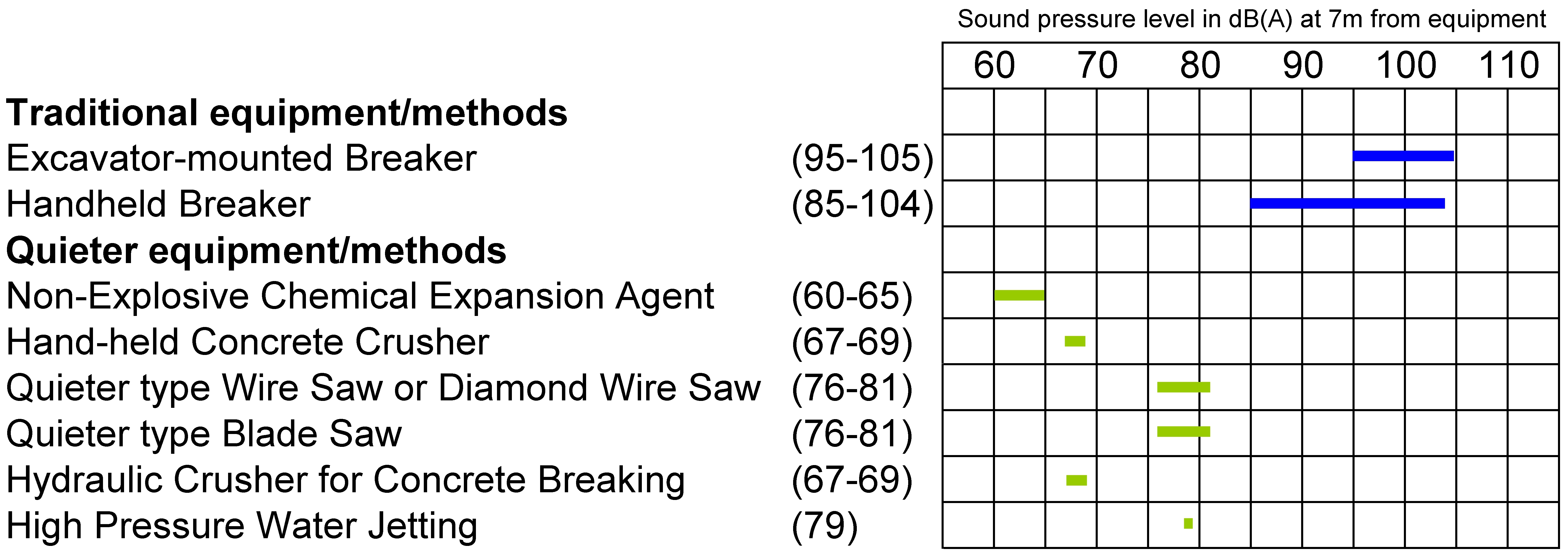

Handheld or excavator mounted concrete breaker is a traditional mechanical equipment for concrete breaking and removal. Using such equipment will generate loud noise, with sound power levels generally range from 108 dB(A) to 122 dB(A). Nowadays, a number of commercially available quieter equipment or methods for concrete breaking or removal could be less noisy or could reduce the noise propagation. These include high pressure water jet system, handheld concrete crusher, medium duty breaker, blade saw, wire saw and noise enclosure.

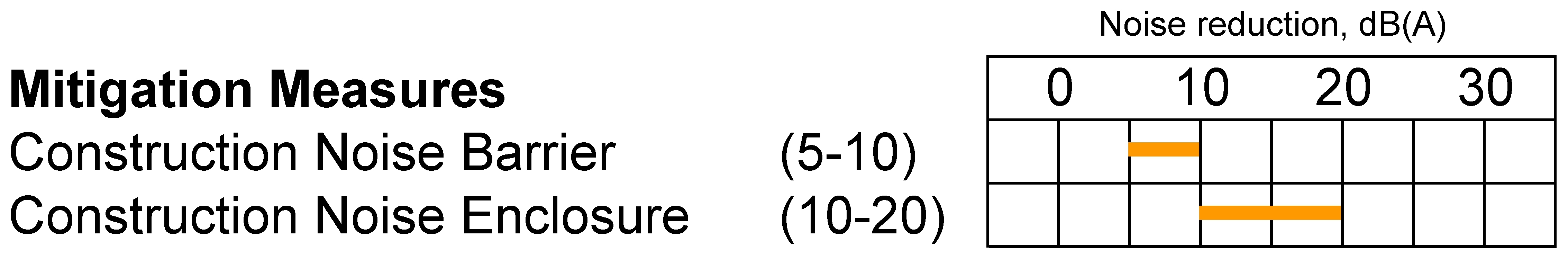

Noise reduction for some mitigation measures for reference.

Concrete Removal

Use of acoustic enclosure for stationary plant can achieve a noise reduction up to 20dB(A) easily.

An effective way of reducing noise is to install a purpose-built barrier between the noisy equipment and the noise sensitive receiver.

Unlike explosive chemicals or expansive compounds, soundless chemical demolition agents do not produce vibrations, and hence, they are completely quiet and safe to use.

Use of hydraulic concrete crusher is much quieter than using hydraulic breaker in demolition project.

Wire-sawing is a flexible sawing technique that can be applied under various situations with excellent cutting performance.

High pressure water jetting is a concrete removal technique mainly to remove deteriorated concrete, and tiles.

The Quieter Type Blade saw with higher speed and smoother balde reduces the excitation of vibration and hence the propagation of sound.

Less vibration and impulsive noise generated by hand-held concrete crusher than jackhammer.