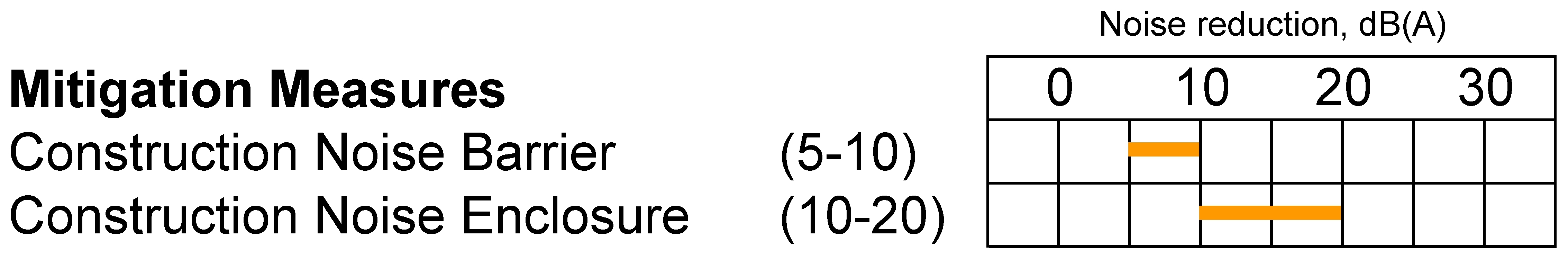

Use of acoustic enclosure for stationary plant can achieve a noise reduction up to 20dB(A) easily. The enclosure should cover the machine as fully as possible and the inside of it should be lined with sound absorbing materials such as mineral wool, woodwool propriety absorbent tiles or fiberglass. Such enclosures can be constructed from a variety of readily available building materials or can be constructed from commercially available panels which are lined with sound absorbing materials to achieve the maximum sound attenuation. Any opening in the enclosure will tend to compromise the noise reduction effect and should therefore be minimized. Where access and forced ventilation is required for the enclosure, proper acoustic door and suitably designed silencers fitted with the air intake and outlet should be carefully considered.

Courtesy of APAC Building Acoustics Limited

Courtesy of NAP Acoustics (Far East) Ltd.

Courtesy of Industrial Acoustics Co. (HK) Ltd.

Courtesy of Wilson Acoustics Limited