|

Agreement

No. CE 72/2019 (EP) Environmental Impact Assessment (EIA) Report for the New Contaminated Sediment Disposal Facility to the West of Lamma Island

July 2022

|

2.

Project Description

2.1

Background and History of the Project

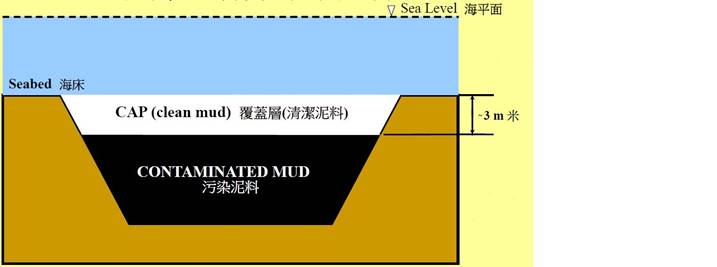

Since 1992, CEDD has been managing a number of contaminated sediment disposal facilities in the Hong Kong waters, including the CMPs at ESC and SB. These facilities consist of some series of seabed pits, formed by the removal of existing marine sediments, for disposal of contaminated dredged/ excavated sediment generated from works within Hong Kong. When their designed capacities have been reached, the pits would be separated from the adjoining environment by a layer of uncontaminated sediment (or naturally excavated materials) of no less than 3 m thick. Operations at these facilities are monitored through the implementation of a purposely designed environmental monitoring and auditing programme, comprising monitoring of water quality, sediment quality, sediment toxicity, marine biota, human health and ecological risk and benthic recolonisation. Monitoring results for the existing CMPs at ESC and SB indicate that operations at these facilities are environmentally acceptable. For details of the monitoring results, please refer to the EM&A reports submitted under the respective environmental permits EP-312/2008/A and EP-427/2011/A.

According to the latest estimate by CEDD, the total remaining capacity of the existing disposal facilities at ESC can only cope with the demand up to 2027 for the public and private projects. A new sediment disposal facility has to be planned and the proposed new facility will be located in the West Lamma Channel – in an area to the west of Lamma Island and to the east of the recommended Traffic Separation Scheme between south of Kau Yi Chau and Fan Lau (route via south of Cheung Chau).

2.2

Purpose and Objectives of the Project

The Project aims to plan and design the new contaminated sediment disposal facility at the west of Lamma Island (WL Facility). The proposed WL Facility aims to meet the sediment disposal demand upon the anticipated exhaustion of the existing CMPs at ESC in 2027, arising from routine harbour / channel / river maintenance dredging works and other projects, as discussed in Section 1.1. The facility is intended to cater for an estimated annual average disposal demand of 0.6 Mm3 of contaminated sediment within the Study Area.

2.2.1

Environmental Benefits of the Project

Although non-dredged methods are encouraged for marine infrastructure projects in Hong Kong, disposal facility for handling dredged sediment is still necessary for essential maintenance works for harbours, fairways, anchorage or drainage channels. Following the spirit of the "Convention on the Prevention of Marine Pollution by Dumping of Wastes and Other Matter" (commonly known as the "London Convention", to which China is a signatory), a centralised management and monitoring scheme has been set up to provide overall control over the disposal of marine mud in Hong Kong. Dedicated marine contaminated mud disposal facilities adopting the contained aquatic disposal (CAD) design has been implemented at ESC and SB since 1990s, and the associated environmental monitoring and audit programme at ESC and SB has demonstrated that the operation of the facilities did not cause adverse environmental impacts to the surroundings. The WL Facility would adopt a similar CAD design and continue to serve as a centralised facility in Hong Kong, providing an overall control for the disposal of contaminated sediment in an environmentally acceptable manner. Based on the previous experience from the ESC and SB facilities, benthic recolonisation occurs after the completion of the final capping layer with uncontaminated sediments and/or natural uncontaminated soil and the site is expected to return to the pre-dredged state within a relatively short period of time. The employment of such environmental protection methods in the design of WL Facility will, therefore, act as an environmental benefit.

2.2.2

Scenario without the Project

The existing CMPs at ESC and SB are anticipated to be exhausted by 2027 and they cannot be expanded further due to the limited usable seabed in the vicinity based on the findings of two previous studies (under (i) Agreement No. CE 105/98 – Strategic Assessment and Site Selection Study for Contaminated Mud Disposal and (ii) Agreement No. CE 12/2002 (EP) – Detailed Site Selection Study for a Proposed Contaminated Mud Disposal Facility within the Airport East/East of Sha Chau Area). If new disposal facility is not developed in time to meet the forecasted disposal demand, flood protection works, harbour maintenance dredging works, and the implementation of on-going and planned building/ infrastructure projects will either come to a halt or not be able to proceed. It will also result in navigation risks to marine traffic due to insufficient water depth along the channel if maintenance dredging work could not be carried out in time.

2.2.3

Scenario with the Project

With the Project in place, sediments could be disposed of at the WL Facility after the existing CMPs at ESC are exhausted by 2027. Given the Project is the only sediment disposal facility for disposal of contaminated sediments after the exhaustion of the existing CMPs, it is crucial to have such facility in place matching with the usage of existing CMPs and the anticipated disposal demand in the coming years. To cater for possible surge of disposal demand which may expedite the exhaustion of existing CMPs and any unforeseeable interruption to the project progress, it is necessary to have the new facility ready for disposal by 2025, allowing a transitional period of about two years before the anticipated exhaustion of the existing CMPs. An uninterrupted disposal service could therefore be maintained and flood protection works, harbour maintenance dredging works and the implementation of the on-going and planned building/ infrastructure projects will be able to proceed.

2.3

Need for Marine Disposal of Contaminated Sediment

As stated in ETWB TC(W) No. 34/2002, prior to dredging / excavation of sediments, each project proponent has to provide the rationale for sediment removal. To protect the marine environment and make the best use of the limited capacity of the disposal facilities, project proponents are required to avoid and / or reduce dredging where practicable, and to explore the feasibility of reusing the dredged / excavated sediment as fill material as far as possible. The Marine Fill Committee (MFC) will only consider granting allocation when the need for removal of sediment has been satisfactorily demonstrated. Although non-dredged methods are encouraged for construction of infrastructure projects in Hong Kong, dredging is necessary for essential maintenance works for harbours, fairways, anchorage or drainage channels. According to the latest estimate of the MFC, the annual average contaminated sediment disposal demand is about 0.6 Mm3, with major contribution from the maintenance dredging works, even when project proponents are required to avoid, minimise, reduce dredging where practicable, and reuse sediment if possible. It is therefore not possible to completely eliminate the need of sediment disposal and it is important to maintain a disposal facility for contaminated sediment arising from routine harbour / channel / river maintenance dredging works and other projects.

2.4

Consideration of the Different Development Options

There are various approaches for management of dredged materials worldwide. The Civil Engineering Department (CED) initiated a study in 1998 entitled the Strategic Assessment and Site Selection Study for Contaminated Mud Disposal (Agreement CE 105/98) (“CE 105/98 Study”) with the purpose of providing a preliminary, strategic assessment of potential contaminated dredged material management options and recommending a suitable site or sites for the preferred options. Several contaminated mud disposal options including CAD, confined disposal facility (CDF) and upland disposal were considered in terms of three initial screening criteria:

n implementation at the required scale either in Hong Kong or elsewhere;

n appropriate given the characteristics of Hong Kong's contaminated dredged material; and

n consistent, if implemented, with all applicable Hong Kong legislation, regulations and policies.

This initial screening was designed to eliminate disposal options which are unsuitable or impractical for Hong Kong regardless of siting considerations. The information below was originally prepared in 1999 and has been updated to reflect applicable new technical guidance issued since 1999 and new project experiences.

2.4.1

Contained Aquatic Disposal (CAD)

CAD options may involve use of excavated borrow pits, or may involve purpose-built excavated pits. CAD sites are those which involve filling a seabed pit with contaminated mud and capping it with uncontaminated material such that the original seabed level is restored and the contaminated material is isolated from the surrounding marine environment (Figure 2.1).

Figure 2.1 Typical Design of CAD Facility

The concept of CAD was considered as early as 1977 when the United States Army Corps of Engineers (USACE) conducted an inventory of subaqueous borrow pits across the US. Since then the CAD alternative has seen an expanding use worldwide. Several case studies of CAD projects are summarized in the recent guidance by the International Navigation Association Environmental Working Group (PIANC) ([1]) showing the range of scale and placement methods for these projects. CAD is actively being considered as an option for a number of additional projects worldwide.

Hong Kong's experience with CAD facilities is substantial and the capped and existing CMPs at ESC and SB are the proven examples of successful CAD facilities for management of contaminated sediments. Comprehensive environmental monitoring, comprising water quality, sediment quality, fisheries, ecotoxicity, benthic recolonisation, has been conducted since 1990s and the results demonstrated that the CMPs were effective in containing contaminated sediments without adverse environmental impacts. Given the success of CAD facilities in Hong Kong, as evidenced by the results of monitoring studies and other related assessments, it is likely that new CAD facilities engineered using similar principles would be equally environmentally acceptable and cost effective.

The main environmental issues to consider when proposing particular sites for CAD are the dispersive characteristics of the site and its proximity to sensitive receivers. If materials are placed in the CAD through simple bottom dumping from barges, sediment plumes will form and may disperse toward areas of high ecological value or beneficial use, such as beaches or fish culture zones. Consequently, selection of sites in areas of low current is seen as highly beneficial. Loss of materials during and after placement (but before capping) can be managed through disposal rates, controlled disposal procedures and adopting lower backfill heights. CAD options must also be designed as effective containment sites for retention of contaminants taking into account long-term processes such as, erosion, bioturbation or pore water release. This can be achieved through cap design of the appropriate materials and thickness.

Existing seabed pits have no inherent advantages over a purpose-built pit in ease of operation or effectiveness of containment. However, existing pits would not require initial excavation, and disposal of excavated sediment, and thus would be preferable.

Use of either existing and purpose-built seabed pits as a disposal option for contaminated dredged material has already been implemented at the required scale and found to be suitable for Hong Kong sediments.

2.4.2

Confined Disposal Facilities (CDF)

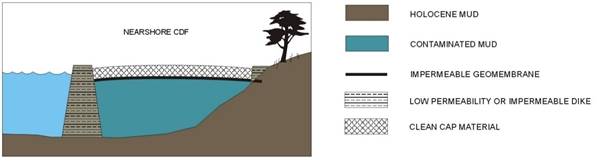

CDFs are nearshore or island diked containment structures which serve to isolate contaminated dredged material, but extend up to and possibly above sea level (Figure 2.2). Large scale CDFs have been developed in the Netherlands and elsewhere for both highly and moderately contaminated dredged material.

Figure 2.2 Typical Design of Nearshore CDF

The environmental impacts of CDFs relate primarily to the degree of contaminant containment in the adopted CDF design. In general, designs with greater control over contaminant pathways will have higher associated costs of construction, operation and maintenance. Features such as installing a liner to gather leachate, implementing a system to treat leachate and effluent, and/or controlling placement using an enclosed pipeline system can be used to mitigate contaminant release to the environment. The impacts of constructing a CDF, such as building seawalls/dikes and sourcing these materials, can be mitigated. However, these impacts are likely to be of greater magnitude than impacts associated with CAD construction, and thus the effectiveness and cost of the proposed mitigation becomes a key issue. Moreover, the CDF is a permanent structure that will result in a permanent loss of fishing ground and loss of habitats for fisheries and marine ecological resources.

Although similar CDF operations have been demonstrated in the Netherlands, the United States and Japan, the size of a CDF with sufficient volume to accommodate the projected sediment arisings in Hong Kong would be large and may be difficult to site along the coast. While the CDF could be incorporated into part of a new reclamation, the limitation on the future land use of the completed CDF has to be carefully assessed with the overall land use planning of the reclamation. Therefore, CDF option is considered less preferable for Hong Kong.

2.4.3

Upland Options

Suitability of Landfill Disposal: Information available indicated that dewatering and solidifying sediments would allow landfill criteria (Toxic Characteristics Leaching Procedure and water content) to be met. However, as a moderately contaminated sediment (Type 2) disposal option, the use of an existing landfill was deemed impractical because the large quantities requiring disposal would result in an unacceptable reduction of capacity for the landfills. Although utilising an existing landfill only as a highly contaminated sediment (Type 3) disposal option would place a smaller demand on capacity, any reduction of capacity is undesirable.

Suitability of Existing / Planned Waste Treatment Facilities: Hong Kong’s Chemical Waste Treatment Centre and the Sludge Treatment Facility were considered to provide sufficient capacity only for materials requiring Type 3 disposal and their use for treatment of dredged material would comply with Hong Kong's legal and policy framework. However, existing waste treatment facilities are not suitable for dealing with materials that are contaminated with high levels of inorganics (i.e. metals), which is typically the case for contaminated dredged/excavated sediment in Hong Kong. Although findings from previous studies indicated that the contaminated sediment could be reused after treatment with certain binders (e.g. cement), only limited sediment samples had been tested and further studies have to be conducted to evaluate the cost effectiveness in large-scale application. Therefore, selection of this option was not recommended.

Suitability of Developing a New Dedicated Facility: Development of a new dedicated upland containment facility for contaminated materials could be accomplished on the appropriate scale and could be designed specifically for Hong Kong sediments. There is limited land supply for disposal of large amount of contaminated sediment on land. Site selection is also constrained as such facility has to be kept away from the communities and areas of ecological importance. There is also possibility of contaminant leakage due to transportation of sediment to land and to the upland facility.

Overall, given the apparent suitability of many existing options, and the large land requirement for a new upland facility, this option was not recommended as suitable.

2.4.4

Recommendation of Preferred Development Option

Implementation of the CDF option in Hong Kong would not only require identification of a suitable site but also formulation, and perhaps testing, of an appropriate design. The CDF’s ability to meet all applicable engineering and environmental criteria would need to be demonstrated before full-scale operations are initiated. Also when compared to CDF, of which the size and area is fixed and needs to be built in a single construction to cater for the need, CAD facilities allow more flexibility as they could be built one by one according to the need. Another benefit for adopting CAD but not CDF is that the former option would only cause a temporary loss of fishing ground and marine habitat, while the latter would cause a permanent loss of fishing ground and marine habitat. Beneficial after use could serve as both Type 2 and Type 3 options. Further study on the treatment of contaminated sediments demonstrated that the cost for sediment treatment is very high and require high capital cost for developing an upland facility in treating sediments before further disposal ([2]).

Based on the initial assessment presented above, CAD is a preferred option for the contaminated sediment disposal facility, with reasons as follows:

n Hong Kong's experience in handling contaminated materials using CAD is among the most extensive and well documented in the world, which provides a sound engineering and environmental basis for continuing with this option. On the other hand, the implementation of the CDF option in Hong Kong would require a formulation, and perhaps testing, of an appropriate design and further trials may be required before full-scale implementation;

n CAD facilities allow more planning flexibility as they can be developed in phases according to the disposal demand, whereas the size of a CDF will be governed in the early planning phase and it will be more difficult to alter at later stage; and

n CAD facilities will only result in temporary loss of marine habitats and fishing ground, and benthic recolonisation is expected to take place after completion of capping based on experience from the ESC and SB CMP facilities, whereas CDF development will result in permanent loss of marine habitats and fishing ground.

2.5

Consideration of Viable Sites

2.5.1 Identification of Available Areas

Various sites were identified under the CE 105/98 Study and a review of the early study findings has been conducted to confirm that:

n the eastern Hong Kong waters are generally not suitable for the development of CAD facilities in view of the ecological sensitivities (e.g. corals and Finless Porpoise), seasonal monsoon, water depth and hydrodynamic conditions;

n the remaining portion of western Hong Kong waters (excluding the existing CMPs at East of Sha Chau and South of The Brothers) are not suitable due to strong current flow from Pearl River Estuary and the importance of the area as Chinese White Dolphin habitats; and

n the south-western Hong Kong waters are not suitable due to the ecological sensitivities (e.g. Chinese White Dolphin during wet season and Finless Porpoise during dry season) and planning of marine parks.

The southern and central waters remain to be feasible for CAD development. The areas, however, have mostly been occupied by existing Marine Vessel Fairways ([3]), and earmarked for various development plans ([4]) and possible reclamation plans ([5]). With the reference to the latest available information, there is no other planned development within the portions of southern waters between Cheung Chau and Lamma Island. The selection of the Study Area is further discussed in Section 2.5.2 and suitability assessment of the Study Area is discussed in Section 2.5.3.

2.5.2

Selection of the Study Area

In order to identify usable areas for the potential CAD site in the southern waters of Hong Kong, constraint mapping has been undertaken following the approach of the CE 105/98 Study to identify absolute and potential environmental, physical and social constraints for the development of CAD facility. Absolute constraints are areas of either high ecological importance, or a physical constraint that may either impact / conflict the CAD development or locations that government departments would not allow the CAD to be present and were thus recommended to be avoided while potential constraints are areas considered to be either important in terms of their ecological/environmental value, or hold physical attributes recognized by government departments. Although potential constraint areas were not considered to be “no go areas”, their sensitivity was taken into account during the feasibility of siting a new CAD as significant issues could still be potentially present as an obstacle to the development of a new CAD facility. The identified absolute and potential constraints are listed in Table 2.1 below and presented in Figure 2.3a-c and Figure 2.4a-c, respectively. The Study Area has been selected to avoid key marine ecological habitats, including marine mammals (especially Finless Porpoise (FP)) and areas with high fisheries production. The impacts on marine ecology and fisheries will be discussed in detailed in Sections 4 and 5, respectively.

Table 2.1 Identified Absolute and Potential Constraints in Southern Waters of Hong Kong

|

Absolute Constraints |

Potential Constraints |

|

Environmental Constraints (Figure 2.3a and Figure 2.4a) |

|

|

· Restricted Areas under Wild Animals Protection Ordinance, including Sham Wan Restricted Area (Green Turtle Nesting Ground) · Coastal Protection Areas (CPAs) · Seawater Intake Points · Country Parks and Special Areas · Sites of Special Scientific Interests (SSSIs) · Coral Communities with High Ecological Value · Gazetted Fish Culture Zones

|

· Wintering or Nesting Grounds for Birds · Mangroves · Living Horseshoe Crab Records (Post 1995) · Potential Marine Park · 1 km radius buffer zone around Fish Culture Zones · 1 km radius buffer zone around coral communities with high ecological value · 1 km radius buffer zone around seawater intake points

|

|

Physical Constraints (Figure 2.3b and Figure 2.4b) |

|

|

· Water depth (0 to -5 mCD) · Designated or gazetted areas of marine dredging and mud disposal · Anchorages Areas including midstream anchorages, dangerous goods anchorages, immigration anchorages and typhoon shelters · Marine Vessel Fairways (major fairways) · Designated Bunkering Area · Submarine Cables, Pipelines and Outfalls · Ongoing Coastal Developments and Reclamation · Private Moorings · Wave monitoring station

|

· Planned / potential coastal developments and reclamation · 200 m radius buffer zone around Marine Vessel Fairways · 200 m radius buffer zone around Submarine Cables, Pipelines and Outfalls |

|

Social Constraints (Figure 2.3c and Figure 2.4c) |

|

|

· Gazetted Bathing Beaches |

· 1 km radius buffer zone around gazetted Bathing Beaches · Non-gazetted beaches |

Note: (1) Marine mammal habitats with low to moderate abundance and spawning and nursery grounds of commercial fisheries resources are widespread in the region. These constraints are not appeared to be showstoppers for the development of CAD given the wide range of habitats in the region and the loss of habitats is temporary for CAD development. As such, these are excluded from the potential constraints for the identification of useable areas for CAD facilities in southern waters of Hong Kong.

Based on the constraint mapping, no absolute constraint was identified in the Study Area and the potential constraints are mostly outside the Study Area. The Study Area is thus identified as usable areas for the potential CAD site in the southern waters of Hong Kong.

2.5.3

Suitability Assessment of the Study Area

In order to evaluate if the Study Area is suitable for CAD development, the Study Area has been assessed according to the recommended CAD suitability assessment criteria determined in the CE 105/98 Study. The criteria covered environmental, engineering and planning factors including:

n water quality;

n dispersal characteristics;

n sediment characteristics;

n cumulative effects;

n ecological and fisheries characteristics;

n potential environmental benefits;

n technical uncertainty and risk of failure;

n placement/berthing;

n interference with marine traffic and risk of collision;

n ability to isolate contaminants as a function of cost;

n ability to receive arisings;

n cost of construction and management;

n ease and practicality of use and management;

n procedural impacts;

n conflicts with beneficial uses; and

n degree of compatibility with development plans.

In order that consistent means of evaluating the suitability of an alternative for deployment were employed, a categorization system was applied using either positive signs (“+”) or negative signs (“-“) to reflect the degree of suitability of the alternative, in terms of the relevant criteria, for contaminated mud disposal.

The categories are as follows:

(++) indicates the alternative is highly suitable and does not have any apparent drawbacks;

(+) indicates the alternative is suitable although some minor drawbacks may be encountered;

(0) indicates the alternative is suitable but only if special and unanticipated engineering, design or management features are incorporated; if incorporated, drawbacks associated with the alternative can be overcome;

(-) indicates the alternative is somewhat unsuitable since special and unanticipated engineering, design or management features would be required yet would not guarantee the success of the alternative;

(- -) indicates the alternative is unsuitable since the cost and / or practicability of the special and unanticipated engineering, design or management features required to overcome drawbacks would likely be prohibitive.

Alternatives assigned a rating of (- -) were considered unsuitable as part of the overall strategy and excluded from further consideration. The evaluation against the assessment criteria is presented in Table 2.2.

Table 2.2 Evaluation of the Study Area against the Assessment Criteria

|

Assessment Criteria |

Study Area |

|

Environmental Criteria |

|

|

Water Quality |

Suspended sediments from the construction and operation of this site are unlikely to impact any non-mobile sensitive receivers, the closest of which are the potential South Lamma Marine Park and gazetted beaches at Lamma Island locating > 2.5 km away. (+)

|

|

Dispersal Characteristics |

High current speed and strong wave activity will facilitate dispersal and prolonged suspension of the disposed sediment and thus more likely to result in higher level of water quality impacts. High natural sedimentation rate will lead to loss of effective capacity of the CMP over the course of operation and reduce the efficiency of the CMP.

Current speeds at this site are low to moderate (0.12 - 0.43 ms-1), which are comparable to those at ESC and SB (0.16-0.77 ms-1). The wave activity is considered to be calm (wave height < 0.5m for > 90% occurrence). Natural sedimentation rate is not significant over the years (< 10 cm yr-1). (+)

|

|

Sediment Characteristics |

Based on EPD Routine Marine Sediment Quality monitoring data, the seabed sediments are predominantly cohesive that are suitable for CAD development and are unlikely to be contaminated with high levels of heavy metals. The sediments have a moderate chemical oxygen demand. (0)

|

|

Cumulative Effects |

Other concurrent projects which could cause cumulative impacts are disposal of uncontaminated mud at South of Cheung Chau, South of Tsing Yi, dredging under Improvement Dredging for Lamma Power Station Navigation Channel, dredging under Providing Sufficient Water Depth for Kwai Tsing Container Basin and its Approach Channel and potential reclamation at Central waters. Water quality modelling has been conducted to evaluate any cumulative impacts from other concurrent projects. (0)

|

|

Ecological and Fisheries Characteristics |

FPs are occasionally sighted in the vicinity of the Study Area. Part of the area is spawning and nursery grounds of commercial fisheries resources. The Study Area supports relatively lower fisheries production and fishing operation when compared with the areas in the vicinity of the Lamma Island and Cheung Chau, yet potential impacts on fisheries are expected. Concerns regarding contamination of seafood posing risks to human health are unlikely with reference to the long-term environmental monitoring data from the operation of ESC CMPs, indicating there is no evidence of adverse impact to fisheries resources collected near the CMP area due to the potential release of sediment-bounded contaminant (0).

|

|

Potential Environmental Benefits

|

Maintain environmentally neutral in the long term. Benthic communities are expected to recolonize the seabed at CMP after the capping works. The site is expected to return to the pre-dredged state within a relatively short period of time (0) |

|

Engineering Criteria |

|

|

Technical Uncertainty and Risk of Failure

|

Although the sediments are likely to be cohesive with high silt and clay content, the technical uncertainty could be overcome from the experience of CMP construction at ESC and SB. Given hydrodynamic factors (current speed and exposure to wave activity) are likely to be similar to those in ESC and SB and sediments are likely to be cohesive, it is considered the site is suitable with limited risk of failure. (++)

|

|

Placement/Berthing |

Local currents may influence approach/departure routes. Southern end of site exposed to southerly winds and waves but no physical placement constraints. (+)

|

|

Interference with Marine Traffic and Risk of Collision

|

The site does not encroach on any existing traffic separation schemes and principal fairways. The site is located near to and between Adamasta and West Lamma Channels. (+) |

|

Ability to Isolate Contaminants as a Function of Cost

|

A cost-effective cap of normal thickness and maintenance will be required as the site is infrequently disturbed by wave action. (++)

|

|

Ability to Receive Arisings

|

The site is located near to the major sources of contaminated mud and does not appear subject to any constraints which would particularly limit disposal rates. (++) |

|

Planning Criteria |

|

|

Cost of Construction and Management

|

Dredging is likely to be required creating by-products for disposal. The site is relatively close to the South Cheung Chau disposal site. Water depth is ~10 m. There are no specialized technology/ materials involved in construction. The level of on-site management required is likely to be moderate. (0)

|

|

Ease and Practicality of Use and Management

|

Hong Kong has extensive experience in the management of CAD facilities. Environmental monitoring requirements are likely to be similar to the existing CMPs at SB and ESC. (++)

|

|

Procedural Impacts

|

CAD has been previously adopted in Hong Kong and thus pre-implementation testing is not likely to be required. The site is not within an existing gazette area. (+)

|

|

Conflicts with Beneficial Uses

|

The nearest gazetted beaches are at Lamma Island locating >3 km away from the site. (+)

|

|

Degree of Compatibility with Development Plans |

No conflicting future development plans have been identified. (++) |

Following this process, the Study Area is considered suitable for development of CAD facility. Furthermore, as the Study Area is located ~3 km away from the nearby landmass at west of Lamma Island and it is in the order of approximately 600 hectares, it is suitable to cope with long term disposal demand with minimal impact to nearby sensitive receivers.

2.6

Details of the Project

2.6.1

Site Location and Site History

The Site is located in the West Lamma Channel to the west of Lamma Island and to the east of the recommended Traffic Separation Scheme (TSS) between south of Kau Yi Chau (KYC) and Fan Lau (route via south of Cheung Chau) as presented in Figure 1.1.

Back in 1997, there was a plan for the provision of additional shelters in West of Lamma area to support the midstream and container terminal related development ([6]). However, the Port 2030 Study anticipated that it would be sufficient to enhance the handling capacity of existing container terminals to cope with future growth and thus the planning for Container Terminal No.10 before 2030 was not recommended. In addition, there is no other planned development within the portions of southern waters between Cheung Chau and Lamma Island from the HK2030 Study. In view of the above, it is considered that area to the west of Lamma Island would have potential for housing a new CAD facility.

The Study Area is in the order of approximately 600 hectares, with decreasing seabed levels from -8 metres above Chart Datum (mCD) to -14 mCD from north to south.

2.6.2

Key Area Identified for Assessment and Design of the

CMPs

To facilitate the preliminary design and layout of the CMP within the Study Area, an initial site investigation was conducted at the northern portion of the Study Area to obtain surface sediment samples for preliminary identification of sediment quality within the Study Area. Sediment sampling and testing of surface grab samples were conducted between 29 May and 19 June 2020 and the sediment sampling locations under 200 x 200m grid arrangement (GS-1 – GS-90) are presented in Figure 2.5. It should be noted that because of the close proximity to the West Lamma Channel, sediment sampling was not conducted along the west boundary of the Study Area to minimise potential conflict with nearby marine traffic. The chemical screening results showed that all the sediment quality parameters required under ETWB TC(W) No. 34/2002 were lower than the Lower Chemical Exceedance Levels (LCELs) and hence the surface sediments within the northern part of the Study Area are uncontaminated Category L sediments.

Marine geophysical surveys were also conducted within the Study Area to investigate the seabed features and shallow geology. The survey area of the marine geophysical surveys is presented in Figure 2.5. The survey results indicated that the survey area was mostly covered by silt and clay and a number of sonar contacts were identified but all of them were not of archaeological interest (see details in Section 7). Based on the site investigation data, the Study Area is generally compatible for the development of CMPs.

As the Study Area is relatively large when comparing to the required area for the WL Facility, further review of baseline information was undertaken to identify other constraints in developing CMPs within the Study Area. Consultation with Government departments was also undertaken to identify any areas within the Study Area that might be under existing / planned use. The area for potential CMP development has been refined and the key area identified for potential CMP development under the Project (“the Key Area”) is presented in Figure 2.6. The Key Area is selected so as to avoid interacting with the wave recorder at the northern part of the Study Area. Furthermore, as the Study Area is situated with increasing water depths from north (~ -8 mCD) to south (~-14 mCD), it is preferred to utilise shallower waters to optimise the efforts in dredging operation for pit formation to enhance cost-effectiveness of the Project. The identified Key Area has a size of ~ 235 ha with water depth ranged from -8 mCD to -10 mCD from north to south. There are no submarine gas pipeline/ utilities within and in the vicinity of the Key Area and thus no impacts to these facilities are expected from the Project. The impact assessment to be discussed in the following chapters will focus on the Key Area where the CMPs will be located.

Further ground investigation works were conducted within the Key Area between March and May 2021 to obtain further geotechnical information and sediment quality information for further assessment and design of the CMPs. The sampling locations for marine drillholes and vibrocores are presented in Figure 2.7.

The results of the ground investigation works were adopted for further analysis on slope stability and other geotechnical design considerations for the CMPs. The results of the vibrocores showed that all the collected sediment samples down to ~20m below seabed were of low contamination (i.e. the sediment quality parameters required under ETWB TC(W) No. 34/2002 were lower than the LCELs) (see details in Section 6). The Key Area is thus suitable for CAD development.

2.6.3

Design of the CMPs

Based on the latest available information from desktop review and supplemented by the ground investigation, the preliminary layout of the CMPs for the Project within the Key Area is illustrated in Figure 2.8. The proposed CMPs are located ~2 km away from the nearby landmass at Lamma Island and is located ~50 m away from the wave recorder at West Lamma. The approximate distances between the proposed CMPs and nearby constraints are summarised in Table 2.3. Each CMP has an area ranged from ~23 ha to ~33 ha and each of them is able to handle ~2-4 Mm3 contaminated sediments. The total maximum capacity for contaminated sediment disposal of the proposed CMPs within the Key Area is 20 Mm3. A total of about 24 Mm3 uncontaminated sediment is estimated to be dredged for the construction of proposed CMPs within the Key Area. Considering the slope stability and other geotechnical constraints in CMP formation, the pit walls will have a shallow slope gradient and each CMP will be separated from each other for at least 50 m. The detailed layout and configurations of the proposed CMPs will be subject to review and optimisation in the design and implementation stage.

Table 2.3 Nearby Physical Constraints

|

Physical Constraint |

Approximate distance from the proposed CMP |

|

Wave recorder |

50 m |

|

Submarine cable/pipeline to the east of the Study Area |

310 m |

|

Lamma Power Station (LPS) pipeline for the HKOLNG Terminal project |

930 m |

Given the majority of the Key Area is suitable for developing CAD facilities with reference to project-specific ground investigation data, the whole Key Area is considered suitable for handling contaminated sediment. As the CMPs will be constructed and operated sequentially, no more than three pits will be active (dredging / backfilling / capping) at any one time. For the purpose of impact assessment, representative worst case scenario will be selected for assessment to be presented in the remaining sections.

2.6.4

Key Construction and Operation Activities of the

Project

The CMPs will be formed and used one by one taking into consideration of the latest forecasted demand of sediment disposal and no more than three pits will be active (dredging / backfilling / capping) at any one time. The construction and operation activities of each proposed CMP are listed below and discussed in the following sections. Depending on the requirements of the Marine Department Notice for the Project, boundary buoys may be set up to demarcate the works area of the CMPs during construction and operation of the Project.

Construction activities:

n Dredging of the seabed for the formation of CMP

Operation activities:

n Disposal of contaminated sediment in the formed CMP

n Capping of the exhausted CMP by uncontaminated sediment up to the original seabed level

2.6.4.1 Dredging

of the seabed for the formation of CMP

For construction of the Project (i.e. dredging of the seabed for the formation of CMPs), either one trailing suction hopper dredger (TSHD) with a maximum working rate of 256,200 m3/week or up to two grab dredgers with a total maximum working rate of 100,000 m3/week would be deployed depending on the plant availability at the time of construction works. It is assumed each CMP will be dredged down to ~15-20 m below seabed to form a pit with a disposal capacity of about 2-4 Mm3. The construction of each CMP would take about 1 - 2 years, depending on the dredging rate. It should be noted that the WL Facility will be implemented in phases. Timing of dredging the next CMP would depend on the actual contaminated sediment disposal demand. Given the long service lifetime of the WL Facility, the dredging schedule / rate in reality could be adjusted in view of the interface with other concurrent activities / projects as appropriate to minimise potential environmental impacts.

The dredged sediments will be disposed of at the designated sediment disposal facilities in accordance with the Dumping at Sea Ordinance (Cap. 466). Prior to the dredging works, sediment quality within the CMP area will be determined in accordance with the requirements in the ETWB TC(W) No. 34/2002 and sediment quality report will be prepared to the Director of Environmental Protection for approval such that the dredging contractor(s) could apply for marine dumping permit for disposal of dredged sediment. Depending on the sediment quality based on the chemical and biological test results, the dredged sediments will be disposed at open sea or confined marine disposal sites. Based on the available sediment quality data from the ground investigation works, it is expected the dredged sediments would require Type 1 open sea disposal and the sediments could be disposed at the South of Cheung Chau, the South of Tsing Yi, the East of Ninepin, the East of Tung Lung Chau, ESC as capping materials, as well as within WL Facility as capping materials when any CMP of the WL Facility reached its capacity in receiving contaminated sediments. As a conservative approach for impact assessments, for disposal activities generated by construction dredging in following sections, it is assumed there would not be any on-site reuse of the uncontaminated sediment generated from excavation of the CMPs as the capping materials. The dredged materials are assumed to be delivered to the other existing disposal facilities, mainly to the open sea disposal area to the South of Cheung Chau, the South of Tsing Yi and to East of Sha Chau as capping materials. The dredged materials will be transported to the disposal site using TSHD or hopper barges with tug boats depending on the type of dredging plant to be used at the time of construction works.

2.6.4.2 Disposal

of Contaminated Sediment in the Formed CMP

With reference to the typical arrangement of the existing CMP, disposal barges are typically instructed to dispose of sediments within the CMP area and located at least 50 m away from the CMP boundaries. The actual disposal location will depend on the water current speed and direction, as well as the sub-area usage to ensure an even backfill level. With reference to the disposal arrangement at the CMPs to ESC and SB, the maximum disposal rate for the Project is assumed to be 26,700 m3/day using TSHD or hopper barges with tug boats. It should be noted that the maximum working rate used in this assessment adopts a conservative approach. Assuming the estimated annual average contaminated sediment disposal demand of 0.6 Mm3 (equivalent to an average of ~1,650 m3/day) for future operation, the actual working rate under normal situation can be much lower throughout most of the service lifetime of the WL Facility.

The disposal procedures below were introduced in 1997 during the backfilling of CMP IIId at ESC ([7]) as well as the recent CMP at SB and CMP V at ESC. The main objectives of the disposal procedures for barges were to ensure that, as far as possible:

n disposal always takes place on the up-current side of the pit in order to allow as much time as possible for sediment to settle;

n backfilling takes place evenly over the whole area of the pit; and

n the movement of vessels under power in the pits is minimised.

The procedure for sediment disposal is summarised as follows:

1. the water current speed and direction are measured continuously using instruments (e.g. Acoustic Doppler Current Profiler) installed on site in the form of a smart buoy or equivalent close to the pit which is being backfilled. The current data are transmitted to the computer of CMP management contractor to be procured and supervised by CEDD; and are used to determine the optimum disposal position;

2. when a barge arrives at the pit, and after completion of the registration procedures, a Guide Boat from CMP management contractor will lead the barge towards the pit from the up-current direction;

3. the position of the Guide Boat, the current speed and direction and the outline of the pit are displayed on a monitor in the wheelhouse of the Guide Boat. The staff on board select an optimum disposal position which depends on the current speed and direction;

4. as the barge approaches the target disposal area, the tug skipper is instructed to allow the barge/tug combination to drift with the current;

5. when the barge has drifted into the optimum disposal location, the skipper is given the instruction to dispose sediment and the exact position of the disposal location is recorded; and

6. after sediment discharge, the tug/barge continues to drift for a few minutes during which time the barge is closed. The tug skipper is then instructed to apply power and to move the barge away from the pit area.

Although the method was not originally intended for use with trailer dredgers, a simplified procedure was developed and has been continuously used for CMP at ESC and SB. This procedure is designed to achieve the same basic objectives described above and the trailers must discharge through a diffuser arrangement in such a manner that:

n the hourly rate of discharge does not exceed 6,000 m3; and

n the exit velocity of the material from the diffuser outlet does not exceed 1.5 ms-1.

These requirements mean that it is not possible to vary the disposal location within the pit to suit the current speed and direction at the time of disposal. However, controlled discharge through a diffuser will minimise the loss of sediment to the water column and the losses will only occur close to the bottom of the pit. In consequence, this type of disposal is deemed acceptable at fixed locations, irrespective of current conditions. The disposal procedures are relatively simple in comparison with those used for disposal from barges. However, the disposal location may need to be varied from time to time, depending on the overall amount of material which is to be placed using trailers. In addition, all barge disposal operations must be suspended when a trailer is in the pit in order to minimise the risks of collision. This may give rise to periodic delays to barge disposal operations for a few hours depending on the size of the trailer which is discharging contaminated mud.

2.6.4.3 Capping

of the exhausted CMP by uncontaminated sediment up to the original seabed level

Previous purpose-dredged contaminated sediment disposal facilities at the ESC and SB area have had backfill levels up to 3 m below original seabed and the pits were capped with 3 m layer of uncontaminated sediments to keep the contaminated material beyond the reach of bioturbation and to protect it against storm erosion. Environmental monitoring at ESC and SB has demonstrated that the pits with 3 m layer of capping were able to retain disposed mud and did not cause contamination of sediments even after major storm events which might stir up sediments. Given the hydrodynamics and water current speeds at the Study Area are comparable to those at ESC and SB, it is considered that 3 m layer of capping for the WL Facility is sufficient to retain contaminated sediments without unacceptable environmental impacts to the surroundings.

Once the CMP of the WL Facility is backfilled with contaminated sediments to 3m below original seabed level, the CMP will be capped with uncontaminated sediments using the same disposal procedure for backfilling as discussed in Section 2.6.4.2, until the CMP is capped to the original seabed level. With reference to the capping arrangement at the CMPs to ESC and SB, the maximum capping rate for the Project is assumed to be 26,700 m3/day using TSHD or hopper barges with tug boats. It should be noted that the maximum working rate used in this assessment adopts a conservative approach. The actual working rate under normal situation is expected to be much lower throughout most of the service lifetime of the WL Facility depending on the availability of uncontaminated sediments for capping.

The potential for damage and breaching of the cap due to anchorage has been investigated. Considering the water depth at the WL Facility, the potential penetration depth of anchors would unlikely be over 3 m. Therefore, in case of anchoring activities within the CMP, the anchors would not reach the layer of contaminated sediments and thus the contaminated sediments would still be retained within the CMP.

2.7

Construction and Operation Programme

Once the EIA Report has been formally approved by EPD, CEDD will obtain an Environmental Permit (EP) for construction and operation of the Project. Once the EP has been obtained, the first CMP of the Project is planned to start construction in 2024 for operation by 2025/2026, allowing a transitional period of about two years before the anticipated exhaustion of the existing CMPs at ESC in 2027. Such transitional period is allowed to cater for possible surge of disposal demand which may expedite the exhaustion of existing CMPs and any unforeseeable interruption to the project progress. An uninterrupted disposal service could therefore be maintained. The actual disposal demand will depend on the future need for dredging due to navigation channels maintenance and construction projects which could not be ascertained at the moment. With an estimated annual average disposal demand of 0.6 Mm3 of contaminated sediment, each CMP of the proposed WL Facility is expected to provide disposal service for approximately 3 years. The tentative programme as shown in Table 2.4 demonstrates the typical construction and operation cycle for the first three CMPs of the proposed WL Facility, which covers a total period of about 10 years (including dredging, backfilling and capping). As the CMPs will be constructed and operated sequentially depending on the disposal demand, the duration for dredging, backfilling and capping of a CMP is estimated for presentation purpose only. Overall, subject to future disposal demand, the proposed WL Facility is expected to have a service lifetime for up to 20 years. The remaining CMPs are anticipated to follow a similar implementation programme for use upon exhaustion of the first three CMPs. It should be noted that no more than three CMPs will be active (dredging / backfilling / capping) at any one time. While backfilling of contaminated sediment is expected to be carried out throughout the operation of the Project, the exact schedule/ working rates of dredging and capping works would be adjusted to minimise potential environmental impacts in view of actual disposal demand of contaminated sediment, availability of uncontaminated sediment for capping and the interface with concurrent projects/ activities, etc.

Table 2.4 Tentative Programme of the Project (Indicative for the first three CMPs)

|

Pit |

Construction/Operation |

Year 1 |

Year 2 |

Year 3 |

Year 4 |

Year 5 |

Year 6 |

Year 7 |

Year 8 |

Year 9 |

Year 10 |

Year 11 |

Year 12 |

Year 13 |

|

1st |

Dredging |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Backfilling |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capping |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2nd |

Dredging |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Backfilling |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capping |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3rd |

Dredging |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Backfilling |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capping |

|

|

|

|

|

|

|

|

|

|

|

|

|

2.8

Development / Infrastructure Projects under Planning

or Construction

The existing, proposed and potential projects in the vicinity of the Study Area are described below. Where sufficient information is available, the cumulative impacts from these projects, if any, are addressed in the technical assessments in this EIA Study if these projects are located within the assessment areas for the respective technical aspects. Existing operations in these areas which may also interact with the construction and operation of this Project are considered in the technical assessments as baseline/ background conditions as relevant and are therefore not summarised in Annex 2A.

2.8.1 Key Existing Facilities, Utilities and Infrastructure

There are a number of key existing facilities and infrastructure in the vicinity of the Study Area listed below which are detailed in Annex 2A.

n Improvement Dredging for LPS Navigation Channel

n Wave Recorders at West Lamma Channel and Kau Yi Chau

n South of Cheung Chau Sediment Disposal Area

n Providing Sufficient Water Depth for Kwai Tsing Container Basin and its Approach Channel

n Submarine Cables and Pipelines

n Port Operations, including anchorage areas and typhoon shelters

n Existing and Closed Sites for Disposal of Sediments

n Potentially Contaminated Sites

2.8.2 Key Proposed and Potential Facilities, Utilities and Infrastructure

There are a number of key proposed and potential facilities and infrastructure in the vicinity of the Study Area listed below which are detailed in Annex 2A.

n Hong Kong Offshore Liquefied Natural Gas (LNG) Terminal

n 1,800MW Gas-fired Power Station at Lamma Extension

n Re-provision of Open Cycle Gas Turbines at LPS

n Development of a 100MW Offshore Wind Farm in Hong Kong

n Artificial Islands in the Central Waters (including Reclamation for Kau Yi Chau Artificial Islands, Kau Yi Chau Artificial Islands Development and Hong Kong Island – Northeast Lantau Link)

n Shek Kwu Chau Integrated Waste Management Facility (IWMF) Phase 1

n Outlying Island Sewerage Stage 2 - Upgrading of Cheung Chau Sewage Collection, Treatment and Disposal Facilities

n Outlying Islands Sewerage Stage 2 - South Lantau Sewerage Works

n Pier Improvement Works

n Other Potential Reclamations including Tsing Yi Southwest

([1]) PIANC (2002) Guidelines for Marine, Nearshore, and Inland Confined Disposal Facilities, Report of the Working Group No 5 of the permanent Environmental Committee, Permanent International Association of Navigation Congresses, Brussels, Belgium

([2]) Agreement No. CE 65/2015 (CE) The Application of Sediment Treatment Technologies for Beneficial Reuse and Handling of Sediment and Integrated Use of Confined Disposal Facilities (CDFs) in Future Reclamation Projects in Hong Kong – Feasibility Study.

([3]) Drawing No. 2018MAR005 - Traffic Separation Schemes and Principal Fairways. Prepared by the Hydrographic Office, Marine Department. January 2018.