal of temporary pier, modification of the existing pier and installation of piles for the new pier;

· Construction of new pier structures (e.g. installation of precast elements on the pier structure etc.); and

· Construction of associated facilities on the new pier.

5.4.1.2

Potential

water quality pollution sources from the Project during the construction phase

are summarized as follows.

·

Marine-based

site investigation works;

·

Marine-based

foundation works;

·

Above-water

construction works;

·

Demolition

Works;

·

Hydrodynamic

impact;

·

Site

run-off from general site operation;

·

Accidental

spillage of chemicals; and

·

Sewage

from workforce.

5.4.2 Prediction and Evaluation of Environmental Impacts

Marine-based Site Investigation Works

5.4.2.1

Before

sampling, the jack-up barge will be fixed in a position by extending its 4 legs

into the seabed, the legs and borehole locations will be inspected by diver

survey to ascertain no coral colonies will be affected as far as practicable. After

positioning, the barge will be jacked up until the barge bottom is elevated

above the high tide level. Minimal disturbance of existing seabed level during

positioning would be resulted but

significant dispersion of suspended solids is not expected.

5.4.2.2

Before the

commencement of rotary drilling works, all drill rig, circulation tank and

equipment shall be thoroughly cleaned off-site. An outer casing shall be first

placed on the seabed level to avoid the spillage of drilling

fluid during drilling works. Throughout the drilling process, seawater shall be

used as drilling fluid for lubricating the drill bit, and no lubricants or other

additives shall be introduced. The drilling fluid shall be circulated within

the system through the circulation tank, where the recycled fluid with small amount of suspended solids will be settled and collected in

the tank. The inner casing shall be advanced to the rockhead by rotary core

drilling and shall be cleaned by the recirculated flushing water before

extraction. Thereafter, the inner and outer casings shall then be extracted

slowly to the barge deck. Final disposal of the drilling fluid would be

discharged offsite with a valid discharge license under the WPCO with the

provision of silt removal facilities, or to the facilities of the Contractor.

The discharge requirements shall comply with TM-WPCO as specified in Table 5.2. No marine

sediment is anticipated to be collected from the site investigation works.

Hence, impact of marine sediment on water quality is not anticipated.

Marine-based Foundation Works (for Temporary Pier

and Proposed Pier)

5.4.2.3

The

pre-drilling works of foundation for proposed TPC Public Pier would be in the

similar fashion as the site investigation work as described in Section 5.4.2.1 and Section 5.4.2.2.

Pile Installation Works

5.4.2.4

The

foundations of the proposed TPC Public Pier and the temporary pier will be

composed of in-situ bored piles or

similar pile types (e.g. rock socketed Steel H-pile). A working platform in

form of a working barge and/or temporary steel structure supported by mini-piles (~219 or 273mm dia.) will be adopted to

facilitate the pier construction works. Working barges will be fixed in a

position by anchoring concrete mooring sinkers onto the seabed while the mini-piles used to support the temporary steel structure

would follow the confined pile casing method as discussed in Section 2.6.3.2 to Section 2.6.3.3. in order to control the water quality and ecological impacts. Prior to the construction work, the sinkers and/or mini-piles

locations will be inspected by diver survey to ascertain no coral colonies will

be affected as far as practicable before installation. Minimal disturbance of existing seabed level during positioning would be

resulted but significant dispersion of suspended solids is not expected.

5.4.2.5

For

each pile construction, confined pile casing method as

discussed in Section 2.6.3.2

and Section 2.6.3.3 would

also be followed. Inner casing of approximately 0.8-1.0m in diameter will be

installed into the seabed by using hydraulic oscillator from a working

platform. Pile shaft excavation by using hammer grab will be carried out within

the casing. Closed grab excavator will be deployed to minimise the leakage of

material collected during the process. The grabbed material will be bought to

and be settled in the sedimentation tank. The steel casing will then be jacked

down into the ground by oscillator prior to carry out next grabbing process

until reaching rockhead. Reverse Circulation Drill (RCD) will be deployed to

drill through the bedrock and any hard material encountered until reaching the required

level. No grabbed material will be made in direct contact with the open sea

water.

5.4.2.6

Such

confined pile casing method has been adopted for the Hong Kong-Zhuhai-Macau

Bridge Hong Kong Link Road construction of marine bored piles for the piers of viaducts.

The set-up avoids the use of silt curtains for the protection of Chinese White

Dolphin. Based on the environmental monitoring data of the project, there were

no project-induced exceedances of water quality monitoring parameters. Likewise,

for this Project, the movement of the silt curtain due to the water current may

cause damage and injury to the coral colonies nearby. Deployment of silt

curtain is therefore considered not suitable for this Project. Based on the

previous experience, confined pile casing method is therefore proposed for

effective confinement of the suspended solids inside the pile casing for this

Project. An illustrative figure of the tentative set-up of the marine-based

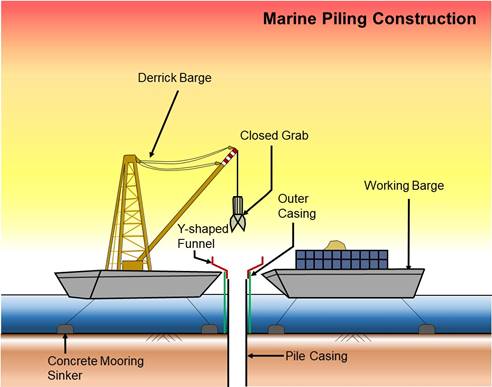

foundation work is shown in Image 5.1.

Image 5.1 Tentative Set-up of Marine-based

Foundation Work

5.4.2.7

Seabed

disturbance is anticipated during the insertion and removal of pile casings. As

discussed in Section 11.5.2.1, the seabed features in the vicinity of

the Project are mostly sand/silt, boulders and rocks. No sediment and clay are

found within the Project site. As sand and silt have higher density and larger

particle sizes than clay or marine sediment, the sand and silt particles have

much higher settling velocity, and re-suspended solids in the water column

could be quickly settled. Moreover, the pile casings would be inserted and

removed in a gradual manner to reduce the disturbance of the seabed. Adverse

water quality impacts due to the installation and removal of the casings are

therefore not anticipated.

5.4.2.8

The

steel casing will then be jacked down into the ground by the oscillator again

and will continue the next grabbing process until reaching bedrock. Reverse

Circulation Drill (RCD) will be deployed to drill through the bedrock and hard

material encountered until reaching the required founding level.

5.4.2.9

The

grabbed materials collected in the circulation tank will be transported by

barge or marine vessel to the public fill reception facilities (e.g. Tseung Kwan O Area 137 Fill Bank which receives public fill

only) or the Outlying Island Transfer Facilities (which receive both public

fill and non-inert C&D materials).

5.4.2.10

Upon

completion of excavation and removal of the drill bit, air-lifting

will be carried out to remove debris inside the casing. Drilling fluid in the

pile casing will be continuously pumped out to the circulation tank on the

barge to avoid muddy water overflown from the casing to the sea directly. The

drilling fluid will be stored on barge where the recycled fluid with small amount of suspended solids will be settled and collected in

the tank. The recycled fluid will be used for the subsequent piling works. No

drilling fluid and suspended solids will be discharged on site or within the

boundary of Tung Ping Chau Marine Park, Plover Cove (Extension) Country Park,

Ping Chau SSSI and the other identified WSRs.

5.4.2.11

Final

disposal of the drilling fluid would be discharged offsite with a valid

discharge license under the WPCO with the provision of silt removal facilities,

or to the facilities of the Contractor. The discharge requirements shall comply

with TM-WPCO as specified in Table 5.2.

Thus, water quality and ecological impacts are not anticipated from the

marine-based foundation works on the identified WSRs.

Above-water Construction Works

5.4.2.12

The proposed deck of the temporary pier would

be a steel structure of about 20m long and 5.5m wide above the sea. Prefabricated elements of

steel structure will be shipped and installed on site. No adverse water quality

impact is anticipated from the installation work.

5.4.2.13 For the permanent pier, the above-water construction works would involve the establishment of a proposed pier of concrete structure of typically about 5.5m to 6m wide, increased to 15m at the head, and 123m long above the sea. The scale of the construction works is considered to be minor. Prefabrication approach will first be considered when designing concrete superstructures. Selected concrete structures will be formed by pre-cast concrete offsite in a controlled environment and installed on site when ready. This can directly avoid on-site casting activities that would have potential impact on water quality. Moreover, this approach can minimise the extent and duration of on-site construction activities. As a result, the water quality impacts associated with these construction activities including site run-off, accidental spillage of chemicals and sewage from workforce could thus be avoided or minimised.

5.4.2.14 However, due to site constraints or design requirements, prefabrication approach may not be always feasible. For small quantities of structural elements e.g. decks above shallow waters to be casted on site and in-situ stitching, the formworks shall be water-tight to avoid leakage. Concrete shall be poured slowly with due care to avoid spillage of concrete into nearby water bodies.

Demolition Works

5.4.2.15

The

temporary pier and part of existing pier will be demolished after the

completion of a new berth of the pier. The temporary pier and part of the

existing pier will be cut into parts and shipped away by vessels. Piles of temporary pier will be cut by wire saw, blade saw or

similar method as close to the seabed as possible, and the demolished portions

of the piles will be removed off site. The portions of the piles embedded in

the ground will be left untouched below the seabed.

5.4.2.16

Part of the existing pier will also

be cut by wire saw, blade saw or similar method above and some of the concrete

blocks of the existing pier will be removed one-by-one by the crane directly.

All demolished portions will be removed off site. Neither open sea dredging works nor disturbance

to seabed is anticipated. Therefore,

no adverse water quality impact is anticipated.

Hydrodynamic Impact

5.4.2.17 The Project is located at the eastern coast area of Tung Ping Chau facing towards Ping Chau Hoi. The island is in a slight crescent shape where the Project is located around the mid-point of its eastern side. In a wider geographical context, Tung Ping Chau is located in the Mirs Bay, which is embraced by Yantain and Dapeng Ren to the north and the east respectively. In the Ping Chau Hoi area, the deepest seabed level is approximately -9mPD which has a water depth of about 9.5m at the mean lower low water (MLLW). Figure 5.2 shows the relative location of the Project in relation to the cove area.

5.4.2.18

Based on the hydrographic

survey (see Figure 5.3), the seabed of the existing pier head is about ‑3.0mPD

which has a water depth of about 3.5m at MLLW. Since the water depth of the existing pier is adequate for berthing,

only a relatively short extension length of 26m is required for the Project.

Along the new pier structure that is 26m long and 15m wide, there would be

about 27 nos. of approximately 0.8m dia. bored piles and 6 nos. of approximately

1m dia. bored piles with typical spacing around 5m to 8m. It is noted the

actual area that would be occupied by those marine piles is not significant. The

pile configuration is typical for other piers in Hong Kong[1] which are of similar dimensions. (see Figure 5.4)

5.4.2.19

For the

temporary pier, it will be constructed near the pier head of the existing pier.

The proposed temporary pier is in the southeast of the existing pier and is

about 20m long and 5.5m wide. During the construction of the temporary pier, 8

nos. of approximately 0.8m dia. bored piles with approximately 7.0m spacing

will be constructed. Regard to the small footprint of the temporary pier and

piles, the piles and pier structures of the temporary pier are likely cause

insignificant changes of the existing flow regime and tidal flux in the eastern

coastal area of Tung Ping Chau in Ping Chau Hoi.

5.4.2.20

Due to the

small footprint of the piled foundation, changes in the flow regime and

hydrodynamic in the eastern coastal area of Tung Ping Chau in Ping Chau Hoi are

limited during the construction phase of the Project.

Site Run-off from General Site Operation

5.4.2.21

Runoff could likely come from

the works during construction. The surface runoff might be polluted by:

·

Wastewater

from structure construction and site facilities;

·

Acid

cleaning, etching and pickling wastewater; and

·

Accidental

spillage of chemicals.

5.4.2.22

Construction runoff may cause

physical, biological and chemical effects. The physical effects include

potential increase in suspended solids levels. Runoff containing significant

amounts of concrete and cement-derived material may cause primary chemical

effects such as increase in turbidity and discoloration, elevation in pH, and

accretion of solids. A number of secondary effects may

also result in toxic effects to water biota due to elevated pH values, and

reduced decay rates of faecal micro-organisms and photosynthetic rate due to

the decreased light penetration. Appropriate precautionary measures shall be

adopted to prevent site runoff to the marine park.

Accidental Spillage of Chemicals

5.4.2.23

The chemicals used during

construction, such as fuel, oil, solvents and lubricants from maintenance of

construction machinery and equipment, may cause pollution and trigger

physicochemical effects in the nearby water bodies if accidental spillage

occurs. To avoid adverse impacts of chemical spillage, best practices of

chemical storage practices such as storage under a covered area, provision of

secondary containment and material safety data sheets are advised. Spill kits

are also advised to handle spillage and the staff should be trained for

handling spillage. Emergency

Spillage Plan should also be prepared by the future Contractor as a

precautionary measure for accidental spillage of chemicals. With the implementation of mitigation measures stated in Section

5.4.4,

neither adverse nor cumulative water quality impact is anticipated.

Sewage from Workforce

5.4.2.24

According

to Table T-2 of Guidelines for Estimating Sewage Flows for Sewage

Infrastructure Planning, the unit flow is 0.23 m3/day/employee. The

number of workforce (clerical staff and

workers) to be employed for the Project is around 10 during the construction period. It is estimated

that the volume of sewage from workforce

would be around 2.3 m3/day. Since temporary

sanitary facilities, e.g. portable chemical toilets, and sewage holding tanks will be provided on

vessels, no adverse water quality impact is anticipated.

5.4.3 Summary of Environmental Impact on WSRs

5.4.3.1

The

Project involves various marine-based construction works, including site

investigation, foundation works for temporary pier and proposed pier, and

demolition of the temporary pier. Potential water quality impacts are

anticipated on the nearby Tung Ping Chau Marine Park (TPC-W1) and Ping Chau

SSSI (TPC-W3). The Project will not encroach on the core areas of the marine

park at Tai Tong Wan (i.e. about 240m to the north of the Project) and A Ma

Tsui (i.e. about 510m to the south of the Project) which are not anticipated to

be affected by the Project. Nevertheless, the marine-based site investigating,

and drilling will be contained in outer casing. In addition, other potential

water quality impact could arise from the site surface runoff, accidental

spillage of chemicals and sewage from workforce. Mitigation measures are

recommended in Section 5.4.4 to

minimise the potential water quality impact.

5.4.3.2

As

the works area of the Project would not encroach on Plover Cove (Extension)

Country Park (TPC-W2), water quality impact form the Project is not anticipated

on this WSR. Regarding the two watercourses (TPC-W4 and TPC-W5), they are

located at inland area of Tung Ping Chau. The watercourses are located at the

upstream of the Project and hydrologically isolated from the Project. Adverse

water quality impact is therefore not anticipated.

5.4.4 Mitigation Measures

Working in Marine Park

5.4.4.1

For any

works in the marine park, the following good site practices and mitigation

measures shall be followed:

·

Observe

and obey the guidelines stipulated under the Marine Parks Ordinance (Cap. 476)

and the Marine Parks and Marine Reserves Regulation (Cap. 476A);

·

The

power-driven vessel shall not exceed a speed of 10 knots at any time inside the

marine park;

·

Restrict

anchor or moor except under and in accordance with a permit or at mooring sites

provided by the Authority;

·

Obstruct

the pollution of the water body or discharge of waste; and

·

Restrict

the collection of any marine life and resources in or from the marine park.

Marine-based Site Investigation Works

5.4.4.2 A number of good site practices and mitigation measures recommended for site investigation works are summarised below.

·

Before

commencement of drilling works, all drill rig, circulation tank and equipment

shall be thoroughly cleaned off-site;

·

Diver

inspection shall be carried out to ascertain no coral colonies will be affected

during the legs positioning and drilling works as far as practicable;

·

Throughout

the drilling process, seawater shall be used for flushing medium and no lubricant,

hydraulic fluid or other additives shall be introduced;

·

The

drilling fluid shall be circulated within the system through the circulation

tank, where the recycled fluid with small amount of suspended

solids be settled and collected in the tank.;

·

Prior to

actual sampling, an outer casing shall be placed on the seabed level to avoid

the spillage of water containing SS;

·

After the

completion of sampling work, casing shall be cleaned by the recycled water and

collected back to the circulation tank. The inner and outer casing shall then be extracted slowly to the

barge deck and the drilling fluid collected in the tank during the drilling

process shall be delivered to the depot of the Contractor; and

·

To ensure

all geotechnical and environmental samples will be collected within the casing

without any contact with the surrounding waterbodies.

Marine-based Foundation Works

Pre-drilling Works

5.4.4.3

Good

site practices and mitigation measures shall be referred to that of

marine-based Site Investigation Works (Section 5.4.4.2).

Pile Construction Works

5.4.4.5 The construction methodology will incorporate all the best practices for the marine works to avoid and minimise water quality impacts. These good practices are summarised below.

· Diver inspection shall be carried out to ascertain no coral colonies will be affected during the legs positioning and drilling works as far as practicable;

· Pile casing should be used for the construction of foundations;

· A temporary funnel to avoid spillage of concrete/ excavated materials should be installed at the top of the pile casing prior to excavation;

· Excavation should only be conducted inside pile casing. Only one closed grab should be used for excavation at the same time;

·

The barge receiving the grabbed

materials will be located as close to the pile casing as possible and

underneath the Y-shaped funnel to avoid the grabbed materials from accidentally

dropped into the surrounding water body;

· All vessels deployed should have adequate clearance from the seabed at all tide levels to ensure no undue turbidity is generated from propeller wash;

· There should only 1-2 piles be constructed at the same time;

· Drilling fluid in the pile casing shall be pumped out to the circulation tanks on the barge to avoid drilling fluid overflown from the casing to the sea directly. The circulation tanks shall be provided with adequate capacity to avoid if any overflow of drilling fluid;

· Drilling fluid shall not be discharged on site or within the boundary of Tung Ping Chau Marine Park, Plover Cove (Extension) Country Park or any other identified WSRs; and

· Final discharge of waste water/ effluent shall be discharged offsite with a valid discharge license under the WPCO with the provision of silt removal facilities, or to the facilities of the Contractor.

Above-water Construction Works

5.4.4.6

To avoid and minimise any potential water quality impacts arising from

the above-water construction works, the following mitigation measures are

proposed.

·

Prefabrication

methods should be adopted during construction whenever possible; and

·

If in-situ concrete casting is required,

formworks should be designed to be water-tight and concrete should be poured

into the formwork slowly and evenly.

Site Run-off from General Site Operation

5.4.4.7 To reduce the potential water quality impact due to construction site runoff, other than the timely implementation of the water storage tanks, the following good site practices in accordance to Practice Note for Professional Persons on Construction Site Drainage, Environmental Protection Department, 1994 (ProPECC PN 1/94) should be implemented to avoid potential adverse water quality impacts.

·

The design

of efficient silt removal facilities should be based on the guidelines in

Appendix A1 of ProPECC PN 1/94. The detailed design of the sand/silt traps

should be undertaken by the contractor prior to the commencement of

construction;

·

Schedule

construction works to minimise surface construction

works during the rainy seasons (April to September);

·

Inspect and maintain all drainage facilities and erosion and sediment

control structures regularly to ensure proper and efficient operation at all

times and particularly

following rainstorms;

·

Cover all

construction materials at temporary storage area with tarpaulin or similar

fabric during rainstorms and implementation of measures to prevent the washing

away of construction materials, soil, silt or debris into any drainage system;

·

Take

precautions at any time of year when rainstorms are likely. The actions to be

taken based on the guidelines in Appendix A2 of ProPECC PN 1/94;

·

Collect,

handle and dispose construction solid waste, debris and rubbish on site to

avoid water quality impacts;

·

Provide

locks for all fuel tanks and storage areas and locate on sealed areas, within

bunds of a capacity equal to 110% of the storage capacity of the largest tank

to prevent spilled fuel oils from reaching water sensitive receivers nearby;

and

·

Regular

environmental audit on the construction site should be carried out in order to

prevent any malpractices. Notices should be posted at conspicuous locations to

remind the workers not to discharge any sewage or wastewater into the water

bodies, marsh and ponds.

5.4.4.8 With the adoption of best management practices, it is anticipated that the impacts arising from general site operation will be reduced to satisfactory levels before discharge. The details of best management practices will be highly dependent on the actual site conditions and contractor shall apply for a discharge license under WPCO if discharge is required.

Accidental Spillage of Chemicals

5.4.4.9

To reduce the potential water

quality impact due to accidental spillage of chemicals, the following

mitigation measures should be implemented to avoid potential adverse water

quality impacts.

·

Properly store

and contain the chemicals used during construction, such as fuel, oil, solvents

and lubricants in a designated area with secondary containment to prevent

spillage and contamination of the nearby water environment.

·

Preferably

carry out any maintenance activities and works with chemicals use outside the

Project site given the advantage that machineries located on barges can be easily

re-located.

·

The

Contractor shall register as a chemical waste producer and employ licensed

collector for collection of chemical waste from the construction site. Any

chemical waste generated shall be managed in accordance with the Waste Disposal

(Chemical Waste) (General) Regulation.

·

The

Contractor shall also prepare an Emergency Spillage Plan to detail the

responses in case of spillage. The outline of the Emergency Spillage Plan is

provided in Appendix 5.1.

Sewage from workforce

5.4.4.10

To

mitigate the water quality impacts of sewage arising from the on-site construction

workers, the following measures should be implemented:

·

Provide temporary

sanitary facilities, e.g. portable chemical toilets and sewage holding tanks with adequate capacity to collect

the sewage from workforce. They should be cleaned by a licensed collector for

proper disposal on a regularly basis.

·

Post

notices at conspicuous locations to remind the workers not to discharge any sewage

or wastewater into the surrounding environment during the construction phase of

the Project.

5.4.5 Cumulative Impacts with Concurrent Projects

5.4.5.1 There is no concurrent project with potential cumulative water quality impact in the vicinity of the Project site. Therefore, no cumulative water quality impact is anticipated.

5.4.6 Residual Impacts

5.4.6.1 With the implementation of the aforementioned mitigation measures, no adverse residual environmental impacts are anticipated.

5.5 Operational Phase Assessment

5.5.1 Identification and Evaluation of Environmental Impacts

5.5.1.1 As mentioned in Section 2, the main objectives of the Project are to improve the existing pier facilities such as providing standard landing steps, adequate berthing space and enhancing accessibility to those in need. There is neither planned increase in the existing Kaito services nor alteration of their routing. Therefore, no adverse water quality impact is anticipated from the Project during the operational phase.

5.5.1.2

As

discussed in Section 5.4.2.17, the Project is located at the

eastern coast area of Tung Ping Chau facing towards Ping Chau Hoi. Based on the

hydrographic survey, the seabed of the existing pier head is about -3.0mPD which has a water depth of about 3.5m at MLLW. The proposed pier is extending from the existing pier towards a

slightly deeper water region of -3.5mPD (i.e. about 4m water depth at MLLW).

5.5.1.3 The design of the proposed pier has duly considered all practicable approaches to minimise hydrodynamic impacts as far as practicable. Instead of adopting a solid design as the existing pier, the proposed pier would adopt marine piles with a deck above. Along the new pier structure that is 26m long and 4-5m wide, there would be about 27 nos. of approximately 0.8m dia. bored piles and 6 nos. of approximately 1m dia. bored piles with typical spacing of approximate 6m. It is noticed that the actual area that would be occupied by those piles is not significant. Such a configuration is typical for other similar piers in Hong Kong. (See Figure 5.4)

5.5.1.4

Due to the

small footprint of the piled foundation, changes in the flow regime and

hydrodynamic in the eastern coastal area of Tung Ping Chau in Ping Chau Hoi are

limited during the operational phase of the Project.

Water Quality Impact

5.5.1.5

During

the operational phase, existing cleaning practices will be maintained. The pier

will be cleaned by natural cleaning mechanism such as rain without the use of

detergents or chemicals. Surface runoff from the pier will not be polluted.

Thus, water quality impact from the spillage of detergents or chemicals are not

anticipated.

5.5.2

Summary

of Environmental Impacts on WSRs

5.5.2.1

As

the pier will be constructed with 33 nos. of bored piles of about 0.8-1m in

diameters with sufficient spacing, the change of flow

regime in the Ping Chau Hoi by the Project is limited. Adverse hydrodynamic

impact on the Tung Ping Chau Marine Park (TPC-W1) and Ping Chau SSSI (TPC - W3)

is not anticipated. For the other WSRs including Plover Cove (Extension)

Country Park (TPC-W2), and the two watercourses (TPC-W4 and TPC-W5), they are

hydrologically isolated from the Project. No impact is expected for these WSRs.

5.5.2.2

Furthermore,

the pier will be cleaned by natural cleaning mechanism such as rain without the

use of detergents or chemicals. Thus, water quality impact is not anticipated

for all WSRs.

5.5.3 Mitigation Measures

5.5.3.1

As the Project would not generate or induce any

additional water quality impact, migration measures are considered not

necessary.

5.5.4 Cumulative Impacts with Concurrent Projects

5.5.4.1 As the Project would not generate or induce any additional water quality impact, no cumulative water quality impact with concurrent projects during the operational phase is anticipated.

5.5.5 Residual Impacts

5.5.5.1 As the Project would not generate or induce any additional water quality impact, it is anticipated that there would be no residual water quality impact during the operational phase.

5.6 Environmental Monitoring and Audit (EM&A)

5.7.1 Construction Phase

5.7.1.1

Potential hydrodynamic and water quality impact from

the construction activities have been assessed. Given the small scale of the pier

and the adoption of piled foundation with sufficient spacing, hydrodynamic impact from the

structures of the new pier and the temporary pier is not anticipated.

5.7.1.2 Potential water quality impact would arise from the construction activities, in particular the marine-based site investigation and foundation works. Nevertheless, the seabed features in the vicinity of the Project are mostly sand/silt, boulders and rocks, which have much higher settling velocity and could be quickly settled. With the implementation of recommended mitigation measures such as the use of double casing system, Y-shape funnel and closed grab to be implemented during marine-based site investigation and construction works, adverse water quality impact is not anticipated. There will neither be directly discharge on-site, within the Tung Ping Chau Marine Park nor other WSRs. In addition, with good site control practices, emergency spillage plan and provision of portable toilets, adverse impacts from surface runoff from construction site operation, accidental spillage of chemicals and sewage from workforce are not anticipated.

5.7.2 Operational Phase

5.7.2.1

The main objectives of the

Project are to improve the existing pier facilities such as providing standard

landing steps, adequate berthing space and enhancing accessibility to those in

need. There is no planned increase in the existing Kaito services nor alteration of

their routing. Therefore, no adverse water quality impact is anticipated from

the Project during the operation phase. Given the small scale of the pier and the adoption of

piled foundation with sufficient spacing, hydrodynamic

impact from the new structures of the improved pier is not anticipated.