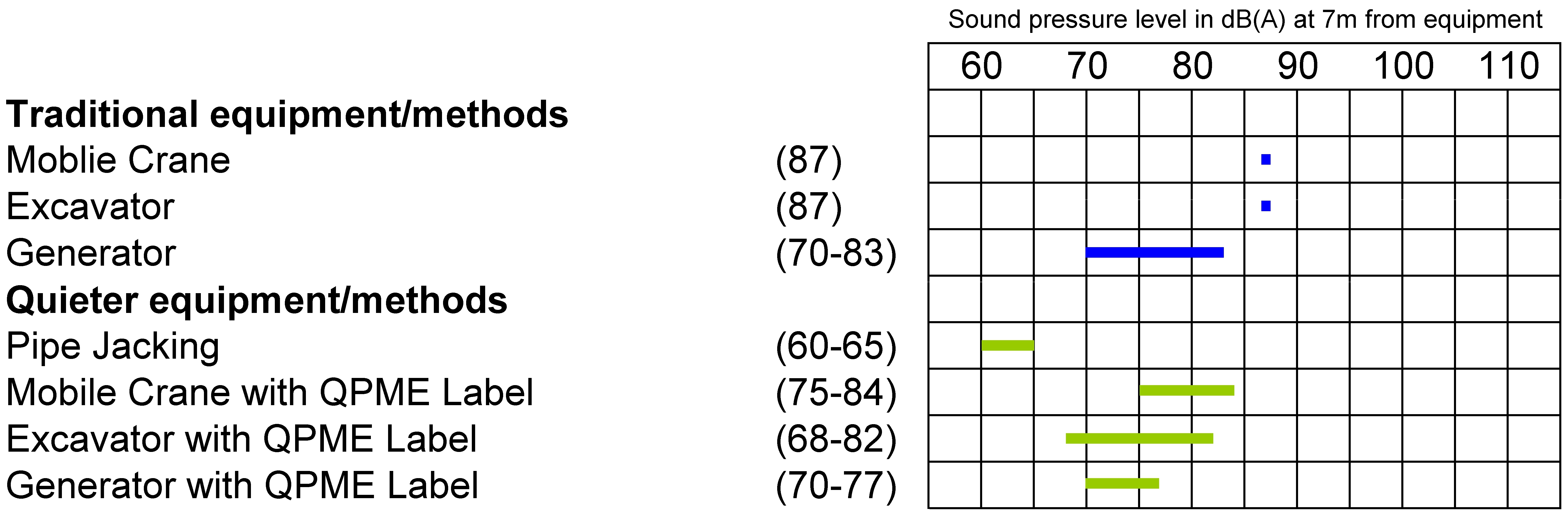

Tunneling and pipe installation for underground utilities involve the use of various mechanical equipment. Quality Powered Mechanical Equipment (QPME) such as excavator, generator and mobile crane which emitted relatively less noise compared with non- QPME are widely available in the territory. Moreover, the employment of some quieter construction methods such as top-down construction method or pipe jacking can also reduce the construction noise generation.

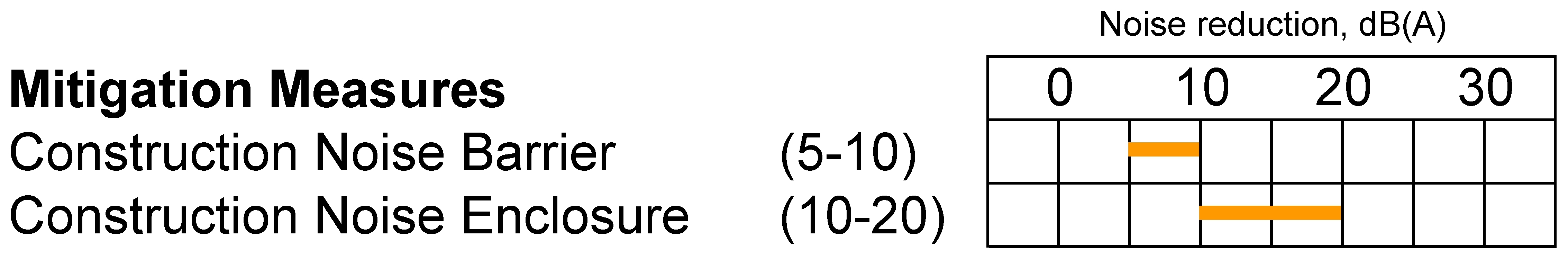

Noise reduction for some mitigation measures for reference.

Quieter Construction Methods

The Spiral Wound Rehabilitation Technology (SPRTMPE) is considered to be one of the quieter construction methods, compared to the traditional "open, cut and replace" method.

Cured-In-Place-Pipe (CIPP) Lining with Enhanced Curing Technology is considered to be one of the quieter construction methods, compared to the conventional "open, cut and replace" method.

Cured-In-Place Pipe (CIPP) Lining is considered to be one of the quieter construction methods, compared to the traditional "open, cut and replace" method.

Unlike cut and cover method, construction work of using tunnel boring machine takes place mainly underground, which signaficantly reduce noise, dust and disruption to nearby NSRs.