Pumping System

Noise & Vibration Pollution

| Common Causes | Relevant Environmental Control |

|---|---|

| Too close to the nearby sensitive receivers | Under the Noise Control Ordinance, Cap. 400, noise caused by any pumping system at industrial or commercial premises should not cause the noise level at Noise Sensitive Receivers (NSRs) to exceed the limit stipulated under the relevant Technical Memorandum. |

| Inadequate noise pollution control measures |

Practical Solutions

- Place pumpset in a plant room with thick walls, sound adsorption materials, sound proof door and silencers for air inlets/outlets

- Separate the plant room from living and noise sensitive areas by at least one floor of non-noise sensitive zone (e.g. carpark & podium)

- Install barrier, partial enclosure or completed enclosure fitted with silencers at air inlets/outlets for pumpset located in an exposed/outdoor environment

- Locate the equipment away from the nearby and known future NSRs

- Adopt noise control measures for pumpset located near to noise sensitive use areas

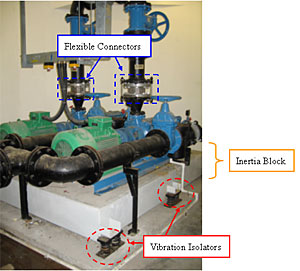

- Pumpset should be isolated from the building structure by the use of inertia blocks and vibration isolators

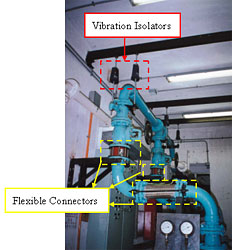

- Provide flexible connectors between the pump and associated pipework to avoid vibration transmission of the pumpset to the pipework

Provide an inertia block, vibration isolators and flexible connectors for the pump set to avoid structural vibration transmission through building structure.

Install isolation pad between fixed structures to avoid structural vibration transmission. - Use vibration isolators for attaching pipes to walls, ceilings or floors

Use vibration isolators and flexible connectors to avoid structural vibration transmission from the pumpsets to the pipes. - Pump pipes that penetrate slabs and walls should be isolated by compressible materials, such as rubber sleeve or glass fibre packing

Line pressure pipes that penetrate building structure with flexible materials, such as expanded polystyrene, to absorb the vibration and avoid structural transmission. - Install pressure reducing valves to regulate water pressure and water flow

- Use pipes with large radius bends to minimize water flow change noise

- Apply pipe lagging to dampen the pipe ringing noise

- Reduce water flow rate or provide air chamber to eliminate water hammering effect

Make reference to the statutory noise limit and include noise levels specification when ordering new equipment

Conduct regular maintenance, check alignment and replace worn-out components

Seek professional advice from acoustic consultant/contractor