5.

WATER

QUALITY IMPACT ASSESSMENT

5.1

Introduction

5.1.1

This Section presents the water quality impact assessment

for the construction and operational phases of the Project. Potential impacts have been identified

and their significance on the Water Sensitive Receivers (WSRs) evaluated. Mitigation measures are recommended,

where necessary, to reduce the potential water quality impacts in order to

control the residual impacts to acceptable levels.

5.2

Environmental Legislation, Policies, Standards and Criteria

5.2.1

The following legislation and relevant guidance or

non-statutory guidelines are applicable to the evaluation of water quality

impacts associated with the construction and operation of the Project:

¡P

Water Pollution Control Ordinance (WPCO);

¡P

Technical Memorandum for Effluents Discharged

into Drainage and Sewerage Systems, Inland and Coastal Waters (TM- ICW);

¡P

Environmental Impact Assessment Ordinance

(Cap. 499. S.16) and the Technical Memorandum on EIA Process (EIAO-TM), Annexes

6 and 14;

¡P

Practice Note for Professional Persons,

Construction Site Drainage (ProPECC PN1/94);

¡P

ETWB

Technical Circular (Works) No. 5/2005 Protection of Natural Streams/Rivers from

Adverse Impacts Arising from Construction Works

¡P

Drainage Services Department Practice Note

No. 3/2021: Guidelines on Design for Revitalisation

of River Channel; and

¡P

Hong Kong Planning Standards and Guidelines

(HKPSG)

Water Pollution Control Ordinance (WPCO)

5.2.2

The Water Pollution Control

Ordinance (WPCO) (Cap. 358) is the primary legislation for the control of

water pollution and water quality in Hong Kong. Under the WPCO, Hong Kong waters are

divided into 10 Water Control Zones (WCZs). Each WCZ has a designated set of

statutory Water Quality Objectives (WQOs).

The proposed Project is located within the Deep Bay WCZ. The WQOs designated for this zone are

thus relevant for assessing the water quality impacts from the construction and

operation of the Project (Table 5.1).

Table 5.1 Water Quality Objectives for Deep Bay Water Control Zones

|

Parameters |

Objectives |

Sub-Zone |

|

Offensive Odour, Tints |

Not to be present |

Whole zone |

|

Visible foam, oil scum, litter |

Not

to be present |

Whole

zone |

|

Dissolved Oxygen (DO) within 2 m of the

seabed |

Not less than 2.0mg/L for 90% of samples |

Outer Marine Subzone excepting Mariculture Subzone |

|

DO within 1 m below surface |

Not less than 4.0mg/L for 90% of samples |

Inner Marine Subzone excepting Mariculture Subzone |

|

Not less than 5.0mg/L for 90% of samples |

Mariculture Subzone |

|

|

Depth-averaged DO |

Not less than 4.0mg/L for 90% of samples |

Outer Marine Subzone excepting Mariculture Subzone |

|

Not less than 4.0mg/L |

Yuen Long & Kam Tin (Upper and Lower)

Subzones, Beas Subzone, Indus Subzone, Ganges Subzone, Water Gathering Ground

Subzones and other inland waters of the Zone |

|

|

5-Day Biochemical Oxygen Demand (BOD5) |

Not to exceed 3mg/L |

Yuen Long & Kam Tin (Upper) Subzone, Beas

Subzone, Indus Subzone, Ganges Subzone and Water Gathering Ground Subzones |

|

Not to exceed 5mg/L |

Yuen Long & Kam Tin (Lower) Subzone and

other inland waters |

|

|

Chemical Oxygen Demand (COD) |

Not to exceed 15mg/L |

Yuen Long & Kam Tin (Upper) Subzone, Beas

Subzone, Indus Subzone, Ganges Subzone and Water Gathering Ground |

|

Not to exceed 30mg/L |

Yuen Long & Kam Tin (Lower) Subzone and

other inland waters |

|

|

pH |

To be in the range of 6.5 ¡V 8.5, change due

to waste discharges not to exceed 0.2 |

Marine waters excepting Yung Long Bathing

Beach Subzone |

|

To be in the range of 6.5 ¡V 8.5 |

Yuen Long & Kam Tin (Upper and Lower)

Subzones, Beas Subzone, Indus Subzone, Ganges Subzone and Water Gathering

Ground Subzones |

|

|

To be in the range of 6.0 ¡V9.0 |

Other inland waters |

|

|

To be in the range of 6.0 ¡V 9.0 for 95%

samples, change due to waste discharges not to exceed 0.5 |

Yung Long Bathing Beach Subzone |

|

|

Salinity |

Change due to waste discharges not to exceed

10% of ambient |

Whole zone |

|

Temperature |

Change due to waste discharges not to exceed

2¢XC |

Whole zone |

|

Suspended solids (SS) |

Not to raise the ambient level by 30% caused

by waste discharges and shall not affect aquatic communities |

Marine waters |

|

Not to cause the annual median to exceed

20mg/L |

Yuen Long & Kam Tin (Upper and Lower)

Subzones, Beas Subzone, Ganges Subzone, Indus Subzone, Water Gathering Ground

Subzones and other inland waters |

|

|

Unionized Ammonia (UIA) |

Annual mean not to exceed 0.021mg/L as

unionized form |

Whole zone |

|

Nutrients |

Nutrients shall not be present in quantities sufficient to cause excessive or nuisance growth of algae

or other aquatic plants. |

Inner and Outer Marine Subzones |

|

Total Inorganic Nitrogen (TIN) |

Annual mean depth-averaged inorganic nitrogen

not to exceed 0.7mg/L |

Inner Marine Subzone |

|

Annual mean depth-averaged inorganic nitrogen

not to exceed 0.5mg/L |

Outer Marine Subzone |

|

|

Bacteria |

Not exceed 610per 100ml, calculated as the

geometric mean of all samples collected in one calendar year |

Secondary Contact Recreation Subzones and Mariculture Subzones |

|

Should be zero per 100 ml, calculated as the

running median of the most recent 5 consecutive samples taken between 7 and

21 days. |

Yuen Long & Kam Tin (Upper) Subzone, Beas

Subzone, Indus Subzone, Ganges Subzone and Water Gathering Ground Subzones |

|

|

Not exceed 180per 100ml, calculated as the

geometric mean of the collected from March to October inclusive in one

calendar year. Samples should be taken at least 3 times in a calendar month

at intervals of between 3 and 14days. |

Yung Long Bathing Beach Subzone |

|

|

Not exceed 1000 per 100ml, calculated as the

running median of the most recent 5 consecutive samples taken at intervals of

between 7 and 21days |

Yuen Long & Kam Tin (Lower) Subzone and

other inland waters |

|

|

Colour |

Not to exceed 30 Hazen units |

Yuen Long & Kam Tin (Upper) Subzone, Beas

Subzone, Indus Subzone, Ganges Subzone and Water Gathering Ground Subzones |

|

Not to exceed 50 Hazen units |

Yuen Long & KamTin

(Lower) Subzone and other inland waters |

|

|

Turbidity |

Shall not reduce light transmission

substantially from the normal level |

Yung Long Bathing Beach Subzone |

|

Phenol |

Quantities shall not sufficient

to produce a specific odour or more than 0.05mg/L as C6H5OH |

Yung

Long Bathing Beach Subzone |

|

Toxins |

Should not cause a risk to any beneficial

uses of the aquatic environment |

Whole Zone |

|

Should not attain such levels as to produce

toxic carcinogenic, mutagenic or teratogenic effects in humans, fish or any

other aquatic organisms. |

Whole

Zone |

Technical

Memorandum for Effluents Discharged into Drainage and Sewerage Systems, Inland

and Coastal Waters (TM- ICW)

5.2.3

All discharges during both the construction and operation

phases of the proposed development are required to comply with the Technical Memorandum for Effluents

Discharged into Drainage and Sewerage Systems, Inland and Coastal Waters

(TM-ICW) issued under Section 21

of the WPCO. The TM-ICW

defines acceptable discharge limits to different types of receiving

waters. Under the TM-ICW, effluents discharged into the

drainage and sewerage systems, inland and coastal waters of the WCZs are

subject to pollutant concentration standards for specified discharge volumes.

These are defined by the Environmental Protection Department (EPD) and are

specified in licence conditions for any new discharge within a WCZ

Environmental

Impact Assessment Ordinance (Cap. 499. S.16) and the Technical Memorandum on EIA Process (EIAO-TM), Annexes 6 and 14

5.2.4 The EIAO-TM was issued by EPD under Section 16 of the EIAO. Annexes 6 and 14 of the EIAO-TM provide general criteria and guidelines to be used in assessing water quality issues.

Practice Note for Professional Persons, Construction Site Drainage

5.2.5 The Practice Note for Professional Persons, Construction Site Drainage (ProPECC PN 1/94) issued by EPD in 1994, also provide useful non-statutory guidelines on the management of construction site drainage and prevention of water pollution associated with the construction activities.

ETWB

Technical Circular (Works) No. 5/2005 Protection of Natural Streams/Rivers from

Adverse Impacts Arising from Construction Works

5.2.6

ETWB Technical Circular (Works) No. 5/2005 provides an

administrative framework to better protect all natural

streams/rivers from the impacts of construction works. The procedures

promulgated under this Circular aim to clarify and strengthen existing measures

for protection of natural streams/rivers from government projects and private

developments. The guidelines and precautionary mitigation measures given in the

ETWB TC (Works) No. 5/2005 should be followed as far as possible to

protect the inland watercourse at or near the Project area during the

construction phase

Drainage Services

Department Practice Note No. 3/2021: Guidelines on Design for Revitalisation of

River Channel

5.2.7

The Practice Note presents the essential environmental and

ecological considerations that should be taken into account

in the design of river channels.

Hong Kong Planning Standards and

Guidelines (HKPSG)

5.2.8

The Chapter 9 (Environment) of HKPSG, provides additional

guidelines against water pollution for sensitive uses such as aquaculture and

fisheries zones, bathing waters and other contact recreational waters.

5.3

Baseline

Water Quality Conditions

Hydrology

and Hydrodynamics

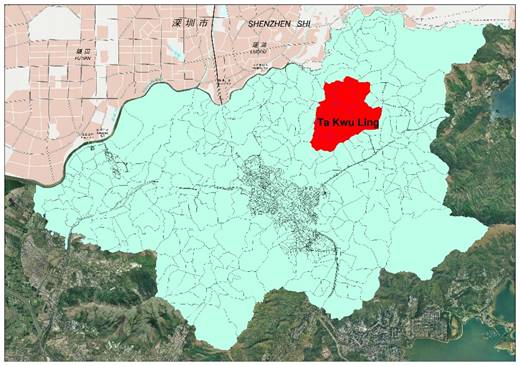

5.3.1

The existing watercourse TKL04 and TKL05 are located

at Ping Che/Ta Kwu Ling areas and within the Ganges

drainage basin which is part of the Shenzhen River catchment. TKL04 runs from east to west across

agricultural lands to the north of Ping Yeung Mural Village while TKL05 is a meandering

channel which runs from Ping Che Road at the upstream to the trained Ping Yuen

River at the downstream. TKL04 and

TKL05 are not subjected to tidal influence from the Deep Bay.

5.3.2

At present, stormwater runoff collected within Ping

Che catchment is discharged to Ping Yuen River via the existing watercourse

TKL04 and TKL05 which is eventually discharged to Deep Bay through Shenzhen

River. The surface runoff collected

by three channels/watercourses namely TKL02, TKL04 and TKL07 are discharged to

TKL05. The current flood protection standard of existing channel TKL04 and

TKL05 is less than 1 in 5 years return period. Areas around Ping Che are susceptible to

flooding during severe rainstorms due to inadequate capacity of existing

channel TKL04 and TKL05.

5.3.3

The upgraded Drainage Channels TKL02 and TKL07 have

flood protection standard of 1 in 10 years return period. As stated in Section

1.2, it is anticipated that the flood problem in Ping Che could be worsened

subsequent to the completion of the drainage

improvement works at Drainage Channel TKL02 and TKL07 as more surface runoff

will be conveyed to the existing TKL05. However, the situation will be improved

under this Project.

Baseline

River Water Quality

5.3.4

The proposed Project starts from Ping Che Road and

ends at the trained section of the Ping Yuen River (Figure 5.1). Water courses identified within the

Study Area (defined as 500 m from the boundary of the Project Site) include the

Shenzhen River, and Ping Yuen River.

Water Quality of Ping Yuen River

5.3.5

A routine river water quality monitoring programme has been undertaking in Hong Kong by the EPD

since 1986. Two monitoring

stations, GR1 and GR2, are located within and downstream of the Project site,

respectively (Figure 5.1).

5.3.6

A summary of river water quality data collected at stations

GR1 and GR2 of Ping Yuen River by EPD from 2018 to 2020 ([1])([2])([3]) is shown in Table 5.2.

Table

5.2 Summary of River Water Quality Monitoring Data collected by EPD River Water

Quality Monitoring Programme for Stations GR1 and GR2 of Ping Yuen River (2018

- 2020)

|

Parameter |

Unit |

WQO |

GR1 |

GR2 |

||||

|

2018 |

2019 |

2020 |

2018 |

2019 |

2020 |

|||

|

Dissolved oxygen (DO) |

mg/L |

≥4 |

8.4 (6.8-14.0) |

7.6 (4.7 - 8.7) |

6.7 (5.2 - 9.2) |

5.5 (3.1-7.4) |

5.4 (2.6 - 7.0) |

4.7 (3.2 - 6.6) |

|

pH |

- |

6.5-8.5 |

7.4 (6.9-8.6) |

7.2 (7.1 - 7.5) |

7.5 (7.2 - 7.7) |

6.8 (6.5-7.3) |

7.3 (7.0 - 7.7) |

7.3 (6.7 - 7.6) |

|

Suspended solids (SS) |

mg/L |

≤20 |

11 (5.4-69) |

12.0 (6.8 - 19.0) |

16.0 (6.4 - 22.0) |

9.5 (3.8-29.0) |

10.0 (8.0 - 25.0) |

9.7 (3.9 - 22.0) |

|

5-Day Biochemical Oxygen

Demand (BOD5) |

mg/L |

≤3 |

6.6 (1.6-26.0) |

5.4 (0.4 - 12.0) |

7.3 (2.8 - 20.0) |

4.2 (1.5-7.5) |

3.5 (0.2 - 9.5) |

3.8 (1.9 - 5.3) |

|

Chemical Oxygen Demand

(COD) |

mg/L |

≤15 |

16 (11-34) |

17 (13 - 25) |

20 (11 - 30) |

12 (7-21) |

16 (11 - 25) |

18 (9 - 23) |

|

Oil & Grease |

mg/L |

- |

<0.5 (<0.5-<0.5) |

<0.5 (<0.5 - <0.5) |

<0.5 (<0.5 - <0.5) |

<0.5 (<0.5-0.6) |

<0.5 (<0.5 - 2.1) |

<0.5 (<0.5 - <0.5) |

|

Faecal coliforms |

cfu/100mL |

- |

11,100 (1,300-81,000) |

12,000 (4,900 ¡V 25,000) |

5,700 (570 ¡V 21,000) |

13,000 (930-74,000) |

23,000 (3,600 ¡V 330,000) |

4,300 (1,000 ¡V 53,000) |

|

Escherichia coli (E.coli) |

cfu/100mL |

- |

4,100 (700-70,000) |

4,600 (580 ¡V 13,000) |

14,000 (810 - 170,000) |

3,400 (380-16,000) |

4,900 (800 ¡V 51,000) |

14,000 (2,400 ¡V 100,000) |

|

Ammonia-nitrogen (NH3-N) |

mg/L |

- |

5.50 (0.31-32.00) |

4.30 (0.44 - 21.00) |

11.00 (0.52 - 30.00) |

5.30 (0.24-26.00) |

7.40 (0.30 - 31.00) |

7.70 (0.42 - 38.00) |

|

Nitrate-nitrogen |

mg/L |

- |

1.150 (0.900-2.500) |

1.020 (0.680 - 2.300) |

1.200 (0.32 - 2.20) |

0.865 (0.027-1.700) |

0.600 (0.055 - 1.500) |

0.385 (0.065 - 1.800) |

|

Total Kjeldahl

nitrogen (TKN) |

mg/L |

- |

6.40 (1.00-36.00) |

5.40 (0.80 - 21.00) |

13.00 (0.89 - 32.00) |

6.00 (0.40-28.00) |

9.15 (1.40 - 34.00) |

10.50 (0.59 - 40.00) |

|

Ortho-phosphate |

mg/L |

- |

0.480 (0.160-3.000) |

0.555 (0.120 - 2.100) |

0.660 (0.130 - 1.100) |

0.180 (0.067-0.730) |

0.230 (<0.002 - 0.620) |

0.240 (0.120 - 0.540) |

|

Total phosphorus |

mg/L |

- |

0.66 (0.32-3.10) |

0.72 (0.39 - 2.70) |

1.10 (0.16 - 2.00) |

0.36 (0.20-1.20) |

0.47 (0.18 - 2.00) |

0.68 (0.24 - 1.30) |

|

Sulphide |

mg/L |

- |

<0.02 (<0.02-<0.02) |

<0.02 (<0.02 - 0.02) |

<0.02 (<0.02 - <0.02) |

<0.02 (<0.02-<0.02) |

<0.02 (<0.02 - 0.02) |

<0.02 (<0.02 - <0.02) |

|

Aluminum |

£gg/L |

- |

52 (<50-111) |

<50 (<50 - 222) |

<50 (<50 - 103) |

51 (<50-538) |

66 (<50 - 222) |

<50 (<50 - 125) |

|

Cadmium |

£gg/L |

- |

<0.1 (<0.1-<0.1) |

<0.1 (<0.1 - 0.1) |

<0.1 (<0.1 - 0.1) |

<0.1 (<0.1-0.4) |

<0.1 (<0.1 - <0.1) |

<0.1 (<0.1 - <0.1) |

|

Chromium |

£gg/L |

- |

<1 (<1-<1) |

<1 (<1 - <1) |

<1 (<1 - <1) |

<1 (<1-<1) |

<1 (<1 - <1) |

<1 (<1 - <1) |

|

Copper |

£gg/L |

- |

3 (1-13) |

7 (2 - 20) |

7 (1 - 31) |

3 (<1-29) |

4 (<1 - 9) |

1 (1 - 3) |

|

Lead |

£gg/L |

- |

<1 (<1-2) |

<1 (<1 - 2) |

<1 (<1 - <1) |

<1 (<1-20) |

1 (<1 - 25) |

<1 (<1 - 1) |

|

Zinc |

£gg/L |

- |

<10 (<10-24) |

15 (<10 - 30) |

12 (<10 - 16) |

<10 (<10-80) |

18 (<10 - 29) |

11 (<10 - 37) |

|

Flow rate |

m3/s |

- |

0.020 (0.005-0.180) |

0.067 (0.012 - 0.266) |

0.117 (0.020 - 0.422) |

0.035 (0.015-0.300) |

0.114 (0.020 - 0.289) |

0.102 (0.064 - 0.289) |

Notes:

o Data presented are in

annual medians of monthly samples; except those for faecal

coliforms and E. coli which are in annual geometric means.

o Figures in brackets are

annual ranges.

o Values at or below

laboratory reporting limits are presented as laboratory reporting limits.

o Equal values for annual

medians (or geometric means) and ranges indicate that all data are the same as

or below laboratory reporting limits.

o Shaded values indicate

non-compliance of WQO.

* GR1 and GR2 are located within Ganges Subzone of

Deep Bay Water Control Zones.

5.3.7

The overall WQO compliance for River Ganges (Ping Yuen

River) has been decreased, sharing the compliance rate of 84% ,80% and 79% in

2018, 2019 and 2020 respectively. Level of 5-day Biochemical Oxygen Demand (BOD5)

has shown non-compliances with WQO at GR1 and at GR2 from 2018 to 2020. For

Chemical Oxygen Demand (COD), non-compliance with the WQOs was recorded at GR1

in 2018 and 2019 and GR2 in 2019 and 2020. E.

Coli levels for both stations between 2018 to 2020 has obtained high values

up to 14000 cfu/100ml. These parameters indicate that

the water in Ping Yuen River is potentially affected by pollution from the

livestock farms, unsewered villages and small industrial establishments in the

catchment. From 2018 to 2020, GR1 and GR2 maintained ¡§Fair¡¨ in the Water

Quality Index (WQI).

5.4

Assessment

Methodology

5.4.1

The assessment area covers an area within 500 m of the

Project site boundary. The assessment has be extended

to include other areas such as stream courses and associated water systems,

ponds in the vicinity being impacted by the construction and/or operation of

the Project which include all water sensitive receivers identified in Section

5.5. Potential sources of water quality impact that may arise during the

construction and operation of the Project were analysed

and discussed. All the identified potential sources of water quality impact and

their impact significance was presented in Section 5.6. Mitigation

measures was then suggested in Section 5.8 to reduce any identified

adverse water quality impact.

5.4.2

The Project is located within the Deep Bay WCZ. Latest

Outline Zoning Plan (OZP) including OZP No. S/NE-TKL/14 (Ping Che and Ta Kwu Ling) and No.S/NE-TKLN/2

(Ta Kwu Ling North). The project is mainly

improvement works to the tributary sections of Ping Yuen River (River

Ganges-TKL04 and TKL05; and drainage improvement works at Ping Yeung Village,

constructing of road drainage system at Ping Che Road.

5.4.3

Site Visit has been conducted in March 2021, site

photos are recorded in Appendix 5.1.

5.5

Water

Sensitive Receivers

5.5.1 The

Water Sensitive Receivers (WSRs) that may be affected by changes in water

quality arising from the Project are identified in accordance with the EIAO-TM.

The water sensitive receivers (WSRs) include a number of fish

ponds, water courses, channelised watercourse,

conservation area, fishing ground and oyster cultural area. These WSRs (Figures 5.1)

and their approximate distances are given in Table 5.3.

Table 5.3 Water Sensitive

Receivers

|

ID |

WSRs |

Status |

Potential Impact from the Project |

|

WSR1 |

Ping

Yuen River (River Ganges) near Shenzhen

River |

Channelized watercourse |

Construction works will be undertaken to

connections with the proposed improvement works of downstream TKL05 |

|

WSR2 |

Shenzhen

River |

Natural watercourse |

Approx. 500 m away from the Project, no

direct impact |

|

WSR3 |

TKL04

Watercourse |

Natural watercourse |

To be widened |

|

WSR4 |

TKL05

Watercourse |

Natural watercourse |

To be widened |

|

WSR5 |

TKL02

Watercourse |

Channelized watercourse |

Direct upstream of the Project, minor

impact may anticipate |

|

WSR6 |

TKL07

Watercourse |

Channelized watercourse |

Direct upstream of the Project, minor

impact may anticipate |

|

WSR7 |

Watercourse

near Sing Ping Village |

Natural watercourse |

Minor impact may anticipate at the

connection of the WSR 10 and the construction works of TKL04 |

|

WSR8 |

Ping

Yuen River |

Natural watercourse |

Minor construction works will be undertaken

to connections between Ping Yuen River (WSR 8) and the improvement works of

downstream TKL04 |

|

WSR9 |

Watercourse

near Ping Yeung |

Natural watercourse |

Close proximity

to the Project, minor impact may anticipate |

|

WSR10 |

Area

of Fish Pond |

Fish Pond |

Over 9000m, no direct impact |

|

WSR11 |

Deep

Bay Oyster Culture Area |

Oyster Culture Area |

Over 16000m, no direct impact |

|

WSR12 |

Watercourse

near Ta Kwu Ling Farm |

Natural watercourse |

Minor impact may be anticipated at the

connection o the WSR 12 and the construction works

of TKL05 |

|

WSR13 |

Yuen

Leng Chai |

Conservation Area |

Over 3000m from the Project, no direct

impact |

|

WSR14 |

Hoo

Hok Wai |

Conservation Area |

Over 4000m from the Project, no direct

impact |

|

WSR15 |

Ha

Wan Tsuen |

Conservation Area |

Over 8000m from the Project, no direct

impact |

|

WSR16 |

Sam Po Shue |

Conservation Area |

Over 9000m from the Project, no direct impact |

|

WSR17 |

Mai

Po Marsh SSSI |

SSSI |

Over 11000m from the Project, no direct

impact |

|

WSR18 |

Inner

Deep Bay Ramsar Site |

Ramsar |

Over 10000m from the Project, no direct

impact |

5.5.2

Although waters from the Project Site will eventually

be discharged into the Deep Bay through the Shenzhen River, it is considered

unlikely that the Project will lead to any adverse water quality impacts to the

Conservation Area and ponds along Shenzhen River (Yuen Leng

Chai, Hoo Hok Wai, Ha Wan

Tsuen and Sam Po Shue), Mai Po Marsh SSSI, Inner Deep

Bay Ramsar Site near the Shenzhen River estuary, area of fish pond and oyster

culture area in Deep Bay given the large separation distance from the Project

Site as presented in Table 5.3 above.

5.6

Potential Sources of Impacts

Construction Phase

5.6.1

The main construction activities associated with the

Project that have the potential to cause water quality impacts involve the

following:

¡P

Temporary flow diversion

and excavation works;

¡P

Sewage discharges from

the construction work force;

¡P

Widening of Drainage

Channels;

¡P

Construction runoff and

drainage; and

¡P

Pollutants entering the

receiving waters due to accidental spillage /uncontrolled discharge from the

general construction activities.

Operation Phase

5.6.2

During the operation phase of the Project, potential water

quality impacts that may arise are identified as follows:

¡P

Maintenance and desilting

works within the proposed drainage channel to remove excessive silt,

vegetation, debris and obstructions within the drainage channel which may lead

to disturbance and re-suspension of river sediments and thereby affecting water

quality;

¡P Changes in hydrodynamic conditions, water quality and local erosion and sedimentation patterns during the operation of the drainage channel; and

¡P Potential effect of brackish tidal influence from Inner Deep Bay or Lower Ping Yuen River.

5.7

Impact Assessment

Construction Phase

Temporary Flow

Diversion and Excavation Works of the Existing Watercourse

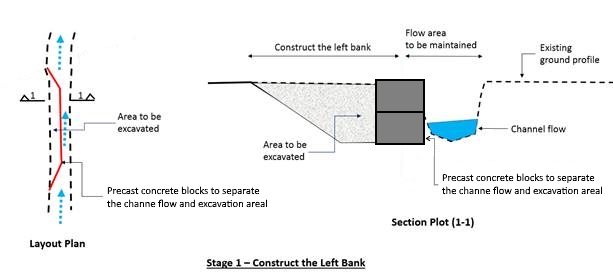

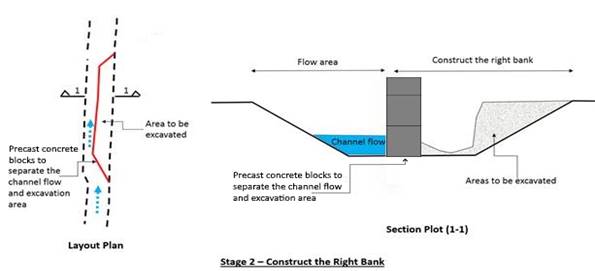

5.7.1

The major construction activities will include temporary flow

division, sewage discharge from the construction workforce, construction runoff

and drainage and widening drainage channel. Temporary flow division will

reroute water from the upstream flow to a designed portion of the downstream to

allow for construction activities to take place in the channel of TKL04 &

TKL05. Temporary flow diversion and excavation works for the Project along the

entire TKL04 and TKL05 will be divided by segments in dry condition. It is

anticipated that the temporary flow diversion and excavation works will be

carried out in each segment of approximate 50m in length. Temporary flow

diversion will be undertaken before any excavation works within the existing

watercourse to ensure that the flow is not affected and to provide dry

condition for excavation. As the temporary flow diversion and excavation works

will be undertaken in dry conditions with segment division, it will not lead to

disturbance of the river bed material. Unacceptable water quality impacts are

thus not anticipated.

5.7.2

Overall, no unacceptable adverse impacts to water quality are

anticipated to occur as a result of the temporary flow diversion and excavation

works within the existing watercourse TKL04 and TKL05.

Sewage

Generated from the Construction Workforce

5.7.3

Sewage will be generated from the construction workforce,

site office¡¦s sanitary facilities and from portable toilets. If not properly managed, these

wastewaters could cause adverse water quality impacts.

5.7.4

It is estimated that about 80 to 100 construction workers

will be involved in the construction of the Project during the peak

construction period. With a sewage generation rate of 0.15 m3/worker/day

(Table T-2 of EPD¡¦s Report No.: EPD/TP 1/05 Guidelines for Estimating Sewage

Flows for Sewage Infrastructure Planning Version 1.0.), about 15 m3

of sewage will be generated per day. The sewage is characterised by high levels

of Biochemical Oxygen Demand (BOD), ammonia, E.coli

and oil/grease. An adequate number of portable toilets will be provided at the

Project Site to ensure that sewage from site staff is properly collected. No adverse impacts are envisaged

provided that the portable toilets are properly maintained by a contractor and

the collected sewage is disposed at the designated sewage treatment works.

Construction Runoff and Drainage

5.7.5

Runoff and drainage from construction activities may contain

elevated levels of suspended solids and possibly other contaminants (e.g. oil

and grease from machinery).

Potential sources of water pollution from site runoff include the

following:

¡P

Runoff and erosion of

exposed bare soil and earth and temporary stockpiles;

¡P

Release of cement

materials with rain wash;

¡P

Wash water from dust

suppression sprays and vehicle wheel washing facilities; and

¡P

Fuel, oil, and lubricants

from maintenance of construction vehicles and mechanical equipment.

5.7.6

Potential adverse water quality impacts may arise if

construction site runoff is allowed to spill outside

the construction site area and drain into the nearby streams, storm drain or

natural drainage without treatment.

The Best Management Practices outlined in ProPECC

PN 1/94 will be implemented to control site runoff and drainage during

construction phase. Precautionary measures relating to rainstorms as stated in

Appendix A2 of ProPECC PN 1/94 will also be

implemented to avoid water pollution due to site runoff during inclement

weather. With the proper implementation of appropriate mitigation measures,

good site practices and housekeeping as discussed in Section 5.7, unacceptable water quality impacts due to construction

runoff and drainage are not expected to occur.

Widening of Drainage Channels

5.7.7

As indicated in Section 2, the area for the proposed

widening and deepening of channels will be excavated. Upon completion of

excavation, fixing of reinforcement bars and concreting would be carried out on

site for the structures of the proposed channels.

5.7.8

During construction phase, there will be potential water

quality impact due to the alternation of watercourses. The existing streams at

TKL04 and TKL05 will be upgraded/widened.

5.7.9

The channel widening will involve excavation, formation of

embankments and temporary diversion of watercourses, which would probably lead

to temporary obstruction of flows. In addition, construction activities being

carried out along the channels without adequate mitigation measures may likely

cause erosion and lead to suspended solids elevation in the waterbody.

5.7.10

To minimize potential impacts on water quality during the

channel works for the proposed drainage improvements, the excavation works

would be carried out in dry condition. Construction would be strictly carried

out by land-based plant. Potential impacts on water quality would be minimised

by restricting the excavation works within an artificially enclosed dry section

of the river/stream.

5.7.11

De-watering of streams and sediment removal would be

conducted during channel widening works. Temporary access and maintenance

access along the proposed drainage channel will be constructed prior to all

construction works, and due consideration for the overland flow patterns and

the drainage connections will be given if flow diversion is necessary. As the

alignment of the proposed channel coincides with the existing stream, channel

diversions will be required to divert existing flow, in

particular when the construction coincides with the wet season (April to

September). Relevant requirements and stipulations from ETWB TCW No.5/2005 ¡§Protection

of Natural Streams/Rivers from Adverse Impacts Arising from Construction Works"

will be complied to better protect the natural watercourses from the impacts of

construction works.

5.7.12

Works will commence from downstream

and proceed to upstream. Diversion of the channel flow is required before

excavation works start. Shallow water levels were noted in the existing

channels and dewatering will be required in trenches below channel inverts or

after heavy rainstorm. Adequate knowledge of subsurface conditions is required before

excavation. All excavated materials will be stockpiled outside the existing

stream/channel but within the defined works area, and temporarily stabilized to

prevent re-entry into the stream/channel. The stockpile should not create

adverse drainage impacts and not impede the overland flow patterns. The area

next to the proposed channel works shall be fully utilized as temporary

workplace and storage of construction plant. Where possible, the excavated

materials will be utilized in any backfilling. On balance, it is anticipated

that some fill will need to be imported to form the embankments.

5.7.13

The

proposed channel will be constructed in segments from downstream to upstream.

When the segment under construction requires stream diversion, sheet pile will

be installed both upstream and downstream of the existing stream to separate

the flow through the bypass channel so that the works area will remain dry for

later excavation and widening works. To reduce resumption of private land lots

for temporary construction works, where possible, all stream diversion and

widening works will be strictly confined within the site boundary.

5.7.14

Construction of embankment will be undertaken after

excavation works. Ramps shall also be required to provide a pathway for

machinery to utilize the excavated channel bottom for construction and

maintenance of the embankment and channel. Lining of channel bank will be

followed and the lining material to be used will be fully agreed with DSD.

5.7.15

With good implementation of appropriate working method

controls and good management practices, it is anticipated that unacceptable

water quality impacts would not arise at the identified WSRs during

construction phase. However, monitoring and audit of water quality during the

construction phase is recommended.

Accidental Spillage

5.7.16

Accidental spillage of liquid and chemicals stored on-site,

such as oil, diesel and solves etc., and illegal disposal of these chemicals

would cause soil contamination and adverse impact to the groundwater quality.

The Code of Practice on Packaging, Labelling and Storage of Chemical Wastes

released by the Waste Disposal Ordinance will be used as a guideline for

chemical waste handling. All chemicals disposal should comply with the

requirement imposed by the Waste Disposal Ordinance.

5.7.17

With proper measures to prevent accidental spillage, no

adverse impacts to water quality are anticipated due to accidental spillage of

liquid or chemicals.

Uncontrolled Discharge from

General Construction Activities

5.7.18

The following pathways of uncontrolled discharge and spillage

of contaminants from general construction activities may lead to adverse water

quality impacts to nearby WSRs:

¡P Uncontrolled

discharge of wastewater generated from concrete and vehicle washing;

¡P Uncontrolled

discharge of debris and rubbish such as packaging, construction waste and

refuse, etc.; and

5.7.19

Wastewater generated from concrete and vehicle washing may

contain elevated levels of suspended solids. Wastewater from concrete washing is also

noted with high pH value. Debris

and rubbish generated by the construction activities, if allowed to enter

nearby streams, storm drain or natural drainage, may cause blockages, water

quality impacts and hygiene issues.

5.7.20

The effects on water quality from the construction activities

are, however, likely to be minimal, provided that the site is well maintained

and that good construction practices and well

designed temporary drainage system and mitigation measures, as

described in Section 5.8, are

implemented properly.

Operation Phase

Maintenance Works

5.7.21

Regular maintenance would be necessary for the proposed

drainage channel in order to maintain the flow in the channel and its

structural integrity. Siltation

will generally be allowed to accumulate and removal of silt, vegetation growth,

debris and obstructions would only be carried out at locations where water flow

is impeded. Such small scale maintenance would require

only light mechanical equipment such as a small loader and/or a small crane

truck. Hand-held equipment will be

used for vegetation removal.

5.7.22

Whilst possible changes to water quality may be expected

during the removal of silt, vegetation growth, debris and obstruction, such as

increases in suspended solids due to disturbance of river bed material and

subsequently increased sedimentation onto the river bed, it is expected that

these changes will be short term and occur only within the area of maintenance

works and for a short distance downstream due to rapid settling out of any

disturbed river bed material.

Changes in suspended solids concentrations and sedimentation rate would

be expected to be similar to ambient conditions

following heavy storms and increased sediment run-off. With the implementation of the

precautionary measures in Section 5.8, no unacceptable water quality

impacts are anticipated to occur as a result of the small

scale maintenance works.

Water quality impacts to the water and ecological sensitive receivers

located downstream of the proposed drainage channel (Wetland Conservation Area

and Mai Po and Inner Deep Bay Ramsar Site near the Shenzhen River estuary) are

also not expected to occur.

Changes in Hydrodynamic Conditions

5.7.23

According to the Drainage Impact Assessment (DIA) of the

Project, by achieving the flood protection standard of 1 in 10 years after

implementation of the Project, water level within the Project Site will be

slightly lower than the water level before implementation in a 1 in 10 years

flooding event. It is thus

considered that implementation of the Project will be beneficial to the

hydrodynamics of the Project Site by improving the flood prevention

performance. Water level at the

downstream boundary of the proposed Drainage Channel TKL05 will be slightly

increased (i.e. 26mm) during the operation phase in a 1 in 10 years flooding

event. Therefore, implementation of

the Project is not expected to significantly affect the hydrodynamic conditions

downstream of the Project Site. As indicated in the DIA report, the associated

drainage sub-catchments are highlighted in red in the diagram below. Compared to

the total catchment area of the North district catchment, drainage

sub-catchments of the Project is relatively small.

Therefore, it is considered that the flow discharged from drainage

sub-catchments of the Project will have a limited impact to the hydraulic

condition. In addition, unacceptable water quality impacts to the downstream

WSRs due to the insignificant changes in hydrodynamic conditions caused by the

Project are not expected.

Changes in Water Quality

5.7.24

The operation of the proposed Drainage Channel TKL04 and 05

will not generate any new pollution load to the catchment. Instead, vegetation

re-established/planted along the gabion mattress at river bed

will help to remove dissolved and particulate contaminants through absorptive,

filtration and biological mechanisms. The water quality pollutants (e.g. SS,

BOD and COD) are expected to be reduced. In addition, it is expected that foul

odour of polluted water and river bed material during

low flow periods would be alleviated with the improved flow conditions and

removal of river bed material during channel construction and operation. Since

the Project will not induce additional discharge or pollutants from the

Project, there will not be changes on downstream salinity profile nor effect on

aquatic organisms. It is thus anticipated that the Project will not cause any

significant adverse changes to water quality thus impacts are not expected

during the operation phase.

5.7.25

Long term reduction of pollution load into the channels is

necessary to improve the water quality in the proposed Drainage Channel TKL04

and TKL05. It is expected that the

water quality of the drainage channel can be improved by the continuous

enforcement of Livestock Waste Control Scheme which will regulate discharge of

livestock waste into the drainage channel.

In addition, the existing watercourse TKL05 is currently receiving some

domestic waste discharge. Provision

of sewers connecting the village households to treatment works will thus lead

to improvement of water quality of the proposed Drainage Channel TKL05. Such provision of public sewers to the

unsewered villages is being implemented under the North District Sewerage

Master Plan.

Change in Sediment Deposition and Erosion Pattern

5.7.26

The improved flow condition (i.e. higher flow rate of runoff)

in the proposed Drainage Channel TKL04 and TKL05 may alter the pattern of

sediment deposition and erosion within the drainage channel and along the

downstream section of Ping Yuen River and Shenzhen River. However, as regular maintenance works

will be undertaken within the proposed drainage channel and at the downstream

sections to remove excessive sediments (regular maintenance

works will be undertaken by DSD at these downstream sections with some

hand-held tools which are not within the scope of the Project), it

is not anticipated that the Project will lead to any adverse water quality

impacts within the Project Site and along the downstream section of Ping Yuen

River and Shenzhen River by altering sediment deposition and erosion

patterns. It is also not expected

that the Project will lead to any unacceptable water quality impacts at the

Wetland Conservation Area and Mai Po and Inner Deep Bay Ramsar Site since these

areas which are susceptible to changes in sediment deposition and erosion

pattern are in considerable distance from the proposed Drainage Channel TKL04

and TKL05 (i.e. >4, >11 and >10 km, respectively). Therefore, we

expect same/similar scale of upstream water volume (i.e. in the unit of ¡§m3¡¨)

discharging into the channel. After improvement works, the cross-section is

expected to be larger, hence the water flow (i.e. in the unit of ¡§m3/s¡¨)

shall be decreased. The drainage velocity will be slightly decreased with

implementation of drainage improvement works due to wider cross-sections.

5.7.27

Bottom sediment re-suspension will be alleviated because of

the decreased flow. Sediment erosion would be substantially reduced, which lead

to reduction of drainage maintenance desilting frequency and minimize the potential

water quality impacts which may arise from maintenance desilting

activities. Sedimentation rate is a function associated with densities

of the particle and water, effective particle diameter and dynamic

viscosity (Stokes Law). Thus, the change of flow regime will

not change the sedimentation rate significantly.

Potential effect of brackish tidal influence

5.7.28

As the invert level of the proposed channels are over 3.5m,

which is higher than the highest predicted tide level at Tsim

Bei Tsui (<3.5m) and thedownstream Invert level is

+4.8mPD. Therefore, the effect of brackish tidal influence from Inner Deep Bay

or Lower Ping Yuen River is not expected. Mitigation measures such as tidal

barriers / flow management devices are therefore considered not necessary.

5.8

Mitigation Measures

Construction

Phase

5.8.1

Potential impacts on water quality as a result of

construction activities of the Project, including temporary flow diversion,

excavation works within the existing watercourse, sewage generation from

workforce, construction runoff and drainage, unplanned accidental spillage and

uncontrolled release of pollutants have been assessed in Section 5.7 above. The

following section describes the mitigation measures proposed to alleviate water

quality impacts during construction of the Project.

5.8.2

The contractor should comply with the Water Pollution

Control Ordinance (WPCO) and its

subsidiary regulations. The

contractor should carry out works in such a manner as to minimise adverse

impacts on the water quality during execution of the works. In particular, the contractor should

arrange his method of working to minimise the effects on the water quality

within and outside the site and on the transport routes.

5.8.3

Best Management Practices should be implemented in

controlling water pollution during the construction phase. The contractor

should follow the practices, and be responsible for the design, construction, operation

and maintenance of all the mitigation measures below and as specified in ProPECC PN 1/94 ¡V Construction Site Drainage. In particular, the contractor should

submit and implement an Water Pollution Control Plan (as part of the Environmental

Management Plan (4), thereafter called

¡§the Plan¡¨) which should incorporate details of the mitigation measures

recommended below to reduce water quality impacts arising from construction

works. There is also need to apply to the EPD for a discharge licence for

discharge of effluent from the construction site under the WPCO. All discharges

during the construction phase of the Project should comply with the Technical Memorandum for Effluents

Discharged into Drainage and Sewerage Systems, Inland and Coastal Waters

(TM-ICW) issued under the WPCO.

5.8.4

For construction works in the vicinity of natural rivers and

streams, the contractor should follow the recommendations given in ETWB TC (Works) No. 5/2005-

Protection of Natural Streams/Rivers from Adverse Impact Arising from

Construction Works, including but not limited to:

¡P

The use of less or

smaller construction plants may be specified in areas close to the water

courses to reduce the disturbance to the surface water.

¡P

Temporary storage of

materials (e.g. equipment, chemicals and fuel) and temporary stockpile of

construction materials should be located well away from any water courses when

carrying out of the construction works.

¡P

Stockpiling of

construction materials and dusty materials should be covered and located away from

any water courses.

¡P

Construction debris and

spoil should be covered up and / or disposed of as soon as possible to avoid

being washed into the nearby water receivers.

¡P

Adequate lateral support

may need to be erected in order to prevent soil or mud from slipping into the

watercourses.

Temporary

Flow Diversion and Excavation Works of the Existing Watercourse

5.8.5

The following good practices should apply

at all times during excavation works:

¡P

Excavation within the

existing watercourse TKL04 and TKL05 should be carried out in dry

conditions. The dry excavation

condition could be created with temporary flow diversions as described in

detail in Section 5.7.

¡P

The excavated material, especially

river bed material, should be temporary stored in the

stockpile areas for dewatering by natural ventilation. Runoff from these stockpile areas should

be collected for treatment by sedimentation with the addition of coagulant. The treated water should be reused on

site for water spraying or wheel washing.

¡P

The dried/dewatered

excavated material should be reused on-site as backfilling material, as far as

practicable.

Sewage

Generated from the Construction Workforce

5.8.6

Domestic sewage/wastewater generated by workforce on-site

should be collected in a suitable storage facility such as portable chemical

toilets. An adequate number of

portable toilets should be provided during the construction phase. These toilets should be maintained in a

state that will not deter the workers from using them. The collected sewage/wastewater should

be discharged into the foul sewer or transferred to the Government sewage

treatment works by a licensed collector. Other measures, such as providing

notices at conspicuous locations, regular site audit etc., would be conducted.

Widening of Drainage Channels

5.8.7

Due to the characteristics of narrow width and small water

flow of the existing channel, the excavation should be carried out in dry

condition (even in wet season) by diverting the stream flow from upstream by a

temporary drainage channel with a temporary sheetpiles,

earth bund or barrier; so that the works area will remain dry for later

excavation and widening works.

5.8.8

The temporary drainage channel would be removed when the

construction works are completed or the temporary

diversion is no longer required. Although flooding of the proposed contaminant

section seldom occurs in dry season, the excavation would be considered to

suspend when flood water enters the containment and causes leakage of runoffs

to stream water.

5.8.9

After dewatering of the streams, the sediments should be

allowed to dry before excavation (yet still maintain a moist state to avoid

dust nuisance). This will facilitate excavation of the sediments and also minimize the risk of drained water flowing back

into watercourses or diversion channels as the sediment is handled. Where time

or weather constraints require handling of wet sediment, care should be taken

in the removal of sediment and the storage area should be bunded to prevent

silty runoff entering watercourses. Given its small quantity, all excavated

sediment should be reused on-site as backfilling material.

5.8.10

To further minimize the leakage and loss of sediments during

excavation, tightly sealed closed grab excavators should be employed in river

sections where material to be handled is wet. Where material is dry and in

non-river sections, conventional excavations can be used.

5.8.11

Excavated sediment will likely be temporarily stored on-site

for reuse as backfilling material. This should be stored in a bunded area and

covered at any time to avoid inadvertent release of silts and suspended solids

to nearby water bodies.

5.8.12

Regular monitoring of suspended solids, pH and turbidity

should be conducted during excavation works. Any exceedance of water quality in

the nearby water bodies caused by inadvertent release of site runoff should be

rectified in accordance with EM&A programme for this Project.

Construction

Runoff and Drainage

5.8.13 Good construction site practices outlined in ProPECC PN 1/94 ¡§Construction Site Drainage¡¨ should be followed as far as practicable in order

to minimise surface runoff and the chance of erosion, and

also to retain and reduce any suspended solids in surface runoff prior

to discharge. These practices include the following:

¡P

Prior to discharge of

site runoff into the nearby water bodies, site runoff should be treated via

sand/silt removal facilities such as sand/silt traps or sedimentation

facilities on-site to remove sand/silt particles and to meet the discharge

standards of the TM-ICW under the WPCO. The design of sand/silt

removal facilities should be based on the guidelines provided in ProPECC PN 1/94. All drainage facilities

and erosion and sediment control structures should be

inspected regularly and maintained to confirm proper and efficient operation at

all times during construction phase and particularly before and after

rainstorms. Deposited silt and grit

should be removed regularly.

¡P

Appropriate surface

drainage should be designed and provided, where necessary. In particular, surface runoff should be

collected along the river banks and be diverted to

sedimentation tank/pond before discharge into the river.

¡P

The precautions to be

taken at any time of year when rainstorms are likely together with the actions

to be taken when a rainstorm is imminent or forecasted and actions to be taken

during or after rainstorms are summarised in Appendix A2 of ProPECC PN 1/94 and

should be followed.

¡P

Oil interceptors should

be provided in the drainage system where necessary and regularly emptied to

prevent the release of oil and grease into the stormwater drainage system after

accidental spillages.

¡P

Temporary and permanent

drainage pipes and culverts provided to facilitate runoff discharge should be

adequately designed for the controlled release of storm flows. The design of

permanent drainage pipes should follow the guidelines provided in ProPECC PN 5/93 Drainage plan subject to comment

by the Environmental Protection Department.

¡P

The temporary diverted

drainage should be reinstated to the original condition when the construction

work has finished or when the temporary diversion is no longer required.

¡P

Construction materials

stored on-site should be covered with tarpaulin sheets to prevent from being

washed away. Other measures such as

containment bunds, sand bags and temporary drainage

should also be considered, especially during wet season or heavy rainstorm

events. Such runoff could be

minimized through reduction of flat exposed open area, and through diversion

and collection via temporary drainage system on the periphery of the Project

site.

5.8.14 Site

runoff during concrete curing period should be carefully contained and diverted

to treatment facilities on-site to prevent it from entering existing

watercourses directly. Adjustment

of pH should be carried out by adding a suitable neutralising reagent to the

wastewater collected.

5.8.15 Any

exceedance of pH level against acceptable range in WQO in the nearby

watercourse should be closely monitored during the construction phase. Such situation should be rectified in

accordance with the EM&A programme for this Project. Adoption of lesser or

smaller construction plants would be proposed to reduce disturbance to the

channel bed and to the nearby sensitive receivers; and the use of concrete or

the like should be avoided or minimized.

Accidental Spillage / Uncontrolled Discharge

from General Construction Activities

General Construction Activities

5.8.16 The

following good site measures should be implemented to prevent uncontrolled

discharge or spillage from the general construction activities:

¡P

Site office, workshop and

depot should be located on hard standing grounds with provision of temporary

drainage channel and sedimentation tanks with oil interceptor if required. The oil interceptor should be inspected

regularly to prevent blockage and oil overflow during storm events.

¡P

Debris and refuse

generated on-site should be collected, handled and disposed of properly to

avoid entering the existing Ping Yuen River and Shenzhen River downstream of

the Project site. Stockpiles of cement and other construction materials

should be kept covered when not being used.

¡P

Good site practices

described in ProPECC PN 1/94, such as

avoidance of excavation works in rainy / wet season should be complied.

Storage and Handling of Oil, Other Petroleum

Products and Chemicals

5.8.17 The following mitigation measures should be implemented for the storage and handling of oil, other petroleum products and chemicals:

¡P

Waste streams

classifiable as chemical wastes should be properly stored, collected and

treated for compliance with Waste

Disposal Ordinance or Waste Disposal

(Chemical Waste) (General) Regulation requirements.

¡P

All fuel tanks and

chemical storage areas should be provided with locks and be sited on paved

areas.

¡P

The storage areas should

be surrounded by bunds with a capacity equal to 110% of the storage capacity of

the largest tank to prevent spilled oil, fuel and chemicals from reaching the

receiving waters. The storage areas should be located away from water bodies as

far as possible.

¡P

Waste oil should be

collected and stored for recycling or disposal, in accordance with the Waste Disposal Ordinance.

¡P

Vehicle and plant

servicing areas, vehicle wash bays and lubrication bays should, as far as

possible, be located within roofed areas.

The drainage in these covered areas should be connected to foul sewers

via a petrol interceptor.

Handling of Spillage / Leakage

5.8.18

In the event that accidental spillage or

leakage of hazardous substances / chemical wastes occur, the response

procedures as listed below should be followed. It should be noted that the procedures

below are not exhaustive and the contractor should

propose other response procedures in the Emergency Contingency Plan based on

the particular types and quantities of chemicals or hazardous substances used,

handled and stored on-site.

¡P

Oil leakage or spillage

should be contained and cleaned up immediately. Waste oil should be collected

and stored for recycling or disposal in accordance with the Waste Disposal Ordinance.

¡P

Instruct untrained

personnel to keep at a safe distance well away from the spillage area.

¡P

If the spillage / leakage

involves highly toxic, volatile or hazardous waste, initiate emergency

evacuation and call the emergency service.

¡P

Only trained persons

equipped with suitable protective clothing and equipment should be allowed to

enter and clean up the waste spillage / leakage area.

¡P

Where the spillage/

leakage is contained in the enclosed storage area, the waste can be transferred

back into suitable containers by suitable handheld equipment, such as hand

operated pumps, scoops or shovels.

If the spillage / leakage quantity is small, it can be covered and mixed

with suitable absorbing materials such as tissue paper, dry soft sand or

vermiculite. The resultant slurry

should be treated as chemical waste and transferred to suitable containers for

disposal.

¡P

For spillage / leakage in

other areas, immediate action is required to contain the spillage /

leakage. Suitable liquid absorbing

materials such as tissue paper, dry soft sand or vermiculite should be used to

cover the spill. The resultant

slurry should be treated as chemical waste and transferred to suitable

containers for disposal.

¡P

Areas that have been

contaminated by chemical waste spillage / leakage should be cleaned. While water is a soluble solvent for

aqueous chemical wastes and water soluble organic

waste, kerosene or turpentine should be used for organic chemical wastes that

are not soluble in water. The waste

from the cleanup operation should be treated and

disposed of as chemical waste.

¡P

In incidents where the

spillage / leakage may result in significant contamination of an area or risk

of pollution, the EPD should be informed immediately.

¡P

The Code of Practice on

Packaging, Labelling and Storage of Chemical Wastes published under the WDO

should be used as a guideline for handing chemical wastes.

Operation

Phase

Maintenance Works

5.8.19

Maintenance would be necessary for the proposed drainage

channel at regular intervals to remove excessive silts, vegetation, debris and

obstruction.

5.8.20

Before proceeding with any maintenance works, except for

emergency works, the maintenance engineer should check to ascertain if any of

the proposed works should be located in or near an

environmentally sensitive and/or ecologically important areas. In case of doubt, advice from

5.8.21

If the proposed works should be located inside or near one of

the environmentally sensitive and/or ecologically important areas, careful

consideration should be given to the proposed method of implementation so as to

minimise any adverse environmental impact.

Depending on the extent of the maintenance works,

5.8.22

The following precautionary measures should be included in

planning for the maintenance works for the proposed channels:

(a)

Maintenance of the channels should be restricted to annual

silt removal when the accumulated silt should adversely affect the hydraulic

capacity of the channel, except during emergency situations where flooding risk

is imminent. Desilting should be

carried out by hand or light machinery during the dry season (October to March)

when water flow is low.

(b)

Vegetation removal should be limited to manual cutting to be

carried out during dry season and only when growth of vegetation is very likely

to impede channel flow.

(c)

Phasing of the works should be considered to better control

and reduce any impacts caused.

Where possible, works should be carried out along half width of the

drainage channel in short sections. A free passage along the drainage channel

is necessary to avoid forming stagnant water in any phase of the works.

(d)

Containment structures (such as sand bags barrier) should be

provided for the desilting works area to facilitate a dry or at least confined

working area within the drainage channel.

(e)

Where no maintenance access is available for the channel,

temporary access to the works site should be carefully planned and located to

reduce disturbance caused to the drainage channel, adjacent vegetation and

nearby sensitive receivers by construction plants.

(f)

The locations for the disposal of the removed materials should

be identified and agreement sought with the relevant departments before

commencement of the maintenance works.

Temporary stockpile of waste materials should be located away from the

channel and properly covered. These waste materials should be disposed of in a

timely and appropriate manner.

(g)

The use of lesser or smaller construction plants should be

considered to reduce disturbance to the channel bed where fish habitats are

located and to the nearby sensitive receivers;and

(h)

The use of concrete or the like should be avoided or minimzed.

5.9

Residual Impacts

5.9.1

With the proper implementation of the recommended mitigation

measures described in Section 5.8

above, it is expected that unacceptable residual water quality impacts would

not arise from the construction and operation of the Project.

5.10

Cumulative Impacts

5.10.1

The potential for cumulative water quality impact during the

construction phase has been checked against the following known committed/existing

projects at the time the EIA is prepared, and the project proponents of these

projects have been approached and will be closely consulted throughout this

Project:

¡P

Implementation

of Water Intelligent Network (WIN), Remaining District Metering Areas and

Pressure Management Areas in Yuen Long and Sheung Shui & Fanling Major Supply Zones;

¡P

Widening

of the Western Section and Eastern Section of Lin Ma Hang Road (Ping Yuen River

to Ping Che Road / Tsung Yuen Ha to Lin Ma Hang).

5.10.2

Implementation of WIN will fall within the Study Area while

the works will be confined into localised works area with little potential to

generate water quality impacts. In

addition, the widening of the Western Section and Eastern Section of Lin Ma

Hang Road (Ping Yuen River to Ping Che Road / Tsung Yuen Ha to Lin Ma Hang) is

not substantial and is over 500m of this Project. Therefore, the potential of causing

unacceptable cumulative water quality impacts from these projects is considered

low.

5.10.3

In addition to the above projects, there are also three

planning studies with study areas within and in the vicinity of the Project

Site, which included the following:

¡P

Preliminary Feasibility

Study on Developing the New Territories North (NTN);

¡P

Drainage Improvement

Works in Hang Tau, Kong Ha and Sha Tau Kok Town, and Lower Ping

Yuen River; and

¡P

North East New

Territories Sewerage System Upgrade.

5.11

Monitoring and Audit

Requirement

Construction

Phase

5.11.1

With proper implementation of the recommended mitigation

measures, adverse water quality impacts at the identified WSRs are not expected

to occur. However, a water quality

monitoring programme is recommended to verify the predictions of the EIA and

ensure compliance with the assessment criteria.

5.11.2

Detailed approach and methodology of the water quality

monitoring programme are presented in the Environmental Monitoring and Audit

Manual (EM&A Manual) under a separate cover and are briefly described

below.

5.11.3

Baseline monitoring should be undertaken for three times per

week for a period of four weeks before commencement of the construction works

to establish baseline water quality conditions of the area. Impact monitoring should be undertaken

for three times per week during the construction period to obtain updated water

quality data of the area for comparison with the baseline water quality data

and hence determine any water quality impacts from the construction

activities.

5.11.4

Monitoring should be undertaken at stations located upstream

and downstream of the Project Site.

The upstream station should serve as control station at which the water

quality is unlikely to be affected by the Project¡¦s activities while the

downstream station will serve as impact station. Data will be compared between the

upstream and downstream station to determine any adverse water quality impacts

as a result of the construction works of the Project. Locations of the monitoring station are

recommended in the EM&A Manual.

5.11.5

The following parameters will be monitored under the water

quality monitoring programme:

¡P

Dissolved Oxygen (mg/L) (in situ measurement);

¡P

Temperature (in situ measurement);

¡P

pH (in situ measurement);

¡P

Turbidity (NTU) (in situ measurement);

¡P

Suspended Solids (mg/L)

(laboratory analysis);

¡P

Salinity (in situ measurement);

¡P

Water depth (in situ measurement)

5.11.6

Weekly site inspections and monthly site audits will

be conducted to ensure that the recommended mitigation measures are properly

implemented during the construction stage.

Operation

Phase

5.11.7

Adverse water quality impact is not expected during

operation phase of the Project and hence monitoring is considered not

necessary.

5.12

Conclusion

5.12.1

The potential sources of water quality impacts associated

with the construction and operation of the Project have been identified and the

potential impacts were evaluated.

5.12.2

Potential impacts arising from the proposed construction

works are predicted to be largely confined to the specific works areas. With

proper implementation of the recommended mitigation measures, in particular the

establishment of dry conditions for excavation works within the existing

watercourse and good construction site practices as recommended in relevant

regulatory guidelines, adverse water quality impacts are not expected at the

identified WSRs.

5.12.3

During the operation phase, changes to hydrodynamic regime

within the Project Site are predicted to have no adverse impacts. Adverse water quality impacts are not

expected at any identified WSRs during the operation phase as the Project will

not generate any new pollution loads and the maintenance works to remove

excessive silt, vegetation, debris and obstructions are small scale in

nature. The improved flow condition

in the proposed Drainage Channel TKL04 and 05 may alter the pattern of sediment

deposition and erosion along the downstream section of Ping Yuen River and

Shenzhen River. With regular

maintenance works at these downstream sections to remove excessive sediments,

it is not anticipated that the Project will lead to any unacceptable adverse

water quality impacts by altering their sediment deposition and erosion

pattern.

5.12.4

With the implementation of the recommended mitigation

measures, it is expected that unacceptable residual water quality impacts would

not arise from the construction and operation of the Project. Nevertheless, a monitoring programme is

recommended during construction phase to verify the predictions of the EIA and

ensure compliance with the assessment criteria.