Ventilation System

Air Pollution

| Common Problems | Causes | Relevant Environmental Control |

| Excessive emission of cooking odour & greasy fumes | Exhaust outlets locating too close to the nearby air sensitive receptors | Under the Air Pollution Control Ordinance, Cap. 311, all air emissions from a restaurant should not cause air pollution problem, including odour nuisance, and should be free from visible fume. Any person causing air nuisance must adopt air pollution abatement measures. |

| Inadequate air pollution control measures |

Practical Solutions

- Avoid locating the exhaust outlets in close proximity to the air sensitive receptors for restaurants and food business

- Locate the exhaust outlets in a good ventilated and dispersive area, e.g. extending kitchen exhausts to rooftop

- Locate and orientate the exhaust away from the nearby air sensitive receptors

- Preference should be given to extend the exhaust to a level of at least 3m above the highest point of the restaurant's own building and any adjacent or attached buildings within a 20m radius

- Seek advice from environmental professionals when locating exhaust outlet

- Install appropriate air pollution control equipment (recent tests indicated that the combined use of electrostatic precipitator and hydrovent can remove up to 94% of oily fumes)

- Install appropriate odour control equipment, such as activated carbon filter, for cooking activities which emit strong odour

- Conduct regular cleaning and maintenance of all air pollution control equipment

- Maintain an easy access for serving and inspecting air pollution control agent

- Monitor the quality of cooking fumes and odour emissions regularly during peak hours

- Install transparent inspection window/panel for the air pollution control equipment

- Adopt automatic switch-on function to synchronize the operation of the cooking device with air pollution control equipment

| Indoor Air Pollutants | Typical Sources | Potential Health Effects |

| Carbon dioxide (CO2) | Smoking, breathing & burning | Headaches, dizziness & nausea at high concentration |

| Carbon monoxide (CO) | Burning, smoking & engine exhaust | Headaches, decreased alertness, flu-like symptoms, nausea, fatigue, rapid breathing, chest pain, confusion, impaired judgment & even death at high concentration |

| Respirable suspended particulates (RSP) | Burning, smoking, photocopying & engine exhaust | Allergic reactions, e.g. dry eyes, nose, throat, skin irritation, coughing, sneezing & respiratory difficulties |

| Nitrogen dioxide (NO2) | Burning, smoking & engine exhaust | Eyes & throat irritation |

| Ozone (O3) | Photocopying, printing using laser printers & high voltage discharged from air purifiers | Tingling sensation in the nose, dry & sore throat, tearing, burning, stinging & pain in the eyes |

| Volatile organic compounds (VOCs) | Cleansing agents, disinfectants, paints, solvents, printing inks, furniture, furnishings & smoking | Some VOCs are carcinogen, e.g. benzene |

| Formaldehyde (HCHO) (also a VOC) | Pressure-wood products, urea-formaldehyde foam insulation, adhesives, paints, furniture & smoking | Irritation to eyes, respiratory tract & damage to lung tissues at high concentration |

| Radon (Rn) | Granitic products | Lung cancer |

| Microbials (bacteria & fungi) | Proliferation under humid & suitable conditions | Flu-like symptoms & fever |

| Environmental tobacco smoke (ETS) | Smoking | Respiratory irritation, adverse effects on the cardiovascular system & lung cancer |

Practical Solutions

- Appoint an indoor air quality manager to conduct indoor air quality assessment and supervise the management of the indoor air quality programme

- Locate the fresh air intake in well ventilated area and free from obstruction

- Arrange a regular cleaning and maintenance programme for ventilation and air-conditioning systems

- Avoid setting low temperature and adopt humidity control equipment, such as heatpipe, to minimize growth of microorganisms such as molds and fungi

- Conduct pest control practices in non-business hours and adopt non-chemical methods where possible

- Prohibit tobacco smoking or establish smoking area with independent exhaust

- Isolate renovated areas with physical barrier and introduce local exhaust and air pollution control equipment, such as photocatalytic oxidation reactor (PCO Reactor)

- Promote good practices on improving indoor air quality to internal staff, occupiers and tenants:

- Fix all water leakages and water spills promptly to minimize the growth of microorganisms

- Schedule renovation activities in non-business hours

- Use product with no/low volatile organic compound

- Naturally aerate new furniture before use to reduce chemical emissions and odours

- Isolate and provide special ventilation for pollutants-generating office equipment such as copiers, printers and fax machines

- Establish clear procedures for responding to indoor air-related complaints

- Keep a record of reported health complaints to aid in solving indoor air-related problems

Noise & Vibration Pollution

| Common Causes | Relevant Environmental Control |

| Too close to the nearby sensitive receivers | Under the Noise Control Ordinance, Cap. 400, noise caused by any ventilation system at industrial or commercial premises should not cause the noise level at Noise Sensitive Receivers (NSRs) to exceed the limit stipulated under the relevant Technical Memorandum. |

| Inadequate noise pollution control measures |

Practical Solutions

- Place noisy equipment inside a plant room with thick walls as far as possible

- Locate the equipment away from the nearby and future NSRs

- Orientate the duct openings/air inlets/air outlets away from NSRs

Orientate the exhaust outlet away from noise sensitive receivers to minimize air flow noise.

- Choose equipment of low noise brands or models

- Make reference to the statutory noise limit and include noise levels specification when ordering new equipment

- Conduct regular maintenance, such as lubricating moving parts, tightening loosen parts (bolts/nuts, driving belts, panels, etc.), replacing worn-out components (bearings) and inspecting equipment alignment

- Implement proper noise control measures:

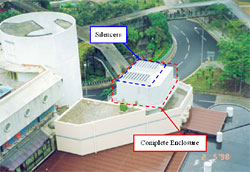

- Erect noise barrier, partial and completed enclosures to block the noise propagation path to the NSRs

Use noise barrier to block the noise propagation path to the nearby NSRs. - Install silencers at air inlets and outlets

Install complete enclosure for noisy machine and silencers for air exhausts. - Install inertia block and vibration isolator to isolate the vibrating machines and to prevent structural vibration transmission

- Apply damping material on the vibrating duct work

- Provide acoustic mat on the water surface of water cooling towers to reduce the water splashing noise

- Adjust the operation mode, such as reducing fan speed and switching off non-essential equipment at night