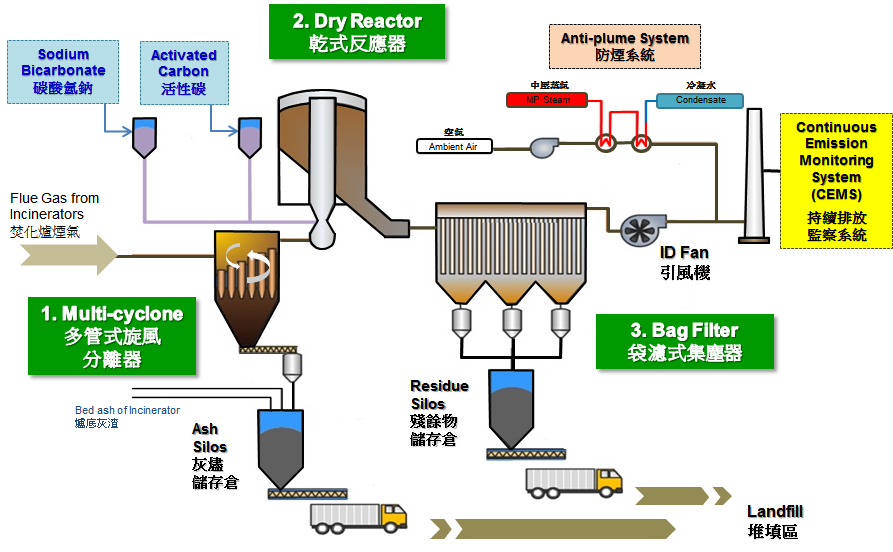

Although the high temperature combustion destroys the majority of pollutants during the incineration process, fly ash and small quantity of pollutants are still present in the flue gas. Highly efficient flue gas treatment equipment comprises the multi-cyclone, dry reactor and bag filter captures the remaining pollutants, and ensures the emission in compliance with the stringent emission standards.

The multi-cyclone removes the majority of particulates in the flue gas using centrifugal forces. Most of the heavy particulates fall through gravity into the hoppers, and store in the ash silos together with the bed ash from the bottom of the fluidized bed incinerator.

Inside the dry reactor, heavy metals, acidic gas and organic compounds are removed through different physical and chemical processes. Sodium bicarbonate and activated carbon are added to remove acidic gases and capture organic compound and heavy metals respectively.

Fine ashes and by-products generated from the dry reactor are removed in the bag filter, in a very similar way dust being trapped inside a bag in a vacuum cleaner. There are around 1000 filter units inside each bag filter, providing a large surface area to efficiently separate the very fine particles from the flue gas. The filtered particles are periodically cleaned off and disposed of as residues.

The clean flue gas is emitted to the environment through the stacks equipped with continuous emission monitoring system (CEMS) for round-the-clock monitoring of the instantaneous air emission data.