Chapter Title

Tables

Figures

Charts

Drawings

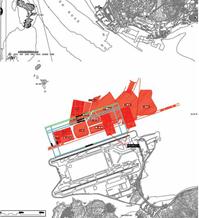

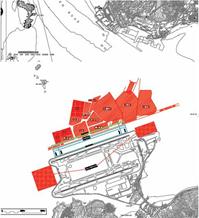

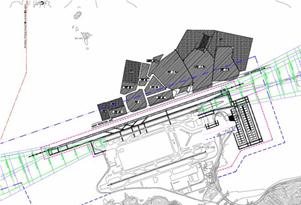

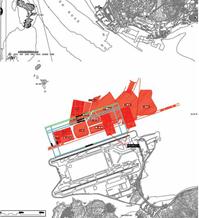

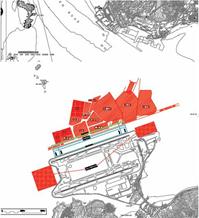

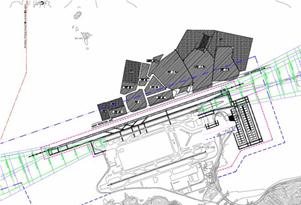

MCL/P132/EIA/3-001 P132 – Engineering Feasibility &

Environmental Assessment Study for Airport Master Plan 2030 Layout of Airport

Expansion Option 1

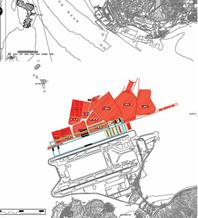

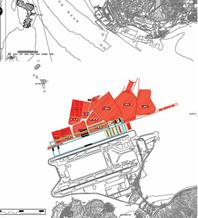

MCL/P132/EIA/3-002 P132 – Engineering Feasibility &

Environmental Assessment Study for Airport Master Plan 2030 Layout of Airport

Expansion Option 2

MCL/P132/EIA/3-003 P132 – Engineering Feasibility &

Environmental Assessment Study for Airport Master Plan 2030 Layout of Airport

Expansion Option 3

MCL/P132/EIA/3-004 P132 – Engineering Feasibility &

Environmental Assessment Study for Airport Master Plan 2030 Layout of Airport

Expansion Option 4

MCL/P132/EIA/3-005 P132 – Engineering Feasibility &

Environmental Assessment Study for Airport Master Plan 2030 Reduced Extent of

Land Formation for Option 3

MCL/P132/EIA/3-006 Preferred Airport Layout Option

MCL/P132/EIA/3-007 Proposed Ground Improvement Methods

MCL/P132/EIA/3-008 Terminal 2 Options

MCL/P132/EIA/3-009 Options for Diversion of Submarine Fuel

Pipeline

MCL/P132/EIA/3-010 Options for Diversion of Submarine 11kV

Cable

3.1.1.1

Chapter

2 of this

Environmental Impact Assessment (EIA) report discussed the expansion of Hong

Kong International Airport (HKIA) through the construction of a third runway.

This is considered necessary to meet the forecast air traffic demand up to the

Year 2030 without compromising on airport safety, airport service quality and

customer choice, and without adversely affecting the economic

benefits (such as local

employment, international business and trade) that are linked to growth in

aviation and air logistics in Hong Kong. Alternatives (to expansion) were

discussed in Chapter 2 and are considered to be inferior.

3.1.1.2

This

section identifies options and opportunities available for provision of a third

runway in Hong Kong, in terms of its alignment, the associated airport layout and construction methods.

3.1.2.1

This

section is structured as follows:

Section 3.2 – General

Considerations

presents the objectives of the airport expansion and the main constraints to

operation of the existing runways.

Section 3.3 –

Consideration of Alternatives for the Third Runway Alignment presents the runway alignment options

assessment leading to identification of the shortlisted alignments.

Section 3.4 –

Consideration of Alternatives for Airport Layout under a Three-Runway System presents the engineering and

environmental evaluation of the shortlisted airport layout options leading to

identification of the preferred option.

Section 3.5 – Further

Development of the Preferred Runway and Airport Layout presents the further considerations

and fine-tuning of the preferred option leading to the preferred runway and

airport layout.

Section 3.6 –

Consideration of Alternative Construction Methods for Land Formation presents the options for ground

improvement and seawall construction leading to the recommended construction

method for land formation.

Section 3.7 –

Consideration of Alternative Construction Methods for Marine Infrastructure

Facilities presents

the options for construction of airport facilities and infrastructure including

the runway approach lights, diversion of the submarine aviation fuel pipelines

and diversion of the submarine 11 kV cables.

Section 3.8 – References lists all the reference documents

which have been referred to in this section.

3.2.1 Objectives of Airport Expansion

3.2.1.1

The

need for airport expansion has been elaborated in Chapter 2. If a three-runway system (3RS) is developed, it must meet the

needs of the aviation

sector in Hong Kong and the aspirations of the public through the following attributes:

¡ Provision

for the additional capacity projected in the

Airport Master Plan 2030

(MP2030) – in the absence of this criterion, the third runway

would not meet the need identified in Chapter 2 of this report;

¡ Provision for the safe approach, landing and take-off procedures required by

the Civil Aviation Department

(CAD) – this is a mandatory requirement that overrides most other

considerations, as passenger and crew safety must never be compromised;

¡ Be optimally located and configured – this affects the effectiveness

of the third runway and impacts on the ability of the third runway to meet

forecasted demand;

¡ Provision

of sufficient space for all other related facilities

(e.g. passenger terminal expansion

and new concourses, Baggage Handling System (BHS), Automated People Mover (APM), aircraft aprons, taxiways, navigation aids, air traffic control tower, etc.) needed to support the operation of a third runway; and

¡ Be compatible with the operation of the existing HKIA.

3.2.2 Review of Existing Configuration and Constraints

Current Airport Runway

Configuration

3.2.2.1

At

present, there are two runways at HKIA. These parallel runways are aligned

along 07/25 orientation (i.e. runways aligned along an axis of 70° and 250°

from the north). The runways are slightly staggered with a 1,540 m separation

[1].

Major Constraints to the Existing Runway

Operations

3.2.2.2

The

majority of constraints that affect runway operations relate to safety

requirements. While airports around the world are subject to international

rules and regulations that control (or constrain) their operation, there are

some constraints which are specific to the local environment. The main

locally-specific constraints affecting operation of the two existing runways at

HKIA include:

¡ Topography;

¡ Territorial boundaries;

¡ Anthropogenic (man-made) structures;

¡ Populated areas; and

¡ Current runway configuration.

Topography,

Territorial Boundaries and Anthropogenic Structures

3.2.2.3

Topography

affects runway operations by physically restricting flight movements. There is high terrain to the south of HKIA

on Lantau Island and to

the north-east of the airport in North West New Territories [3]. The permanent

presence of high terrain means that only certain approach and departure routes are viable from a

safety perspective [1].

3.2.2.4

Territorial

boundaries affect runway operations by restricting the permitted flight routes

for arrivals and departures from outside of Hong Kong Special

Administrative Region (HKSAR).

This constraint is however partially negotiable.

3.2.2.5

Man-made

structures, particularly major infrastructure and superstructures, can also

restrict flight movements as well as the vertical climb and descent

requirements for aircraft. In some instances, certain built facilities are

associated with ‘no fly’ zones that effectively bar all routes over that area.

Populated Areas

3.2.2.6

Populated

areas can affect the operation of a runway by imposing operational, temporal,

and aircraft restrictions on runway operations, such as restrictions on

aircraft types (i.e. those that do not comply with certain noise standards),

take-off / landing procedures and routes and operating times. These measures are usually adopted

for aviation noise

abatement reasons rather than because of safety issues. The noise control initiatives specified by CAD for the

existing operation of the

runways at HKIA include the following [2]:

¡ Aircraft arriving during midnight to 07:00 am are arranged

to land from the southwest, subject to acceptable wind

direction and safety consideration;

¡ Aircraft departing to

the northeast of the airport during

11:00 pm and 07:00 am are required to use a southbound

route via the West Lamma Channel, subject to acceptable operational and safety

consideration;

¡ Aircraft departing to

the northeast of the airport are required to adopt the International Civil Aviation Organization (ICAO) Noise

Abatement Departure

Procedures;

¡ Aircraft which can make use of

the satellite navigation technology are recommended, when departing to the

northeast of the airport between 11:00 pm and 07:00 am, to adopt the “Radius-to-Fix”

turn procedures when making south turn to the West Lamma Channel so as to

reduce the noise impact to residents in the areas;

¡ All noisy aircraft*

are barred from landing

and taking off in Hong Kong (* noisy aircraft refer to

those which do not comply with the noise standard in Chapter 3 of Annex 16

Volume I, Part II to the Convention on International Civil Aviation.); and

¡ All aircraft on

approach to HKIA from the northeast during

11:00 pm and 07:00 am are encouraged to adopt the continuous descent approach

(CDA), which involves aircraft flying higher and normally on a low power / low drag configuration.

Configuration of Existing Two Runways

3.2.2.7

The

physical location of the existing two runways has created some operational

constraints, in terms of interdependence of aircraft management (take-off and

landing as well as taxiing and queuing procedures) and in this

case, safety requirements

are the main drivers. For airports with more than one runway, the taxiway

system may maintain taxiing routes that create additional restrictions on the

maximum capacity of the runways (i.e. runway crossings or incursions).

3.2.2.8

In

theory, the most effective mode of operation for two runways is the mixed mode of operations1. In Hong Kong this mode theoretically allows a maximum capacity of 44 air traffic movements (ATMs) per hour on

each runway [3]. However, this theoretical maximum capacity cannot be achieved

with the existing two-runway system (2RS) at HKIA, because in

Hong Kong the airport is

required to operate under a “dependent” mixed mode for the following reasons

[3]:

¡ The terrain on Lantau Island constrains the South Runway’s mixed mode

capacity to 34 ATMs per hour.

¡ The terrain to the east of HKIA, such as Tai Mo Shan, and airport

traffic interaction with Macao airport to the west, prevents the

current two-runway configuration from accepting independent parallel approaches.

¡ The South Runway’s constrained circumstance requires a larger

spacing between landing aircraft, with similar requirements on the North Runway,

thereby preventing the runways from achieving a theoretical maximum capacity

under a mixed mode operation.

1 Mixed mode refers to an

operation mode of the runway whereby both ‘departures’ and ‘arrivals’ is

permitted on the same runway. ‘Dependent’ mixed mode refers to a mixed mode of

operations that is constrained by factors other than the maximum capacity of

the runway.

3.3 Consideration

of Alternatives for the Third Runway Alignment

3.3.1.1

The

alignment of a runway is governed by the geographical location as well as the

predominant wind direction for landings and take-offs. Considerations for

runway alignment form the first major foundation for any airport project, as

runway alignment effectively governs available options for future layout and

operation of airport facilities and can result in permanent operational constraints on an airport.

3.3.1.2

This

section describes the methodology adopted for consideration and evaluation of

different runway alignment options as well as summarising the assessments leading to

identification of a shortlist of

alignment options.

3.3.2.1

To

evaluate the runway alignment options, both a set of evaluation criteria and a

long list of runway

options were first defined. A process was then developed for reviewing each option against the relevant criteria to identify differences in

performance between options.

3.3.2.2

Considering

the constraints described in Section 3.2.2 as well as the potential additional

constraints associated with construction and operation of a new runway and

airport facilities, the main criteria for analysis of the various third runway

alignment options are described in Table

3.1

below.

Table 3.1: Alignment Options Evaluation Criteria [1]

|

Major Criteria

|

Key Considerations

|

Criteria

Importance1

|

|

Airport integration (aprons and terminals)

|

This includes consideration of passenger and cargo

transfers between new and existing facilities and the need for additional

airfield facilities to serve the new runway.

|

Non-mandatory criteria for comparative analysis

|

|

Airside integration (operational)

|

This includes the ability of the new runway to

integrate with existing airport facilities and operations and considerations of

traffic flows, physical constraints, and availability of contingency.

|

Mandatory compliance required

|

|

Airspace and airport capacity

|

All options are faced with Pearl River Delta (PRD)

airspace implications due to the addition of a third runway. These affect the

operational feasibility and capacity gain potential of each option.

|

Non-mandatory criteria for comparative analysis

|

|

Construction issues

|

This includes the contaminated mud pits (CMPs), potential impacts on local

shipping routes and other constraints to construction phase.

|

Non-mandatory criteria for comparative analysis

|

|

Environmental issues

|

This includes broad impacts due to aircraft noise,

impacts to marine habitats, water quality and changes in hydrodynamics.

|

Non-mandatory criteria for comparative analysis

|

|

Surface access

|

This includes the ability to extend existing surface

access facilities to serve the extended airport.

|

Non-mandatory criteria for comparative analysis

|

|

Topographical factors

|

This includes physical features (high ground) as well

as local meteorological conditions.

|

Mandatory compliance required

|

Note 1: Criteria

importance relates to the evaluation process in Stage 1 of the ‘Evaluation of

the Third Runway Alignment Options’

section of this document.

3.3.2.3

These evaluation criteria were the main

consideration in assessing

and comparing

individual alignment

options during different stages of the evaluation process.

Evaluation of the Third Runway Alignment

Options

3.3.2.4

The

evaluation process comprised the following steps:

1.

Stage 1 – 16

alignment options were

subject to assessment against a set of mandatory

compliance criteria (see mandatory criteria

list specified in Table

3.1). The purpose was to

review only the most important criteria (i.e. those that are

fundamentally required to ensure safe and viable operation of the runway) to

identify which alignments are compliant, and hence can be considered in Stage 2 of the evaluation. A relative comparison of non-mandatory criteria was also

reviewed.

2. Stage 2 – comprised

a more specific analysis of the operational

characteristics of the preliminary shortlisted options to further verify

the feasibility of each option. This stage produced a shortlist of options

for further analysis in

conjunction with different options for airport

facility layouts.

3.3.3.1

Stage

1 of the runway alignment options development focused on generic layouts to

demonstrate the broadest range of possible runway alignments for initial

assessment. This stage was based on information taken from the Airspace and Runway Capacity Study Phase 2 –

Final Runway Options Report, a report undertaken in 2008 by the UK-based

consultancy firm National Air Traffic Services (NATS) (1]. A total of

15 alignment options were developed, based on four runway concepts as

summarised below:

Concept 1 – Third runway aligned at an angle to

the existing runways (Options A and B);

Concept 2 - Third runway aligned parallel with

the existing runways (Options C, D, E, F, G, and H);

Concept 3 - Third runway aligned parallel and

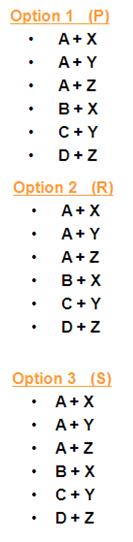

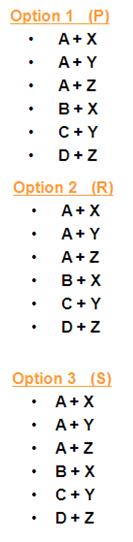

significantly staggered from the existing runways (Options K, N, P, R and S);

and

Concept 4 - Third runway located remotely from

HKIA (Options J and M).

Option A

|

Option B

|

Option C

|

Option D

|

Option E

|

Option F

|

Option G

|

Option H

|

Option J

|

Option K

|

Option M

|

Option N

|

Option P

|

Option R

|

Option S

|

3.3.3.2

Stage

1 compared each of the 15 Options along with a sixteenth option (S extended

option) and its variants against the mandatory criteria, taking into account the paramount ability to provide safe

and viable arrival, departure and missed approach paths for safe and efficient operation of the

runway. Table

3.2

summarises the results of the mandatory criteria

assessment.

Table 3.2: Summary

of Mandatory

Criteria Compliance

|

Mandatory Requirements

|

Failed Options

|

Reason

|

|

Airside Integration (Operational)

|

A, B, C, J, M

|

These options

provide either limited or no integration with the existing airport, thereby

creating severe operational constraints

|

|

Topographical Factors (Operational Viability)

|

C, D, E, F, G, H,

K, N, S

|

The runway

associated with these options are either located too close to the mountains

at Castle Peak or Lantau, or are too close to the existing runways, thereby

compromising the viability of safe arrival / departure / missed approach

procedures

|

3.3.3.3

The

findings of the mandatory criteria analysis identified that only Option P, R

and S extended are able to pass all the mandatory criteria for the safe and

viable operation of the third runway.

Additional variants of the S extended option were also found to provide

compliant and viable solutions and were further developed as follows:

Option S Extended

(Variant A and B)

|

Option S Extended (Variant C)

|

|

|

Option S Extended (Variant D)

|

Option S Extended (Variant E)

|

|

|

3.3.4 Options for the Third

Runway Alignment Stage 2 – Shortlisted Options

3.3.4.1

For

the three shortlisted options (Options P, R and S extended variants), a more

detailed and in-depth analysis of operational compliance was undertaken in

order to further verify option feasibility. This assessment was undertaken as

part of the Airspace and Runway Capacity

Study Phase 1b – Final Report by NATS in 2008 [4]. The main operational

requirements considered included viable aircraft arrival and departure modes;

emergency procedures; ground manoeuvring; and expansion potential of each

option. Other operational requirements and considerations including airborne

crossover issues; scheduling to maximise capacity; safeguarding for future

flight routes; ability to implement (control) the three-runway airport; and

interactions with adjacent airfields were also considered but were in general

found to be affecting all options equally.

3.3.4.2

The

following summarises findings from the operational compliance review:

¡ Option S extended (Variants A to E) were found not viable due to

unresolvable flight movement issues associated with breakout manoeuvring2. Option S extended was eliminated from further analysis, however,

taking into account issues identified with previous variants, a viable revised

Option S was introduced;

¡ Revised Option S however was assessed as having limited capacity

potential due to constraints associated with dependent parallel approaches as

well as being subject to some ground congestion concerns;

¡ Options P and R were generally found to have fewer operability

issues and concerns compared to Option S.

2 Breakout manoeuvring refers

to the emergency manoeuvring procedures that an aircraft needs to deploy when

the parallel aircraft alongside it ‘blunders’, i.e. veers off its original

flight path on decent.

3.3.4.3

As

the operational review identified that runway alignment Options P, R and the

revised Option S were all operationally feasible,

these three runway alignments were adopted as the basis for evaluating a range

of potential airport layout options.

3.4.1.1

The

evaluation process for airport layout alternatives is shown in Chart 3-1 and

comprised the following key steps:

Initial Stage: A broad evaluation of

constructability and operational requirements to create a shortlist of airport

layout options for detailed evaluation.

Final Stage: A detailed evaluation

covering both non-environmental considerations and environmental considerations,

leading to identification of a preferred option.

Chart 3-1: Evaluation process for three-runway system layout options

Starting

Point

|

|

Initial

Stage

|

|

|

|

Final

Stage

|

|

|

|

3.4.1.2

Details

of the airport layout evaluations are presented in the following subsections.

3.4.2.1

Based

on the three shortlisted runway alignment options identified, a total of 18

airport layout options were developed, covering all possible permutations of

apron, passenger terminal and concourse expansion locations. The 18 airport

layout options considered four possible locations for the new passenger

processing terminal (denoted as A, B, C, and D) and three possible locations for

the aircraft aprons and passenger concourse areas (denoted as X, Y, and Z) as

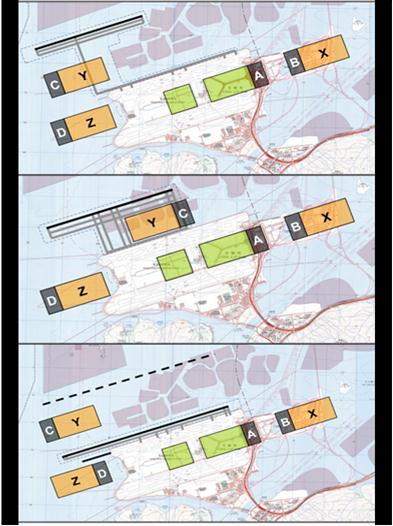

shown in Figure 3.1 (from

MP2030).

|

Figure 3.1: Eighteen

layout

options

|

|

LEGEND

A,

B, C & D show possible location of passenger processing

terminal (where passengers are processed for check-in,

Customs/Immigration/Quarantine and security screening)

X,

Y & Z show the possible location of aircraft apron and

passenger concourse area (where aircraft gates are located)

P,

R & S denote spacing between the third and existing North Runways (i.e. far-spaced, normal-spaced and close-spaced)

respectively

|

3.4.2.2

A qualitative review of the evaluation

criteria (shown in Table 3.3)

was then conducted by the MP2030 Study Consultant, to select better performing

airport layout representative(s) from each of the three shortlisted runway

alignment options (i.e. Option P, Option R and Option S) for carry forward to

the detailed evaluation stage.

Table 3.3: Criteria

for Initial Stage Airport Layout Options Evaluation

|

1.

|

AIRFIELD

|

|

|

|

- Taxiing

Time / Distance

|

Relative compared

to each option

|

|

|

- Runway

Crossings

|

Relative compared

to each option

|

|

|

- Additional

Control Tower

|

If needed for

operations or for blocked lines of sight

|

|

|

- Balance

East / West

|

-

|

|

|

- Cargo

Connectivity

|

Proximity of stands / access to cargo

|

|

2.

|

TERMINAL

|

|

|

|

- Passenger

Connectivity

|

Minimum transfer time, APM complexity and capacity

|

|

|

- Baggage

Connectivity

|

Connection time / connectivity

|

|

|

- Duplication

of Facilities

|

Terminal processor, retail, surface access

interchange, APM, etc.

|

|

|

- Synergy

with Airport Related Development (ARD)

|

Proximity

|

|

3.

|

SURFACE ACCESS

|

|

|

|

- Road

Access & Capacity

|

Extension of existing roads and capacity of new road

|

|

|

- Airport

Express Line (AEL)

|

Ability to extend existing line, or the need to

create a secondary bifurcation

|

|

|

- Cross

Boundary Transport Facilities

|

Ability to serve cross boundary air / surface transit

passengers via Coach, SkyPier and potentially the Hong Kong-Shenzhen Western

Express Line (WEL)

|

|

4.

|

LONG-TERM

CAPACITY / FLEXIBILITY

|

|

|

|

- Strategic

Consideration

|

Ability to meet demand growth beyond 2030

|

|

5.

|

CONSTRUCTIBILITY

/ COST

|

|

|

|

- Runway

/ Taxiways

|

Runway / taxiway length or area

|

|

|

- Construct

over Mud Pits

|

Cost (and possible lead time)

|

|

|

- Terminal

Processor

|

Expansion / Extension of Terminal 1 (T1) / Terminal 2

(T2), or land formation for a new terminal

|

|

|

- Surface

Access – Road / Rail

|

Short extension of existing versus major line

extensions / bifurcation

|

|

|

- Total Land Formation Area

|

Land take-up

|

|

|

- Operational

Impact

|

-

|

Source: Airport

Authority Hong Kong, Hong Kong

International Airport,

HKIA Master Plan 2030 Technical Report, July 2011, http://vps.hongkongairport.com/mp2030/TR_24May_Eng_Full.pdf

3.4.2.3

Four

airport layout options were shortlisted as a result of the qualitative review

as shown in Drawing Nos. MCL/P132/EIA/3-001 to

MCL/P132/EIA/3-004. The main characteristics of the shortlisted options

are summarised in Table

3.4.

Table 3.4: Summary of Shortlisted

Options

|

Shortlisted Option

|

Summary

|

|

Option P (A +

Y)

|

This

option adopts the original P runway alignment from NATS with a remote

satellite concourse to the northwest of the existing airport platform that is

connected to T2. The principal objective of this option is to avoid construction

over the CMPs and position passenger stands between a new widely spaced

parallel runway and the existing North

Runway.

|

|

Option R (A +

X)

|

This

option revises the original R runway alignment from NATS by shifting it as west

as practicable up to the Mainland territorial waters boundary, with a remote

linear satellite concourse north of the existing airport platform that is

connected to T2. The principal objective of this option is to minimise

construction over the CMPs and position passenger stands between a new widely

spaced parallel runway and the existing North Runway.

|

|

Option R (A +

Y)

|

This

option revises the original R runway alignment from NATS by shifting it

slightly to the east and north in order to fit in a remote satellite

concourse to the north of the existing airport platform, assuming

construction over the CMPs is feasible. The principal objective of this

option is to position passenger stands between a new widely spaced parallel

runway and the existing North

Runway that is connected

nearer to T2 as compared to

Option R (A+X)

|

|

Option S (D +

Z)

|

This

option adopts the original S runway alignment from NATS with a new passenger

terminal and concourse at the western end of the airport platform as the close

spacing between the third runway and the existing North Runway

would not allow for new facilities to be built in between. The principal

objective of this option is to avoid construction over the CMPs and position

a new passenger terminal and passenger stands to the west of existing airport

platform. The length of the new

runway is almost twice that of the P and R runway layout options to meet

flight procedure and safety requirements in operating the new runway and the

existing North Runway independently under a close-spaced arrangement.

|

3.4.2.4 The final stage of evaluation of the shortlisted

airport layout options

comprised an in-depth evaluation across key operational and functional parameters

collectively called “Non-Environmental Evaluation” as well as an engineering feasibility and

qualitative environmental assessment to identify an overall preferred option.

3.4.3.1

Based

on new land requirements for siting infrastructure required for the 3RS, the four

shortlisted airport layout options could be generally categorised

into two categories of

options, namely “Northward Expansion” and “Westward Expansion”.

An in-depth assessment of relative

performance across key operational and functional parameters

was undertaken for Northward and Westward expansion options.

Westward Expansion - Option

S (D+Z)

¡ The third runway adopts a close-spaced separation from the existing North Runway, with new operational infrastructure required to support the 3RS to be located on

land formation to the west of the existing airport island.

Northward

Expansion - Option P (A + Y), Option R (A + X) and Option R (A + Y)

¡ The third runway adopts a wide-spaced separation from the existing North Runway, with additional operational infrastructure required to support

the 3RS to be sited on land formation to the north of the existing airport

island.

The outcome of

the non-environmental relative performance evaluation of the two families of

airport expansion options, as set out in MP2030, is recapped in

Table 3.5.

Table 3.5: Comparative Performance Between Two Airport Expansion Options

|

Criteria

|

Westward

Expansion

|

Northward

Expansion

|

|

Airfield Efficiency

|

O

|

P

|

|

Passenger Convenience

|

O

|

P

|

|

Surface Access

|

O

|

P

|

|

Cargo Operations Efficiency

|

O

|

P

|

Note: where the criteria are met, this is denoted by ‘P ‘. Where the criteria is not met, this is

denoted by ‘O ‘.

Source: Airport

Authority Hong Kong, Hong Kong International Airport, HKIA Master Plan 2030

Technical Report, July 2011, http://vps.hongkongairport.com/mp2030/TR_24May_Eng_Full.pdf

3.4.3.2

A summary of the comparison between the Westward expansion

option relative to the Northward expansion option is as follows:

Airfield

Efficiency

a)

For

close-spaced parallel runways to be able to maintain independent segregated

operations under ICAO guidelines, it is necessary to extend the third runway

length from 3,800 m to 6,750 m, and the second runway

(i.e. existing North Runway) length by 950 m to the

west so that a 1,950 m stagger towards

the arriving aircraft is available for both runway directions 07 and 25 (see Figure 3.2).

|

Figure 3.2: Illustration of runway extension required under a close-spaced parallel runway arrangement

|

|

This entails a

substantial additional land formation area for the third runway as compared to the Northward expansion option, which has sufficient runway separation to adopt

a normal length of 3,800 m for the third runway.

b)

The

separation of the close-spaced third runway from the first

runway (i.e. existing South Runway) is also not sufficient to support

independent parallel approaches. Only dependent staggered approaches can be

accepted which will reduce the overall capacity of the 3RS to 97 movements per hour as compared to

102 under the Northward expansion option supporting independent parallel

approaches (see Table 3.6).

Table 3.6: Runway Capacity of the Westward

Expansion Option

|

Runway

|

Use

|

Capacity

|

Arrivals

|

Departures

|

|

07L/25R

|

Arrivals

|

31

|

31

|

─

|

|

07C/25C

|

Departures

|

35

|

─

|

35

|

|

07R/25L

|

Mixed

|

31

|

15.5

|

15.5

|

|

Total

|

─

|

97

|

46.5

|

50.5

|

Note: Values refer to the number of aircraft movements per

hour.

Source: Airport

Authority Hong Kong, Hong Kong International Airport, HKIA Master Plan 2030 Technical

Report, July 2011, http://vps.hongkongairport.com/mp2030/TR_24May_Eng_Full.pdf

c)

The

close-spaced third

runway does not allow room

for locating the additional passenger aircraft stands requirement adjacent to

the third

runway as compared to the

Northward expansion option. Aircraft arriving on the third runway need to taxi across the existing airfield to the apron on the western land formation or Midfield area, creating longer taxiing

time, increased ground congestion and delays, and more

runway crossings than the Northward expansion

option which will likely further reduce

runway capacity to less than 97 movements per hour (see Figure 3.3).

|

Figure 3.3: Aircraft

ground

movements

congestion

under the Westward

expansion

options

|

|

Passenger Convenience

3.4.3.3

The Westward expansion option for developing a new passenger

processing terminal (Terminal 3 or T3) and a new passenger concourse at the

western side of the airport island would require passengers to make an early

decision when approaching T1, T2 or T3 (i.e. boarding public transport routes

bound for T1 / T2 versus a separate route bound for T3). Due to the large

distance separation between T3 and T1/ T2, an accommodation for route recovery

would be require in the event when passengers proceed to the wrong terminal.

There would also be added inconvenience and longer travelling distances for

inter-terminal transfers and inter-modal connections with Hong Kong - Zhuhai -

Macao Bridge (HZMB) (see Figure 3.4)

and SkyPier located on the eastern side of the airport island.

|

Figure 3.4: Passenger

inconvenience

of the Westward expansion

options

|

|

3.4.3.4

The Northward expansion option for the development of

the new passenger concourses would lessen passenger inconvenience associated with

the Westward expansion option. The Northward expansion option would have

passengers from the new concourses processed through the existing passenger

terminal zone via expansion of the existing T2 into a full-fledged departures

and arrivals terminal with dedicated underground APM and BHS linked to the new

passenger concourses.

Surface Access Quality

3.4.3.5

The

Westward expansion option cannot share the existing fully integrated ground

transportation facilities already established at the eastern side of the airport

island, particularly the direct connections to the AEL

station to downtown and the APM station to the SkyPier ferry terminal and

future Hong Kong Boundary Crossing Facilities (HKBCF) (see Figure 3.5). The split passenger terminal zones

associated with the Westward expansion option would inevitably lead to inferior

surface access quality compared to that of a centralised passenger processing

terminal zone that is provided for under the Northward expansion option.

Figure 3.5: AEL and SkyPier ferry terminal

Cargo Operations Efficiency

3.4.3.6

Given

that cargo transport is time-critical, it is preferred to locate the new

freighter stands at the Midfield to allow shorter towing distances between the

new freighter stands and the cargo terminals in the southern cargo precinct (see

Figure 3.6). This

could only be achieved under the Northward expansion option but not the

Westward expansion option which needs to assign the entire Midfield area for

new passenger concourses development to minimise taxiing distance to/from

passenger aircraft stands.

|

Figure 3.6: Preferred location of future cargo apron and freighter stands

|

|

|

3.4.3.7

The non-environmental evaluation has identified that “Northward

Expansion” is preferred to “Westward Expansion” in enlarging the footprint of

HKIA into a 3RS. The outcome

of the non-environmental evaluation was supported by the “Engineering

Feasibility and Environmental Assessment Study for Airport Master Plan 2030, Comparative

Environmental Assessment” with

Option R (A + Y) within

the Northward expansion family options also being identified as the best environmental performing option,

which was consequently adopted by MP2030 for development into the recommended

layout for the 3RS

scenario.

3.4.4.1

The

environmental evaluation was undertaken in parallel with the non-environmental

evaluation and forms part of the assessments in the Engineering Feasibility and Environmental Assessment Study for Airport

Master Plan 2030, Comparative Environmental Assessment Report completed in

2009 by Mott MacDonald [5].

Early Consideration of

Environmental Implications associated with Engineering Design

3.4.4.2

The

main potential environmental implications of a third runway result primarily

from both the physical location / footprint of the airport expansion and

construction methods that are developed for land formation. Thus, engineering

design considerations and requirements do have significant impacts on the environmental

performance of different airport layout options. Table

3.7

shows the major land formation characteristics

associated with each shortlisted option.

Table 3.7: Summary of the Major Characteristics

of Each Shortlisted

Option [5]

|

Major Characteristics

|

P (A + Y)

|

R (A + X)

|

R (A + Y)

|

S (D + Z)

|

|

Total land formation area

|

743 ha

|

790 ha

|

827 ha

|

819 ha

|

|

Encroachment to CMPs

|

3 ha

|

32 ha

|

200 ha

|

Nil

|

|

Seawall length

|

18 km

|

18 km

|

11 km

|

15 km

|

|

Minimum clearance to Chinese Territorial Waters

boundary

|

150 m

|

100 m

|

1 km

|

1 km

|

|

Minimum clearance to Sha Chau and Lung Kwu Chau Marine

Park

|

350 m

|

1 km

|

1 km

|

2 km

|

Identification of the Key Environmental

Differentiators for Comparison of Options

3.4.4.3

A

set of environmental performance indicators was developed to facilitate a

simple ‘option to option’ comparison of the key anticipated environmental

impacts, at construction and operation stages.

The comparison exercise was not intended to be a thorough “quantitative”

assessment of environmental impacts and their acceptability, rather, a simple

differentiation of the shortlisted options based on “larger” or “smaller”

impact in the indicator area for each of the options – allowing for a simple

ranking of options3. The key environmental

differentiators adopted for shortlisted airport layout options evaluation are

presented in Table

3.8.

3

Environmental differentiators are those environmental parameters assessed as

exhibiting potential variability between options. Certain environmental

parameters, such as construction phase air quality impact, were not included as

they were assessed as exhibiting no significant variability between options.

Table 3.8: Summary of Key Environmental

Differentiators During Construction

and Operation Phase [5]

|

Key Environmental Differentiators

|

Construction

Phase

|

Operation

Phase

|

|

Air Quality

|

N/A

|

§

Airport operational efficiency1

|

|

Chinese White Dolphins (CWD)

|

§

Disturbance to CWD feeding grounds

§

Disturbance to dolphin calves

|

§

Permanent loss of feeding grounds

§

Proximity of northern site boundary to Sha

Chau and Lung Kwu Chau Marine Park

(and associated risk of CWD injury due to collision with vessels)

|

|

Fisheries

|

§

Disturbance to fisheries production

§

Disturbance to fishing operation

§

Loss in fisheries value due to construction

|

§

Permanent loss in fisheries production

§

Habitat loss

§

Fishing operation

§

Fisheries value

§

Impact of Hong Kong International Airport Approach Area

(HKIAAA) on fisheries operation

|

|

Marine Ecology

|

§

Disturbance to horseshoe crab nursery grounds

§

Impact of increased suspended solids (SS)

concentrations on marine ecological sensitive receivers

§

Disturbance to existing coral and artificial

reefs

|

§

Loss of intertidal habitats

§

Loss of soft-bottom habitats

§

Loss of coral communities

|

|

Noise

|

§

Cumulative impact due to concurrent projects

on noise sensitive receivers (NSRs)

|

§

No. of dwellings situated within a preliminary

noise exposure forecast (NEF) 25 contour projection

|

|

Visual

|

§

Disturbance to visually sensitive receivers

(VSRs) at Sha Lo Wan and Tung Chung

|

§

Disturbance to VSRs at Sha Lo Wan and Tung

Chung

|

|

Waste

|

§

Quantity of dredged sediment (outside of CMPs)

|

N/A

|

|

Water Quality and Hydrodynamics

|

§

Increase in SS concentrations at water

sensitive receivers

§

Release of sediment fines and contaminants

during ground improvement at CMPs

|

§

Change in tidal flow

§

Erosion of seabed

§

Change in flushing capacity at the existing airport channel

§

Potential water quality impact from a poorly

flushed embayment

|

Note 1: This provides a measure of the potential operation phase air

quality as it relates to aircraft emissions.

3.4.4.4

Other

environmental parameters, such as construction phase air quality impact, hazard to life, terrestrial ecology,

landscape and cultural heritage, were identified as not being significant differentiators that

could be used in the options evaluation and hence were excluded from the

options selection process.

Environmental Evaluation of the Shortlisted

Options – Benefits

and Dis-Benefits

3.4.4.5

For

the differentiators identified under each key environmental aspect, relative

environmental performance was summarised into an equivalent relative ranking

for each shortlisted option. The

ranking evaluation was made based on best professional judgement of the information available at the time

of evaluation, giving

more focus on key long-term and irreversible environmental impacts. A summary

of findings from the comparative environmental assessment is presented in Table

3.9.

Table 3.9: Summary of Environmental

Evaluation

of the Shortlisted Options [5]

|

Key Environmental Differentiators

|

Option

1 – P (A + Y)

|

Option

2 – R (A + X)

|

Option

3 – R (A + Y)

|

Option

4 – S (D + Z)

|

Preferred

Option

|

|

|

Environmental

Benefit

|

Environmental

Dis-benefit

|

Environmental

Benefit

|

Environmental

Dis-benefit

|

Environmental

Benefit

|

Environmental

Dis-benefit

|

Environmental

Benefit

|

Environmental

Dis-benefit

|

|

|

Air Quality

|

·

No defining benefit compared to other options

|

·

No defining benefit compared to other options

|

·

No defining benefit compared to other options

|

·

No defining benefit compared to other options

|

·

No defining benefit compared to other options

|

·

No defining benefit compared to other options

|

·

No defining benefit compared to other options

|

·

Generally associated with less operational

efficiency compared to other options.

|

No

definitive option is preferred.

|

|

CWD

|

·

Affect a smaller area associated with CWD calves

sighting, therefore has lower

potential to adversely impact CWD breeding grounds.

·

Smallest

area of permanent habitat loss and a smaller number of CWDs potentially affected.

|

·

Affect a larger area associated with CWDs engaged

in socialising activities, therefore has higher potential to adversely affect CWD

social activities (along with Option 2).

·

Located closest to the Sha Chau and Lung Kwu

Chau (SCLKC)

Marine Park, therefore has higher potential

disturbance to CWD protected area.

·

Evaluated

to have higher

potential severity of impacts to CWDs during operation phase

|

·

Affect a smaller area associated with CWDs engaged in feeding activities, therefore

has lower

potential for disturbance to feeding grounds (along with Option 3).

|

·

Affect a larger area associated with CWDs engaged

in socialising activities, therefore has higher potential to adversely affect CWD

social activities (along with Option 1).

|

·

Affect a smaller area associated with CWDs engaged in feeding activities, therefore

has lower

potential for disturbance to feeding grounds (along with Option 2).

|

·

Largest

area of habitat loss (but the lost habitat was less used by CWDs)

|

·

Affect a smaller area associated with CWDs engaged

in socialising activities, therefore has lower potential to adversely affect

CWD social activities.

·

Located furthest from the SCLKC Marine Park, therefore has lower potential disturbance to CWD

protected area.

|

·

Affect a larger area associated with CWD calves

sighting, therefore has higher

potential to adversely impact CWD breeding grounds.

·

Affect a larger area associated with CWDs engaged in feeding activities, therefore

has higher

potential for disturbance to feeding grounds.

·

Larger

area of permanent habitat loss and number of CWDs potentially affected.

·

Evaluated

to have higher

potential severity of impacts to CWDs during both construction and operation

phase.

|

Option 3 – generally associated with

less CWD impacts compared to the other options.

|

|

Fisheries

|

·

Smallest area of potential fisheries habitat

loss

|

·

Future HKIAAA may extend outside Hong Kong

marine waters boundary and would lie closest to the SCLKC Marine Park, which may

discourage fishing activities in this area.

|

·

No defining benefit compared to other options

|

·

Future HKIAAA may extend outside Hong Kong

marine waters boundary and make access to the high fisheries production areas

at northwest Lantau difficult for fishermen.

|

·

Relatively less potential impact to fisheries

activities due to wider separation between the new HKIAAA, SCLKC Marine Park and Hong Kong

marine waters boundary.

|

·

Largest area of potential fisheries habitat

loss

|

·

No defining benefit compared to other options

|

·

Future HKIAAA may discourage fishermen from

fishing at northwest Lantau.

|

Option 3 – generally considered to

have marginally less impact on fisheries activities compared to other

options.

|

|

Marine Ecology

|

·

No defining benefit compared to other options

|

·

Located

closest to the SCLKC

Marine Park, therefore is associated with higher potential impact on the Marine Park due to SS

release during construction phase.

|

·

No defining benefit compared to other options

|

·

No defining dis-benefit compared to other

options

|

·

Located

furthest from the

Sha Lo Wan horseshoe crab habitat, therefore is associated with less potential impact on the habitat due to SS release

during construction phase.

|

·

No defining dis-benefit compared to other

options

|

·

Located

furthest from the SCLKC

Marine Park, therefore is associated with less potential impact on the Marine Park due to SS release

during construction phase.

|

·

Located

closest to the Sha Lo Wan horseshoe crab habitat,

therefore is associated with higher potential impact due to SS

release during construction phase.

|

Option 3 – associated with less

dis-benefits compared to Options 1 and 4, and more benefits compared to

Option 2.

|

|

Noise

|

·

Potentially associated with less aircraft

noise impacts to NSRs (due to larger runway separation distance).

|

·

No defining dis-benefit compared to other

options

|

·

No defining benefit compared to other options

|

·

No defining dis-benefit compared to other

options

|

·

Further separation distances from NSRs along North Lantau.

·

Potentially associated with less aircraft

noise impacts to NSRs (due to larger runway separation distance).

|

·

No defining dis-benefit compared to other

options

|

·

No defining benefit compared to other options

|

·

Shorter separation distances from NSRs along North Lantau.

·

Potentially associated with more aircraft

noise impacts to NSRs

|

Option 3 – generally associated with

more benefits compared to other options.

|

|

Landscape & Visual

|

·

Relatively further from VSRs at Tung Chung

|

·

Relatively closer to VSRs at Sha Lo Wan

|

·

Relatively further from VSRs at Tung Chung

|

·

Relatively closer to VSRs at Sha Lo Wan

|

·

Generally further from VSRs at both Sha Lo Wan

and Tung Chung

|

·

No defining dis-benefit compared to other

options

|

·

No defining benefit compared to other options

|

·

Closest to VSRs at Sha Lo Wan

|

Option 3 – generally associated with

less dis-benefits compared to other options.

|

|

Water Quality and Hydrodynamics

|

·

No defining benefit compared to other options

|

·

Relatively higher SS concentration at some water sensitive receivers (WSRs) compared to other options.

·

Re-deposition of sediment on corals is highest

compared to other options

·

Area of stagnant water produced due to eastern

embayment

·

Highest erosion potential around the new

runway

|

·

Lower SS concentration at some WSRs compared

to other options.

|

·

Area of stagnant water produced due to eastern

embayment

|

·

Generally lower SS concentration at WSRs

compared to other options.

·

Not associated with significant flow

stagnation.

|

·

No defining dis-benefit compared to other

options

|

·

Relatively lower SS concentration at some WSRs

compared to other options.

·

Not associated with significant flow

stagnation.

|

·

Relatively higher SS concentration at some

WSRs compared to other options.

·

Reduce flushing capacity at Airport Channel

·

Higher siltation potential at Airport Channel

than other options

|

Option 3 – generally associated with

less water quality impacts compared to the other options.

|

|

Cultural Heritage

|

Not

a key environmental differentiator as all options would have similar potential marine

archaeological impact, and no direct impacts to terrestrial cultural

heritage.

|

|

Hazard to Human Life

|

Not

a key environmental differentiator as all options would have similar potential hazard to human

life impacts

associated with diversion of submarine fuel pipeline, extension of fuel

hydrant system, and dangerous goods storage (diesel, gasoline and liquid

petroleum gas).

|

|

Terrestrial Ecology

|

Not

a key environmental differentiator as all options would have similar impacts (mainly

indirect impacts) to terrestrial ecology.

|

|

Waste*

|

·

Lowest quantity of dredged sediment (outside

CMP area)

|

·

No defining dis-benefit compared to other

options

|

·

No defining benefit compared to other options

|

·

No defining dis-benefit compared to other

options

|

·

Lowest quantity of

dredged sediment requiring disposal (outside CMP area)

|

·

No defining dis-benefit compared to other

options

|

·

No defining benefit compared to other options

|

·

Highest quantity of dredged sediment requiring

disposal (outside CMP area)

|

No longer applicable

|

Note:

The evaluation was based on the findings of the “Contract P132 – Engineering

Feasibility and Environmental Assessment Study for Airport Master Plan 2030,

Comparative Environmental Assessment Report”, (Deliverable D1.8), May 2009,

Mott MacDonald Hong Kong Limited ( http://vps.hongkongairport.com/mp2030/consultancy_report/Mott_1.pdf), which was compiled according to the

information available at the time of preparing that report.

*

The waste differentiator was based on previous assumptions of using dredged

land formation. As the project is now confirmed to use non-dredge methods, this

key differentiator is no longer applicable (but it is nevertheless presented

for completeness).

3.4.4.6

The

findings of the comparative environmental evaluation identified Option 3 as

performing relatively better than the other options with respect to the

majority of environmental differentiators.

3.4.5.1

The

results of both non-environmental and environmental evaluations concluded that

Option 3 – R (A + Y) is the best performing option of those shortlisted. Option

3 – R (A + Y) was also recommended as the preferred three-runway MP2030 layout.

3.4.6.1

Some

possible refinements to the shortlisted options were analysed as part of the Engineering Feasibility and Environmental

Assessment Study for Airport Master Plan 2030, Comparative Environmental

Assessment Report [5] to facilitate further development of the layout with

a view to enhancing their environmental performance. Table

3.10

summarises the further environmental refinements that

were considered.

Table 3.10: Summary of Possible Refinements and Environmental Benefits

/ Dis-benefits

[5]

|

Option

|

Possible

Refinement

|

Environmental

Benefits / Dis-benefits of Refinement

|

|

Option 1 – P (A + Y)

|

Maximise

the distance from the SCLKC Marine

Park

|

This

seeks to increase the distance from the SCLKC Marine Park from 350 m to 700 m by reducing the

northern extent of land formation. However, this option would still be closer

to the Marine Park than the other options,

hence no significant change to the environmental impact levels and relative

ranking is anticipated.

|

|

Reducing

the extent of land formation at the western side of the existing North Runway

|

The possibility of reducing the extent of land

formation at the western side would lead to improvements in terms of:

§

reduced disturbance to CWD feeding grounds and

calves;

§

reduced loss of soft-bottom habitats and coral

communities; and

§

reduced quantity of dredged sediment

However,

the creation of a poorly flushed embayment would increase the potential water

quality and hydrodynamic impact for this option.

|

|

Option 2 – R (A + X)

|

Reducing

the extent of land formation and use of decking for the taxiway

|

This

seeks to significantly reduce the extent of land formation and eliminate the

poorly flushed embayment by using decking instead of land formation for the

taxiway. Improvements include:

§

improved flushing capacity;

§

reduced disturbance to fisheries production;

§

reduced loss of intertidal habitats and

soft-bottom habitats;

§

reduced impact of increased SS on marine ecological sensitive

receivers; and

§

reduced quantity of

dredged sediment.

However,

as piling would be required for construction of the decking, the impact on

CWDs would increase.

|

|

Eliminating

the embayed area

|

This

seeks to possibly eliminate the embayed area by shifting the proposed runway

to the south. This would lead to improvements in terms of:

§

reduced impact to CWDs due to greater

separation distance from the Marine

Park and less habitat

loss; and

§

reduced embayment

areas.

|

|

Option 3 – R (A + Y)

|

Reducing

the extent of land formation at the western side

|

The possibility of reducing the extent of land

formation at the western side would lead to improvements in terms of:

§

reduced permanent loss of CWD feeding grounds;

§

reduced impact on fisheries production and

operation;

§

reduced loss of intertidal, soft-bottom and

coral communities / habitats;

§

less disturbance to horseshoe crab nursery

grounds; and

§

reduced quantity of

dredged sediment.

|

|

Shifting

the proposed runway to the east

|

This seeks to give a more streamlined footprint

from a hydrodynamic point of view, however, the findings of the hydrodynamic

assessment found that no significant change in tidal flow was predicted, and

no significant improvement in terms of erosion of the seabed was predicted.

Consequently, no additional environmental benefit was identified with this

refinement.

|

|

Option 4 – S (D + Z)

|

Eliminating

the embayed area

|

This

seeks to create a more streamlined footprint by trimming the eastern end of

the proposed runway to eliminate the embayed area. This would lead to

improvements in terms of:

§

removal of the poorly flushed embayment;

§

reduced impact to CWDs by reducing habitat

loss and disturbance to feeding grounds and dolphin calves;

§

reduced habitat loss and impact on fisheries

production;

§

reduced loss of soft-bottom habitats and

reduced disturbance to artificial reef and impact from SS; and

§

reduced quantity of

dredged sediment.

|

|

Reducing

the extent of land formation by use of decking for taxiway near the airport sea channel

|

This

refinement seeks to minimise hydrodynamic impact by eliminating about 24 ha

of land formation by using decking for the taxiway. This would lead to

improvements in terms of:

§

reduced impact on the flushing capacity at the

channel;

§

reduced loss of soft-bottom habitats and less

disturbance to horseshoe crab nursery grounds; and

§

reduced quantity of

dredged sediment.

However,

as piling would be required for construction of the decking, the impact on

CWDs would increase.

|

|

Trimming

of headland around Sha Lo Wan

|

This

seeks to improve the flushing capacity at the airport sea channel, but would result in permanent loss of

habitats for horseshoe crabs.

|

Source: Based

on Airport Authority Hong Kong, Hong Kong International Airport, Contract P132

– Engineering Feasibility and Environmental Assessment Study for Airport Master

Plan 2030, Comparative Environmental Assessment Report, (Deliverable D1.8), May

2009, Mott MacDonald Hong Kong Limited, http://vps.hongkongairport.com/mp2030/consultancy_report/Mott_1.pdf

3.4.6.2

The

possible refinements considered in Table

3.10

were used to re-evaluate the options and the findings showed that refinements did not result in any

change to the fundamental environmental performance of shortlisted options, confirming Option 3 – R (A + Y) as the

preferred option to take forward.

3.4.6.3

Taking

into account the environmental benefits identified in Table

3.10,

the preferred Option 3 was revised accordingly and the improved preferred

option is shown in Drawing No. MCL/P132/EIA/3-005.

3.5.1.1

With

a preferred option selected, it was possible to explore in greater detail

specific operational issues and to further refine individual components to

maximise operational efficiency, particularly airside access and integration of

existing airport operations. The most significant changes included:

¡ Minor reshaping of the eastern edge of the new land formation; and

¡ Introduction of ‘wrap-around’ taxiways to minimise runway

‘crossing’ to enhance operational safety for aircraft crossing the future

‘centre’ runway.

3.5.1.2

These

changes were primarily due to operational requirements, and given that the

modified layout remains conceptually similar to the preferred option, the

environmental performance of this modified layout is expected to be consistent

with the preferred option.

3.5.2.1

As

part of the initial scheme design for the project, a number of concourse layout

options were considered and evaluated. Table

3.11

presents a summary of the TRC options that were

considered for the 3RS.

Table 3.11: Summary

of Third Runway Concourse Options

|

|

Option 1

BASELINE

|

Option 2

TRIPLE CONCOURSES

|

Option 3

Y-Y

|

Option 4

TWIN - STAR

|

Option 5

TWIN - TRIANGLE

|

Option 6

HORSESHOE

|

Preferred Option

|

|

General Description

|

|

|

|

|

|

|

|

|

|

Based on the

existing T1, the Baseline scheme adopts the same T1 concourse width with the

baggage hall located underground.

|

Based on the

MP2030 layout. This scheme adopts three separate concourses with the baggage

hall located underground.

|

Single concourse

layout derived from the Baseline scheme, with wider concourse to accommodate

baggage hall at apron level.

|

Based on the

Baseline scheme but with an expanded area within the concourse to create

additional reserve areas and accommodate baggage hall at apron level.

|

Similar to the

Twin Star scheme with larger reserved area at each concourse for future

expansion and accommodate baggage hall at apron level.

|

This scheme

represents the ultimate shape that provides the largest area to perimeter

ratio. The aim of this configuration

is to maximise the area available for reserve land for future expansion and

accommodate baggage hall at apron level.

|

N/A

|

|

Capacity

|

62 contact stands

47 remote stands

|

60 contact stands

40 remote stands

|

60 contact stands

45 remote stands

|

62 contact stands

36 remote stands

|

62 contact stands

42 remote stands

|

54 contact stands

25 remote stands

|

Option 1 or 3

|

|

Operational Efficiency

|

This option has

high taxiway efficiency and user friendliness with easy route recovery and

transfers between the concourse, but has limited

space for passenger / commercial facilities.

|

This option presents

a risk of taxiing congestion and increased airside road journey times between

the two farthest nodes, though it has the benefit of providing taxi-lane

alternatives and shorter taxiing distance for certain stands.

In terms of

terminal operations, more concourses complicate passenger wayfinding and the

additional facilities required (e.g. three APM stations and separate baggage

systems) would increase both journey / transit times and operational costs.

This option is the

least efficient overall.

|

This option

provides greater operational efficiency and user friendliness with easy route

recovery and transfers between the concourse and better space allocation to

accommodate different passenger / commercial facilities.

Baggage

operational efficiency is generally higher than other configurations.

|

Similar efficiency

to the Baseline scheme and provides shorter taxiing distance for certain

stands, but concourse operational efficiency is affected by the split

concourses, which necessitates some duplication of facilities.

|

Similar efficiency

to the Baseline scheme, but concourse operational efficiency is affected by

the split concourses, which necessitates some duplication of facilities.

|

This option has

poor taxiway efficiency due to uni-directional taxi-lane layout.

Concourse

operational efficiency is also affected by the split and uneven concourses.

|

Option 3

|

|

Phasing / Flexibility

|

Single concourse

enables consolidation of terminal facilities and provides more flexibility

for phased commissioning.

Limited

opportunity for creating outdoor spaces.

No reserve area

for future expansion.

|

Based on capacity

requirements, at least two of the three buildings will need to be

commissioned in Phase 1.

Limited opportunity

for creating outdoor spaces.

No reserve area

for future expansion.

|

Single concourse

enables consolidation of terminal facilities and provides more flexibility

for phased commissioning.

Opportunities

available for creating outdoor spaces which can be safeguarded for future

expansion.

|

Large central

concourse area allows for future expansion flexibility, but less capacity for

phased commissioning of facilities.

|

Large central

concourse area allows for future expansion flexibility, but less capacity for

phased commissioning of facilities.

|

Large central

concourse area allows for future expansion flexibility, but less capacity for

phased commissioning of facilities.

|

Option 3

|

|

Programme and Costs

|

No significant difference

in construction programme compared to other options.

|

No significant

difference in construction programme compared to other options.

Higher

construction cost due to multiple terminal buildings and associated APM / BHS

facilities.

|

No significant

difference in construction programme compared to other options.

Cost for the wider

concourse is offset by the bag hall at apron level.

|

No significant

difference in construction programme compared to other options.

Generally higher

construction cost due to larger building area.

|

No significant

difference in construction programme compared to other options.

Generally higher

construction cost due to larger building area.

|

No significant

difference in construction programme compared to other options.

Generally higher

construction cost due to larger building area.

|

Option 1 or 3

|

|

Environmental

|

Requires

excavation into CMPs

|

Requires

excavation into CMPs

|

Avoids the need

for excavation into CMPs

|

Avoids the need

for excavation into CMPs

|

Avoids the need

for excavation into CMPs

|

Avoids the need

for excavation into CMPs

|

Option 3 to 6

|

Environmental

Benefits / Dis-Benefits

3.5.2.2

In

general, the only environmentally significant consideration between different

TRC configuration options is whether excavation into the CMPs is required or

not, which would affect the quantities of excavated marine sediment. Apart from

this aspect, the various TRC options do not have a significant bearing on the

environmental acceptability of the project, as there are no other significant

environmental differences among the TRC options. Based on this environmental consideration, Options

3 to 6 would be equally more preferable from an environmental perspective when

compared to Options 1 and 2.

3.5.2.3

Given

that there are limited environmental differences between options, the decision

for selection of the preferred scenario for TRC configuration is thus dominated

by capacity and operational considerations. However, in selecting the TRC

option that provides the best overall operational and efficiency gains, there

are inherent environmental benefits resulting from these efficiency gains, such

as reduced raw materials requirement during construction phase, and reduced

building energy consumption during operation phase. Similar ‘environmental

dis-benefits’ would apply to options that are less operationally efficient.

Selection

of Preferred Scenario – Third Runway Concourse

3.5.2.4

Based on the comparison of TRC options as

shown in Table

3.11, the single

concourse Y-Y configuration (Option 3) has been identified and selected as the

preferred scenario for the 3RS.

In a similar manner to the existing T1, the single concourse configuration is

considered to offer important operational benefits including:

¡ Ground vehicle movements not impeded by having to cross cut through

taxi lane;

¡ Single baggage hall at apron level to allow efficient baggage ramp

handling and reducing tug and dolly travel distances;

¡ Flexibility to allocate aircraft to stands and increased efficiency

in terms of staffing / resource allocation;

¡ Requires fewer ground service equipment (GSE) to service aircraft

as vehicles do not need to be allocated to separate terminals;

¡ Can be built incrementally, which provides flexibility in planning

and phasing; and

¡ Flexibility in terms of catering to future demands, i.e. airline

allocation.

3.5.2.5

Accordingly, the preferred scenario would

provide environmental benefits in terms of:

¡ Avoidance of excavation into CMPs and less waste generated due to

excavation;

¡ Reduced GSE emissions (due to few GSE and more efficient vehicle

movements); and

¡ Less building energy demand (due to improved operational

efficiency).

3.5.3.1

As an outcome of the airport layout options assessment, the

existing T2 will be partly demolished, modified extensively and expanded to become

a full-fledged passenger processing terminal to serve the new third runway. Two

options for T2 expansion and associated road network were considered and

evaluated. Table

3.12

presents a summary of these options and the road

network options are shown in Drawing No. MCL/P132/EIA/3-008.

Table 3.12: Summary of Descriptions and Construction Methods for Terminal 2

Expansion and the Associated Road Networks Options

|

Parameters

|

Terminal

Concept A

|

Terminal

Concept F

|

|

General Design

|

Terminal:

This option assumes

that T2 has to be partially shut down and modified in order to expand to the

new terminal layout, while keeping operation in T2 throughout the entire

construction period. Facilities of the expanded T2 include the main building

composed of Departures Hall, Check-in Hall, Departures Kerb, Baggage Claim

Hall, Meeters and Greeters Hall, Custom, Immigration and Quarantine (CIQ)

Area, Baggage Handling Area, APM Interchange Station and BHS North Basement,

and the North and South Annex Buildings accommodating coach staging, car

parking, loading and unloading, and limousine lounge provisions. As the

Departures Kerb is positioned on the eastern side of the main building,

bi-directional passenger flows from new Departures Kerb and existing AEL

Station to Check-in Hall at Departures Level are anticipated.

Associated Road

Networks Option A1:

The departures

kerb of this option is located at the eastern side of the terminal. This road option provides a longer length

of departures kerb comparing to Option A2 below. A slip road linking the northern elevated

road to existing Airport Road is proposed for recirculation to T1 departures

kerb. Slip roads connecting to North Lantau Highway (NLH)/Airport Road and

HKBCF are also allocated at the south of the CLP substation.

Based on this

configuration, the proposed northern elevated road and realigned SkyCity Road

will encroach onto the North Commercial District (NCD) development area and

the AsiaWorld Expo (AWE)

Phase 2 Expansion site.

Associated Road

Networks Option A2:

The departures

kerb of this option is located at the eastern side of the terminal. To minimise the encroachment into AWE Phase

2 Expansion Area, a “ring road” option is developed with the elevated road