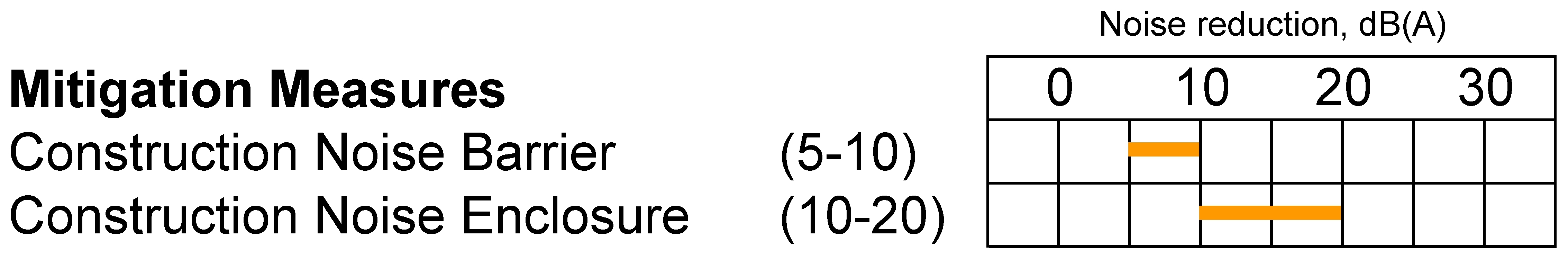

An effective way of reducing noise is to install a purpose-built barrier between the noisy equipment and the noise sensitive receiver. These can either be fabricated on site from readily available building materials or can be constructed from commercially available panels which are lined with sound absorbing materials to achieve the maximum shielding effect. For maximum effectiveness, a barrier should be located as close as possible to either the noise source, and should be built so as to shield totally the noise source. Gaps and openings at joints in the barrier material should be avoided. Barrier material of surface mass in excess of 7kg/m2 is desirable to achieve the maximum screening effect. The length of a straight vertical barrier should generally be at least five times greater than its height and minimum height of a barrier should be such that no part of the noise source will be visible from the noise sensitive receiver being protected. An overall reduction of between 5 to 10 dB(A) can be achieved by these means.

Courtesy of Wilson Acoustic Limited