11.1

Background

11.1.1 This

section of the EIA presents the analysis and findings of the Hazard to Life

Assessment undertaken for the Project.

11.1.2 In

accordance with Section 3.4.9 of the EIA Study Brief (ESB-323/2019), a hazard

to life assessment should be conducted to evaluate the risks associated with Potentially

Hazardous Installation (Sha Tin Water Treatment Works) and the LPG storage

installation at Worldwide Gardens during both construction and operation phases

of the Project.

Sha Tin Water Treatment

Works

11.1.3 The

Sha Tin Water Treatment Works (Sha Tin WTW) is designated as a Potentially

Hazardous Installation (PHI) owing to its use and storage of chlorine in 1

tonne drums. A Consultation Zone (CZ), centred at the chlorine store, of 1000m

radius but excluding the areas located at over 150m above sea level is

established around the Sha Tin WTW. Consultation Zones are established around

PHIs to control developments in the vicinity and prevent population

accumulating to the point where societal risks may become unacceptable. Any

new development within the CZ of a PHI that may lead to an increase in

population requires a hazard assessment to be conducted to ensure that the

societal risks remain acceptable.

11.1.4 According

to the latest information provided by the Water Supplies Department (WSD), it

is understood that the upgrading works of the disinfection facilities in Sha

Tin WTW will be completed in Year 2022, and all chlorine drums in Sha Tin WTW

would be removed by Q4 2022 after the on-site chlorine generation (OSCG) plant

is put into operation.

11.1.5 Based

on the tentative construction programme of this Project, the construction works

will be commenced in Year 2025, at which time the upgrading works of the Sha

Tin WTW would already been completed. As such, risk impact due to storage of

liquid chlorine in Sha Tin WTW would not be expected during the construction

and operation phases of this Project, and thus no hazard to life assessment for

the Sha Tin WTW is required.

LPG Storage

Installation

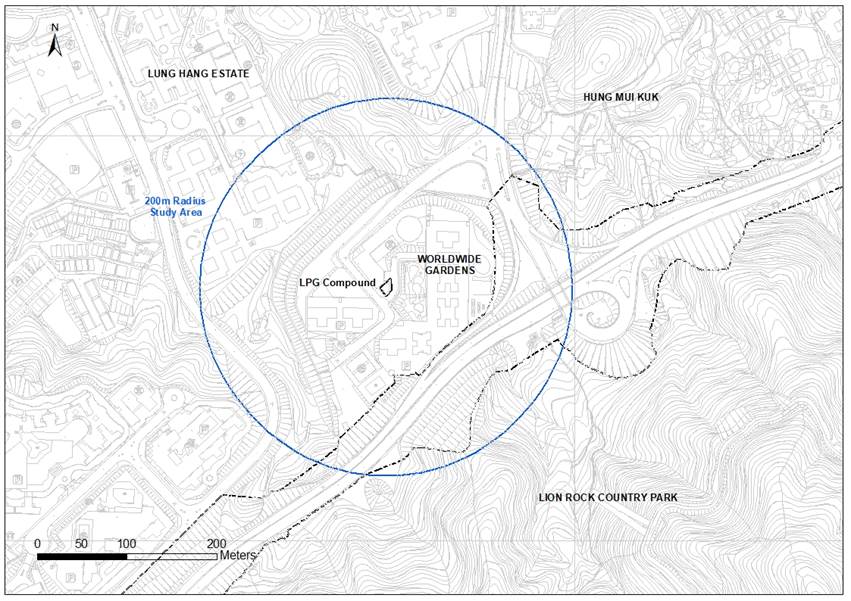

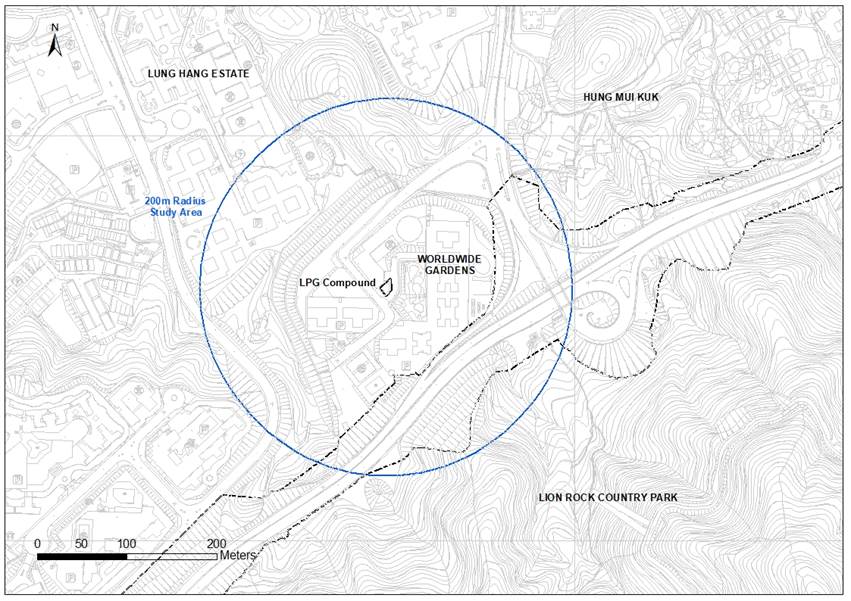

11.1.6 The

LPG Storage Installation (LPG Compound) in the Worldwide Gardens comprises of

two 2.4 tonnes (water capacity of 4.3 kL each) underground storage vessels,

which supplies LPG to the local residents of the Worldwide Gardens. Part of

the LRT Road at Sha Tin side and the works areas near the junction of Lion Rock

Tunnel Road and Hung Mui Kuk Road are located in close vicinity to the LPG

Compound. Hence, a Quantitative Risk Assessment (QRA) was carried out to

evaluate the potential hazard to life during both construction and operation

phases of the Project. Plate 11.1 shows the location of the LPG

Compound.

Plate 11.1 Location

of the LPG Compound

Objectives

11.2.1 The

Hazard to Life Assessment requirements for the LPG storage installations as

detailed in Appendix G of the EIA Study Brief are shown below:

(a)

Identify

hazardous scenarios associated with the on-site transport, storage and use of

gas as defined in the Gas Safety Ordinance (Cap. 51) at the LPG Storage

Installation and then determine a set of relevant scenarios to be included in a

Quantitative Risk Assessment (QRA);

(b)

Execute

a QRA of the set of hazardous scenarios determined in (a), expressing

population risks in both individual and societal terms;

(c)

Compare

individual and societal risks with the criteria for evaluating hazard to life

as stipulated in Annex 4 of the TM; and

(d)

Identify

and assess practicable and cost-effective risk mitigation measures.

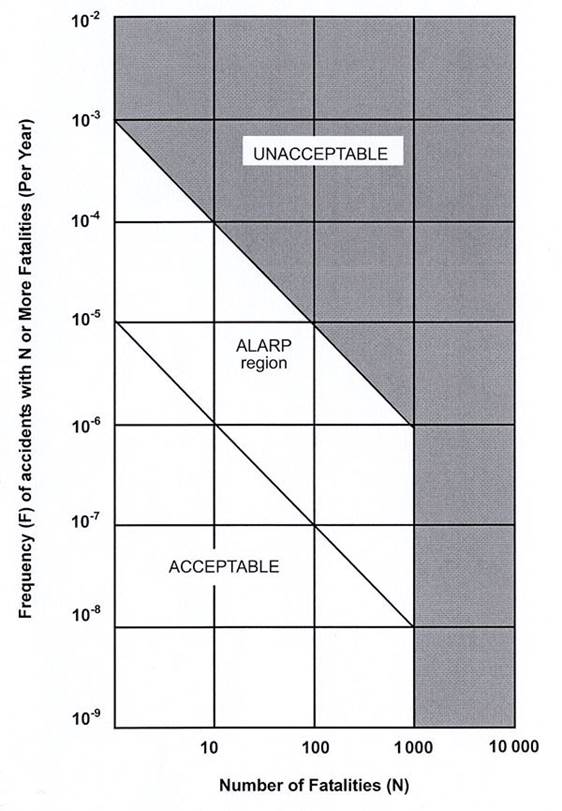

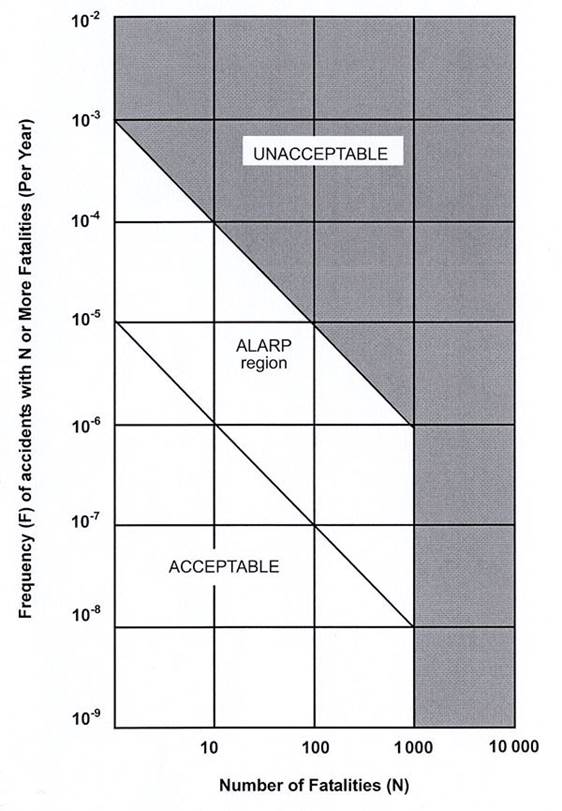

EIAO TM Risk Criteria

11.2.2 Annex

4 of the EIAO-TM specifies the Individual and Societal Risk Guidelines. The

Hong Kong Risk Guidelines (HKRG) per the EIAO-TM Annex 4 states that the

individual risk is the predicted increase in the chance of fatality per year to

an individual due to a potential hazard. The individual risk guidelines require

that the maximum level of individual risk should not exceed 1 in 100,000 per

year i.e. 1×10-5 per year. Societal risk expresses the risks to the

whole population. It is expressed in terms of lines plotting the cumulative

frequency (F) of N or more deaths in the population from incidents at the

installation. Two F-N risk lines are used in the HKRG that demark “Acceptable”

or “Unacceptable” societal risks. To avoid major disasters, there is a vertical

cut-off line at the 1000 fatality level extending down to a frequency of 1 in a

billion years. The intermediate region indicates the acceptability of societal

risk is borderline and should be reduced to a level which is “as low as

reasonably practicable” (ALARP). It seeks to ensure that all practicable and

cost-effective measures that can reduce risk are considered. The HKRG is

presented graphically in Plate 11.2.

Plate 11.2 Societal

Risk Guidelines

11.3.1 This

assessment consists of the following six main tasks:

(a)

Data

/ Information Collection and Update: collect relevant data

/ information that is essential for the hazard assessment;

(b)

Hazard

Identification: identify credible set of hazardous scenarios associated

with the operation of the LPG Compound;

(c)

Frequency

Estimation:

estimate the frequencies of each hazardous event leading to fatalities based on

the collected data and operation data for LPG Compound with the support of

justifications from reviewing historical accident data and previous hazard

assessments;

(d)

Consequence

Analysis:

analyze the consequences of the identified hazardous scenarios;

(e)

Risk

Assessment and Evaluation: evaluate the risks associated with the

identified hazardous scenarios. The evaluated risks will be compared with HKRG

to determine their acceptability. Where necessary, risk mitigation measures

will be identified and assessed to comply with the “as low as reasonably

practicable” (ALARP) principle used in the HKRG; and

(f)

Identification

of Mitigation Measures: review the recommended risk mitigation

measures from previous studies. Practicable and cost-effective risk mitigation

measures will be identified and assessed as necessary. The risk outcomes of

the mitigated case will then be reassessed to determine the level of risk

reduction.

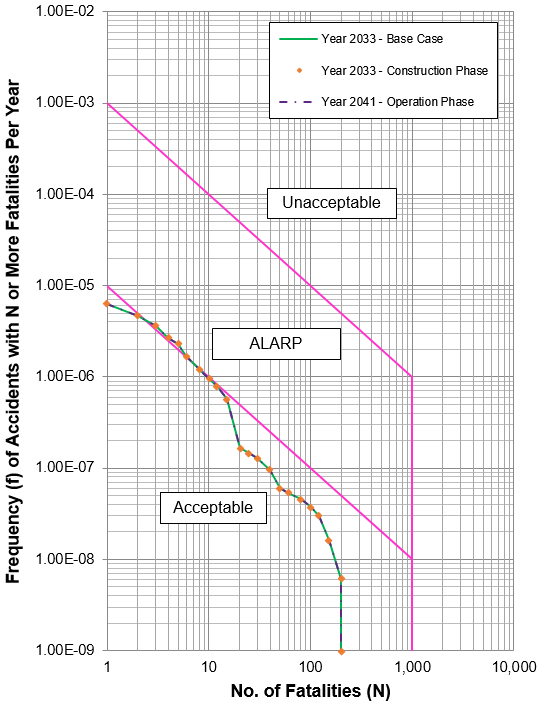

11.3.2 The

hazard assessment covers three scenarios:

·

Year

2033 without Project (Base case) – The risk imposed by the LPG Compound to the

planned population in 2033, in the absence of the Project.

·

Year

2033 with Project (Construction phase) – The risk imposed by the LPG Compound

to the planned population in 2033. This also accounts for the presence of the construction

workers operating in close vicinity of the LPG Compound and any potential

impacts associated with the construction activities.

·

Year

2041 (Operation phase) – The risk imposed by the LPG Compound to the planned

population in 2041 upon completion of the Project.

Study Area

11.4.1 The

LPG Compound is located at the southern direction of the commercial complex of

the Worldwide Gardens, which is currently occupied by the Anfield School. The

study area of 200m radius from the LPG compound was adopted in the study, as

shown in Plate 11.1.

11.4.2 Based

on information from survey maps and observations during the course of site

visit in May 2020, the LPG Compound is surrounded by Lung Pak Road, the Anfield

School and residential buildings. There is a 2m high cut slope located on the

north-west boundary of the LPG Compound.

Description of the LPG

Compound

LPG Storage

11.4.3 DSG

Energy Limited (DSG) is the operator of the LPG Compound which supplies LPG to

the local residents of Worldwide Gardens. According to the information

provided by DSG, the LPG Compound consists of two 2.4 tonnes (water capacity of

4.3 kL each) underground storage vessels, which are filled to a maximum

permissible level (85% of the maximum capacity) and equipped with two

vaporizers onsite. Furthermore, the two storage vessels were manufactured in

1998 and 2011 and were neither stress relieved nor radiographed.

LPG Delivery

and Transfer

11.4.4 LPG

is delivered to the LPG Compound by road tankers. The maximum capacity of the

road tanker is about 9 tonnes. Based on the information provided by DSG, there

are approximately 40 annual LPG deliveries and about 2 tonnes of LPG is being

transferred to the LPG Compound per delivery. The average resident time of the

LPG road tanker at the LPG Compound is around 45 minutes, which includes the

preparation time for facilitating the unloading operation.

11.4.5 Owing

to the site constraint, dedicated road tanker parking area is unavailable

within the LPG Compound and the LPG road tankers have to be parked at the

predefined area on the roadside next to the entrance of the LPG Compound during

unloading operation. This practice was adopted since its operation in the

1970s. As advised by DSG, precautionary measures specified for the concerned

LPG Compound are provided to minimize the potential risks due to this unloading

arrangement.

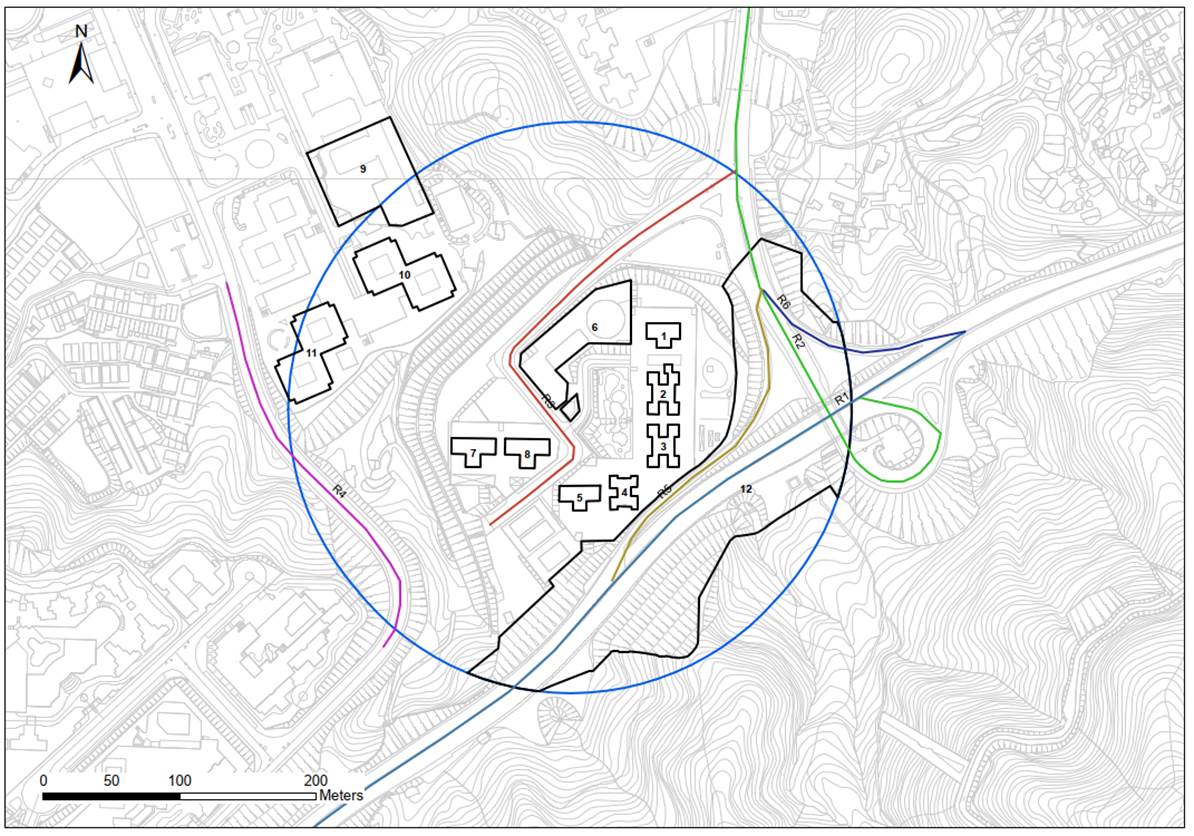

Population

11.4.6 Societal

risk is a measure of the consequence magnitude and the frequency of the

hazardous events. To establish the impact of any release (expressed as the

number of people likely to be affected), it is necessary to have a good

knowledge of the future population levels around the LPG Compound. This includes

residential population, institutional / commercial population and transport

population. However, the road tanker operators at the LPG Compound are

considered to be voluntary takers of risk and thus, excluded from the assessment.

11.4.7 The

location of population groups and roads covered in the assessment is presented

in Plate 11.3, while photos of the surrounding population, as taken on

26th January 2021, are provided in Appendix 11.1. Additionally,

details on the estimated population for each population group are provided in Appendix 11.2.

Proposed Road Works for

the Project

11.4.8 Based

on the tentative construction programme of the Project, construction activities

on the portion of LRT Road and Hung Mui Kuk Road that fall within the 200 m

radius from the LPG Compound will be undertaken between Q4 of 2028 to Q2 of 2033.

These include:

·

Site

clearance

·

Slope

formation works

·

Noise

barrier & pipe pile wall/ L-shape retaining wall installation

·

Roadworks,

drainage, utilities, water mains

·

Landscape

works for slope

11.4.9 The

number of construction workers is estimated according to the Consultant’s

experience/ analysis based on projects of similar nature. It is assumed that

there will be 186 construction workers involved in the nearby construction

activities. This estimate represents the maximum number of nearby construction

workers envisaged during the peak construction period. The actual number of construction

workers engaged in the road widening works along the portion of Lion Rock

Tunnel Road and Hung Mui Kuk Road located within 200m radius study area is

expected to be smaller. Nonetheless, this estimate is applied as a

conservative approach.

Land and Building

Population

11.4.10 Hong Kong conducts

a population census once every ten years and a by-census in the middle of the

intercensal period. The Census data on the number of floors and units of the

residential developments, together with the Territory Population and Employment

Data Matrix (TPEDM) data on average household size, were used to estimate the

existing population of these developments.

11.4.11 The TPEDM

population projections for different Planning Data Zones (PDZ) were obtained

from the Planning Department (PlanD) to forecast the population for the

assessment years.

11.4.12 The

2016-based TPEDM data showed a negative growth of average domestic household

size in the PDZ 209 from 2016 to 2041. To be conservative, the residential

population in the future assessment years are assumed to remain the same as

those in Year 2016.

11.4.13 The

population in each area are listed in Table 11.1 and details on the

estimated population for each population group at different time modes and provided

in Appendix 11.2.

It is estimated with the following assumptions:

(a)

According

to 2016-based TPEDM data, a negative growth rate of -0.27% is observed for the

average domestic household size in Sha Tin District (i.e. PDZ 209) from 2016 to

2041, which decreases from 3.26 to 3.05. To be conservative, the average

domestic household size in the future assessment years are assumed to remain

the same as those in Year 2016 (i.e. 3.26).

(b)

For

Pok Oi Hospital Chan Kai Memorial College, the number of students was estimated

based on the maximum capacity per classroom (i.e. max. capacity of 45 students

for 26 classrooms), while the

number of staff recorded as of year 2020 is 56.

(c)

For

Anfield School, the number of students was estimated based on the maximum

capacity per classroom (i.e. max. capacity of 25 students for 12 classrooms and

max. capacity of 15 for 1 classrooms), while the

number of staff is estimated as 47.

(d)

School

populations was estimated based on the maximum student intake per class.

Furthermore, it is anticipated that majority of students attending Anfield

School and Pok Oi Hospital Chan Kai

Memorial College reside within Sha Tin District. According to

2016-based TPEDM data, a negative growth rate for residential population is

generally observed for PDZ 209 and the surrounding populations (i.e. PDZ 205,

206, 208, 210, 211, 384 and 385). As such, the changes in school populations

is expected to be minimal.

Occupancies

of different population groups at different time modes are summarised in Table 11.5. In

general,

(e)

The

weekday and weekend night-time population are assumed to be 100% of the maximum

residential population.

(f)

The

weekday and weekend daytime population are assumed to be 50% and 70% of the

residential population, respectively.

(g)

The

weekday daytime population is assumed to be 100% of the maximum school population.

(h)

An

average of 5% outdoor populations is considered for both residential and school

population group.

(i)

For

the proposed Project works area, the weekday and weekend daytime population are

assumed to be 100% and 50%, respectively and 100% outdoor population is

considered.

Table 11.1 Land and

Building Population Data

|

ID

|

Description

|

Population

|

|

|

Year 2033 – Base Case

[Note 1, 2]

|

Year 2033 – Construction Phase

|

Year 2041 – Operation Phase

|

|

|

1

|

Pine Court, Worldwide

Gardens

|

98

|

98

|

98

|

|

|

2

|

Hibiscus Court,

Worldwide Gardens

|

261

|

261

|

261

|

|

|

3

|

Lily Court, Worldwide

Gardens

|

261

|

261

|

261

|

|

|

4

|

Laurel Court,

Worldwide Gardens

|

274

|

274

|

274

|

|

|

5

|

Bauhinia Court, Worldwide

Gardens

|

137

|

137

|

137

|

|

|

6

|

Anfield School

|

362

|

362

|

362

|

|

|

7

|

Begonia Court,

Worldwide Gardens

|

150

|

150

|

150

|

|

|

8

|

Cypress Court,

Worldwide Gardens

|

150

|

150

|

150

|

|

|

9

|

Pok Oi

Hospital Chan Kai Memorial College

|

1226

|

1226

|

1226

|

|

|

10

|

Sheung

Sum House, Lung Hang Estate

|

|

10a

|

Low Block

|

1109

|

1109

|

1109

|

|

|

10b

|

High

Block

|

1275

|

1275

|

1275

|

|

|

11

|

Wai Sum

House, Lung Hang Estate

|

|

11a

|

Low Block

|

1109

|

1109

|

1109

|

|

|

11b

|

High

Block

|

1275

|

1275

|

1275

|

|

|

12

|

Proposed

Project Works Area [Note 3]

|

0

|

186

|

0

|

|

Note

1: Populations for residential were estimated based on domestic household

size in 2016-based TPEDM.

Note

2: School population for Pok Oi Hospital Chan Kai Memorial College and

Anfield School was estimated based on the school information from the Education

Bureau and school website.

Note 3: It

was assumed that there will be a maximum of 186 construction workers in the

nearby construction activities during the construction phase.

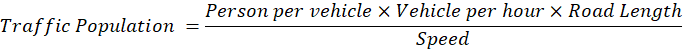

Road Population

11.4.14 The traffic

population considered in this assessment included the population travelling in

motor vehicles on Lion Rock Tunnel Road, Hung Mui Kuk Road, Chung Pak Road

& Lung Pak Street, Fu Kin Street and slip roads (i.e. LRT Road to Hung Mui

Kuk Road and Hung Mui Kuk Road to LRT Road). Speed limit on Lion Rock Tunnel

Road was assumed to be 80km/hr and 50km/hr was considered for the remaining

roads/ streets. The traffic population is predicted based on the following

equation:

11.4.15 Based on

the latest Annual Traffic Census (ATC) [2], the occupancies for each vehicle

type and vehicle mix were taken as the average at the core station no. 5024 (Lion

Rock Tunnel) which are considered representative of the road traffic in the

study area.

11.4.16 The traffic

population was assumed to be 100% outdoor. The estimated road population in

Year 2033 and Year 2041 are presented in Table

11.2 and Table 11.3, respectively and the detailed calculations are

provided in Appendix 11.2.

Table 11.2 Estimated

Road Population (Year 2033)

|

Population

ID

|

Description

|

Maximum Population [Note 1]

|

|

Daytime

|

Night-time

|

|

R1

|

Lion

Rock Tunnel Road

|

895

|

431

|

|

R2

|

Hung Mui

Kuk Road

|

711

|

341

|

|

R3

|

Chung

Pak Road & Lung Pak Street

|

10

|

8

|

|

R4

|

Fu Kin

Street

|

11

|

9

|

|

R5

|

Slip

road (Lion Rock Tunnel Road to Hung Mui Kuk Road)

|

20

|

15

|

|

R6

|

Slip

road (Hung Mui Kuk Road to Lion Rock Tunnel Road)

|

8

|

8

|

Note 1: Road

population was estimated based on Traffic Impact Assessment forecasted for Year

2034. This was conservatively applied for the assessed scenarios (i.e. Year 2033

– Base Case and Year 2033 – Construction Phase).

Table 11.3 Estimated

Road Population (Year 2041)

|

Population

ID

|

Description

|

Maximum Population [Note 1]

|

|

Daytime

|

Night-time

|

|

R1

|

Lion

Rock Tunnel Road

|

901

|

432

|

|

R2

|

Hung Mui

Kuk Road

|

711

|

341

|

|

R3

|

Chung

Pak Road & Lung Pak Street

|

10

|

8

|

|

R4

|

Fu Kin

Street

|

11

|

9

|

|

R5

|

Slip

road (Lion Rock Tunnel Road to Hung Mui Kuk Road)

|

20

|

15

|

|

R6

|

Slip

road (Hung Mui Kuk Road to Lion Rock Tunnel Road)

|

8

|

8

|

Note 1: Road

population was estimated based on Traffic Impact Assessment forecasted for Year

2041 and this was applied for Year 2041 – Operation Phase.

Time Modes

and Occupancies of Population Groups

11.4.17 Four

representative time modes were identified to address the variations in levels

of activities that could lead to a release and the variation in population in

the study area with time. Table 11.4 shows the time periods used in the

study. Furthermore, the assumptions of the occupancy rate for these specified

time modes including the indoor ratio considered for various population groups

are summarized in Table 11.5.

Table 11.4 Definitions

of Time Modes

|

Time

Period

|

Definition

|

Proportion of Time

|

|

Weekday

Day

|

Mon-Fri,

7am-7pm

|

35.71%

|

|

Weekday Night

|

Mon-Fri, 7pm – 7am

|

35.71%

|

|

Weekend Day

|

Sat-Sun, 7am-7pm

|

14.29%

|

|

Weekend Night

|

Sat-Sun, 7pm – 7am

|

14.29%

|

Table 11.5 Occupancies

of Population Groups at Different Time Modes

|

Population

Group

|

Percentage of Occupancy at Different Time Modes

|

Indoor Ratio

|

|

Weekday (Day)

|

Weekday

(Night)

|

Weekend (Day)

|

Weekend

(Night)

|

|

Residential

|

50%

|

100%

|

70%

|

100%

|

95%

|

|

School

|

100%

|

0%

|

0%

|

0%

|

95%

|

|

Proposed

Project Works Area

|

100%

|

0%

|

50%

|

0%

|

0%

|

|

Lion Rock

Tunnel Road/ Hung Mui Kuk Road

|

100%

|

50%

|

100%

|

50%

|

0%

|

|

Chung Pak

Road & Lung Pak Street/ Fu Kin Street/ Slip road (Lion Rock Tunnel Road

to Hung Mui Kuk Road)

|

100%

|

80%

|

100%

|

80%

|

0%

|

|

Slip road

(Hung Mui Kuk Road to Lion Rock Tunnel Road)

|

100%

|

100%

|

100%

|

100%

|

0%

|

11.5.1 Meteorological

data is required for consequence modelling and risk calculation. Consequence

modelling (dispersion modelling) requires wind speed and stability class to

determine the degree of turbulent mixing potential whereas risk calculation

requires wind-rose frequencies for each combination of wind speed and stability

class.

11.5.2 Meteorological

data was obtained from Sha Tin Weather Station (2019) where wind speed,

stability class, weather class and wind direction are available. This data

represents the weather conditions for the whole year in 2019 and has already

taken into account of seasonal variations and is therefore considered

applicable for the assessment. Table 11.6 shows the wind

speed-stability frequencies.

Table 11.6 Stability

Category-Wind Speed Frequencies at Sha Tin Station

|

Daytime

|

|

Wind

Speed (m/s)

|

A

|

B

|

C

|

D

|

E

|

F

|

Total

(%)

|

|

0.0-1.9

|

10.41

|

6.96

|

0.00

|

9.47

|

0.00

|

11.99

|

38.83

|

|

2.0-3.9

|

7.69

|

18.85

|

8.33

|

9.84

|

4.38

|

0.73

|

49.82

|

|

4.0-5.9

|

0.00

|

4.75

|

3.38

|

2.31

|

0.11

|

0.00

|

10.55

|

|

6.0-7.9

|

0.00

|

0.00

|

0.21

|

0.57

|

0.00

|

0.00

|

0.78

|

|

Over 8.0

|

0.00

|

0.00

|

0.02

|

0.00

|

0.00

|

0.00

|

0.02

|

|

All (%)

|

18.10

|

30.56

|

11.94

|

22.19

|

4.49

|

12.72

|

100.00

|

|

Night-time

|

|

Wind

Speed (m/s)

|

A

|

B

|

C

|

D

|

E

|

F

|

Total

(%)

|

|

0.0-1.9

|

0.00

|

0.00

|

0.00

|

2.24

|

0.00

|

63.72

|

65.96

|

|

2.0-3.9

|

0.00

|

0.00

|

0.00

|

8.84

|

17.21

|

3.26

|

29.31

|

|

4.0-5.9

|

0.00

|

0.00

|

0.00

|

4.25

|

0.34

|

0.00

|

4.59

|

|

6.0-7.9

|

0.00

|

0.00

|

0.00

|

0.14

|

0.00

|

0.00

|

0.14

|

|

Over 8.0

|

0.00

|

0.00

|

0.00

|

0.00

|

0.00

|

0.00

|

0.00

|

|

All (%)

|

0.00

|

0.00

|

0.00

|

15.47

|

17.55

|

66.98

|

100.00

|

11.5.3 According

to Table 11.6, 6 combinations (2B, 1D, 3D, 6D, 2E and 1F)

and 5 combinations (1D, 4D, 6D, 2E and 1F)

of wind speed and stability class were chosen for daytime and night-time

meteorological conditions, respectively. These combinations are considered

adequate to reflect the full range of observed variations in these quantities. It

is not necessary and efficient to consider every combination observed. The

principle is to group these combinations into representative weather classes that

together cover all conditions observed.

11.5.4 Once

the weather classes have been selected, frequencies for each wind direction for

each weather class can then be determined. The frequency distributions for the

daytime and night-time meteorological conditions are summarized in Table 11.7.

Table 11.7 Weather

Class-Wind Direction Frequencies at Sha Tin Station

|

Daytime

|

|

Direction

|

2B

|

1D

|

3D

|

6D

|

2E

|

1F

|

Total (%)

|

|

0 – 30

|

5.21

|

1.05

|

2.52

|

0.00

|

1.78

|

1.21

|

11.77

|

|

30 – 60

|

13.45

|

1.05

|

4.47

|

0.05

|

1.28

|

1.07

|

21.37

|

|

60 – 90

|

5.66

|

1.31

|

3.14

|

0.12

|

1.05

|

1.69

|

12.97

|

|

90 – 120

|

6.70

|

1.02

|

4.11

|

0.00

|

1.59

|

1.31

|

14.73

|

|

120 – 150

|

5.23

|

0.40

|

2.81

|

0.02

|

0.86

|

0.38

|

9.70

|

|

150 – 180

|

1.12

|

0.14

|

0.67

|

0.00

|

0.17

|

0.21

|

2.31

|

|

180 – 210

|

1.26

|

0.24

|

0.78

|

0.00

|

0.31

|

0.52

|

3.11

|

|

210 – 240

|

7.42

|

0.29

|

6.51

|

1.50

|

0.78

|

0.43

|

16.93

|

|

240 – 270

|

2.54

|

0.24

|

1.66

|

0.19

|

0.38

|

0.21

|

5.22

|

|

270 – 300

|

0.26

|

0.10

|

0.07

|

0.00

|

0.00

|

0.10

|

0.53

|

|

300 – 330

|

0.02

|

0.05

|

0.00

|

0.00

|

0.00

|

0.24

|

0.31

|

|

330 – 360

|

0.45

|

0.19

|

0.07

|

0.00

|

0.05

|

0.29

|

1.05

|

|

All (%)

|

49.32

|

6.08

|

26.81

|

1.88

|

8.25

|

7.66

|

100.00

|

|

Night-time

|

|

Direction

|

1D

|

4D

|

6D

|

2E

|

1F

|

Total

(%)

|

|

0 – 30

|

0.50

|

1.09

|

0.00

|

5.04

|

6.22

|

12.85

|

|

30 – 60

|

0.30

|

1.86

|

0.02

|

5.59

|

6.10

|

13.87

|

|

60 – 90

|

0.17

|

1.99

|

0.02

|

5.14

|

8.86

|

16.18

|

|

90 – 120

|

0.15

|

1.34

|

0.00

|

5.84

|

6.12

|

13.45

|

|

120 – 150

|

0.10

|

0.82

|

0.00

|

3.06

|

4.80

|

8.78

|

|

150 – 180

|

0.00

|

0.30

|

0.05

|

0.84

|

3.80

|

4.99

|

|

180 – 210

|

0.02

|

0.12

|

0.00

|

0.92

|

3.31

|

4.37

|

|

210 – 240

|

0.00

|

4.90

|

0.22

|

5.34

|

2.29

|

12.75

|

|

240 – 270

|

0.05

|

2.16

|

0.02

|

2.34

|

1.64

|

6.21

|

|

270 – 300

|

0.05

|

0.00

|

0.00

|

0.15

|

1.69

|

1.89

|

|

300 – 330

|

0.07

|

0.00

|

0.00

|

0.02

|

1.37

|

1.46

|

|

330 – 360

|

0.17

|

0.00

|

0.00

|

0.32

|

2.71

|

3.20

|

|

All (%)

|

1.58

|

14.58

|

0.33

|

34.60

|

48.91

|

100.00

|

Introduction

11.6.1 A

hazard is described as the property of a material or activity with the

potential to do harm. A release of flammable gas such as LPG has the potential

to cause fire or explosion if ignited. Without ignition, the gas vapour will

disperse harmlessly. Under normal conditions, the LPG at the existing LPG

Compound will be stored and handled under contained and controlled manners. For

LPG to pose a hazard to the people in the surrounding area, a release must

occur as a result of a failure of that containment or as a result of faulty

transfer procedures.

11.6.2 This

section of the report summarizes all possible failure cases and associated

failure rates that could lead to a release of LPG. The failure rates adopted

throughout this report are quoted in the paper on “Quantitative Risk Assessment

Methodology for LPG Installations (Reeves, Minah and Chow, 1997)” [4]. Furthermore,

reference for certain frequencies are drawn from approved EIA Reports [5][6]

and QRA studies [7][8] where necessary and appropriate. In addition, possible

initiating events are identified.

Behaviour of LPG Releases

11.6.3 LPG

is a mixture of butane and propane. The gas is twice as heavy as air. For a

release of LPG, the nature of the combustion will depend on the timing of

ignition and the size of the release.

11.6.4 A

release of several tonnes of LPG, if ignited immediately, will produce a

fireball. Initially, the gas concentration in the mixture will be above the

Upper Flammability Limit (UFL). As burning occurs around the edges of the

release, this will entrain more air into the mixture and more combustion will

take place. The process accelerates until the mixture rising above the ground

as a ball of fire. A fireball may also result from a boiling liquid expanding

vapour explosion (BLEVE). This results from the bursting of a vessel (owing to

a high internal pressure and a weakening of the vessel material, as a result of

a fire for example). The vessel contents rapidly vaporize and are ignited.

11.6.5 If

not ignited immediately, the gas will disperse and dilute. If ignition occurs

when the gas concentration is between the lower Flammability Limit (LFL) and the

Upper Flammability Limit (UFL), a flame front will propagate to produce a flash

fire.

11.6.6 For

small releases, immediate ignition will produce a long vigorous jet flame from

the point of release. As for large releases, delayed ignition will generally

produce a flash fire.

11.6.7 For

all sizes of release, the LPG will disperse harmlessly if there is no source of

ignition.

Hazard

Analysis

Spontaneous Failures

Failure of Storage Vessel

11.6.8 Failure

of a vessel can be resulted from (i) a cold catastrophic failure leading to

instantaneous release of the full inventory and (ii) a partial failure leading

to continuous release of the full inventory via a 25mm hole. The causes of

failure are summarized as follows:

(a)

Spontaneous

failure due to corrosion, fatigue, etc.

(b)

Overfilling

(c)

Earthquake

Failure of Road Tanker

Guillotine Failure of Liquid

Filling Line to Storage Vessel

11.6.10 Failure of the

liquid line is possible as a result of corrosion or fatigue, vehicle impact and

external events. Only guillotine failure of the LPG pipework is considered in

this study as partial failure of pipework is deemed as an insignificant

contributor towards the overall risk levels. The failure would result in LPG

leaking from the full bore of the pipe. Moreover, part of the pipework is

installed aboveground. Failure of the aboveground portion of the liquid

filling line can result from vehicle impact while failure of the underground

portion of the liquid filling line can result from earthquake.

Guillotine Failure of Liquid

Supply Line to Vaporizers

11.6.11 The liquid

supply line connects the underground storage vessel and vaporizers. Failure of

the liquid line is possible as a result of corrosion or fatigue, vehicle impact

and external events. Only guillotine failure of the LPG pipework is considered

in this study as partial failure of pipework is an insignificant contributor to

the overall risk levels. The failure would result in LPG leaking from the full

bore of the pipe. Since the pipework is protected by fencing, vehicle impact is

not considered credible. However, failure of the liquid line can result from

earthquakes.

Failure of Vaporizers

11.6.12 Two units

of vaporizers are installed at the LPG Compound. Each vaporizer can convert

LPG to gaseous fuel at the maximum capacity of 0.15 tonnes / hour. Apart from

spontaneous failure and loading failure, failure of the vaporizers can result

from earthquakes and aircraft crashes.

Guillotine Failure of Liquid

Line from Tanker Pipe to Loading Hose

11.6.13 The cause

of failure of this line is similar to that of the liquid filling line to the storage

vessel, namely mainly corrosion or fatigue. Moreover, the failure can be due

to vehicle impact and other external events.

Failure of Flexible Hose

11.6.14 The loading

hose could fail due to the following causes:

(a)

Fatigue

(b)

Hose

misconnection

(c)

Hose

disconnection during loading or unloading process

(d)

Operator

/ driver error

Loading / Unloading Failures

11.6.15 When LPG

releases occur as a direct result of the road tanker unloading operation, the

failure events can be regarded as loading failures. The failure events that

were considered in the study include:

(a)

Hose

misconnection and disconnection error

(b)

Tanker

drive away error

(c)

Road

tanker collision

(d)

Vehicle

impact with road tanker during unloading

(e)

Storage

vessel overfilling

(f)

Over-pressurization

of pipework.

Hose Misconnection and

Disconnection Error

11.6.16 A

significant release of LPG during its transfer from road tanker to storage

vessel could occur as a result of the failure of the transfer hoses and

coupling, human error, or vehicle impact.

Tanker Drive away Error

11.6.17 This error

could result from: (i) repositioning of the road tanker during delivery; and/or

(ii) the driver driving the road tanker away before the delivery is completed. Since

the LPG road tankers are to be parked uphill during the unloading operation,

wheel-stoppers will be applied as an additional precautionary measure to

prevent the road tankers from rolling backwards in case the conventional

parking brake malfunctions.

Road Tanker Collision

11.6.18 Road tanker

collision refers to an event in which an LPG road tanker strikes the facilities

of the LPG Compound and causes damages to these facilities. There is no

dedicated road tanker parking area and unloading area within the LPG Compound

due to the site constraint and the LPG road tanker parked outside the LPG

Compound during the LPG unloading operation. However, speed control and

well-adopted training system are safety measures commonly adopted to avoid

serious collision incidents. The probability of minor impact of the road tanker

with sufficient energy to cause damage of its vessel (either rupture or

leakage) mounted on the tanker is considered to be insignificant. The LPG

facilities such as LPG storage vessels, vaporizers and pipework would not be

affected by this event since they are installed within the LPG Compound.

Vehicle Impact with Road

Tanker during Unloading

11.6.19 Dedicated

road tanker parking area and unloading area is unavailable within the LPG

Compound and the LPG road tankers park on the public road outside the LPG

Compound. Safety precaution measures including safety cones and warning signs

will be provided to warn other road users during unloading operation. Although

the driver / assistant will monitor the road condition and signal will be

provided on the road during the LPG unloading operation, there is a possibility

that a vehicle collides with the road tanker during unloading operation leading

to LPG release.

Storage Vessel Overfilling

11.6.20 Failure of the

LPG storage vessel could occur as a result of overfilling of LPG from the road

tanker to the vessel.

Over-pressurization of

Pipework

11.6.21 Over-pressurization

could be caused by continuing unloading operation when a storage vessel is

overfilled or the isolation valves at the receiving storage vessel are closed.

External Events

11.6.22 A LPG release

event could occur as a result of external events and the consequences could be

catastrophic. The related external events are listed as follows:

(a)

Earthquake

(b)

Aircraft

crash

(c)

Landslide

(d)

Severe

environmental event such as typhoon or tsunami and subsequent outcomes such as

falling trees

(e)

Subsidence

(f)

Lightning

(g)

High

wind loading

Earthquake

11.6.23 According

to Reeves et al. (1997) [4], an earthquake of Modified Mercalli Intensity (MMI)

VIII could provide enough intensity to result in damage to the storage vessel

or pipework. Therefore, earthquake was considered in this study.

Aircraft Crash

11.6.24 Aircrafts

crashing into the LPG Compound due to take-off and landing as well as arrival/

departure flight paths were accounted for in this study. The method given in

HSE (1997) [10] for the calculation of aircraft crash frequency was adopted.

Landslide

11.6.25 The LPG

Compound is not situated near any natural terrain, there is a 2m high cut slope

located on the north-west boundary of the LPG Compound. The cut slope has been

protected with 100% shotcrete that landslide is not anticipated. Therefore,

this external event was not further considered in this study.

Severe environmental event

11.6.26 According to

BDEIA [5], loss of LPG content owing to severe environmental events such as

typhoon or tsunami (i.e. a tidal wave following an earthquake) was considered

to be insignificant as the installation of LPG vessels is situated underground

and away from the seashore. The Super Typhoon Mangkhut is one of the strongest

storms attacking Hong Kong in recent years. It struck the Pearl River Estuary

on 16 September 2018 and resulted in severe disasters in Hong Kong. Heavy

rain, storm surge and high waves caused serious flooding in many coastal and

low-lying areas and there were more than 60,000 reports of fallen trees, the

highest number on record [9]. There is a tree sitting on the northern

boundary of the LPG Compound, separated by a 2m boundary fence. Further, the

LPG vessels are located underground and the vaporizers are sheltered inside a

concrete structure, the probability of fallen trees damaging the LPG facilities

in the LPG Compound was considered to be minimal.

Subsidence

11.6.27 Subsidence

is usually slow in movement and such movement can be observed and remedial

action can be taken in time. Therefore, the probabilities of severe

environmental events and subsidence are very small or negligible and such

external events were not further considered in this study.

Lightning and High wind

loading

11.6.28 The LPG

Compound is surrounded by tall buildings that shield the LPG Compound from

damage by high winds. Also, lightning is more likely to strike the tall

structures. Frequency of high winds damaging the LPG Compound and lightning

strike on the LPG Compound was assumed to be less than the credible frequency

of 1×10-9 per year. A LPG release due to high wind and lightning was

therefore not further assessed in this study.

Safety Features

11.6.29 Safety

features installed in the facilities of the LPG Compound can act in different

combination to mitigate LPG releases. The safety features considered in this

study are listed as follows:

(a)

Non-return

valve

(b)

Excess

flow valve

(c)

Emergency

shutdown system

(d)

Breakaway

coupling

(e)

Manual

isolation system

(f)

Double-check

filler valve

(g)

Relief

valve

Non-return Valve

11.6.30 Non-return

valve on the liquid filling line can isolate release immediately. If it

functions properly, there will be no significant consequence.

Excess Flow Valve

11.6.31 Excess flow

valve installed at the road tanker and the storage vessel is expected to

mitigate a release from guillotine failure of the pipework or the flexible

filling hose.

Emergency Shutdown System

11.6.32 An

Emergency Shutdown (ESD) system is installed on both the road tankers and the

storage vessels. For a release from a road tanker, the emergency isolation

system and engine emergency stop system can be activated to isolate the release

due to equipment failure and human error. For a release from the vessels, the emergency

isolation system can be triggered to prevent a release on the filling line or downstream

of the hose connection.

Breakaway Coupling

11.6.33 There is a

possibility of road tankers being driven away whilst the hose is still

connected, thereby causing damage to the facilities of the LPG Compound and

resulting in the release of LPG. The breakaway coupling is installed to

prevent undue spillage of LPG owing to the movement of road tankers.

Manual Isolation System

11.6.34 A manual

valve is installed for the operators / drivers to shut off the delivery

connection manually in case of failure.

Double-check Filler Valve

11.6.35 Double-check

filler valve is provided at the hose connection point on the liquid filling

line to prevent release to be fed back from the vessel. The design of this

valve is essentially 2 non-return valves in series.

Relief Valve

11.6.36 Relief

valve is employed to ensure that the vessel is not subjected to an excessive

internal pressure that may cause a failure as a result of overfilling. It also offers

protection against excessive pressure build-up within the vessel in case of

fire.

Human Error

11.6.37 When a failure

of equipment or loading process occurs, it is possible for the operator to

rectify the problem before a hazard event occurs. Human error is regarded as a

failure case if the operator fails to rectify the problem.

Fire Protection / Fighting System

Chartek Coating

11.6.38 Chartek

coating is a safety feature of all road tankers. The coating has been reported

to provide protection for at least 30 minutes in the case of a jet fire. The

coating could prevent a hot spot from developing in a jet fire attack on the

road tanker, which can cause thermal weakening of the road tanker wall leading

to BLEVE.

Water Spray System

11.6.39 There is no

water spray system installed at the LPG Compound. No provision for fire

services installation for controlling road tanker fires or lowering the

temperature of fires to avoid BLEVE was applied.

Fire Service

11.6.40 The fire

services will be available within a few minutes in case of a fire. The extinction

of fire by fire fighters prevents BLEVE from occurring.

Escalation

11.6.41 BLEVE of a

LPG road tanker can happen if the road tanker is impinged by jet fire from the aboveground

LPG facilities listed below:

(a)

Cold

partial failure of road tanker

(b)

Guillotine

failure of liquid filling line to vessel

(c)

Guillotine

failure of liquid supply line to vaporizer

(d)

Flexible

hose during loading to storage vessel

(e)

Liquid

line from tanker to loading hose

(f)

Vaporizer

failure

Summary

11.6.42 The possible

hazard events for the day-to-day operation of the LPG Compound have been

identified and reviewed in previous section. Only those possible failure cases

considered to have the potential to cause off-site fatality are summarized in Table 11.8.

Table 11.8 Identified

Failure Case of the LPG Compound

|

Failure Types

|

Failure Cases

|

|

Spontaneous

Failure of Pressurized LPG Equipment

|

· Storage Vessel

Failure

· Road

Tanker Failure

· Pipework

Failure

· Hose

Failure

· Vaporizer

Failure

|

|

External

Event

|

· Earthquake

MMI VIII

· Aircraft

Crash

|

|

Delivery

Failure

|

· Hose

Misconnection Error

· Hose

Disconnection Error

· Tanker

Drive-away Error

· Road

Tanker Collision during Unloading

· Vehicle

Impact with Road Tanker during Unloading

· Storage

Vessel Overfilling

· Over-pressurization

of pipework

|

|

Safety

System Failure

|

· Pressure

Relief Valve Failure

· Non-return

Valve Failure

· Excess

Flow Valve Failure

· Emergency

Shutdown System Failure

· Double-check

Filler Valve Failure

· Breakaway

Coupling Failure

· Human

Error

· Manual

Isolation Valve Failure

|

|

Fire

Fighting System Failure

|

· Fire

Services Failure

· Chartek

Coating Failure

|

Introduction

11.7.1 Subsequent

to the Hazard Identification and Analysis, the next step is to estimate the

likelihoods of various LPG release scenarios. There are combinations of hazard

initiating events, as identified in previous section, which would lead to a LPG

release.

11.7.2 Fault

Tree Analysis (FTA) permits the hazardous incident (“Significant Failure

Events”) frequency to be estimated from a logical model of the failure

mechanisms of a system. The model is based on the combinations of failures of

more basic components, safety systems and human errors.

11.7.3 FTA

is the use of a combination of simple logic gates, “AND” and “OR” gates, to

synthesize a failure model of the hazardous installation. The “Significant

Failure Events” frequency is calculated from failure data of more simple

events.

11.7.4 A

basic assumption in FTA is that all failures in a system are binary in nature,

a component or operator either performs successfully or fails completely. In

addition, the system is assumed to be functioning if all sub-components are

operating properly.

11.7.5 The

stepwise procedure for undertaking FTA is presented below:

(a)

Hazard

identification and selection of the “Significant Failure Events”

(b)

Construction

of fault tree

(c)

Quantitative

evaluation of the fault tree

Frequency Estimation

Spontaneous Failure of Pressurized LPG Equipment

Storage Vessel Failure

11.7.6 A

release of LPG could occur as a result of catastrophic failure or partial

failure of the storage vessel and such a failure would lead to either a loss of

entire contents of the vessel or a continuous release of LPG to atmosphere.

11.7.7 Generic

failure rates of 1.8×10-7 per vessel year [4] and 5.0×10-6

per vessel year [4] were adopted for cold catastrophic failure and cold partial

failure, respectively.

11.7.8 The

service life of both storage vessels will exceed 20 years by 2018 and 2031

respectively. Considering the assessment year for base case is 2033, a corrosion

modification factor of 2 is applied to account for the age of vessels [4] for

all hazard scenarios.

Road Tanker Failure

11.7.9 As

discussed in Section 11.6.9, the definitions of catastrophic and partial

failures are similar to those of the storage vessel. It is generally

considered that catastrophic failure rate for LPG road tankers could be higher

than for a fixed storage vessel because of a) stresses experienced by the road

tanker due to vibration during transportation; and b) cyclic loading associated

with filling/unloading the road tanker.

11.7.10 Failure

rates of 2.0×10-6 per tanker year [4] and 5.0×10-6 per

tanker year [4] were adopted for catastrophic tanker failure and partial

failure of road tanker, respectively.

Pipework Failure

Vaporizer Failure

11.7.12 The effect

of partial failure of the vaporizer is ignored. A generic guillotine failure

rate of the vaporizer coil was taken to be 1.0×10-6 per meter per

year [4].

Hose Failure

External Events

Earthquake MMI VIII

11.7.14 The

probability of 1.0×10-5 per year was adopted for the occurrence of an

MMI VIII earthquake. The failure rate of pipework and partial failure of

underground vessel owing to earthquakes was assumed to be 0.01 [5], whereas the

probability of failure for road tanker was considered to be zero.

Aircraft Crash

11.7.15 The distance between the

nearest arrival flight path for the Hong Kong International Airport (HKIA) and

the LPG Compound is approximately 2.1km. The distance between the LPG

Compound and HKIA is about 26km, which exceeds the criteria of 5 miles (8 km)

for the consideration of airfield accident. At such distances, the LPG

Compound does not come into the flight paths of the critical takeoff and

landing phases, and therefore only the background crash rate and airway crash

rate were accounted for. The frequency of aircraft crash was estimated using

the methodology of the HSE (1997) [10]. The model took into account specific

factors such as the target area of the LPG Compound and the distance between

the LPG Compound and the runway threshold. The aircraft crash frequency per

year was calculated as:

Frequency (per year) = Background Crash Rate +

Airway Crash Rate

Frequency (per year) = (A x Bi )+ (A x Ni

x Ri x afac/ alt)

Where

A = Area of the LPG Compound (8.3×10-5 km2)

N = Number of aircraft movements per year

Bi = Background crash rate for aircraft (2×10-6

per year per km2 [10])

Ri = Aircraft in-flight reliability (4.7×10-11

per year per km per aircraft movement [10])

afac = Area factor obtained from Table 9 of UK HSE

report [10]

Alt = Mean altitude of aircraft (5 km)

11.7.16 The area

factor (afac) is defined as the probability of a crash at a given location

relative to the airway. With reference to Table 9 of UK HSE report [10], afac

of 0.37 was adopted based on the corresponding x1 of 0.42, as estimated from

the below equation:

x1 = x/ alt

Where

x = Minimum horizontal distance from the nearest

flight path to the LPG Compound (2.1km)

Alt = Mean altitude of aircraft (5 km)

Loading / Unloading Failures

Hose Misconnection Error

11.7.18 A

significant release of LPG during its transfer from the road tanker to the storage

vessel could occur as a result of failure of the transfer hoses and coupling,

human error, or vehicle impact. The likelihood of such an event was taken as

3×10-5 per operation [4].

Hose Disconnection Error

11.7.19 A failure

rate of 2.0×10-6 per operation [4] was adopted for this failure case.

Tanker Drive-away Error

11.7.20 Tanker

drive-away error refers to an event in which the tanker moves away with the

hose still connected. It could result from the tanker driver inadvertent driving

the vehicle away before delivery is completed. It was considered that

drive-away is unlikely. Even if such error do occur, it is highly likely that

the failure can be immediately rectified since the delivery process would not

go unattended. A failure rate of 4.0×10-6 per operation [4] was adopted.

Tanker Collision during

Unloading

11.7.21 A release

of LPG cloud occurs as a result of an incident involving an LPG tanker and LPG

equipment during delivery. The failure rate of tanker impact during unloading was

assumed to be 1.5×10-4 per delivery [4].

Vehicle Impact with Road

Tanker during Unloading

11.7.22 A rate of

1×10-8 per operation [4] was adopted for the case that a vehicle

impact into road tanker during unloading.

Overfilling of Storage Vessel

11.7.23 The

practice on-site in unloading LPG to the storage vessel is that the vessel will

only be filled to 85% of its maximum capacity. It was considered that the

probability of the driver overfilling a storage vessel is low. A rate of

2.0×10-2 per operation [4] was adopted for this failure case.

Over-pressurization of

Pipework

11.7.24 This event

has been taken into account by pipework and hose failure data in Sections 11.7.11 and 11.7.13. Hence, it was not considered separately in the

assessment.

Safety System Failure

11.7.25 If the

safety system operates as designed then releases would not present an off-site

hazard. There is, however, potential for failure of the safety system. The typical

safety systems involve pressure relief valve, non-return valve, excess flow

valve, emergency shutdown system, breakaway coupling and double-check filler

valve.

Pressure Relief Valve Failure

11.7.26 The pressure

relief valve avoids the LPG pipework or underground storage vessels from

getting overpressure. A generic failure of 1×10-4 [4] for the pressure

relief valve per demand was adopted.

Pump Overpressure Protection

System

11.7.27 Such system

is installed on LPG road tankers to control the maximum outlet pressure of the

pump. In addition to the internal pump overpressure by-pass, the pump or

adjacent pipework is fitted with a separate by-pass valve that set at a lower

differential pressure to automatically carry any excess liquid back to the road

tanker vessel when the delivery valve is closed.

11.7.28 A generic

failure of pump overpressure protection system of 1×10-4 per demand

[4] was adopted.

Non-return Valve Failure

11.7.29 The non-return

valve is intended to prevent back flow of LPG. A generic failure rate of 0.013

per demand [4] was adopted.

Excess Flow Valve Failure

11.7.30 The excess

flow valve installed at the road tanker and the storage vessel is expected to

be functional when guillotine failure of pipework or flexible hose occurs. A

generic failure rate of 0.13 per demand [4] was adopted for the line to

vaporizer.

Emergency Shutdown System

Failure

11.7.31 A generic

failure rate of 1.0×10-4 per demand [4] was assumed.

Breakaway Coupling Failure

11.7.32 A generic

failure rate of 0.013 per demand [4] was adopted for the road tanker.

Double-check Filler Valve

Failure

11.7.33 A

double-check filler valve prevents the LPG release to be fed back from the

storage vessel. The design has two non-return valves in series. A generic

failure rate of 2.6×10-3 per demand [4] for common mode failure was

adopted.

Manual Isolation Valve

11.7.34 Manual

valve is installed for operators / drivers’ intervention in case of failure.

11.7.35 A generic

failure rate of 0.5 per demand [4] was adopted.

Human error

11.7.36 A probability

of 1.5×10-3 per demand was assumed to account for the human error in

which the operators fail to rectify the problem before any hazard event occurs.

Fire Fighting System Failure

Water Spray System Failure

11.7.37 Water Spray

System is not installed on site.

Failure of Fire Services

11.7.38 It was assumed

that the Fire Services would always be available, and therefore zero

probability was applied for the failure of “fire services arrive late”. A

generic failure rate of 0.5 per demand [4] was assumed for the fire services to

be ineffective against a fire attack.

Chartek Coating Failure

11.7.39 A generic

failure rate of 0.1 per demand [4] was applied for Chartek coating fails to

prevent a hot spot from developing on the road tanker in a jet fire attack owing

to poor maintenance.

11.7.40 A summary

of the identified failure cases and their associated failure rates adopted are

presented in Table 11.9.

Table 11.9 Summary

of Identified Failure Cases and Their Associated Failure Rates

|

Failure Cases

|

Failure Rates

|

Reference Source

|

|

Spontaneous Failure of Pressurized LPG

Equipment

|

|

Catastrophic Failure

of Storage Vessel

|

1.8×10-7 per vessel year

|

Reference [4]

|

|

Partial Failure of Storage Vessel

|

5.0×10-6 per vessel year

|

Reference [4]

|

|

Catastrophic Failure of Road Tanker

|

2.0×10-6 per tanker year

|

Reference [4]

|

|

Partial Failure of Road Tanker

|

5.0×10-6 per tanker year

|

Reference [4]

|

|

Guillotine Failure of Pipework

|

1.0×10-6 per meter per year

|

Reference [4]

|

|

Vaporizer Failure

|

1.0×10-6 per meter per year

|

Reference [4]

|

|

Hose Failure

|

1.8×10-7 per transfer or

9.0×10-8 per hour

|

Reference [4]

|

|

External Event

|

|

Earthquake MMI VIII

|

1.0×10-5 per year

|

Reference [4]

|

|

Aircraft Crash

|

2.87×10-10 per year

|

Refer to Section 11.7.15 to 11.7.17

|

|

LPG Loading Failure

|

|

Hose Misconnection Failure

|

3.0×10-5 per operation

|

Reference [4]

|

|

Hose Disconnection Failure

|

2.0×10-6 per operation

|

Reference [4]

|

|

Tanker Drive-away Error

|

4.0×10-6 per operation

|

Reference [4]

|

|

Road Tanker Collision

|

1.5×10-4 per operation

|

Reference [4]

|

|

Vehicle Impact into Tanker During

Unloading

|

1.0×10-8 per operation

|

Reference [4]

|

|

Storage Vessel Overfilling

|

2.0×10-2 per operation

|

Reference [4]

|

|

Safety Features Failure

|

|

Pressure Relief Valve Failure

|

1.0×10-4 per demand

|

Reference [4] based on ESD system

|

|

Failure of Pump Over-pressurization Protection

|

1.0×10-4 per demand

|

Based on pressure relief valve

|

|

Non-return Valve Failure

|

0.013 per demand

|

Reference [4]

|

|

Excess Flow Valve Failure

|

1.00 per demand for liquid filling line and flexible hose

0.13 per demand for line to vaporizer

|

Reference [4]

|

|

Manual Isolation Valve Failure

|

0.5 per demand

|

Reference [4]

|

|

Emergency Shutdown System Failure

|

1.0×10-4 per demand

|

Reference [4]

|

|

Breakaway Coupling Failure

|

0.013 per demand for tanker

|

Reference [4] Conservative estimate, based on breakaway

coupling for road tanker

|

|

Double-check Filler Valve Failure

|

2.6×10-3 per demand

|

Reference [4]

|

|

Operator fails to rectify problem

|

1.5×10-3 per demand

|

Reference [3]

|

|

Fire Protection / Fighting System Failure

|

|

Water Spray System Failure

|

1.00 per demand

|

There is no water spray system

|

|

Failure of Fire Services

|

0.5 per demand

|

Reference [4]

|

|

Chartek Coating Failure

|

0.1

|

Reference [4]

|

|

Failure Probability

|

|

Catastrophic failure of vessel provided

over-pressurization

|

0.01

|

Reference [3]

|

|

Partial failure of vessel provided over-pressurization

|

0.1

|

Reference [3]; 10 times of catastrophic failure

|

|

Probability of catastrophic / guillotine failure due to

aircraft crash [Note 1]

|

1

|

Assume 100% failure leading to rupture / guillotine failure

|

|

Probability of partial failure due to aircraft crash [Note

1]

|

0

|

Assume 100% failure leading to rupture / guillotine failure

|

|

Probability of equipment failure due to earthquake

|

0.01

|

Reference [5]

|

|

Probability of catastrophic / partial failure in earthquake

|

0.5 / 0.5

|

It is more likely that an earthquake leads to failure of

pipeline connection rather than vessel failure while washed sand provides

buffering effect to prevent vessel from damages. Pipeline failure has already

been accounted in other hazardous events. Therefore, the 50:50 split is

conservatively adopted in vessel failure events.

|

Note

1: The probability of road tanker rupture and road tanker partial failure

due to aircraft crash are considered as 1 and 0 respectively, which assumes

only catastrophic failure of road tanker will be resulted in the event of

aircraft crash. The probability for storage vessel failure due to aircraft

crash will be significantly less as compared to other equipment since storage

vessels are located underground. Hence, 0.01 and 0.09 are adopted for

catastrophic and partial failure of storage vessels respectively.

Escalation

11.7.41 Escalation

refers to the situation in which a relatively insignificant accident causes an

event with much more significance to occur. This was addressed in this

assessment with the event tree analysis in Appendix 11.3.

Frequency of

Occurrence

Fault Tree Analysis

11.7.42 Fault tree

analysis was used to provide models for the calculation of failure rates or the

probabilities of the hazardous scenarios described in Table

11.10. Sets of fault tree diagrams are attached in Appendix 11.4.

Event Tree Analysis

11.7.43 The event

trees evaluate the hazard event outcomes for the LPG events assessed in this

study and they are shown in Appendix

11.3.

11.7.44 Potential

hazardous event outcomes following an LPG release include BLEVE, fireball, jet fire,

vapour cloud explosion (VCE) and flash fire.

11.7.45 In this

study, it was considered that there are no significant areas of confinement /

congestion to generate the turbulence required for a vapour cloud explosion

upon ignition of a flammable gas cloud. Therefore, the probability of

occurrence of a VCE was assigned a value of 0 for all LPG release events.

11.7.46 The

frequencies of the hazardous outcomes assessed in this study are summarized in Table 11.10.

Risk Mitigation Measure

Identification

11.10.1 The

assessment finding indicated that the risk level associated with the LPG

Compound operation for all the assessed scenarios lies partially within the

“ALARP” region of the risk guidelines. Following the ALARP principle, risk

mitigation measures were proposed for implementation at the Project Site. Cost-benefit

analysis was performed to assess the feasibility of the proposed risk

mitigation measures.

11.10.2 The

proposed risk mitigation measures to be considered include:

·

Installation

of onsite gas detectors at the construction site;

·

Establishment

of emergency response plans;

·

Safety/

emergency response training and drills for all personnel at the construction

site; and

·

Maintain

the number of construction workers onsite to a minimum.

Cost-Benefit Analysis

11.10.3 The cost

effectiveness of the proposed mitigation measure was assessed by Cost-Benefit

Analysis (CBA) using calculation of the Implied Cost of Averting Fatality

(ICAF) for each mitigation measures identified. The ICAF was calculated using

the equation as follows by taking into account the reduction in Potential Loss

of Life (PLL):

|

ICAF =

|

Cost of Mitigation

Measure

|

|

(Reduction in PLL

Value × Design Life of Mitigation Measure)

|

11.10.5 The

aversion factor indicates the level of aversion to accidents causing large

numbers of fatalities [11]. Aversion factor of 20 (Maximum Aversion Factor for

risks at the upper region of the Risk Guidelines) is proposed to adjust the

Value of Life to reflect people’s aversion to high risk. With this factor applied,

the adjusted Value of Life of HK$660M was adopted.

Risk Mitigation Measure

Evaluation

11.10.6 It was assumed

that all onsite construction workers could escape successfully upon detection

of LPG leakage by the gas detectors installed at the construction site. Thus,

the maximum PLL reduction due to successful evacuation of construction workers

for Year 2033 – Construction Phase was found to be 2.87×10-8 per

year.

11.10.7 The cost

for implementing the proposed mitigation measure would be around HK$100,000 and

the design life of the mitigation measure was assumed to be 6 years, which is

equivalent to the tentative duration of the construction period.

11.10.8 The ICAF

for installing the gas detectors for Year 2033 was estimated to be HK$5.82×1011.

Based on the cost-benefit analysis, the proposed mitigation measure to install

gas detectors with PLL reduction of 2.87×10-8 per year was considered

economically unviable since ICAF was found to be significantly larger than the

adjusted Value of Life.

11.10.9 With

consideration of the large separate distance between the LPG Compound and the Project

Site (over 85m), the risk level posed to the populations of the Project would

be insignificant as they are mostly located outside the 1×10-7 per

year contour. The actual risk level posed to an individual would be less than 1×10-7

per year.

11.11.1 Good safety

practices are recommended to further manage and minimize the potential risks

during construction phase of the Project. Regular audit during construction

phase is recommended.

11.12.1 A full quantitative risk

assessment was carried out for the Project Site near the LPG Compound. The

assessment was based on information collected from Census & Statistics

Department, Hong Kong Observatory, Planning Department, Transport Department

and site visits made by the Consultant.

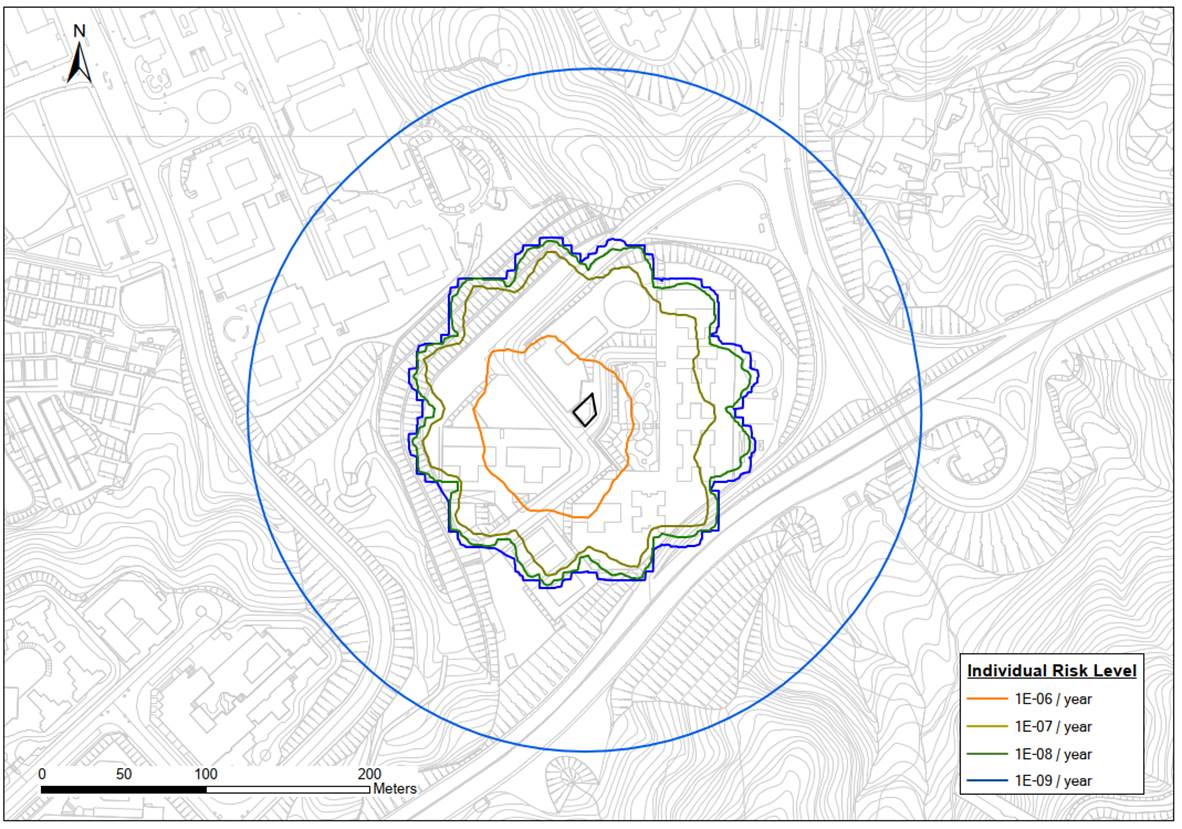

11.12.2 The maximum

individual risk contour of 1×10-6 per year contour extends

approximately 60m from the LPG Compound. Given there is no offsite risk with

frequency greater than 1×10-5 per year, individual risk is

considered acceptable and in compliance with the Hong Kong Risk Guidelines. Part

of the FN curve (i.e. between 3 and 6 fatalities) falls within the “ALARP”

region and this trend is applicable for all assessed scenarios (i.e. Year 2033

– Base Case, Year 2033 – Construction Phase and Year 2041 – Operation Phase). The

total PLLs for all assessed scenarios were found to be about 3.84×10-5

per year and the proposed Project works area accounts for 2.87×10-8 per

year (0.07% of total PLL) during construction phase. Thus, the PLL

contribution to the proposed Project works area as compared with the overall

risk level was considered negligible. Nonetheless, risk mitigation measure,

i.e. installation of gas detectors was proposed following the ALARP principle. Based

on the cost-benefit analysis, the proposed mitigation measure to install gas

detectors with PLL reduction of 2.87×10-8 per year was considered

economically unviable since ICAF (i.e. HK$5.82×1011) was found to be

significantly larger than the adjusted Value of Life (i.e. HK$660M).

11.12.3 Although the

proposed mitigation measure was considered economically unviable for PLL

reduction during construction phase, the following “Good Practices” are

proposed to limit the number of causalities and/ or fatalities:

·

Establishment

of emergency response plans;

·

Safety/

emergency response training and drills for all personnel; and

·

Maintain

the number of construction workers onsite to a minimum.

11.13

References

[1] EMSD (2004). “Code of Practice for Hong Kong LPG Industry -

Module 3 Handling and Transport of LPG in Bulk by Road”, Issue 1, February

2004.

[2] Transport

Department. (September 2020). The Annual Traffic Census 2019.

[3] ERM

(1996). Quantitative Risk Assessment of 18 LPG Installations in Public Housing

Estates: Choi Po Court.

[4] Reeves, A.B., Minah, F.CC. and Chow, V.H.K. (1997).

“Quantitative Risk Assessment Methodology for LPG Installations”, Conference on

Risk & Safety Management in the Gas Industry, EMSD & HKIE, Hong Kong.

[5] Ling

Chan + Partners Limited. (2001). Environmental Impact Assessment for Proposed

Headquarters and Bus Maintenance Depot in Chai Wan (BDEIA) (AEIAR-045/2001).

[6] ERM

(2000). Environmental Impact Assessment for Construction of an International

Theme Park in Penny’s Bay of North Lantau and its Essential Associated

Infrastructures.

[7] MEMCL (2003). Quantitative Risk

Assessment for the Proposed Petrol cum LPG Filling Station at Cornwall Street

[8] Technica

Limited (1989). Tsing Yi Island Risk Assessment. A report prepared for the

Electrical and Mechanical Services Department of Hong Kong Government.

[9] HKO. A Wake Up Call from

Mangkhut.

https://www.hko.gov.hk/en/blog/00000216.htm

[10] Health

and Safety Executives (1997). The Calculation of Aircraft Crash Risk in the UK.

J P Byrne

[11] Health

and Safety Executive (HSE), Application of QRA in Operational Safety Issues,

RR025 (2002).