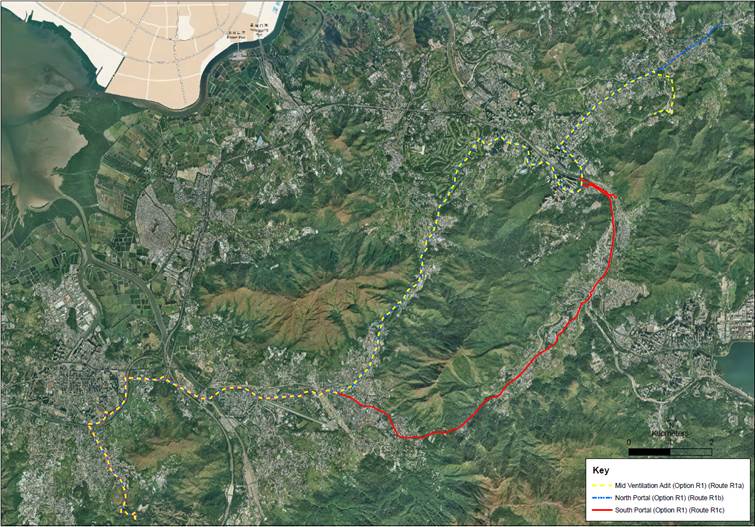

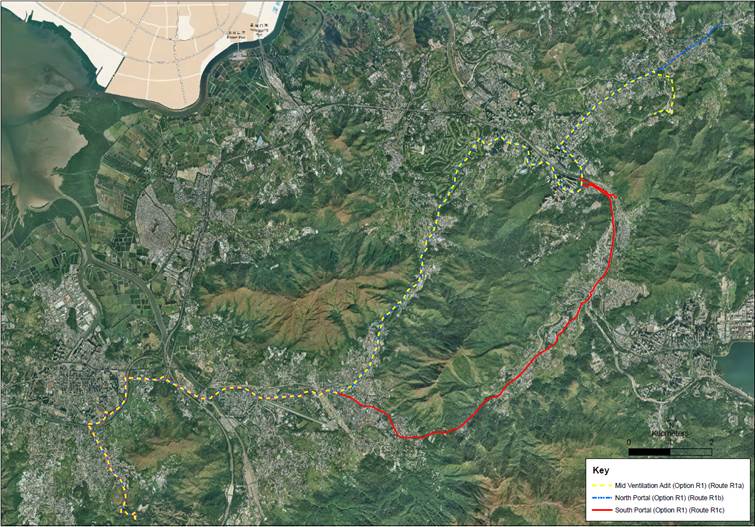

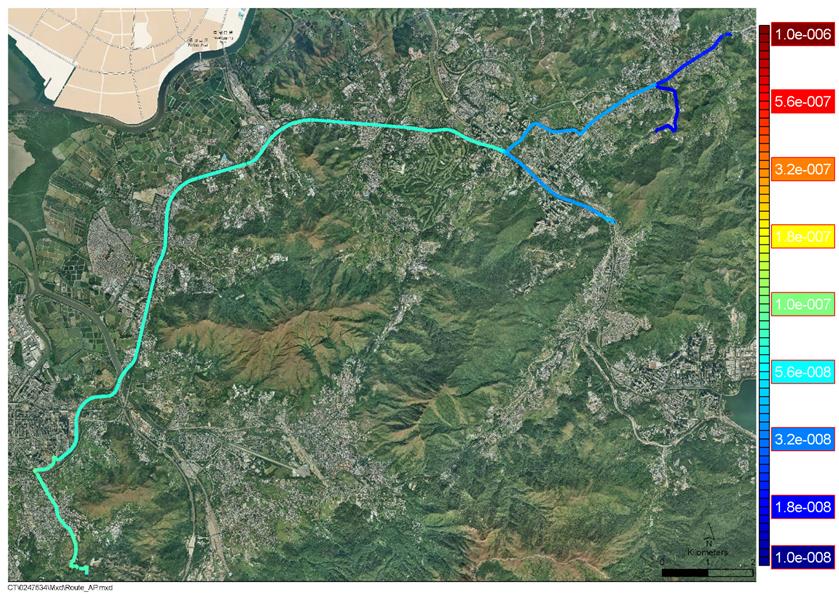

Figure 2.1 Proposed

Explosive Transport Route Option R1

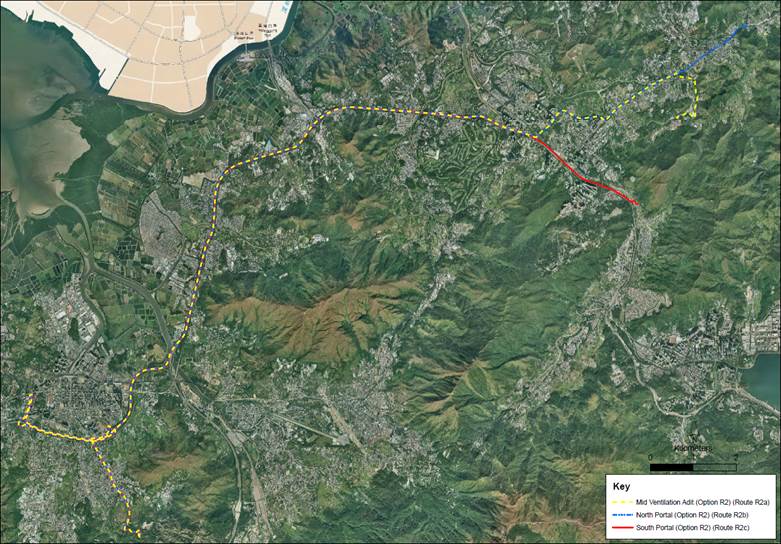

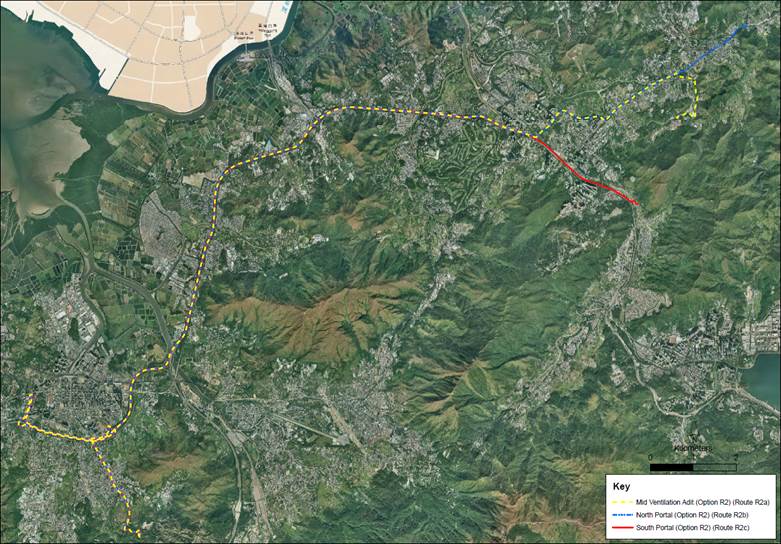

Figure 2.2 Proposed Explosive

Transport Route Option R2

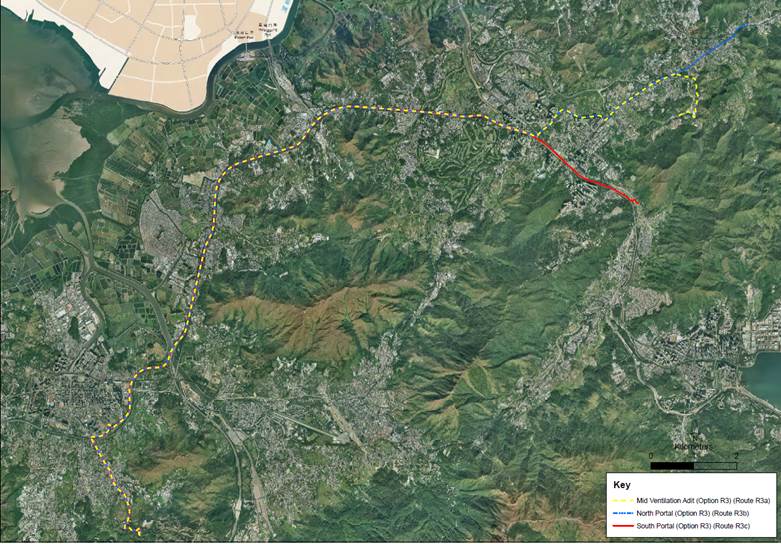

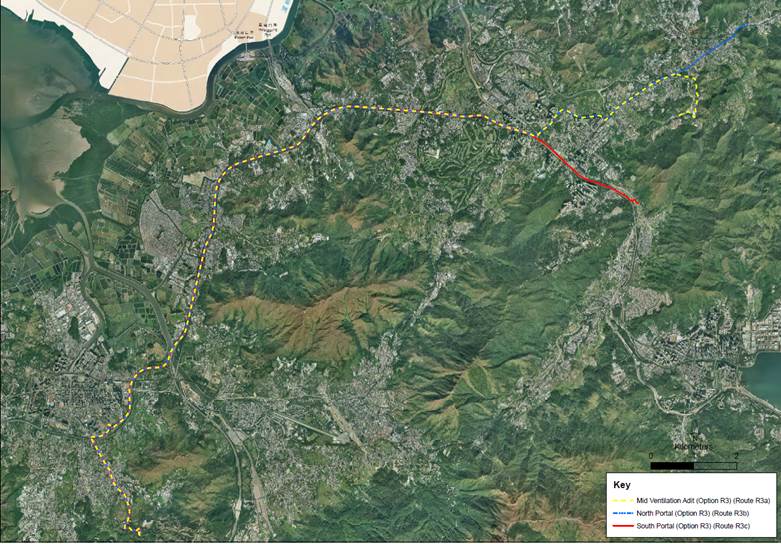

Figure 2.3 Proposed Explosive

Transport Route Option R3

1.1 Background

of the Project

1.2 Purpose

of the EIA

1.3 Scope

of the EIA

1.4 Report

Structure

2.1 Project

Alternatives

2.2 Project

Location

2.3 Project

Schedule

2.4 Description

of Project Facilities, Components and Activities

3 ECOLOGY

3.1 Introduction

3.2 Relevant

Environmental Regulatory Framework

3.3 Baseline

Conditions and Background

3.4 Identification

and Evaluation of Impacts

3.5 Proposed

Mitigation Measures

3.6 Conclusion

and Recommendations

4 AIRBORNE

OPERATIONAL NOISE IMPACT

4.1 Introduction

4.2 Relevant

Environmental Regulatory Framework

4.3 Noise

Sensitive Receiver

4.4 Identification

and Evaluation of Impact

4.5 Conclusion

5.1 Introduction

5.2 Relevant

Environmental Regulatory Framework

5.3 Baseline Conditions

5.4 Study Area and Identification of Air Sensitive

Receivers

5.5 Identification

of Impacts

5.6 Evaluation

of Impacts

5.7 Conclusion

and Recommendations

6.1 Introduction

6.2 Relevant

Environmental Regulatory Framework

6.3 Identification

of Impacts

6.4 Prediction

and Evaluation of Impacts

6.5 Proposed

Mitigation Measures

6.6 Conclusion

and Recommendations

7 OTHER

ENVIRONMENTAL CONSIDERATIONS

7.1 Water

quality

7.2 Landscape

and Visual

7.3 Other

Environmental Media from XRL EIA

7.4 Conclusion

and Recommendations

8.1 Introduction

8.2 Legislation

Requirement and Evaluation Criteria

8.3 Study

Objectives and Methodology

8.4 Facility

Details

8.5 Base

Case and Worst Case for Quantitative Risk Assessment

8.6 Population

data

8.7 Hazard

Identification

8.8 Summary

of Risks

8.9 Conclusion

and Recommendations

8.10 References

9 ENVIRONMENTAL

MONITORING & AUDIT REQUIREMENTS

9.1 Operation

and Decommissioning of the Project

9.2 Upon

Completion of the Project

10 CONCLUSION

10.1 Environmental Benefits of the Project and the

Environmental Protection Measures Recommended

10.2 Population Protection

10.3 Protection of Environmentally Sensitive Areas

10.4 Key Environmental Problems Avoided

10.5 Compensation Areas

10.6 Conclusion

AnnexES

Annex 2A �V Decommissioning

Plan (KEY DETAILS)

Annex

8A - FULL

HAZARD TO LIFE/ QUANTITATIVE RISK ASSESSMENT REPORT (REV 3) [AUGUST 2015]

Annex

9A �VIMPLEMENTATION

SCHEDULE OF RECOMMENDED MITIGATION MEASURES

Annex

10A �VCOMPLIANCE

CHECKLIST FOR EIA STUDY BRIEF NO. ESB-280/2014

Annex

10RtC �VRESPONSES

TO COMMENTS RECEIVED MINUTES OF RELEVANT DISTRICT COUNCIL MEETINGS

The

existing Tai Lam Explosives Magazine (Tai Shu Ha, Yuen Long District, New

Territories, Land Allocation GLA-TYL 1288, forthwith known as ��TLEM��) has been

licensed and is currently in use by the MTR Corporation Limited (MTRC) for the

construction of the Hong Kong Section of Guangzhou-Shenzhen-Hong Kong Express

Rail Link (XRL) until end of 2015 (Environmental Permit No. EP-349/2009/L),

being used by the MTR XRL 824 Contractor.

This

Project is for the continued operation of the existing TLEM at Tai Shu Ha, Yuen

Long for the Liantang/Heung Yuen Wai

Boundary Control Point (BCP) project (hereafter ��HKLTH��) tunnel construction

works. The TLEM will be available

for use from late 2015 or early 2016 (expected January 2016) to December 2017

and Dragages Hong Kong Limited (DHK), contracted by

Civil Engineering and Development Department (CEDD), intends to continue using

it for HKLTH.

The

Project is classified as a Designated Project under Schedule 2, Part I, item

K.10 of the Environmental Impact Assessment

ordinance (EIAO) as ��an explosives depot or explosives manufacturing plant

in a stand-alone, purpose built building��, and art II, Item 11 of the EIAO as ��decommissioning of an

explosives depot��.

MTRC

will use the TLEM up to end 2015.

DHK intends to then continue using it for HKLTH therefore an application

for an Environmental Impact Assessment (EIA) Study Brief under section 5(1)(a) of the Environmental

Impact Assessment Ordinance (EIAO) was submitted on 11 September 2014 with a

project profile (No. PP-516/2014) (the Project Profile), to

enable the continued operation of TLEM.

This

EIA Report presents the results of the EIA study as detailed in the EIA Study

Brief ESB-280/2014 and provides information on the nature and extent of any

environmental impacts arising from the operation and decommissioning of the

Project and any related activities that take place concurrently.

The EIA study

covers the Project and associated works proposed in PP-516/2014 and addresses

any likely key issues. This covers:

�P

the

use of the existing TLEM from late 2015 or early

2016 (expected January 2016)

to December 2017 with the same operation as current users;

�P

Explosives transport from

the existing TLEM to the three worksites by DHK, using trucks approved by Civil Engineering and

Development Department (CEDD)��s Mines Division

(Mines); and

�P

Decommissioning

of the existing TLEM after operation.

The

approved Hong Kong Section of Guangzhou-Shenzhen-Hong

Kong Express Rail Link (XRL) EIA Report (No. AEIAR-143/2009) (hereafter

��XRL EIA��) has been reviewed specifically for the environmental impacts arising

from operation of the Tai Lam Explosive Magazine (TLEM). The scope of the XRL EIA was far broader

than just the TLEM and after review it is considered that as well as the Hazard

to Life assessment the various environmental media relevant to the TLEM are

Ecology, Airborne Noise, Air Quality and Waste Management and these are

elaborated upon further in the remainder of this EIA report. Other media covered in the XRL EIA but

considered either of minor importance or not relevant to the current Project,

are generally discussed in one collective chapter which includes Water Quality,

Landscape and Visual, Cultural Heritage, Fisheries, Ground-borne Noise, Land

Contamination, Landfill Gas Hazard and Impacts on the Restored Ngau Tam Mei

Landfill.

This EIA study

also covers the potential Hazard to Life caused by explosive storage and

transport during operation of the Project.

Finally the EIA

study also considers cumulative impacts of the Project, through interaction or

in combination with other existing, committed and planned projects in the

vicinity of the Project.

The

structure of this EIA Report is as follows:

�P

Chapter

1 presents the introduction to

the EIA Study;

�P

Chapter

2 presents the description of

the Project including the alternatives that have been considered for the

Project;

�P

Chapter

3 presents potential ecological

impacts arising from the Project;

�P

Chapter

4 presents potential airborne

noise impacts arising from the Project;

�P

Chapter

5 presents potential air

quality impacts arising from the Project;

�P

Chapter

6 presents potential waste

management impacts arising from the Project;

�P

Chapter

7 discusses other potential

environmental impacts arising from the Project such as water quality and

landscape and visual resources and justifies why other environmental media

considered in the XRL EIA are not necessary for this EIA;

�P

Chapters

8 presents the findings of the hazard to

life study.

�P

Chapters

9 lists all the environmental monitoring

and audit requirements of the Project.

�P

Chapters

10 summarises the overall

outcomes of the EIA report and provides the conclusion.

In

addition a number of Annexes provide information supporting the main EIA

Report, as detailed in the Table of Contents.

An

Executive Summary of the EIA report is also provided separately.

This chapter of the EIA

report presents information on the Project and its alternatives in sufficient

detail in order to describe, at a level that can be understood by a lay person,

the proposed features and activities of the Project; and facilitate a

comprehensive identification of the potential impacts on resources and

receptors that could result from Project activities.

There are no known

existing, committed and/or planned projects in the vicinity of the Project that

could potentially cause cumulative environmental impacts through their

interaction with the Project.

To enable a timely delivery

of explosives to worksites and in order to meet the proposed construction work

programme, an Explosives Storage Magazine (Magazine) is required for the Liantang / Heung Yuen Wai Boundary Control Point (BCP) Work

which connects the new BCP with Fanling Highway. The purpose of the magazine is to

maintain progress rate for construction activities, i.e. to meet multiple

blasts per day and also act as a buffer in case of delivery interruptions by

Mines from the Geotechnical Engineering Office (GEO), CEDD.

For

the XRL EIA, a long list of potential locations for explosives magazine sites

were identified, reviewed and short-listed for further detailed study and

discussion with Mines. Factors

considered included:

�P

External

separation distance - the distance from the explosive stores to inhabited areas

and sensitive receivers. The required minimum internal and external separation

distances from the magazines should follow the requirements stated in UK Explosives Regulations 2014 published by

the UK Health & Safety Executive, a document as specified by the Hong Kong

Commissioner of Mines (CoM). In addition, it is preferable to limit

the transportation distances as far as practicable when considering the

possible location of magazine. This

is particularly pertinent given explosives are not permitted within road

tunnels, and there would be a considerable distance of about 40 km to

50 km for explosives transported from northern New Territories to Kowloon

via above ground or at grade roads, and vice versa;

�P

Access

for Mines Division explosive delivery vehicles;

�P

Site

constraints such as existing conditions;

�P

Land

availability; and

�P

Potential

environmental and heritage impacts.

The

magazine site selection process for the XRL project is documented in Working Paper No. 13A �VExplosives Magazine

Site Selection and two explosives magazine sites were selected as being

necessary to store the explosives for the XRL project, one being the TLEM site

(and the other at So Kwun Wat).

This

TLEM site has been selected for the current Project given: it is already

constructed so there are no construction impacts or land conversion issues; it

is being used for exactly the required purpose now under EP-349/2009/L

which

would imply any operational and decommissioning impacts associated with the

current Project will be acceptable; it is potentially available from end 2015

which suits the HKLTH

project tunnelling schedule; and its location is suitable for the HKLTH project

as elaborated upon below. In addition, since there is no requirement to build a

new magazine site, the timeline for the tunnel Project may be expedited as well

as there being no requirement to build a new magazine site which may cause more

significant environmental impacts elsewhere.

Further details of the

magazine requirement and selection are presented in Section 9.4.2 of Annex

8A.

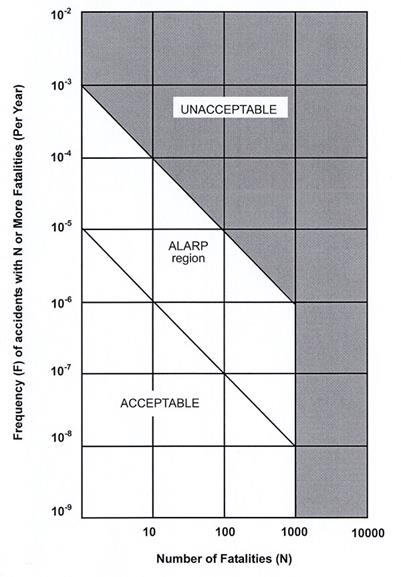

Three possible transport routes that do not pass

through tunnels have been identified for this Project, i.e. the proposed

explosive transport route options R1, R2 and R3, from the magazine site to the

three worksites (i.e. Mid-Ventilation Adit, North

Portal and South Portal). Figure 2.1, Figure 2.2

and Figure 2.3

show plans of the proposed explosive transport route options R1, R2 and R3

respectively and more details of these routes from Tai Lam Explosives Magazine

site to the three worksites are provided in Annex

8A, Table 2.9.

In Route Options R1 and R3, the explosives delivery

truck will pass through Pok Oi

Interchange and Shap Pat Heung Interchange. During the Fourth Meeting of Traffic and

Transport Committee under Yuen Long District Council on 24 July 2014

(Thursday), members expressed concerns on the traffic conditions of Pok Oi Interchange.

Currently there is road improvement work which leads to serious traffic

jams, thus temporary road diversion and traffic control measures are

enforced. The road improvement work

is expected to be completed in 2015 but may be delayed due to the flyover

foundation. Therefore, members

generally did not prefer the use of Pok Oi

Interchange by the explosives delivery truck during the road improvement work,

and recommended to use Tong Yan San Tsuen Interchange and Yuen Long Road, which

is Route Option R2 (see Annex

10RtC

which provides relevant minutes of the July 2014 District Council Meeting).

The explosives delivery routes will be:

�P At

early stage of this project, during road improvement work at Pok Oi Interchange (expected to be completed in 2015 but

may be delayed), Route Option R2 will be used. Route Options R1 and R3 are not feasible

since they both route via Pok Oi Interchange.

�P

After road improvement work at Pok

Oi Interchange is completed, all three routes will be available for use. The Route Option with minimum transport

risk will be used.

Figure 2.1 Proposed

Explosive Transport Route Option R1

Figure 2.2 Proposed Explosive

Transport Route Option R2

Figure 2.3 Proposed Explosive

Transport Route Option R3

Table 2.1

provides a comparison of transport distances to each worksite between the three

proposed explosive transport route options.

Table 2.1 Transport

Distance to each worksite via different

Route Options

|

Worksite |

Transport

Distance (km) |

||

|

Route

Option R1 |

Route

Option R2 |

Route

Option R3 |

|

|

Mid-Ventilation Adit |

27.7 |

30.9 |

24.7 |

|

North Portal |

27.6 |

30.8 |

24.6 |

|

South Portal |

23.2 |

27.8 |

21.6 |

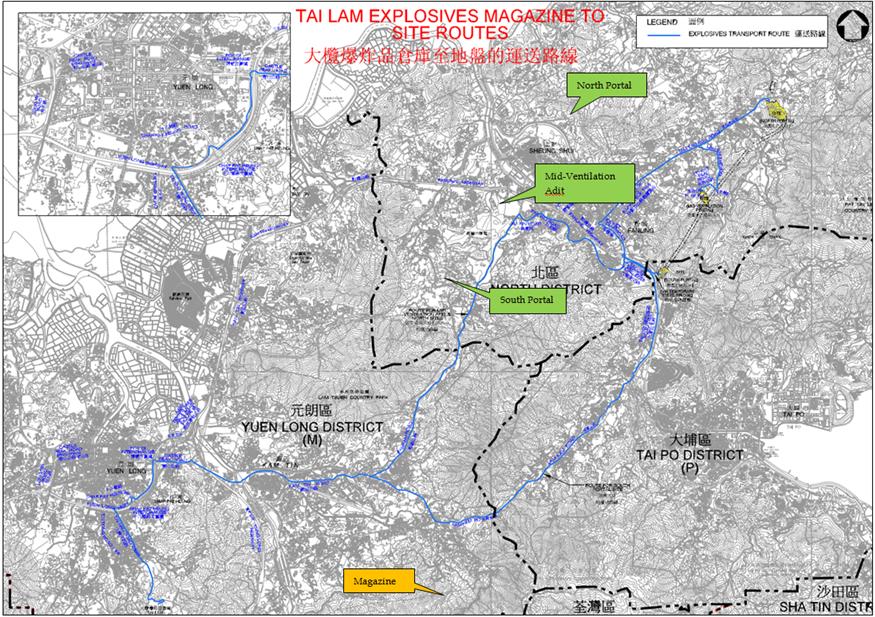

Figure 2.4, Figure 2.5 and Figure 2.6

below show the overall Potential Life Loss (PLL) and Fatality N and frequency f

(FN curves) for all three proposed explosive transport route options and full

details are presented in the EIA Report��s

Annex 8A,

Section 8.

Figure

2.4 F-N Curve for Storage and Transport

of Explosives (Route Option R1)

Figure

2.5 F-N Curve for Storage and

Transport of Explosives (Route Option R2)

Figure 2.6 F-N Curve for Storage and

Transport of Explosives (Route Option R3)

The

Project is located at the existing TLEM in Tai Shu Ha, Yuen Long District, New Territories.

Figure 2.7

shows the location and site plan

of the Project and Figure 2.8

details

the Project Boundary.

The Tai Tong East Borrow Area was excavated in the

1990s and then subjected to reinstatement and management. To restore the borrow area, fast growing

exotic species (e.g. Acacia spp., Melaleuca quinquenervia)

were planted extensively in the area and it has been maintained by AFCD from

2003 until 2015. More recently,

native species (e.g. Machilus spp., Reevesia thyrsoidea, Schefflera heptaphylla, and Phyllanthus emblica)

were planted to increase diversity.

This Conservation Area (CA) is zoned to protect and retain the existing

natural landscape, ecological or topographical features of the area for

conservation, educational and research purposes. The zoning ordinances also separate

sensitive natural environments, such as the Tai Lam Country Park, from the adverse

effects of development.

Given

the loss of a small plantation area under the XRL project that was part of the

restoration planting in the Tai Tong East Borrow area within the CA, the XRL

EIA made provision for reinstatement

planting at the TLEM that would be carried out upon completion of the XRL

project. How this Project will

affect the reinstatement planting is further discussed in Section 3 Ecology.

The TLEM will be available

for use from late 2015 or early 2016 (expected January 2016) to December 2017

with delivery of explosives to the TLEM expected to start in January 2016 and

go through to December 2017. The decommissioning

TLEM will be conducted after the operation and is expected to be completed in

one month.

No construction activity will be

carried out at the TLEM site.

The existing TLEM is composed of

the following components as illustrated in Figure 2.9a & b:

(i) Two stores each with a capacity of

400 kg explosives and dimensions of about 4.7 m (length) x 2.7 m (width) x

2.7 m (height);

(ii) Secure fence;

(iii) CCTV system;

(iv) Guard house

(standard container office, with dimensions of about 6 m (length) x 2.4 m

(width) x 2.4 m (height)); and

(v) Street fire hydrant water tank (245 m3)

and 2 pumps.

The

magazine operation will remain the same as under the current MTR XRL 824

Contractor and the Mines Division of the CEDD (Mines) will deliver a maximum of

800 kg explosives daily to the TLEM along with initiation devices

(detonators). The transportation of

explosives by Mines either to the Magazine or directly to

sites, is under Mines�� responsibility and falls outside the scope of

this EIA study. Only the amount of

explosives required for blasting work will be delivered to TLEM by CEDD Mines

Division. Explosives will then be

withdrawn by DHK as required and delivered using trucks approved by Mines, to

three HKLTH worksites located at:

�P

Sha

Tau Kok Road �V Wo Hang Section (North Portal);

�P

Po

Kat Tsai Road (Mid Ventilation Portal); and

�P

Tong

Hang Tung Chuen (South Portal)

For this Project, explosives transport will be

scheduled with less than 200 kg of explosives per truck (North Portal: 20

- 90 kg, Mid Ventilation Portal: 40 - 70 kg, South Portal: 15 - 140 kg) and a

total of two to eight (2 �V 8) deliveries per day will be carried out to the

worksites (explosives are required at two to three [2 �V 3] worksites per day)

and maximum seven (7) days per week.

Further details of these delivery routes and scheduling can be found in Chapter 8 Hazard to Life.

Only

the amount of explosives required for blasting work will be delivered to TLEM

by CEDD Mines Division. Before the

commencement of decommissioning works, no surplus explosives will be stored at

the explosives magazine.

Based on this, no hazard to life impact is anticipated.

The key activities of the decommissioning works which

will expect to last for about one month include:

�P

Dismantle

and remove E&M, fire services, CCTV and lighting installed for the two

explosive stores;

�P

Demolish

the earth bunds and the two explosive stores;

�P

Frame

cut the re-bar and remove the concrete debris;

�P

Remove

all fire service facilities and all ground services including guard house, road

furniture and lighting;

�P

Remove

fire hydrant water tank (245m3);

�P

Remove

the container guard house and any temporary steel works; and

�P

Demolish

the paved road for reinstatement of planting.

As seen from the above, work activities involved would

mainly be dismantling and removal of structures currently used for the

explosive magazine. Some of the

work activities would be conducted simultaneously, as illustrated in the

Decommissioning Plan as shown in Annex 2A. Powered mechanical equipment that would

generally be used for carrying out the abovementioned work activities is also

shown in Annex 2A.

As

the decommissioning works will only involve dismantling, demolition and removal

of the existing temporary structures, and removal of existing vegetation will

not be required, no landscape and visual impact and terrestrial ecology impact

are anticipated.

As

the site is used as a magazine for storage of explosives only, there is no

chemical store and use of lubricant or other chemicals are not required. The magazine is paved. No surplus explosives will be stored at the

explosives magazine before the commencement of the decommissioning works. Based on the above-mentioned, no land

contamination impact is anticipated due to the decommissioning works.

Due

to the small scale of decommissioning works, site runoff and drainage from the

works areas will be very minimal, and water quality impact is not anticipated

due to the decommissioning works, as discussed further in Section 7.

This

chapter presents the potential ecological impacts associated with the operation

and decommissioning of the Project in accordance with the requirement stated in

Section 3.4.2 of the EIA Study

Brief.

The

ecological findings of the previously approved XRL EIA report (No.

AEIAR-143/2009) are reviewed and updated on the understanding that the Project

Site is currently being used as an explosive magazine site for the construction

of the XRL and therefore there will be no construction phase of this project,

with no land conversion. Operation

of the site is also intended to remain similar to the current operating

procedure described in the approved XRL EIA.

Legislative

requirements concerning the protection of species and habitats of terrestrial

ecological importance such as the Wild

Animals Protection Ordinance (Cap 170), and Protection of Endangered Species of Animals and Plants Ordinance (Cap

586) are not considered of key importance to this study given there is no

construction phase and operation will remain similar to existing.

The

XRL EIA does include mitigation measures to be carried out at the site upon

completion of the XRL project and carrying out planting in the TLEM site. Therefore overall the following is

considered the key legislation for this Study.

�P Environment Impact Assessment Ordinance (Cap. 499) and Environmental Impact Assessment Process

under the Environmental Impact Assessment Ordinance (EIAO-TM), Annexes 16 and 8;

�P

Forests and Countryside

Ordinance (Cap 96);

and

�P

DEVB

TCW No. 10/2013 �V Tree Preservation.

Details

on each of the above are presented below.

The

criteria for evaluating terrestrial ecological impacts are laid out in the EIAO-TM. Annex 16 of the EIAO-TM sets out the general approach and methodology for the

assessment of impacts to ecological resources arising from a project or

proposal, to allow a complete and objective identification, prediction and

evaluation of the potential ecological impacts. Annex

8 of the EIAO-TM recommends the

criteria that can be used for evaluating such ecological impacts.

The

Forests and Countryside Ordinance (Cap 96) prohibits the felling, cutting,

burning or destroying of trees and growing plants in forests and plantations on

Government land. The subsidiary Forestry Regulations prohibit the picking,

felling or possession of listed rare and protected plant species. The list of protected species in Hong

Kong which comes under the Forestry

Regulations was last amended on 11 June 1993 under the Forestry (Amendment) Regulation 1993 made under Section 3 of the Forests and Countryside Ordinance.

DEVB TCW No. 10/2013 �V Tree

Preservation supersedes ETWB TC(W) No. 3/2006 and sets out the policy on tree

preservation from feasibility, planning, design, construction to

post-construction stages of a development, the procedures for control of tree

felling, transplanting and pruning in Government projects, and departmental

responsibilities in handling proposals on tree preservation and removal. It also covers the reporting of unauthorised tree removal or damage of

trees, on both private and unleased Government land and its Appendix A details

the requirements for compensatory planting.

Figure 3.1 gives an overview of the Project Study Area, 500 m from

the Project Site boundary. The

Project falls within the Tai Tong East Borrow Area and the statutory Tai Tong

Outline Zoning Plan (S/YL-TT/16) Conservation Area (CA). It is also near (approximately

300 m from) the Tai Lam Country Park.

The Tai Tong East Borrow Area was excavated in the

1990s and then subjected to reinstatement and management. To restore the borrow area, fast growing

exotic species (e.g. Acacia spp., Melaleuca quinquenervia)

were planted extensively in the area and it has been maintained by AFCD from

2003 until 2015. More recently,

native species (e.g. Machilus spp., Reevesia thyrsoidea, Schefflera heptaphylla, and Phyllanthus emblica)

were planted to increase diversity.

This CA is zoned to protect and retain the existing

natural landscape, ecological or topographical features of the area for

conservation, educational and research purposes. The zoning ordinances also separate

sensitive natural environments, such as the Tai Lam Country Park, from the

adverse effects of development.

The habitat map in Figure 3.2 is

taken from the approved XRL EIA (No. AEIAR-143/2009) with minor revisions

following a site visit in November 2014 and shows the approach to the TLEM as

an existing tarmacked road and the area around the TLEM to be dominated by

plantation with a stream flowing nearby to the south. The key change to baseline condition

since the XRL EIA is that the area now occupied by the TLEM was previously

relatively mature plantation habitat dominated by exotic plant species with some native

species in the understorey (e.g. Melastoma candidum, Psychotria

asiatica) and this area was cleared for the

construction of the TLEM.

The construction of the TLEM was conducted under the

EP from the approved XRL EIA and

there will be no construction phase for this Project.

Operation

of the existing facility will remain similar to the existing operation as

described in the XRL EIA and the decommissioning works will only affect the

existing TLEM which classified as developed areas of negligible ecological

value, and therefore is not considered to cause any direct ecological impacts

to habitats including streams or to species.

Given

the loss of a small plantation area under the XRL project that was part of the

restoration planting in the Tai Tong East Borrow area within the CA, the XRL

EIA made provision for reinstatement planting at the TLEM that would be

carried out upon completion of the XRL project. As part of the XRL EIA and EP (latest

XRL EP no . : EP-349/2009/L) requirements, a detailed Vegetation Survey Report for Tai Shu Ha Road

West have been submitted under XRL EP condition 2.12(iii) and Tree Planting and Landscape Plan TLP-10: Works in Yuen Long District (Tai Shu

Ha), submitted under XRL EP condition 2.14, has been drawn up including

details of the reinstatement of the TLEM site. These reports under the XRL project are

publically available at the following sites http://www.epd.gov.hk/eia/register/english/permit/ep3492009/documents/vsrr1/pdf/vsrr1.pdf

and http://www.epd.gov.hk/eia/register/english/permit/vep3232010/documents/tplpyldtsh/pdf/tplpyldtsh.pdf,

and for ease of reference, the key details of these

reports are provided as Annexes 3A

& 3B to this report.

The current Project extends the operating time of the

TLEM. The XRL project use of the

TLEM was due to be up to the end of 2014 and has been extended until end

2015. Under the proposed Project

the TLEM site will remain in operation up to December 2017 i.e. reinstatement planting

will be

postponed by three years.

The reinstatement of the TLEM is principally in order

to restore the habitat back to borrow area reinstatement plantation and

relative to the whole borrow area reinstatement plantation, it is a very small

area. With respect to fauna, the area

is ecologically connected to nearby Country Parks and Conservation Areas and

may host a number of woodland species.

The XRL EIA baseline surveys recorded six species of conservation

interest with the Study Area including Little Egret Egretta

garzetta, Chinese Pont Heron Ardeola

bacchus, Red-Throated

Pipit Anthus cervinus,

Eurasian Jay Garrulus glandarius,

Pale Palm Dart Telicota colon stinga and

Chinese Pangolin Manis pentadactyla

auritus. All these species were recorded outside

the direct TLEM footprint area and with the exception of the Chinese Pangolin

all to the west off the Study Area in habitats separated from the TLEM by the

Tai Shu Ha Road West.

The Chinese Pangolin was recorded in grassland to the south of the TLEM

site but across the watercourse from the site. Though the area near the TLEM is

dominated by plantations with a canopy of mainly introduced species, it is

possible that fauna from nearby woodland habitats would occasionally use this

plantation habitat once it was reinstated but it is not considered to be a key

habitat to any particular species of conservation interest. Since there is also a relatively large

area of existing plantation in the surrounding area, to postpone the reinstatement

by three years is therefore not thought to have any adverse impact on fauna

that will use this area in the future.

With regard to the impact of postponing the

reinstatement planting by three years on habitat, this time period is

relatively small with regards to vegetation succession and establishment of

soils. Therefore assuming that the

same reinstatement plan as set out in the XRL

EIA Vegetation Survey Report for Tai Shu Ha Road West and Tree Planting and Landscape Plan TLP-10:

Works in Yuen Long District (Tai Shu Ha) can be adhered to, no adverse

impact is expected on habitats.

For the XRL EM&A no water monitoring points were

proposed for the watercourses within the TLEM Study Area. Since operation activities will remain

similar to existing it is therefore not considered necessary to carry out any

monitoring of the watercourses. Chapter 7 provides further detail on the potential impacts to water quality

from this Project.

Upon completion of the Project at the end of 2017 and

the removal of the TLEM, reinstatement planting should be carried out at the

site according to the XRL EIA Vegetation

Survey Report for Tai Shu Ha Road West (hereafter Vegetation Survey Report) and the Tree Planting and Landscape Plan TLP-10: Works in Yuen Long District

(Tai Shu Ha) (hereafter TLP).

The Vegetation

Survey Report and the TLP detail

criteria for selection of suitable vegetation species for this planting and the

selected species are listed in Table 3.1

below. Six tree species were

recommended to compensate for the loss of trees and four shrub species for the

loss of understorey

species, all being species that existed previously in the TLEM site before the

magazine construction.

Table 3.1 Recommended

Species for Reinstatement Planting at TLEM

|

Scientific Name |

Growth Form |

Native / Exotic to Hong Kong |

|

Castanopsis fissa |

Tree |

Native |

|

Celtis sinensis |

Tree |

Native |

|

Cinnamomum parthenoxylon |

Large Tree |

Native |

|

Litsea rotundifolia |

Shrub |

Native |

|

Mallotus paniculatus |

Tree |

Native |

|

Melastoma sanguineum |

Shrub |

Native |

|

Psychotria asiatica |

Tree or shrub |

Native |

|

Reevesia thyrsoidea |

Tree |

Native |

|

Rhodomyrtus tomentosa |

Shrub |

Native |

|

Schefflera heptaphylla |

Tree |

Native |

Other native trees/shrubs that are generally well

self-established and suitable for mitigation planting can also be considered to

further promote the flora biodiversity of TLEM site, as recommended in Table 3.2

Table 3.2 Additional

Recommended Species for Reinstatement Planting at TLEM

|

Scientific Name |

Growth Form |

Native / Exotic to Hong Kong |

|

Bischofia favanica |

Tree |

Native |

|

Elaeocarpus sylvestis |

Tree |

Native |

|

Gordonia axillaris |

Shrub or tree |

Native |

|

Schima suberba |

Tree |

Native |

|

Viburnum odoratissimum |

Shrub or tree |

Native |

In addition, the TLP provides a list of general tree/

palm species that are suitable for Native Woodland Planting (not on SIMAR

Slopes). Those not listed already

in Table

3.1 or Table

3.2,

are listed in Table

3.3.

Table 3.3 Additional

Species generally suitable for Native Woodland Planting (not on SIMAR Slopes)

|

Scientific Name |

Common Name |

Native / Exotic to Hong Kong |

|

Ailanthus fordii |

Ailanthus |

Native |

|

Broussonetia papyrifera |

Paper Mulberry |

Native |

|

Choerospondias axillaris |

Hog Plum |

Native |

|

Cinnamomum burmannii |

Cinnamon tree |

Native |

|

Cleistocalyx operculatus |

Water Banyan |

Native |

|

Ficus microcarpa |

Chinese banyan |

Native |

|

Ficus superba var. japonica |

Superb fig |

Native |

|

Ficus variegata var. chlorocarpa |

Common red-stem |

Native |

|

Ficus virens var. sublanceolata |

Big-leaved fig |

Native |

|

Liquidambar formosana |

Sweet gum |

Native |

|

Litsea glutinosa |

Pond spice |

Native |

|

Litsea monopetala |

Persimmon�Vleaved Litsea |

Native |

|

Machilus chekiangensis |

Chekiang

Machilus |

Native |

|

Machilus chinensis |

Hong Kong Machilus |

Native |

|

Machilus pauhoi |

Many-nerved

Machilus |

Native |

|

Machilus thunbergii |

Red Machilus |

Native |

|

Phoenix hanceana |

Spiny date-palm |

Native |

|

Sapium discolor |

Mountain tallow |

Native |

|

Sapium sebiferum |

Tallow-tree |

Native |

|

Sterculia lanceolata |

Scarlet Sterculia |

Native |

Figure3.3a and

b

taken from the Vegetation Survey Report

and TLP show the proposed location of

tree and shrub planting respectively and include the proposed number of

individuals to be planted. These plans

should be adopted for the future reinstatement planting process.

Vegetation Survey Report, Appendix C and TLP

Appendix V also provide relevant specification for the site restoration

works at the TLEM, including restoration of the soil, to ensure suitable

conditions for planting are reached once operation of the TLEM stops and prior

to planting starting. This Vegetation Survey Report, Appendix C and

TLP Appendix V should also be adhered

to for the future reinstatement planting process.

Under the

Project Implementation Schedule of the approved XRL EIA (provided in the XRL

EIA Report Appendix A), MTR are the

party responsible for the reinstatement planting works. For the proposed Project, DHK should

liaise with MTR and will take over the responsibility of this reinstatement

planting works (as laid out in the Vegetation

Survey Report as well as the TLP,)

including application for a Further Environmental

Permit (FEP) of XRL,

to cover the planting obligation.

Reinstatement

planting at the TLEM site will be carried out upon completion of the Project in

2017 and the removal of the TLEM. Assuming that this reinstatement

planting is carried out by DHK as recommended in the approved

XRL EIA report (according to the Vegetation

Survey Report and the TLP, which

both fall under the requirements of the XRL EIA study, with approval from DEP as necessary for any revisions to these

approved documents),

no adverse impacts on ecology are expected from this Project.

This

chapter presents the potential noise impacts to the identified Noise Sensitive

Receivers (NSRs) associated with the decommissioning and operation of the

Project in accordance with the requirement stated in Section 3.4.2 of the EIA Study Brief. The findings of the previously approved

XRL EIA report (No. AEIAR-143/2009) XRL) are reviewed and updated as necessary.

The EIAO-TM and Technical Memorandum on Noise From Places

Other than Domestic Premises, Public Places or Construction Sites (IND-TM) specifies the applicable ANLs

for the fixed noise sources from the Project. The ANLs are dependent on the ASR and

the time of the day and are presented in Table 4.1.

Table 4.1 Acceptable

Noise Levels

|

Time Period |

LAeq 30min (dB(A)) |

||

|

|

ASR ��A�� |

ASR ��B�� |

ASR ��C�� |

|

Day-time

(i.e. 07:00-19:00 hrs) |

60 |

65 |

70 |

|

Evening

(i.e. 19:00-23:00 hrs) |

60 |

65 |

70 |

|

Night-time

(i.e. 23:00-07:00 hrs of the next day) |

50 |

55 |

60 |

Fixed plant

noise is controlled under Section 13

of the NCO and the predictions will

be undertaken in accordance with the IND-TM. The noise criteria stipulated in the IND-TM are also dependent on the ASR of

the NSR. As the Project Site is located in a rural area and no influencing

factors affect the NSRs, an ASR of ��A�� has been assigned.

The

traffic noise standards for planning purposes specified in Table 1 under Annex 5 of

the EIAO-TM was employed as the noise

limits for the road traffic noise impact assessment. The applicable road traffic noise

standards are 70dB(A)

L10, 1hr for domestic premises and 65dB(A) L10, 1hr for

education institutions and church, respectively. These noise limits were applied for the peak

hour traffic flows and for uses that rely on opened windows for ventilation.

The principal

legislation relating to the control of construction noise is the Environmental Impact Assessment Ordinance

(EIAO) (Cap. 499). The Technical

Memorandum on Environmental Impact Assessment Process (EIAO-TM), issued under the EIAO,

stipulates assessment standards of Leq(30

minutes) 75

dB(A) for all domestic premises and 70/65 dB(A) for educational institutions

during normal school term/examination periods for daytime (i.e. 0700 to 1900

hours on any day not being a Sunday or general holiday) construction activities ([1]). These criteria apply to Noise Sensitive

Receivers (NSRs) relying only on openable windows for ventilation.

The

Noise Control Ordinance (NCO) (Cap 400) also provides means to assess construction noise

impacts. Various Technical

Memoranda (TMs), which stipulate control approaches and criteria during the

restricted hours, have been issued under the NCO. The following TMs

are applicable to the control of noise from construction activities:

�P

Technical Memorandum on

Noise from Percussive Piling (PP-TM);

�P

Technical Memorandum on

Noise from Construction Work other than Percussive Piling (GW-TM);

and

�P

Technical Memorandum on

Noise from Construction Work in Designated Areas

(DA-TM).

The

NCO provides statutory controls on

general construction works during the restricted hours (i.e. 19:00 �V 07:00 hrs

of the next day, Monday to Saturday and any time on Sundays and public

holidays). The use of Powered

Mechanical Equipment (PME) for the carrying out of demolition or construction

works during the restricted hours requires a Construction Noise Permit

(CNP). The EPD is guided by the

GW-TM and DA-TM when assessing such an application.

Percussive piling is prohibited at any

time on Sundays and public holidays and during the weekday evening and

night-time hours (19:00-07:00 hrs of the next day, Monday through

Saturday). A CNP is required for

such works during the weekday daytime hours (07:00 �V 19:00 hrs, Monday through

Saturday). The EPD is guided by the

PP-TM in considering applications of a CNP for such works.

The Noise

Control Authority will consider a well-justified CNP application, for

construction works within restricted hours as guided by the relevant TMs issued

under the NCO. The Noise Control Authority will take

into account adjoining land uses and any previous complaints against construction

activities at the site before making a decision. Nothing in this EIA Report shall bind the Noise Control

Authority in making its decision.

The Noise Control Authority may include any conditions in a CNP that it

considers appropriate. Failure to

comply with any such conditions may lead to cancellation of the CNP and

prosecution action under the NCO.

In accordance with Table

5.5 of the XRL EIA Report, one representative Noise Sensitive Receiver

(NSR) was identified within the Study Area (i.e. within 300m of the Project

boundary) and is listed in Table 4.2. No new or planned NSRs were identified

since the approval of the XRL EIA Report.

The location of the identified NSR is presented in Figure 4.1.

|

NSR No. |

Description |

Type |

Distance from the Magazine Site |

No. of Storey |

|

TS1 |

Village

House next to Tai Shu Ha Road West |

Residential |

297 m (1) |

1 |

|

Note: (1) The

distance between the magazine site and the NSR was reported as 244 m in

approved XRL EIA Report. This distance is further reviewed in this ERR and is

found to be approximately 297 m. |

||||

The magazine site comprises two magazine structures

storing 400kg of explosives each, a secure fence, CCTV system, guard house,

street fire hydrant tank (245m3) and two water pumps. Layout plan of the magazine site is

presented in Figure 4.2.

The

major activities are summarised as follows:

�P

Dismantle

and remove E&M, fire services, CCTV and lighting installed for the two

explosive stores;

�P

Demolish

the earth bunds and the two explosive stores;

�P

Frame

cut the re-bar and remove the concrete debris;

�P

Remove

all fire service facilities and all ground services including guard house, road

furniture and lighting;

�P

Remove

fire hydrant water tank (245m3);

�P

Remove

the container guard house and any temporary steel works; and

�P

Demolish

the paved road for reinstatement planting.

The

normal working hours of the Contractor will be between 07:00 and 19:00 hrs from

Monday to Saturday (except public holidays). Construction activities during

restricted hours are not expected.

Should evening and night works between 19:00 and 07:00 hrs or on public

holidays (including Sundays) be required, the Contractor will submit a CNP

application which will be assessed by the Noise Control Authority.

It

is envisaged that major noise sources will be associated with various PME

including lorries, dump trucks, drills/grinders and

breakers etc to be used for the decommissioning of

the magazine site.

It is recommended that the general noise control

measures as listed in Recommended Clauses

for Construction Contracts �V Section 3 - Noise Control (available on EPD

website at http://www.epd.gov.hk/epd/english/environmentinhk/eia_planning/guide_ref/rpc_3.html), should

also be incorporated in the works contract to ensure that the Contractor will

adopt good site practices and minimise noise

generation. Given that the decommissioning works will

only last for 4 weeks, the nearest NSR is located at ~297 m from the magazine

site, and good site practices to minimise noise

generation will be adopted, no adverse noise impact is anticipated from the

decommissioning works.

Operation of the magazine site will remain the same as

the current XRL project. Potential

sources of noise include fixed plant noise impact from the operation of the

water pumps and street fire hydrant tank. The nearest NSR is located at

approximately 297 m from the fixed plant noise sources. As such, no adverse noise impact to the

NSR is expected.

The operational activities involve the delivery of

explosives to the Magazines by Mines Division on a daily basis and the transfer

of the explosives to the work areas by the contractors daily. Traffic generated from the site is insignificant as a

total of two to eight (2 �V 8) deliveries per day will be carried out to the

worksites. Three proposed explosive

transport routes have been identified for this Project, i.e. Proposed Routes

R1, R2 and R3, from the magazine site to the three worksites (i.e.

Mid-Ventilation Adit, North Portal and South Portal). Figure 2.1, Figure 2.2 and Figure 2.3 show

the proposed explosive transport routes R1, R2 and R3 respectively. With consideration of the low traffic

arising from the Project, no traffic noise impact is anticipated.

No adverse noise impacts are anticipated during

operation or decommissioning, assuming general noise control measures, as

listed in Recommended Clauses for

Construction Contracts �V Section 3 - Noise Control, are adopted during

decommissioning. Noise monitoring

at the NSR is not required as part of the EM&A programme

during operation and decommissioning.

This

chapter presents an assessment of the potential air quality impacts associated

with the operation of the Project in accordance with the requirement stated in Sections 3.4.2 of the EIA Study

Brief. The findings of the

previously approved Hong Kong Section of the XRL EIA report (No.

AEIAR-143/2009) were reviewed and updated in this assessment.

The

principal legislation for the management of air quality in Hong Kong is the Air Pollution Control Ordinance (APCO)

(Cap 311). The APCO Amendment was

passed in July 2013 and a set of new Air Quality Objectives (AQOs) has been

effective from 1 January 2014. The

new AQOs stipulate statutory ambient limits for air pollutants and the maximum

allowable number of exceedances over specific averaging periods. The new AQOs are presented in Table 5.1

and they

were used as the evaluation criteria for this assessment. As stipulated in Annex 4 of the Technical

Memorandum on Environmental Impact Assessment Process (EIAO-TM), the AQOs

and other relevant standards established under the APCO should be met.

Table 5.1 Hong Kong Air

Quality Objectives (mg m-3) (a)

|

Air Pollutant |

Averaging Time |

Concentration (mgm-3) (a) |

No. of Exceedances Allowed per

Year |

|

Sulphur Dioxide (SO2) |

10 minute |

500 |

3 |

|

|

24-hours |

125 |

3 |

|

Respirable Suspended Particulates (RSP) (b) |

24-hours |

100 |

9 |

|

Annual |

50 |

- |

|

|

Fine Suspended Particulates (FSP) (c) |

24-hours |

75 |

9 |

|

Annual |

35 |

- |

|

|

Nitrogen Dioxide (NO2) |

1-hour |

200 |

18 |

|

|

Annual |

40 |

- |

|

Ozone (O3) |

8-hours |

160 |

9 |

|

Carbon Monoxide (CO) |

1-hour |

30,000 |

- |

|

|

8-hours |

10,000 |

- |

|

Lead |

Annual |

0.5 |

- |

|

Notes: (a) Measured

at 293K and 101.325 kPa. (b) Suspended

particles in air with a nominal aerodynamic diameter of 10 �gm or less (c) Suspended

particles in air with a nominal aerodynamic diameter of 2.5 �gm or less |

|||

Annex 4

of the EIAO-TM also stipulates that

any predictive assessment of the odour impact should meet 5 odour units based

on an averaging time of 5 seconds.

The Project Site is located in rural area and no major

air emission source is identified in the area. Since the continued operation of the

magazine site for the HKLTH will commence in 2015, the hourly ambient pollutant

concentration data predicted by the PATH (Pollutants in the Atmosphere and

their Transport over Hong Kong) model for Year 2015 has been adopted to reflect

the future background air quality in the Project Site area during the operation

of the Project. Table

5.2 summarizes the annual

average concentrations of the air pollutants in 2015 predicted by the PATH

model.

Table 5.2 Annual

Averaged Concentrations of Air Pollutants in 2015 Predicted by the PATH Model

|

Air Pollutant |

Annual Averaged Concentration

(mg

m-3) |

|

|

PATH Background in 2015 (a) |

Annual AQO |

|

|

SO2 |

7 |

-

(c) |

|

NO2 |

21 |

40 |

|

RSP |

42 |

50 |

|

FSP

(b) |

30 |

35 |

|

Notes: (a)

The annual averaged concentrations of the air pollutants were extracted from

PATH grid (19, 35) in which the Project Site is located. (b)

FSP data are not available in the hourly PATH background concentration

results. A recommended FSP to RSP

ratio of 0.71 is applied for the estimation of annual FSP results according

to EPD��s ��Guidelines on the Estimation

of PM2.5 for Air Quality Assessment in Hong Kong��. (c)

No annual AQO for SO2. |

||

According to the PATH-predicted

background air quality in the Project Site area in 2015, the annual averaged

concentrations of all concerned air pollutants after commencement of operation

of the magazine site are anticipated to be below their respective AQOs.

The Study Area for the air quality impact assessment is

generally defined by a distance of 500m from the boundary of the Project Site

as shown in Figure 5.1. Air Sensitive Receivers (ASRs) were

identified based on the landuses, latest Outline

Zoning Plan (OZP) and with reference to Table 12.5 of the XRL

EIA Report. Four ASRs were

identified which are presented in Table

5.3 and their locations are

shown in Figure 5.1.

Table 5.3 Air

Sensitive Receivers

|

ASR |

Description |

Type of Use |

Approximate Separation Distance from the nearest site boundary (m) |

No. of storey(s) |

|

TSA1 |

Village

House next to Tai Shu Ha Road West |

Residential |

54 |

1 |

|

HKMEC |

Hong Kong

Model Engineering Club |

Recreational |

200 |

N/A |

|

NHT1 |

Temple at

Nam Hang Tsuen |

Temple |

338 |

1 |

|

NHT2 |

Village

House at Nam Hang Tsuen |

Residential |

332 |

1 |

The magazine site comprises two magazine structures storing

400kg of explosives each, a secure fence, CCTV system, guard house, street fire

hydrant tank (245m3) and two pumps.

Operation of the magazine site will remain the same as

the current XRL project. The

operational activities involve the delivery of explosives to the Magazines by

Mines Division on a daily basis and the transfer of the explosives to the work

areas by the contractors daily.

Potential sources of air quality impacts include dust emissions

from the operation of explosives delivery vehicles.

About two to eight trips per day are expected for the

transportation of explosives to the work areas.

The magazine site will be

decommissioned after the completion of the construction works for the Liantang/Heung Yuen Wai Boundary

Control Point (BCP) project.

Potential dust emissions may also arise during the decommissioning

works.

With reference to Section

12.45 of the XRL EIA Report, the major activities causing dust impacts

during operation would be the vehicles entering or leaving the magazine

site. As the roads to/from and

within the magazine site will be paved, dust impact from the operation of the

magazine sites is anticipated to be insignificant. Hence, adverse air quality impact from

the operation of the Project is not anticipated. Cumulative impact during the operation

of the Project is also not anticipated as no significant air pollution source

is identified within the Study Area.

Since no adverse air quality impact is anticipated during the operation

of the Project, no mitigation measures are deemed necessary.

Operation of the magazine site will remain the same as

the current XRL project. The

operational activities involve the delivery of explosives to and from the

Project Site on a daily basis.

Potential sources of air quality impact include dust emissions from the

operation of explosives delivery vehicles from the magazine to the work areas,

with about two to eight trips per day.

Roads to/from and within the Project Site will be paved, thus dust

impact from the operation of the magazine site is anticipated to be

insignificant. Decommissioning of

the magazine site has the potential to cause dust emissions. Since the decommissioning works will be

small scale, the potential air quality impact is expected to be minimal with

the implementation of proper dust control measures. Air quality monitoring and audit is not

considered necessary during the operation of the Project as no adverse air

quality impact is anticipated.

This

chapter presents the potential impacts from waste generated by the operation

and decommissioning of the Project.

While the previously approved Hong Kong Section of the XRL EIA report

(No. AEIAR-143/2009) XRL) covers waste management implications of the whole XRL

Project, it does not include details specifically for

the TLEM site and therefore an independent assessment of the operational and

decommissioning waste implications for the current Project have been

undertaken.

The

following legislation covers the handling, treatment and disposal of wastes in

�P

Waste Disposal Ordinance (WDO) (Cap 354);

�P

Waste Disposal (Charges for

Disposal of Construction Waste) Regulation (Cap 354N);

�P

Waste Disposal (Chemical

Waste) (General) Regulation

(Cap 354C);

�P

Land (Miscellaneous

Provisions) Ordinance (Cap

28); and

�P

Public Health and Municipal

Services Ordinance (Cap 132) - Public Cleansing and Prevention of Nuisances

Regulation.

The

Waste

Disposal Ordinance (WDO) prohibits the unauthorised disposal

of wastes, with waste defined as any substance or article which is

abandoned. Construction waste is

not directly defined in the WDO but

is considered to fall within the category of ��trade waste��. Trade waste is defined as waste from any

trade, manufacturer or business, wasted building, civil engineering materials,

but does not include animal waste.

Under the WDO, wastes can only

be disposed of at a licensed site.

A breach of these regulations can lead to the imposition of a fine

and/or a prison sentence. The WDO also provides for the issuing of

licences for the collection and transport of wastes. Licences for the collection and

transport of construction waste or trade waste, however, are not issued

currently. For general waste there

is no charge and this needs to be disposed in a licensed facility.

The

Waste Disposal (Charges for Disposal of

Construction Waste) Regulation (Cap

354N) defines construction waste as any substance, matters or things that

is generated from construction work and abandoned, whether or not it has been

processed or stockpiled before being abandoned. It does not include any sludge,

screening or matter removed in or generated from any desludging, desilting or

dredging works. The Construction Waste Disposal Charging Scheme

entered into operation on 1 December 2005.

Starting from 1 December 2005, a main contractor who undertakes

construction work with a contract value of HK$1 million or above is required to

open a billing account solely for the contract for waste disposal. Depending on the percentage of inert

C&D materials in the waste, it can be disposed of at public fill reception

facilities. However mixed

construction waste can be disposed of at construction waste sorting facilities,

landfills and Outlying Islands Transfer Facilities which have different

disposal costs. The scheme

encourages reducing, reusing and sorting of construction waste such that the

waste producer can reduce their disposal fee. Table 8.2 summarises the government

construction and demolition waste disposal facilities and types of waste

accepted.

Table 6.1 Government Facilities

for Disposal of Construction & Demolition Waste

|

Government Waste Disposal

Facilities |

Type of Construction

& Demolition (C&D) Waste Accepted |

|

Public

fill reception facilities |

Consisting

entirely of inert C&D materials |

|

Sorting

facilities |

Containing

more than 50% by weight of inert C&D materials |

|

Landfills

|

Containing

not more than 50% by weight of inert C&D materials |

|

Outlying

Islands Transfer Facilities |

Containing

any percentage of inert C&D materials |

Chemical

waste as defined under the Waste Disposal

(Chemical Waste) (General) Regulation includes any substance being scrap

material, or unwanted substances specified under Schedule 1 of the Regulation,

if such a substance or chemical occurs in such a form, quantity or

concentration so as to cause pollution or constitute a danger to health or risk

of pollution to the environment.

Chemical

waste producers shall register with the EPD. Any person who contravenes this

requirement commits an offence and is liable to a fine and imprisonment. Producers of chemical wastes must treat

their wastes, utilising on-site plants licensed by the EPD or have a licensed

collector take the wastes to a licensed facility. For each consignment of wastes, the

waste producer, collector and disposer of the wastes must sign all relevant

parts of a computerised trip ticket.

The system is designed to allow the transfer of wastes to be traced from

cradle-to-grave.

The

Regulation prescribes the storage

facilities to be provided on site including labelling and warning signs. To minimise the risks of pollution and

danger to human health or life, the waste producer is required to prepare and

make available written procedures to be observed in the case of emergencies due

to spillage, leakage or accidents arising from the storage of chemical

wastes. He/she must also provide

employees with training in such procedures.

The

inert C&D materials (also called public fill) may be taken to public fill

reception facilities. Public fill

reception facilities usually form part of land reclamation schemes and are

operated by the Civil Engineering and Development Department (CEDD) and

others. The Land (Miscellaneous Provisions) Ordinance requires that individuals

or companies who deliver public fill to the public fill reception facilities to

obtain Dumping Licences. The

licences are issued by CEDD under delegated authority from the Director of

Lands.

Individual

licences and windscreen stickers are issued for each vehicle involved. Under the licence conditions, public

fill reception facilities will only accept earth, soil, sand, rubble, brick,

tile, rock, boulder, concrete, asphalt, masonry or used bentonite. In addition, in accordance with

paragraph 11 of DEVB TC(W) No. 6/2010

��Trip Ticket System for Disposal of Construction and Demolition Materials��,

the Public Fill Committee will advise on the acceptance criteria (e.g. no

mixing of construction waste, nominal size of the materials less than 250mm, etc). The

material will, however, be free from marine mud, household refuse, plastic,

metal, industrial and chemical wastes, animal and vegetable matter and any

other materials considered unsuitable by the public fill reception facility

supervisor.

This

Regulation provides further control

on the illegal dumping of wastes on unauthorised (unlicensed) sites. The illegal dumping of wastes can lead

to a fine and/or imprisonment.

Other

'guideline' documents, which detail how the Project Proponent or Contractor

should comply with the local regulations, are as follows:

�P

Code of Practice on the

Packaging, Labelling and Storage of Chemical Wastes (1992), EPD,

�P

New

Disposal Arrangements for Construction Waste (1992), EPD & CED,

�P

WBTC No. 2/93, Public Dumps, Works Branch, Hong Kong

Government;

�P

WBTC

No. 2/93B, Public Filling Facilities, Works Branch,

�P

WBTC Nos. 25/99, 25/99A and

25/99C,

Incorporation of Information on Construction and Demolition Material Management

in Public Works Sub-committee Papers; Works Bureau,

�P

WBTC No. 12/2000, Fill Management; Works

Bureau,

�P

ETWBTC(W) No. 33/2002,

Management of Construction and Demolition Material Including Rock, Environment, Transport and

Works Bureau, Hong Kong SAR Government;

�P

ETWB TC(W) No. 19/2005

Environmental Management on Construction Site, Environment, Transport and Works

Bureau, Hong Kong SAR Government.

�P

DEVB TC(W) No. 6/2010, Trip

Ticket for Disposal of Construction and Demolition Materials;

�P

DEVB TC(W) No. 8/2010,

Enhanced Specification for Site Cleanliness and Tidiness;

�P

DEVB TC(W) No.2/2011,

Encouraging the Use of Recycled and Other Green Materials in Public Works

Projects; and

�P

DEVB TC(W) No. 9/2011,

Enhanced Control Measures for Management of Public Fill.

The major types of solid waste likely to be generated

from the operation of the Project at the magazine site, is general refuse. The operation works will involve only

a very small amount of equipment including delivery vehicles for explosives

transport and two pumps for the Street Fire Hydrant Water Tank.

The

quantities of chemical waste to be generated from regular maintenance of

equipment will be minimal. Table 6.2

indicates

the different waste types and estimated quantities generated throughout the

operation of the Project and how these will be handled and disposed of. All chemical waste will be handled in

accordance with the EPD��s Code of Practice on the Packaging Labelling and

Storage of Chemical Waste and a licenced collector will be employed for the

collection of the chemical waste generated to the licenced disposal

facilities. Hence, no adverse environmental

impact is anticipated due to the management of a small quantity of chemical

waste to be generated from the Project.

Table

6.2 Waste Types

Generated throughout Operation and Decommissioning of the Project

|

Waste Type |

Quantity Generated |

Handling & Disposal Options |

|

Operation |

|

|

|

General

refuse |

Up to

5 kg per day |

As per (2) |

|

C&D

materials |

None |

n/a |

|

Chemical

waste |

Minimal (< 1kg/month) (regular

maintenance of equipment will be carried out offsite) |

As per (3) |

|

|

|

|

|

Decommissioning |

|

|

|

General

refuse |

Up to

5 kg per day |

As per (2) |

|

C&D

materials |

Total

350 m3 |

As per (1)

& (2) |

|

- Inert |

325m3 |

|

|

- Non-inert |

25m3 |

|

|

Chemical

waste |

Minimal (< 10kg) (maintenance

of equipment will be carried out offsite) |

As per (3) |

(1) Inert C&D materials

will be disposed of at Tuen Mun

Area 38 Fill Bank

(2) Non-insert C&D

materials will be disposed of at WENT Landfill

(3) General refuse will be disposed

of at WENT Landfill or via transfer station

(4) All chemical waste will be

handled in accordance with the EPD��s Code

of Practice on the Packaging Labelling and Storage of Chemical Waste. Employ a licenced collector for

collection of chemical waste and disposal at the licenced disposal facilities (eg Chemical Waste Treatment Facility at Tsing Yi)

The major types of solid waste likely to be generated

from the decommissioning works include construction and demolition (C&D)

materials (both inert and non-inert materials), chemical wastes and general

refuse. No

decommissioning materials will be considered for reuse except: metal

scrap/re-bar collected by the recycler; fire extinguishers collected by the

fire service provider; and fire hydrant water tank and water pumps. Negligible

amount of rock or spoil will be generated, and only small amount of metal will

be generated from the decommissioning works. Owing to the small scale of works, the

amount of C&D materials generated will be limited, approximately 350 m3.

Currently the TLEM is operated under Contract

CV/2012/08, and all non-inert waste will be disposed at NENT landfill using the

existing billing account of the Contract i.e. NENT landfill is the designated

disposal site of the Contract. Table 6.2

indicates

the different waste types and estimated quantities generated from the

decommissioning of the Project and how these will be handled and disposed of.

Based

on the above, the potential impacts associated with the handling and disposal

of C&D materials due to the decommissioning works are considered minor.

With

proper housekeeping measures and refuse collection in place, minimal or no

impact is expected to result from refuse generated during the operational

phase.

The

decommissioning works will involve only a very small number of construction

equipment. The quantities of

chemical waste generated will also be minimal. All chemical wastes will be handled in

accordance with the EPD��s Code of

Practice on the Packaging Labelling and Storage of Chemical Waste and a

licenced collector will be employed for the collection of the chemical waste

generated to the licenced disposal facilities (eg

Chemical Waste Treatment Facility at Tsing Yi). Hence, no adverse environmental impact

is anticipated due to the management of a small quantity of chemical waste to

be generated from the Project. With

proper housekeeping measures and refuse collection in place, minimal or no

impact is expected to result from refuse generated (up to about 5 kg per day)

during the decommissioning works.

The inert and non-inert C&D materials will be disposed of at Tuen Mun Area 38 Fill Bank and

WENT Landfill, respectively. The

general refuse will be disposed of at WENT Landfill or via transfer station.

To

minimise the amount of waste, careful design, comprehensive planning and good site

management practice will be adopted by the contractors of the Project and waste

on-site will be properly segregated to increase the potential for reuse and

recycling. Chemical waste generated

from equipment operation and demolition works will be properly stored in

accordance with Code of Practice on the

Packaging, Labelling and Storage of Chemical Waste published by the EPD

before collection for disposal by a licensed Chemical Waste Collector. The quantity of general refuse generated

on-site will be minimal owing to the nature of the operation activities and the

small number of workers involved during decommissioning.

The

amount of general refuse generated from the operation and decommissioning of

the magazine site is expected to be small.

General refuse will be stored and disposed of separately from chemical

waste. C&D materials from the

decommissioning will also be handled and disposed of appropriately. Provided that general refuse is removed

from the Project Site regularly during operation and decommissioning (e.g. once

per day) and C&D materials is disposed of appropriately, no adverse

environmental impact related to handling and disposal of wastes is expected.

This

section presents the potential impacts from the operation and decommissioning

of the Project on water quality.

While the previously approved Hong Kong Section of the XRL EIA report

(No. AEIAR-143/2009) XRL) covers the implication of potential water quality

impacts from the whole XRL Project, this does not include details specifically

at the TLEM site. Section 3 Ecology of the XRL EIA

addresses impacts to two watercourses in the TLEM project site, watercourse 4

and watercourse 5, and equally these are addressed in Chapter 3 Ecology of this report.

The

following relevant legislation and associated guidance are applicable to the

evaluation of water quality impacts associated with the Project:

�P

Water Pollution Control

Ordinance (WPCO);

�P

Technical Memorandum for

Effluents Discharged into Drainage and Sewerage Systems, Inland and Coastal

Waters (TM- ICW);

�P

Environmental Impact

Assessment Ordinance (Cap. 499. S.16) and the Technical Memorandum on EIA

Process (EIAO-TM), Annexes 6 and 14.

The

Water Pollution Control Ordinance (WPCO)

is the primary legislation for the control of water pollution and water quality

in Hong Kong. Under the WPCO, Hong Kong waters are divided into

10 Water Control Zones (WCZs). Each

WCZ has a designated set of statutory Water Quality Objectives (WQOs).

All discharges during both the operation phase of the

proposed Project are required to comply with the Technical Memorandum for Effluents Discharged into Drainage and

Sewerage Systems, Inland and Coastal Waters (TM-ICW) issued under Section 21 of the WPCO.

The TM-ICW

defines acceptable discharge limits to different types of receiving

waters. Under the TM-ICW, effluents discharged into the

drainage and sewerage systems, inshore and coastal waters of the WCZs are

subject to pollutant concentration standards for specified discharge

volumes. These are defined by the

Environmental Protection Department (EPD) and are specified in license

conditions for any new discharge within a WCZ.

Under Section 16 of the EIAO, Environmental Protection

Department (EPD) issued the Technical Memorandum on Environmental Impact

Assessment Process (EIAO-TM) which specifies the assessment methods and

criteria for environmental impact assessment. This section follows the EIAO-TM to

assess the potential water quality impacts that may arise during the operation

and decommission phases of the Project.

Sections in the EIAO-TM relevant to the water quality impact assessment

include: Annex 6 - Criteria for Evaluating Water Pollution; and Annex 14 -

Guidelines for Assessment of Water Pollution.

The Project is located in Tai Shu Ha, which is within

the water catchment of the Yuen Long Creek. As shown in Figure 7.1,

there are two minor watercourses within 500 m from the Project boundary. Both of these watercourses run into a

tributary of Yuen Long Creek, which is continuously monitored by EPD at YL2 and

YL3 as also shown in Figure 7.1. The 2013 river water quality at EPD

monitoring stations YL2 and YL3 downstream of the Project Site is summarized

below in Table 7.1.

Yuen Long Creek��s overall compliance rate in 2013 was

51%, compared with 53% in 2012. The

compliance rate for the more upstream YL2 station (which is still downstream of

the Project Site) was 60% in 2013 as compared 62% in 2012. The compliance rate for the YL3 station

in the middle of Yuen Long township was 42% in 2013 as compared with 42% in

2012. This river is subject to

discharges from livestock farms, unsewered village

houses and industrial establishments.

Table 7.1 River Water

Quality at Yuen Long Creek Downstream to the Project Site in 2013

|

Parameter |

Unit |

Yuen Long Creek |

|

|

YL2 |

YL3 |

||

|

Dissolved

oxygen |

mg/L

|

6.7 (3.0

- 9.6) |

5.0 (2.6

- 6.9) |

|

pH |

|

7.3 (7.2

- 7.6) |

7.6 (7.1

- 8.4) |

|

Suspended

solids |

mg/L

|

10 (4 - 27) |

27 (9 -

140) |

|

5-day Biochemical Oxygen Demand |

mg/L

|

9 (4 -

40) |

38 (4 -

82) |

|

Chemical Oxygen Demand |

mg/L

|

29 (11 -

69) |

45 (9 -

180) |

|

Oil

& grease |

mg/L

|

0.6

(<0.5 - 1.6) |

1.3

(<0.5 - 5.0) |

|

Faecal

coliforms |

cfu/ 100mL |

<130,000

(<1,000 - 740,000) |

870,000

(250,000 - 2,800,000) |

|

E.

coli |

cfu/ 100mL |

<93,000

(<1,000 - 630,000) |

330,000

(71,000 - 1,200,000) |

|

Ammonia-nitrogen

|

mg/L

|

13.50 (0.76

- 20.00) |

2.90

(0.36 - 11.00) |

|

Nitrate-nitrogen

|

mg/L

|

1.85

(0.19 - 6.40) |

<0.01

(<0.01 - 1.30) |

|

Total Kjeldahl nitrogen |

mg/L

|

16.00

(1.30 - 23.00) |

4.10

(0.87 - 14.00) |

|

Ortho-phosphate

|

mg/L

|

2.40

(0.22 - 3.10) |

0.35

(<0.01 - 1.10) |

|

Total

phosphorus |

mg/L

|

2.45

(0.28 - 3.40) |

0.56

(0.21 - 1.90) |

|

Total

sulphide |

mg/L

|

<0.02

(<0.02 - 0.05) |

<0.02

(<0.02 - 0.07) |

|

Aluminium

|

�gg/L

|

110 (70

- 330) |

355 (134