Pollution Problems & Practical Solutions

Lift System

Noise & Vibration Pollution

Practical Solutions

- Preference should be given to place the lift plant in a plant room with thick walls, sound adsorption materials, sound proof door and silencers for air inlets/outlets

- Locate the lift plant in isolation from residential premises, for example, placing the lift room at rooftop

- Select quiet machine

- Conduct regular maintenance, such as lubricating moving parts, tightening loosen parts, replacing worn-out components and inspecting equipment alignment

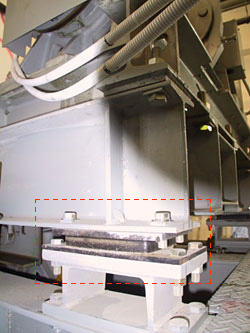

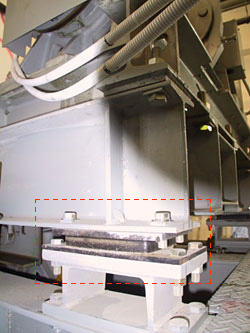

- Use anti-vibration pad or vibration isolator between the vibrating machines and the fixed building structure to avoid structural vibration transmission

|

| Use anti-vibration pad between the vibrating part of the machine and the fixed structure to avoid structural vibration transmission. |

|

- Adopt proper noise control measures for exhaust fans:

- Choose silent type exhaust fan

- Install silencer at the exhaust outlet

- Provide an inertia block with vibration isolators to support the fan

- Provide flexible connectors between the fan and associated ducts

- Seek professional advice from acoustic consultant/contractor